3D printing with metals - technologies and printers

3D metal printing is becoming increasingly popular. And this is not surprising: each metal material for printing offers a unique combination of practical and aesthetic properties in order to meet the requirements for different products, be it prototypes, miniatures, decorations, functional parts, or even kitchen accessories.

The reasons for printing with metals are so compelling that 3D printing with metals is already being introduced into mass production. In fact, some 3D-printed parts have already caught up, and some have surpassed their properties that are produced by traditional methods.

Traditional production from metals and plastics is very wasteful - in the aviation industry, for example, up to 90% of materials are discarded. The output of products, in some industries, is no more than 30% of the used material.

3D printing with metals consumes less energy and reduces waste to a minimum. In addition, the finished 3D printed product can be up to 60% lighter compared to a milled or cast part. The aviation industry alone will save billions of dollars in fuel - by reducing the weight of structures. But the strength and lightness are needed in other industries. Yes, and cost, too.

')

3D printing metal houses

What can you do if you want to try 3D printing with metal at home? Extremely high temperatures are necessary for metal printing, you are unlikely to be able to use a conventional FDM 3D printer for this, at least for now. The situation may change in a few years, but now it is not available to the home 3D-technology.

If you want to make metal-looking printouts at home, the best option is to use plastic containing metal particles.

Such as Colorfabb Bronzefill or Bestfilament Bronze .

These filaments contain a significant percentage of metal powders, but also enough plastic - for printing at low temperature with any 3D printer. At the same time, they contain a sufficient amount of metal in order to adequately look, feel and have a weight close to the weight of a metal object.

Products from the filament containing iron are even rusting under certain conditions, which adds plausibility, but they cannot rust through and deteriorate because of this - and this is their advantage over real metal objects.

Advantages of such materials:

- Unique appearance of printouts

- Ideal for costume jewelry, figurines, household items and decor

- High strength

- Very low shrinkage during cooling.

- Heated table is optional

Minuses:

- Low product flexibility depends on print design

- Not considered safe when in contact with food.

- Requires fine adjustment of the nozzle temperature and filament feed rate

- Postprocessing is needed - grinding, polishing

- Rapid wear of the extruder nozzle - metal filament is very abrasive compared to conventional materials.

The total temperature range of printing is typically 195 ° C - 220 ° C.

3D metal printing in industry

If you want to buy a 3D printer that prints real metal for use in the enterprise, then there are two news for you - good and bad.

The good news is that their range is quite wide and continues to expand - you can choose the device that meets any technical requirements. Further in the article you can see this.

The bad news is the price. The cost of professional metal-printing printers starts anywhere from $ 200,000 and grows to infinity. In addition, even if you choose and purchase the most inexpensive of them, a separate blow will be the purchase of consumables, scheduled maintenance with replacement of components, and repairs. Do not forget about the staff, and the cost of post-processing products. And at the preparatory stage for printing, you need special software and people who know how to handle it.

If you are ready for all these expenses and difficulties - read on, we will present some very interesting samples.

3D metal printing - application

In some industrial sectors, metal 3D-printers are already used, they have become an integral part of the production process, which the average consumer may not even suspect:

The most common examples are medical implants and dental crowns, bridges, prostheses, which are already considered the best option for patients. Reason: They can be faster and cheaper manufactured on a 3D printer and adapted to the individual needs of each patient.

A second, equally common example: jewelery. Most major manufacturers are gradually moving from 3D printing of forms and waxes to direct 3D printing by metal, while printing from titanium allows jewelers to create products of previously impossible design.

In addition, the aerospace industry is becoming more and more dependent on 3D printed metal products. Ge-AvioAero in Italy is the world's first fully 3D printing factory that manufactures LEAP jet engine components.

The next industry using 3D-printers for metal - auto industry. BMW, Audi, FCA are already seriously considering the use of technology in mass production, and not only in prototyping, where they have been using 3D printing for many years.

It would seem - why reinvent the wheel? But here, 3D-printing metal has found application. For several years, manufacturers of bicycle components and frames use 3D printing. Not only in the world, but in Russia it has become widespread. The manufacturer of exclusive bicycles Triton finishes the project with a 3D printed element of the titanium frame, this has reduced its weight without sacrificing strength.

But before 3D printing with metals really takes over the world, several serious problems will have to be overcome. First of all, it is the high cost and low production rate of large batches by this method.

3D metal printing technology

Much can be said about the use of metal-printing 3D-printers. It has its own specifics, but the main issues are the same as with any other 3D printers: software and hardware limitations, optimization of materials and printing with several materials. We will not talk much about software, just to mention that the largest publishers, such as Autodesk, SolidWorks, and SolidThinking, all are developing software products for use in bulk printing with metals so that users can implement a product of any imaginable form.

Recently, there have been examples of the fact that metal-printed 3D parts can be just as strong as the traditionally produced metal components, and in some cases even surpass them. Created with the help of DMLS, the products have the same mechanical properties as the solid cast counterparts.

Let's look at the available metal 3D printing technologies:

Process # 1: Powder Fusion

The process of 3D printing with metals, which most large companies use today, is known as fusing or sintering a powder layer. This means that a laser or other high-energy beam fuses into a single unit the particles of a uniformly distributed metal powder, creating layers of the product, one after the other.

There are eight major manufacturers of metal metal 3D printers in the world, most of them located in Germany. Their technologies are abbreviated as SLM (selective laser melting) or DMLS (direct metal sintering with a laser).

Process # 2: Binder Jetting

Another professional method with a layer-by-layer compound is the gluing of metal particles for subsequent roasting in a high-temperature furnace, where the particles are fused under pressure, forming a single metal unit. The printing head applies the connecting solution to the powder substrate in layers, like an ordinary printer on sheets of paper, after which the product is sent to the kiln.

Another similar, but different, technology based on FDM printing is the mixing of metal powder into metal paste. Using pneumatic extrusion, a 3D printer squeezes it out, much like a construction 3D printer does with cement to form 3D objects. After the desired form is printed, the objects are also sintered in a kiln. This technology uses Mini Metal Maker - perhaps the only more or less affordable 3D metal printer ($ 1600). Add the cost of a small firing oven.

Process # 3: Weld

One might think that among the technologies of metal printing there is no similar to the usual FDM, however, this is not quite so. You will not be able to melt the metal thread in the hot end of your 3D printer, but the major manufacturers own this technology and use it. There are two basic ways to print with all-metal material.

One of them is called DED (Directed Energy Deposition), or laser cladding. It uses a laser beam to fuse a metal powder, which is slowly released and precipitated from the extruder, forming layers of the object using an industrial manipulator.

This is usually done inside a closed chamber, however, using MX3D as an example, we see the possibility of implementing such a technology in the construction of a real full-size bridge, which should be printed in 2017 in Amsterdam.

The other is called EBM (Electron Beam Manufacturing), it is a technology of forming layers of metal raw materials under the influence of a powerful electron beam, with its help they create large and very large structures. If you do not work in the defense complex of the Russian Federation or the United States, you are unlikely to see this technology alive.

Another couple of new technologies that have just appeared, which are used only by their creators, are presented below - in the section on printers.

Metals Used

Ti - Titan

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing, and certainly one of the most versatile, as it is both durable and lightweight. It is used both in the medical industry (in personalized prosthetics) and in the aerospace and automotive industries (for the manufacture of parts and prototypes), and in other areas. The only catch is that it has a high reactivity, which means that it can easily explode when in powder form and must be used for printing only in the inert gas of Argon.

SS - Stainless Steel

Stainless steel is one of the most affordable metals for 3D printing. At the same time, it is very durable and can be used in a wide range of industrial and artistic productions. This type of steel alloy, containing cobalt and nickel, has high elasticity and tensile strength. 3D printing by stainless steel is mainly used only in heavy industry.

Inconel - Inconel

Inconel is a modern supersplash. It is manufactured by Special Metals Corporation and is a patented trademark. Consists, for the most part, of nickel and chromium, has a high heat resistance. Used in the petroleum, chemical and aerospace industries (for example: to create distribution nozzles, onboard “black boxes”).

Al - Aluminum

Because of its inherent lightness and versatility, aluminum is a very popular metal for 3D printing. It is usually used in the form of various alloys, forming their basis. Aluminum powder is explosive and is used in printing in inert gas Argon.

CoCr - Cobalt Chrome

This metal alloy has a very high specific strength. It is used both in dentistry - for 3D printing of dental crowns, bridges and byugel dentures, and in other areas.

Cu - Copper

With rare exceptions, copper and its alloys - bronze, brass - are used for casting using burnable models, and not for direct metal printing. This is because their properties are far from ideal for use in industrial 3D printing; they are more often used in decorative and applied arts. With great success, they are added to plastic filament - for 3D printing on conventional 3D printers.

Fe - Iron

Iron and magnetic iron ore are also mainly used as an additive to the PLA filament. In large industry, pure iron is rarely used, and we have written above about steel.

Au, Ag - Gold, silver and other precious metals

Most powder fused layers of 3D printers can work with precious metals such as gold, silver and platinum. The main task when working with them is to ensure the optimal consumption of expensive material. Precious metals are used in 3D-printing of jewelry and medical products, as well as in the manufacture of electronics.

3D printers printing metal

# 1: Sciaky EBAM 300 - Titanium Bar

For printing really large metal structures, EBAM from Sciaky is the best choice. This device can be any size, to order. It is used mainly in the aerospace and defense industries of the United States.

As a production model, Sciaky sells EBAM 300. It has a work area size with sides of 5791 x 1219 x 1219 mm.

The company claims that the EBAM 300 is one of the fastest commercially available industrial 3D printers. Structural elements of the aircraft, the production of which, according to traditional technologies, could take up to six months, are now printed within 48 hours.

Sciaky's unique technology uses a high power electron beam gun to melt titanium filaments 3mm thick, with a standard deposition rate of about 3-9 kg / h.

# 2: Fabrisonic UAM - Ultrasound

Another way to 3D-print large metal parts - Ultrasound Additive Manufacturing Technology (UAM - Ultrasound Additive Manufacturing Technology) from Fabrisonic. The Fabrisonic brainchild is a three-axis CNC machine with an additional welding head. The metal layers are first cut, and then welded to each other using ultrasound. The largest 3D printer Fabrisonic - “7200”, has an assembly volume of 2 x 2 x 1.5 m.

# 3: Laser XLine 1000 - Metal Powder

One of the largest, on the market of 3D printers printing with the help of metal powder, has long been the XLine 1000 made by Concept Laser. It has an assembly area of 630 x 400 x 500 mm in size, and it takes up space like a small house.

The German company that manufactured it, which is one of the suppliers of 3D printers for aerospace giant companies, such as Airbus, recently introduced a new printer - XLine 2000.

2000 has two lasers and an even larger assembly volume - 800 x 400 x 500 mm. This machine, which uses the patented LaserCUSING technology (type of selective laser melting), can create objects from alloys of steel, aluminum, nickel, titanium, precious metals, and from some pure materials (titanium and high-grade steels.)

All major players in the 3D metal printing market have such machines: EOS, SLM, Renishaw, Realizer and 3D Systems, as well as Shining 3D, a rapidly growing company from China.

# 4: M Line Factory - Modular 3D Factory

Working volume: 398.78 x 398.78 x 424.18 mm

From 1 to 4 lasers, 400 - 1000 watts of power each.

The concept of M Line Factory is based on the principles of automation and interaction.

M Line Factory, from the same Concept Laser, and working on the same technology, does not focus on the size of the work area, but on the convenience of production - it is a modular architecture device that divides production into separate processes so that these processes can occur at the same time, rather than consistently.

This new architecture consists of 2 independent machine nodes:

M Line Factory PRD (Production Unit - production unit)

Production Unit consists of 3 types of modules: dosing module, printed module and overflow module (tray for finished products). All of them can be individually activated and do not form one continuous unit of equipment. These modules are transported through a system of tunnels inside the machine. For example, when a new powder is supplied, an empty powder storage module can be automatically replaced with a new one, without interrupting the printing process. Finished parts can be moved outside the machine and immediately replaced by the following tasks.

M Line Factory PCG (Processing Unit)

This is an independent data processing unit that has a built-in sifting and powder preparation station. Unpacking, preparation for the next print job and screening take place in a closed system, without operator participation.

# 5: ORLAS CREATOR - 3D printer ready for use

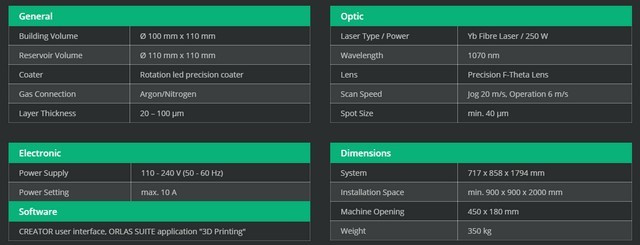

The creators of ORLAS CREATOR position this 3D printer as the most affordable, easy to use and ready to use, not requiring the installation of any additional components and third-party software that can print directly from the complete CAD / CAM file of their own design.

All the necessary components are installed in a relatively compact case, which needs 90x90x200 cm of space. It will not take up much space, although it looks impressive, and it weighs 350 kg.

As can be understood from the manufacturer’s table, the metal powder is sintered with a rotating laser system, layers 20-100 μm thick and with a “pixel” size of only 40 μm, in a nitrogen or argon atmosphere. You can connect it to a conventional household power supply, if your wiring can withstand a load of 10 amperes. That, however, does not exceed the requirements of the average washing machine.

Laser power - 250 watts. The working area is a cylinder 100 mm in diameter and 110 in height.

# 6: FormUp 350 - Powder Machine Part Method (PMPM)

FormUp 350, working in the Powder Machine Part Method (PMPM) system, was created by AddUp, a joint project of Fives and Michelin. This is the newest device for 3D printing with metals, first introduced in November at Formnext2016.

The principle of operation of this 3D printer is the same as that of the above colleagues, but its main feature is different - it lies in its involvement in PMPM.

The printer is designed specifically for industrial use, in 24/7 mode, and is designed for exactly this pace of work. The PMPM system includes the quality control of all components and materials, at all stages of their production and distribution, which should guarantee consistently high quality performance, which Michelin has many years of experience.

# 7: XJET - NanoParticle Jetting - Metal Inkjet Printing

Nanoparticle injection technology involves the use of special hermetic cartridges with a solution containing a suspension of metal nanoparticles.

The nanoparticles are deposited and form the material of the printed product.

Given the declared features of the technology (the use of nano-sized metal particles), it is easy to believe the creators of the device when they claim its unprecedented accuracy and print resolution.

# 8: VADER Mk1 - MagnetoJet - metal inkjet printing

The technology of Zack Vader MagnetoJet is based on the study of magnetic hydrodynamics, and more specifically - the ability to control the molten metal using magnetic fields. The essence of the development is that a drop of strictly controlled size is formed from molten aluminum, and this printing is carried out with these drops.

The size of such a droplet is from 200 to 500 microns, printing occurs at a speed of 1000 drops per second. The working area of the printer: 300 mm x 300 mm x 300 mm

Working material: Aluminum and its alloys (4043, 6061, 7075). And, even if it is only aluminum, but the printer is 2 times faster than powder and up to 10 times cheaper.

In 2018, the release of the Mk2 is planned, it will be equipped with 10 printheads, which should give a print speed increase of 30 times.

# 9: METAL X - ADAM - Atomic Diffusion

The company Markforged has introduced a new technology for 3D metal printing - ADAM, and a 3D printer working on this technology - Metal X.

ADAM (Atomic Diffusion Additive Manufacturing) is an atomic diffusion technology. Printing is done with a metal powder, where the metal particles are coated with a synthetic binder that is removed after printing, allowing the metal to come together.

The main advantage of the technology is the absence of the need to use ultra-high temperatures directly in the printing process, which means that there are no restrictions on the refractoriness of the materials used for printing. Theoretically, the printer can create 3D-models of ultra-strong tool steels - now it prints stainless steel, and in the design of titanium, Inconel and steel D2 and A2.

The technology allows you to create parts with a complex internal structure, such as in honeycombs or in porous bone tissue, which is difficult with other 3D printing technologies, even for DMLS.

Size of products: up to 250mm x 220mm x 200mm. The layer height is 50 microns.

Look, soon you can print a high-quality knife - from scratch, in a couple of hours, giving it any intricate design.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/400731/

All Articles