China SNR Connector Manufacture

Import substitution in Russia is a magic word, and especially for officials, on whom it has a spellbound effect. “Import-replace” we want everything from parmesan to complex computing technology. But, in order to organize the production of even a simple connector , an entire production line is needed, each section of which is a complex machine and the specialist behind it.

We will walk along the workshops of the plant, where “NAG” manufactures SC optical sockets, in order to evaluate what efforts and investments the import substitution will cost our country.

')

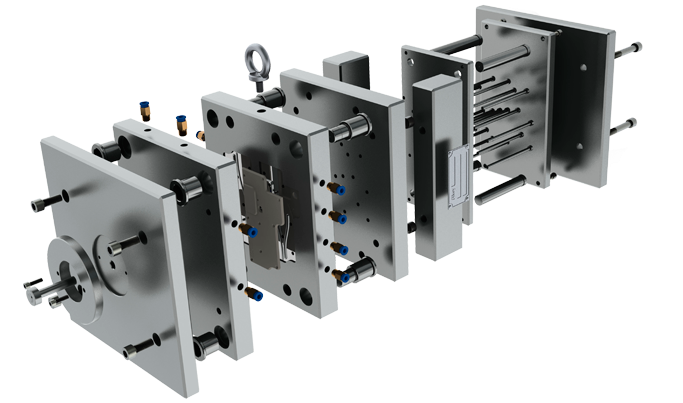

It all starts with the manufacture of molds. The mold is a multi-component constructor with movable rods, interchangeable signs, ejector that form the internal cavities. All this allows to obtain a product with complex geometry with large print runs, which in turn reduces manual labor as much as possible.

For the production of the mold, a competent design engineer is needed, since you need to take into account a lot of nuances when working with plastics. For example, plastic after casting is subject to shrinkage and warping. Also, there is a serious problem of the occurrence of stresses in the material with uneven cooling.

This is how a mold production workshop looks like:

The age of the mold is not long. Its average life is from 100 to 700 thousand closures. Therefore, its production is suitable metal of higher grades. In addition, for the manufacture of the mold requires a whole list of different machines - from milling, planing, EDM and wire-cut, to universal machining centers.

CNC Milling Machine

Horizontal Milling Machine

Electroerosive machine

Wire cut machine

Universal machining center

Surface grinding machine. Finishing.

Electroerosive machine

These machines using pulses destroy the crystal lattice of electrically conductive material. Due to this, it is possible to achieve high precision manufacturing of complex shapes - up to 1 micron and with a roughness of 11-12 class.

Wire cut machine

During the work on the machine the thin wire with a diameter up to 0,1 mm, working by the principle of a tape saw is used. This technology allows faster processing of parts with large linear dimensions.

The output is this.

Filling the form

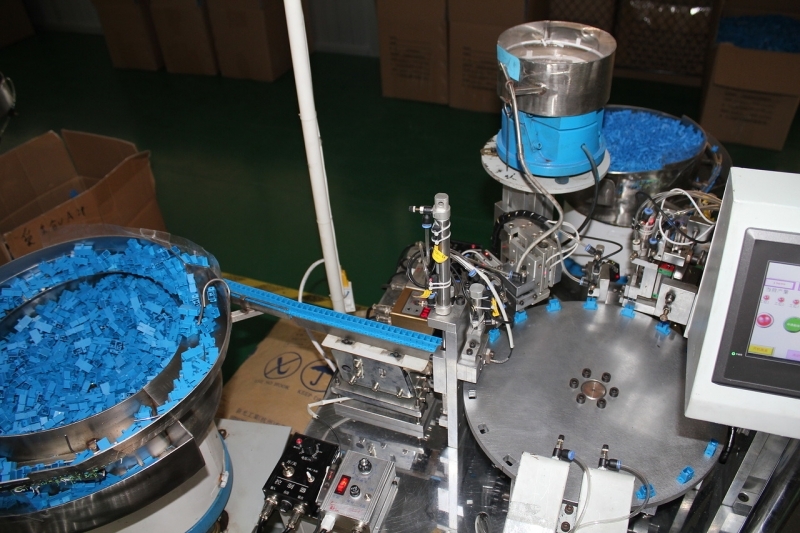

In the workshop are located the whole rows of automatic thermoplastic.

Machines must be constantly loaded with work, because they require a lot of energy to heat up. Therefore, you can not allow them to cool.

Defective connector shanks are mercilessly sent for recycling.

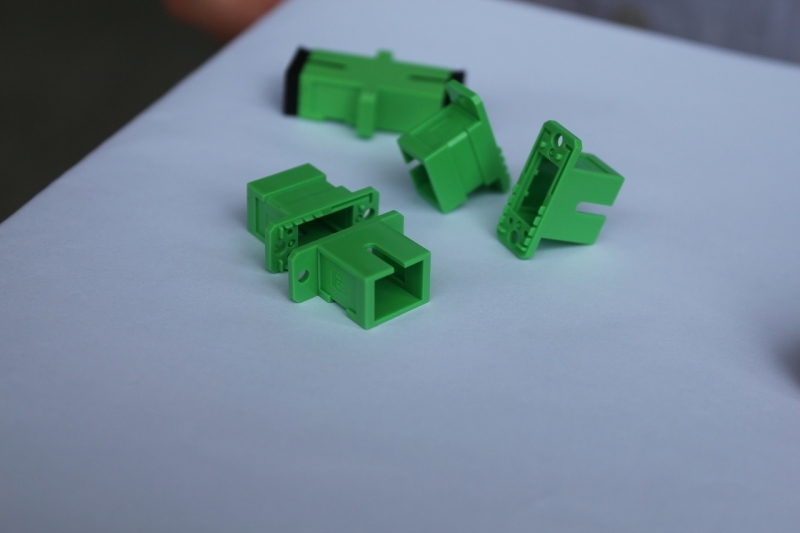

These are plastic handsome men of different modifications and colors obtained after passing through several stages.

The scale of production in the spirit of the Soviet machine-building giants. In these workshops, for example, parts of FC forks are made.

Going further through the shops again meet the slender rows of thermoplastics. All work processes are automated here. People need only to run the equipment.

Excess production is crushed and sent for recycling.

And this is the raw materials supply system.

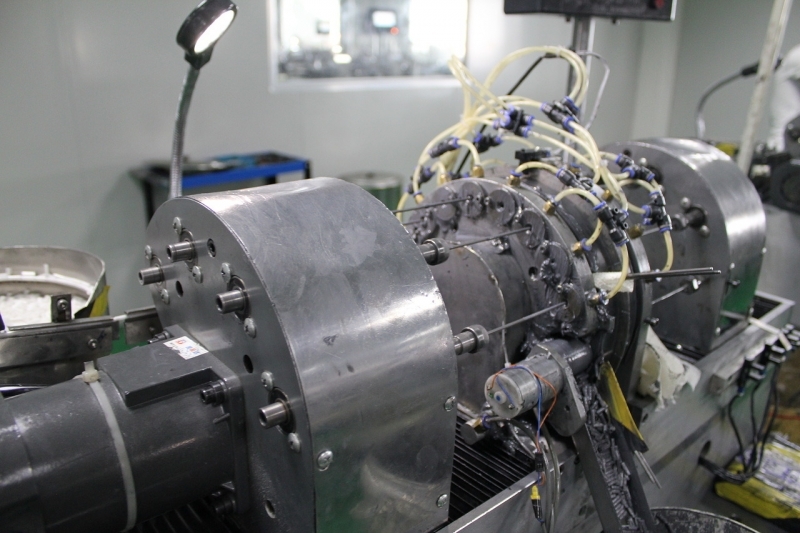

Zirconium Sleeve Fabrication

At present, a billet in the form of a tube is purchased, which later undergoes the necessary processing. First, the sleeve is cut to the desired size.

So is a longitudinal section of the sleeve.

Next is the processing of parts in the centrifuge.

The bushing is dried

Next, the centering bushings go through the grinding process: coarse and then thin.

It looks like the shop. People here are also needed only to maintain machines that do all the work themselves.

These metal sticks bring the sleeves up to standard. It is noteworthy that one stick can process only a few dozen bushings, and after it is sent for processing.

Quality control

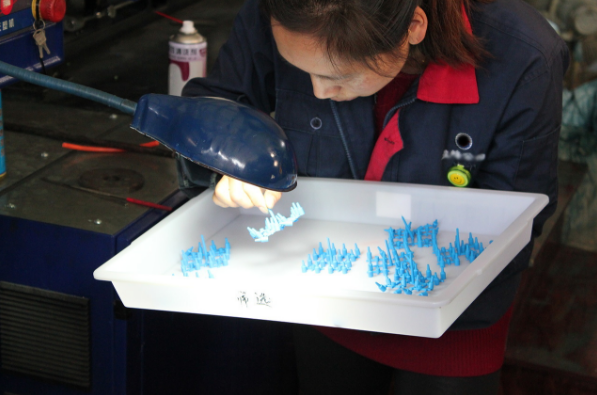

The product pass visual inspection.

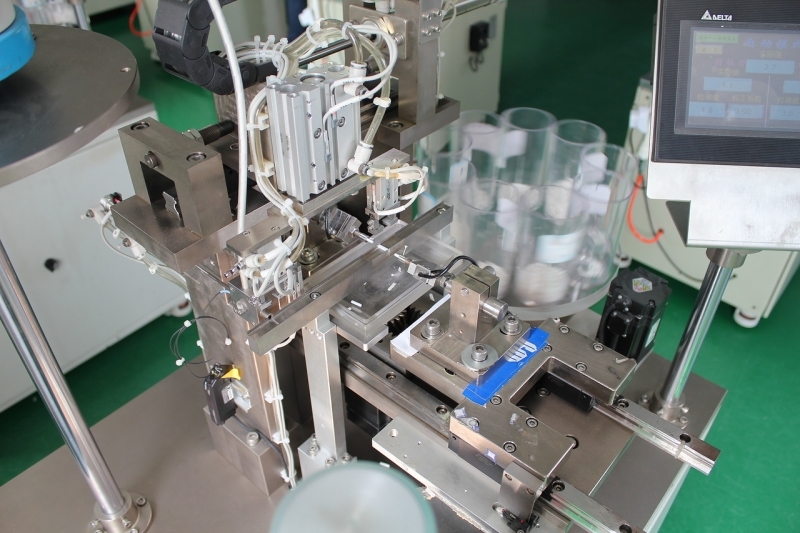

It is followed by the control of geometry. Here everything is on the machine.

There is a process of checking how firmly the ferrule will hold.

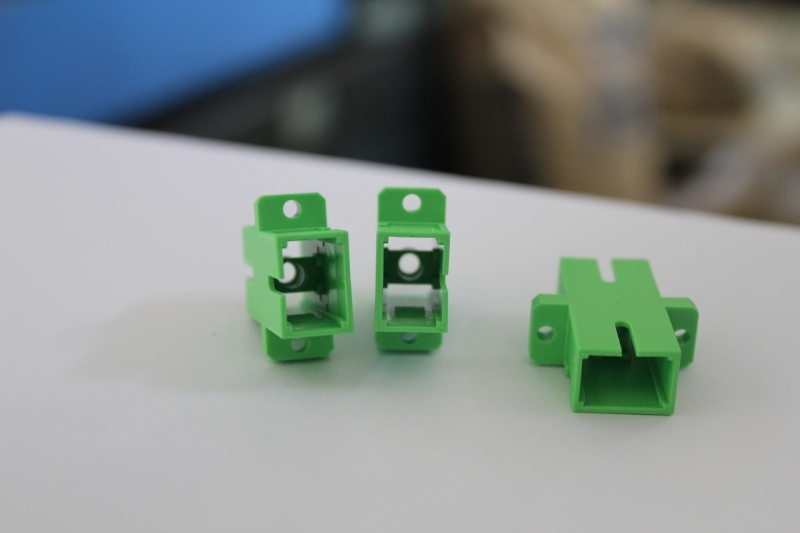

A variant of what can be supplied to our customers.

And here the sleeve is placed in the housing of the optical outlet.

The protective plugs are inserted into the adapter.

At the finish straight product pass the next test for marriage.

As a result, such handsome men are obtained.

Source: https://habr.com/ru/post/400691/

All Articles