What and how to print on Form 2

Review of materials for stereolithography on Formlabs printers: what they are and why they can be useful.

Standard

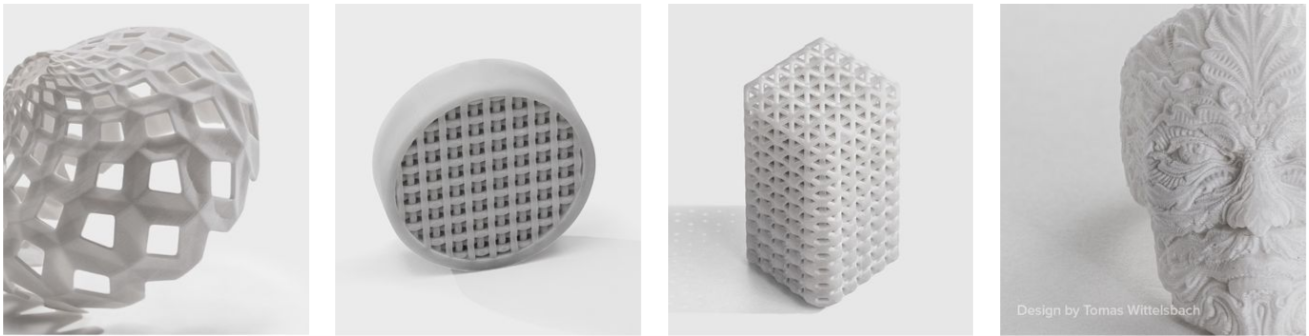

Standard photopolymers Formlabs are created for the most accurate transfer of the details of the printed objects.

Formlabs white resin

Formlabs White Resin is a white photopolymer. The polymer is well suited for rapid prototyping. It perfectly conveys the contours of surfaces and is suitable for the presentation of details.

')

What to print: prototypes, models, souvenirs. Products made from this polymer look good and have acceptable mechanical characteristics.

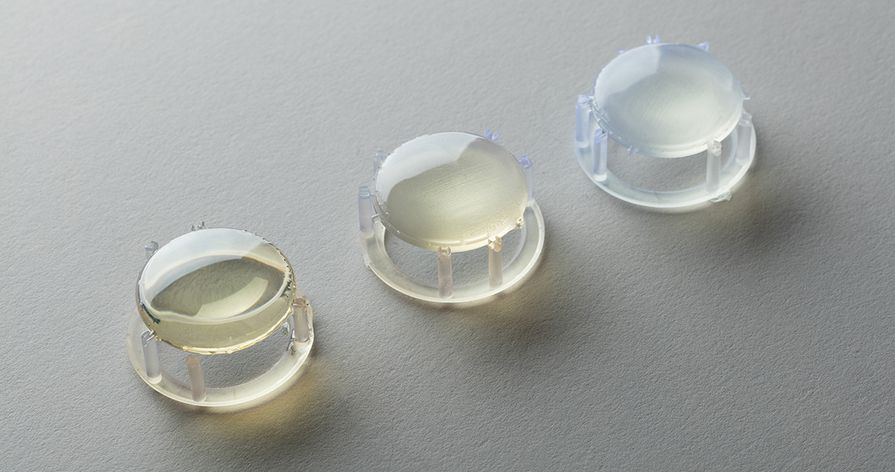

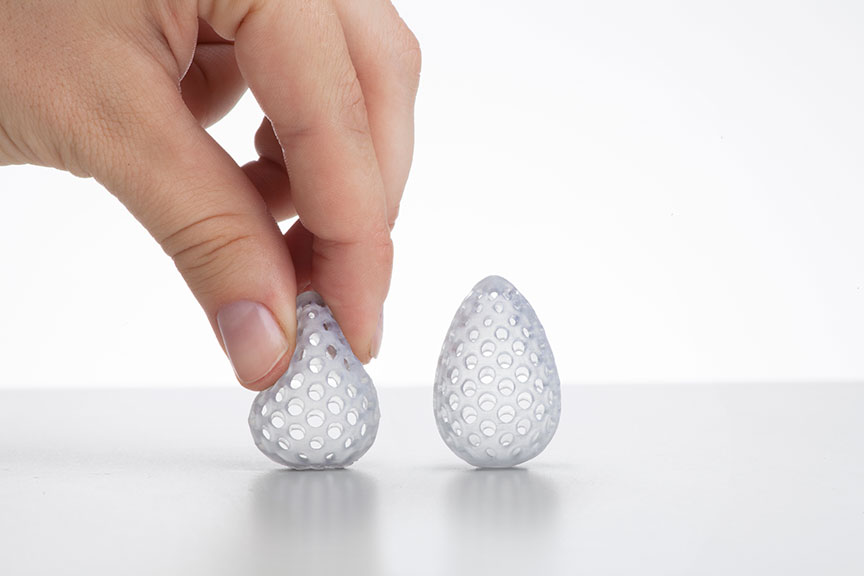

Formlabs Clear Resin

Formlabs Clear Resin is a transparent photopolymer. Clear Resin is very transparent and allows you to work perfectly with the light, detailing complex objects and creating really beautiful products.

What to print: any transparent objects. Enthusiasts managed to print out even lenses for the camera from it, thus creating a fully 3D printing camera.

Of course, the optical properties of such lenses cannot be compared with glass lenses, but the fact and the fact that work in this direction does not stop here is important.

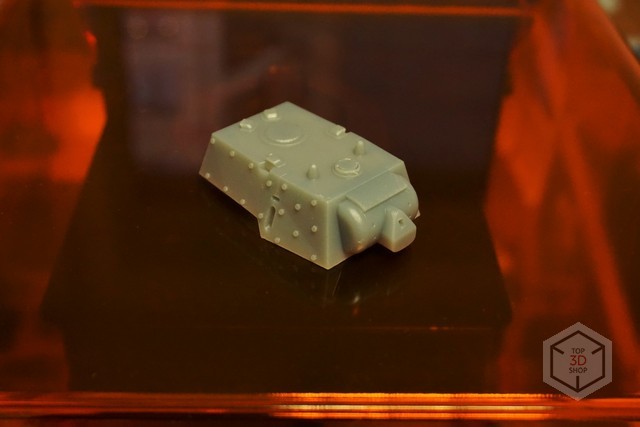

Formlabs Gray Resin

Formlabs Gray Resin is a gray photopolymer resin.

What to print: Gray Resin is good at printing prototypes of high-resolution technical and design models.

Formlabs black resin

Formlabs Black Resin - material for high-precision stereolithography. It has a rich black color.

What to print: Black Resin is used in the prototyping of mechanical devices, in which dimensional accuracy is important, for the interaction of parts with each other; jewelry, souvenirs and toys.

Engineering

Formlabs High Temp Resin

Formlabs High Temp Resin is a heat-resistant photopolymer, products from which withstand temperatures up to 289 ° C, and this is a record for commercially available 3D-printed polymers today.

What to print: molds for various plastics and waxes, prototypes for subsequent testing of models in a hot environment, templates for thermoforming.

Formlabs tough resin

Formlabs Tough Resin is a durable material that is mechanically close to ABS.

What to print: well suited for printing working prototypes and functional parts, such as gears, shells, clothing accessories - buttons, carabiners and latches.

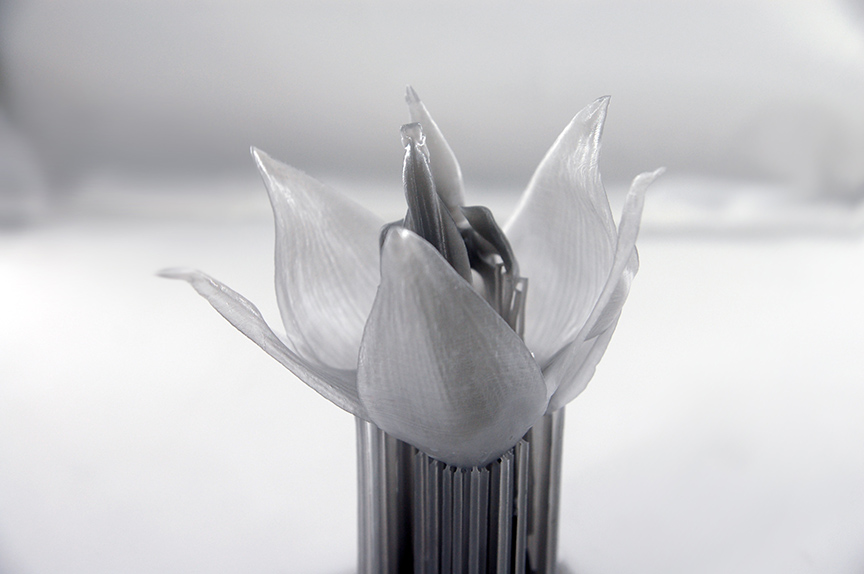

Formlabs Flexible Resin

Formlabs Flexible Resin is an elastic 3D printing material with mechanical properties reminiscent of rubber.

What to print: Formlabs Flexible Resin is the best photopolymer to simulate the appearance and mechanical properties of materials such as soft plastic, rubber and silicone. Well suited for printing any flexible parts and soft surfaces, to create prototypes of rubber parts.

You can print a smartphone case, for example.

Formlabs Durable Resin

Formlabs Durable Resin is a wear-resistant polymer that resists friction and abrasion. Flexible enough.

What to print: Formlabs Durable Resin is used for the manufacture of parts that can withstand prolonged deformation - packages, various household goods, elements of homemade mechanisms.

Jewelry

Formlabs Castable Resin

Formlabs Castable Resin is a special burnable photopolymer for jewelers and everyone involved in metal casting. The material accurately conveys the smallest details, and during casting it burns out completely - allowing the metal to completely replicate the shape of the model and without leaving ashes behind.

What to print: burning models for the manufacture of jewelry and any other cast metal products. The right size, of course.

Dental

Formlabs Dental SG

What to print: Guides and patterns for precision drilling and related operations.

It is a biocompatible polymer designed specifically for creating patterns and drilling guides. It is used in therapy and prosthetics, together with 3D scanning, which allows achieving previously impossible precision in dental operations.

NextDent Ortho Clear

NextDent Ortho Clear is a photopolymer from the Netherlands-based NextDent, which has a long-standing successful practice of creating dental materials. It is a transparent, wear-resistant and biocompatible polymer used in dentistry. It has great bending and abrasion resistance.

What to print: the material is used to print all types of dental orthoses and aligners. The oriners printed from Ortho Clear fix the bite well, at the same time they are almost invisible in the process of wearing and allow you to take them off yourself, for example, for meals.

As it is easy to guess, this is not the only dental material from NextDent, other photopolymers from this company can be found in a more detailed article on dental materials for 3D printing.

Ceramic

Formlabs Form X Ceramic

Form X Ceramic is a pilot project of Formlabs to create materials with new properties. The first one, Ceramic, was presented to the public at CES 2017 in January.

What to print: everything that should look like ceramics and repeat the properties of ceramics - figurines, vases, napkin holders, decorative interior details.

The material is an emulsion of ceramic microparticles in a photopolymer resin and allows you to print on a stereolithographic printer products that look and feel ceramic immediately after printing, and after firing, they become practically real ceramics, which can be painted and glazed, like traditional ceramic products.

Decorative

Formlabs glitter resin

What to print: souvenirs, design and fashion concepts, toys.

Glitter Resin is glitter photopolymer resin. Want to print something brilliant and sparkling, create an original gift or a unique item for interior decoration? Mix Glitter Resin with a transparent polymer, or use it as it is - the result will be at least interesting.

Not the most outstanding material, in terms of durability and accuracy of printing, but - it will take its niche confidently, thanks to its visual properties.

This is not a complete list of available materials - there are still third-party photopolymers that can be used on Form 2 in Open Mode . They often have a more affordable price.

The subtlety is that the “native” resins for Form 2 are tested and tested, their composition is specifically designed to work with this printer. And with the compositions of other manufacturers, if their properties differ, a separate adjustment will be needed, with test print sessions - and this is a waste of time and an expensive polymer.

Yes, and some of the automatic functions in the Open Mode are turned off, which reduces usability - determining the polymer on the cartridge, auto-tuning the printer for it, automatic feeding of the polymer into the tray and mixing. If you do not take into account these details, you can screw up a lot of printouts and spend a lot of nerves.

Here each user will prioritize himself.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/400793/

All Articles