On the modern method of storing spent nuclear fuel

In this article I will try to acquaint the reader with the leading, at the moment, storage technology for spent nuclear fuel - the so-called “dry” storage. And of course, to prove why the storage of SNF is not a “waste dump” or a “nuclear repository”.

Prologue

At present, there is a situation in the world of nuclear energy that was hardly expected to be seen 30-40 years ago.

')

The creators of the "peaceful atom" believed not only in obtaining a large amount of heat using a sufficiently small amount of fuel, but also the "highlight" was considered the possibility of producing this same fuel in breeder reactors, or isolating useful fission products from spent nuclear fuel for further re-engagement them into the nuclear fuel cycle. Not for nothing, the first electricity in the world (not to be confused with the First NPP , which was connected to the grid) was obtained just with the help of a fast neutron reactor, one that can not only generate electricity, but also fuel for subsequent downloads.

The first electricity, suitable for use in terms of parameters, was received on December 20, 1951. The EBR-1 reactor powered 4 200 watt light bulbs.

But, unfortunately, in fact, not everything was as rosy as in theory. Our EBR-1 has faced some problems , and the development of the nuclear industry has largely moved away from the subject of fast reactors, giving way to thermal-neutron reactors.

The processing of spent nuclear fuel to extract useful fission products and reduce residual activity also suffered a difficult fate.

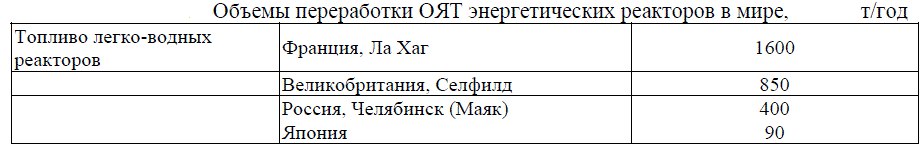

From an economic point of view, reprocessing is beneficial only in large volumes, and also because of the complexity of the technological process and the issues of control of nuclear material, only a few countries were able to allow it as a result.

A total of 2,940 tons / year is released, and this is despite the fact that about 10,000 tons / year is unloaded from all operating reactors.

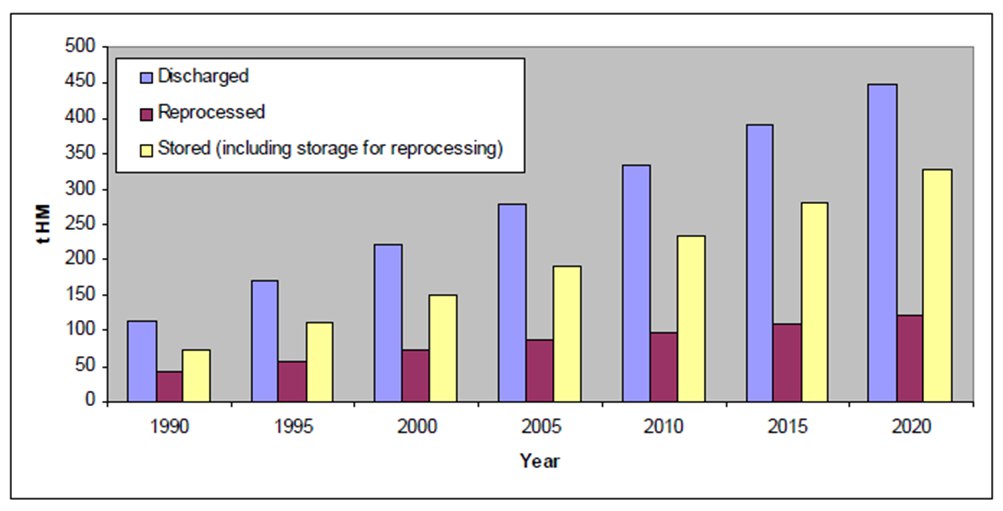

Given the ever-increasing accumulation of spent fuel, in many (almost all) countries that use nuclear energy, the question quickly emerged about how to handle and dispose of spent nuclear fuel.

As can be seen, the amount of SNF that is to be temporarily stored is constantly growing (IAEA ).

At the moment, all countries using nuclear energy are conditionally divided into three camps:

- Countries that completely or partially process SNF to use fission products for the manufacture of MOX fuel.

- Countries that have declared their desire to completely bury their SNF and are actively involved in the development of projects for final disposal.

- Countries that have postponed the final decision on the issue of handling SNF for later (“wait and see” position).

And the latter countries, of course, an absolute set. The problems associated with the storage of SNF every year are becoming more global. Even if the country refuses further plans for the development of the nuclear industry, the issue of ensuring the safe handling of SNF will be relevant for at least several decades.

A bit of history

Initially, the overwhelming majority of spent fuel storage facilities were of the so-called “wet” type. But given their shortcomings, as well as the progress of engineering, gradually, starting from the 80s of the last century, exactly “dry” repositories began to appear.

They have significant advantages, which led to the development of the entire technology:

- the possibility of building bursts and lower initial investment in the building;

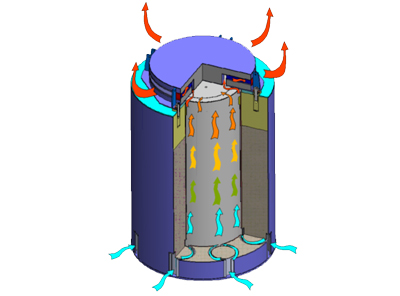

- passive system of residual heat release from SFA;

- insignificant formation of radioactive waste during the operation of the repository, almost complete lack of formation of liquid radioactive waste

- low operating costs (much lower than the costs for storing SFA in pools).

What is a “dry” SNF storage?

In principle, the following types of technologies for dry storage of spent nuclear fuel can be distinguished: container storage technology and modular storage technology. I’ll dwell on container storage.

The history of container storage, perhaps, begins in 1986, when the US nuclear regulator issued a license to operate a dry container storage of spent nuclear fuel at the Sarry site in Virginia.

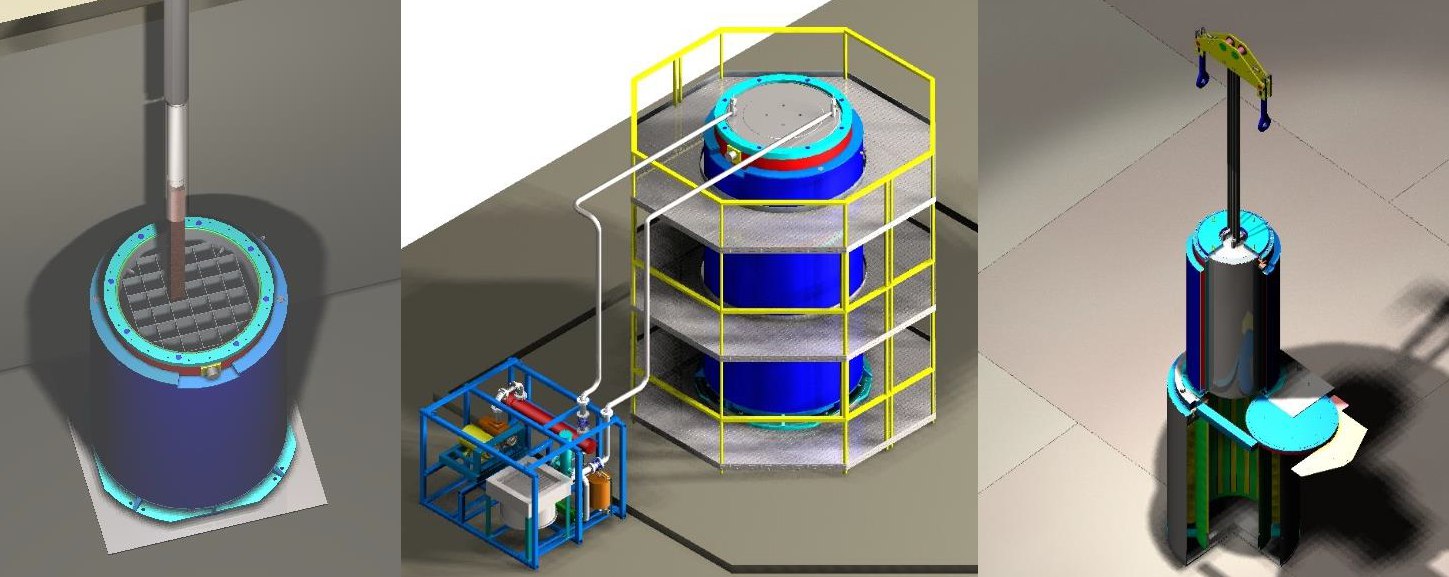

The general principle of containerized storage of SNF is that our spent fuel is stored in sealed metal baskets filled with inert gas, usually helium, and the baskets themselves are located in the protective container case. The robust design of the container body serves as a radiation protection and also prevents damage to the metal basket. The container can be both concrete and metal . The heat sink is carried out by natural convection of ambient air.

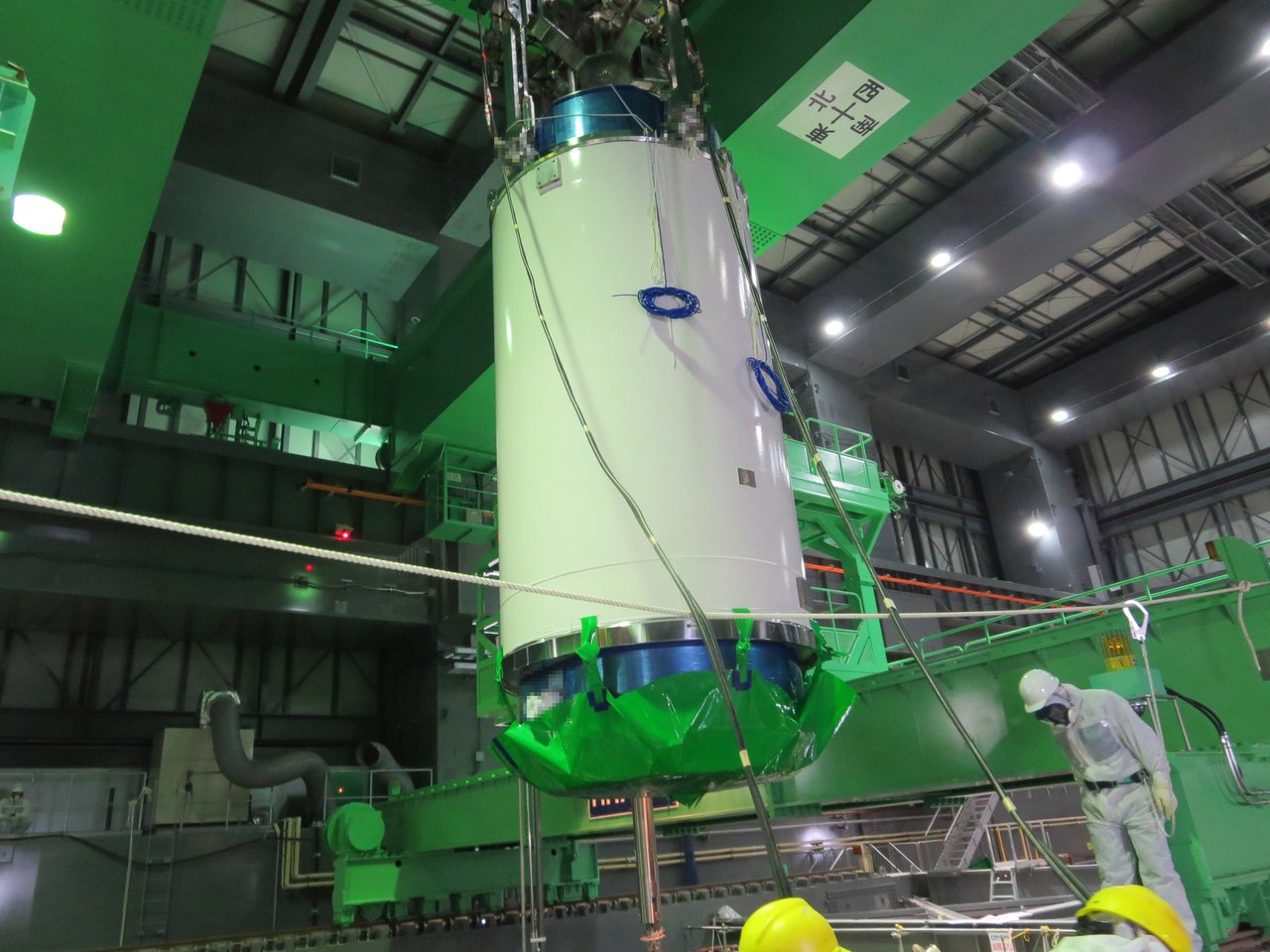

Operations are first performed at the NPP site, and then a container of fuel (the number of fuel assemblies depends on the type of reactor and the design of the container) is sent to the storage site.

Transportation is carried out either by a vertical conveyor (if the storage is stationary), or by road or a special train , traveling on public railways.

The basket is loaded with spent fuel assemblies, then welding, drying and filling the basket with helium and its reloading into a concrete container are carried out.

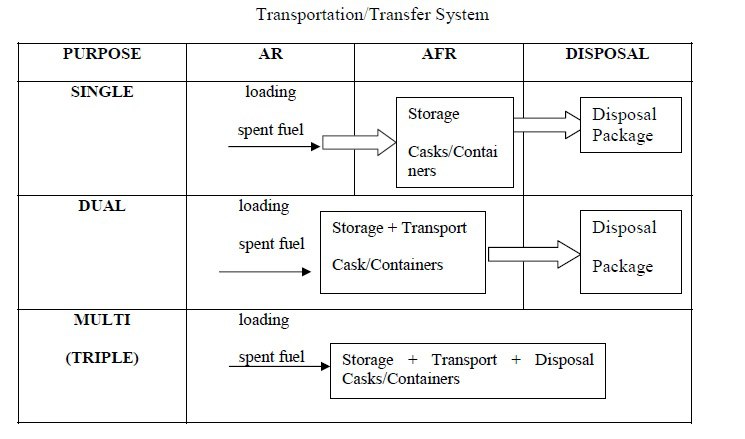

At present, it is customary to distinguish between single-purpose system containers, dual-purpose system containers and multi-purpose system containers. The difference is in the number of operations for which this container can be used: storage, transportation, long-term disposal.

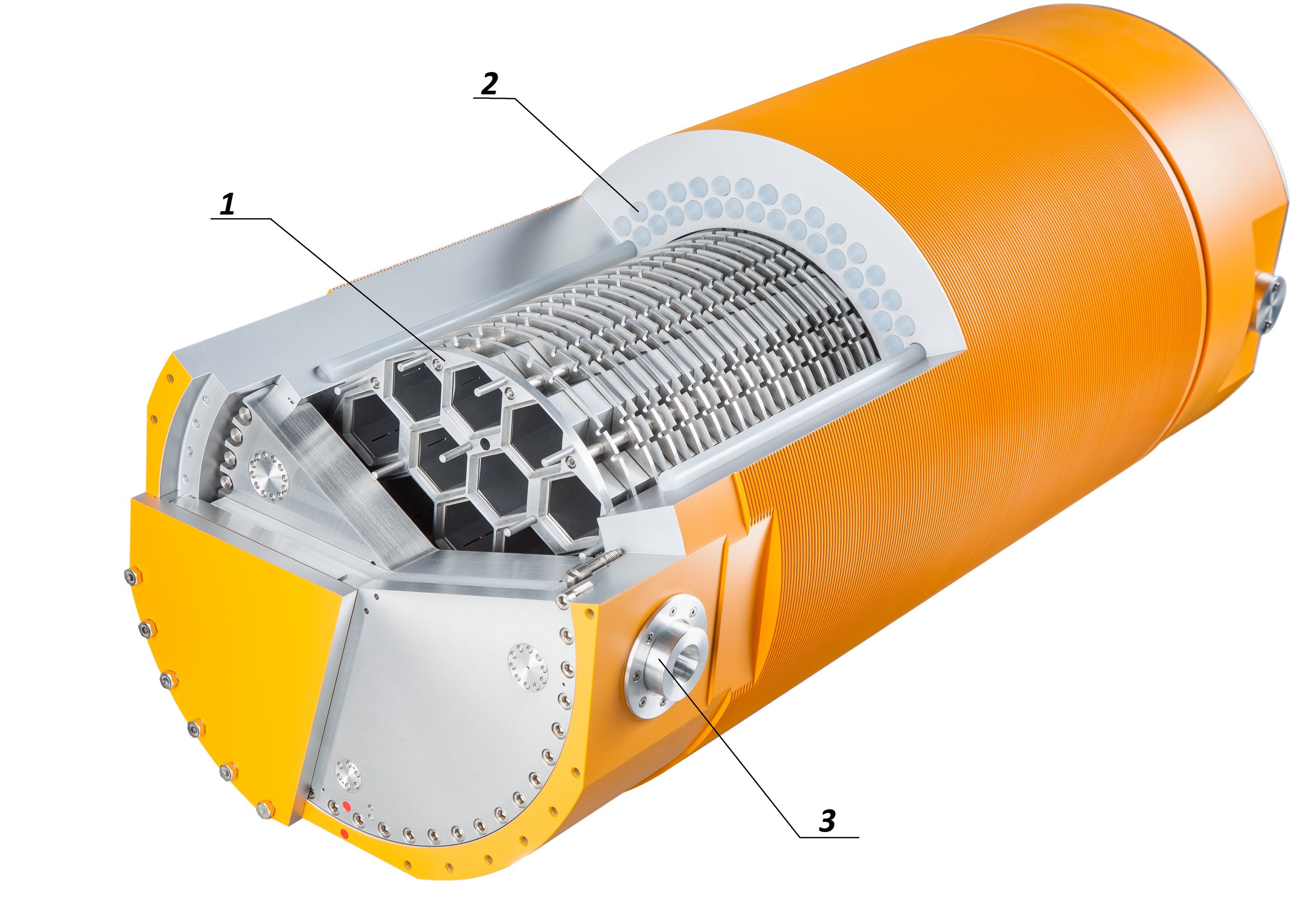

A general view of a metal container for SNF storage will be presented using the example of a container for VVER 1000 SFA.

- The same basket designed for loading SFAs into it (you can see the hex covers in which the SFAs are placed).

- Channels for the installation of neutron absorber (boron-alloyed steel or aluminum rods). Installed to ensure that the system was subcritical, that is, there was no possibility of a fission chain reaction.

- Pins for transport operations with the container.

- Thick-walled metal shell. Provides physical and radiation safety.

- The lids covering the canister (1 lid) and the outer metal container (2 lids), to ensure the best possible radiation situation near the container. They are also completed with holes for installing helium valves, for filling the basket with helium, which provides heat removal and medium inertness in the basket.

On containers with spent nuclear fuel, temperature control sensors are installed, and the containers themselves are installed at a regular place on the storage platform.

As you can see, even the pitch between the containers is set specifically. This is done to ensure the nuclear and radiation safety of personnel.

Sites are stationary, and located separately from NPP sites. Fuel is delivered there in special transport containers.

So is our fuel, for several decades (from 50 to 100), waiting for its fate (whether it will be processing or disposal - each country will decide for itself).

Security

The storage of spent nuclear fuel according to the standards of the IAEA is a nuclear installation. Accordingly, the safety requirements are almost the same as those for nuclear power plants.

When designing containers, strength calculations are performed for emergencies (drop of a shipping container from a height of 9 m.), Calculations of thermal conditions for normal operation and accidents. Of course, much attention is paid to neutron-physical calculations to ensure subcriticality and calculations of biological protection.

The fall of the container from a height of 9 meters (just a test).

With the development of engineering design programs, the volumes of various safety analyzes are constantly increasing. A separate item are laboratory tests and field tests.

Simulation of the fall of the Boeing 767 on a group of containers.

At this stage, studies are being conducted to determine the characteristics of fuel during long-term storage in order to substantiate the resource of containers for more than 100 years. Containers are being designed using materials and geometry to enable the unloading of SFAs with shorter exposure times in a pre-reactor pool or for MOX fuel. Shipping containers are designed for railways, cars, and even airplanes .

As a result, it can be noted that the container storage of SNF is a complicated project from an engineering point of view, and the containers themselves are the fruit of many years of engineering work. Ensuring safety is a major concern when dealing with spent fuel. Therefore, modern systems for the storage and handling of spent nuclear fuel can not be compared with conventional barrels.

Source: https://habr.com/ru/post/400511/

All Articles