ITER in 2016

Project

If 2015 was full of drama and struggle to save the project for a project of an international thermonuclear reactor ITER, then there is nothing special to say about 2016 against it. The construction of 39 ITER buildings and structures, in fact, started precisely in 2015 and continued at a good pace in 2016. The production of components for the future reactor is expanding. The battles in the parliaments of Europe and the United States over the approval of funding for 2017 died down - it was precisely the noticeable progress in project management in 2015 that helped. Everything is going according to plan.

')

However, even at a review level, in 2016 there were several important events that are worth mentioning.

First, in 2016, a detailed plan for the construction of ITER was approved, securing sad news on the landmark project dates. The reactor assembly should be completed in December 2024, the first plasma - in December 2025. Then a ten-year set of reactor capabilities will follow - plasma heating systems, scientific equipment, fuel system, and most importantly - the tritium handling system will be added and the facility will be licensed . And only in 2035 (!) We will see deuterium-tritium burning with a capacity of approximately 100 megawatts, and in 2037 full-launch launches (500 megawatts, up to 400 seconds). In terms of energy, potential ITER competitors clearly have a good temporary odds.

The second important event in the life of ITER managers was the signing of the contract for managing the ITER assembly in the summer of 2016. Gradually, the project shifts from the already annoying construction to installation of equipment - first supporting systems (power supply, cryosupply, water cooling, industrial gases, plasma heating systems, etc.), and from the 3rd quarter of 2019 and the reactor itself (interestingly, installation of the reactor in the mine will take place in the conditions of "clean room").

No less important consequence of the “restart” of ITER was the accession to the project of Australia and Iran. While the conditions of their participation are not clear - but most likely it will be a contribution “cash” in exchange for admission to internal information about the project. This option will somewhat relieve the again increased cost (now the official cost of the project is 22 billion euros).

However, let us go down from the global viewing level to the details: here one can note a lot of interesting and local victories.

Building

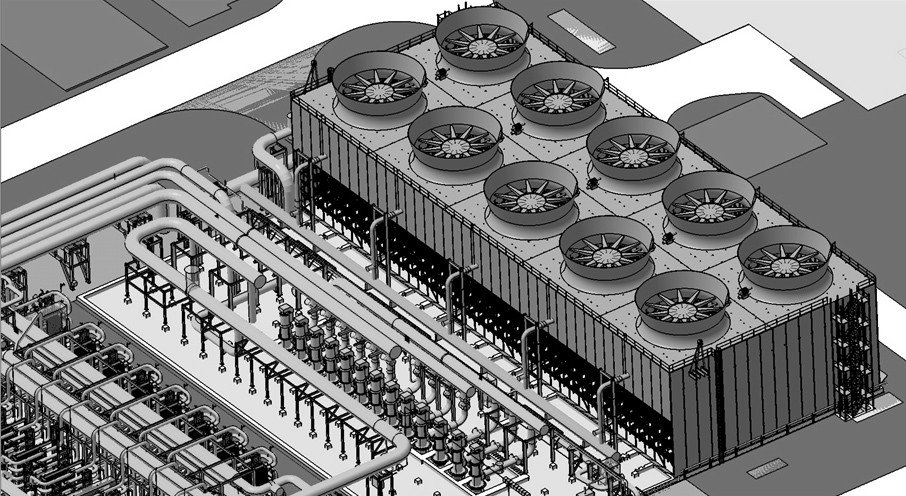

The design image of the ITER heat rejection system with a peak power of 1,150 MW.

The first floor of the ITER building. At this point through the rectangular windows in front there will be cryofeders of the ITER magnetic system.

Installation process of cranes in the pre-assembly building in December 2016. The far wall is temporary, when the tokamak building is completed, it will be disassembled and provide a path for the assembled components to the reactor shaft.

The building is pre-assembled (in the center, in the background), the first above-ground floor of the diagnostic building (to the left) against the background of the foundation of one of the two buildings of magnetic converters.

The coming year 2017 should be the pinnacle of the construction activity of the project - further the scale of construction will gradually fall, but the installation and commissioning efforts should come out on top. In particular, we are waiting for the delivery of buildings of radiofrequency heating systems, a cryogenic plant, laying down plasma diagnostics, building two buildings of magnetic converters.

Component manufacture

In anticipation of the transition to the assembly of the project, the production of ITER components continues to pick up pace. If the unique components of a fusion reactor, such as its vacuum chamber or gyrotrons, are still mostly located in factories, then more standard industrial products like transformers or pipelines are mass arriving at the site, where 16,000 square meters of industrial component warehouses are already running out. Of all these products, we note:

Helium compressors of the ITER cryogenic plant at the factory.

The 30-meter frame for the cryostat base, the 19-meter bottom and the welder (yes, it is in this photo).

And this is 1/4 of the sector, which Korea should pass next year. In addition to the puzzling geometry, the thick walls of the vacuum chamber are technologically unpleasant by the presence of thousands of fasteners that need to be welded from the inside onto its surface.

One of the supporting columns of the assembly stand.

Heat shield in the process of welding coolant pipes.

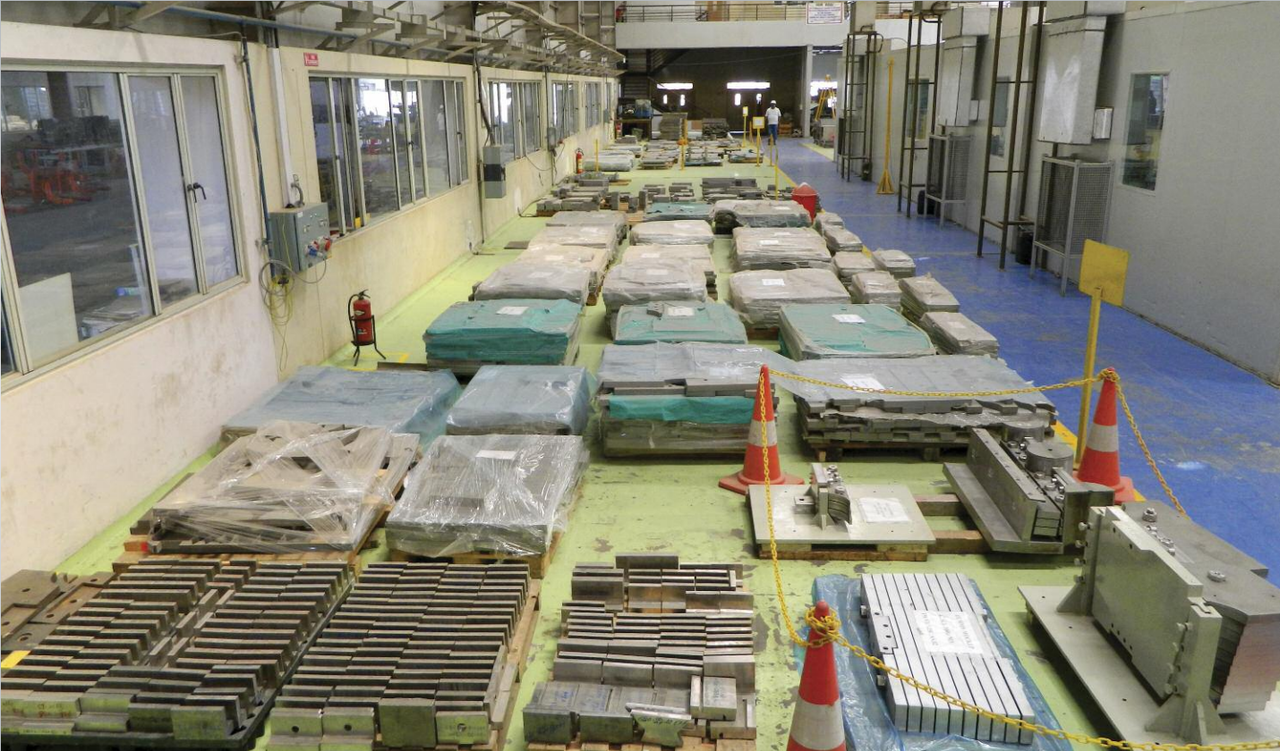

Steel neutron protection blocks at an Indian plant. Below to the right is an example of the assembled element, how they will look inside the double wall of the vacuum chamber

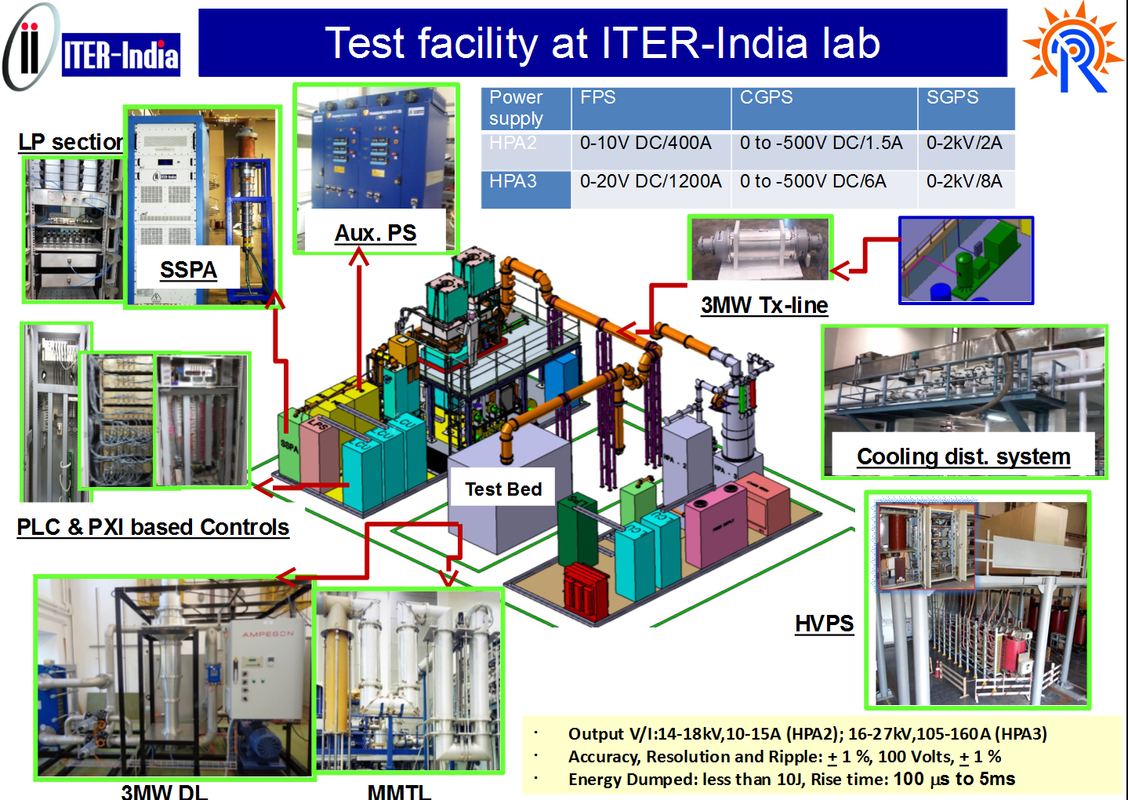

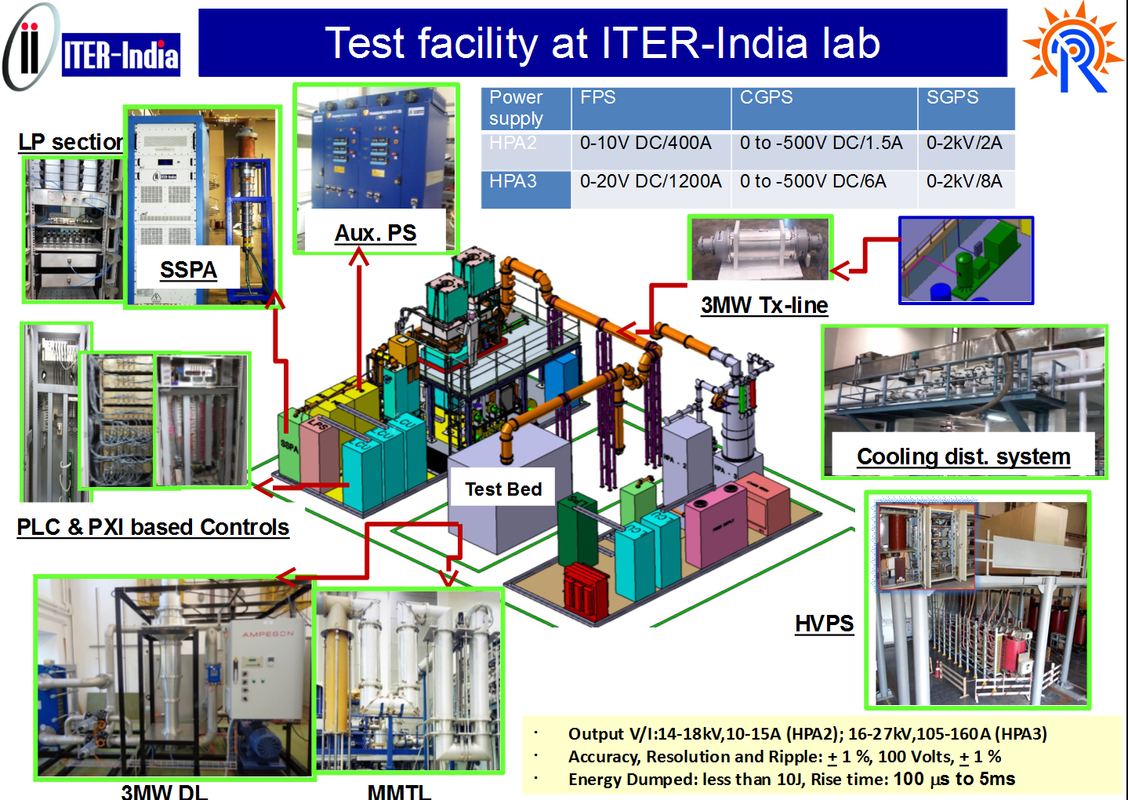

The test bench includes power supplies, 3 cascade tube amplifiers with an output power of 1.8 megawatts, a monitoring and cooling system, a load with adjustable SWR, and much more.

The vacuum vessel of the SPIDER stand, where, from 2017, a 40 amp source of negative hydrogen ions will be tested

Part of the ITER toroidal coil body. 19 hulls should be manufactured in Japan until 2021.

Mechanical processing of an experienced tension bar of a central solenoid. 24 of these strips surround a magnet with a diameter of 4 and a height of 15 meters.

The winding package of the toroidal coil is 134 turns of cable with a current of 68 kA. It must then be installed inside the Japanese case shown above.

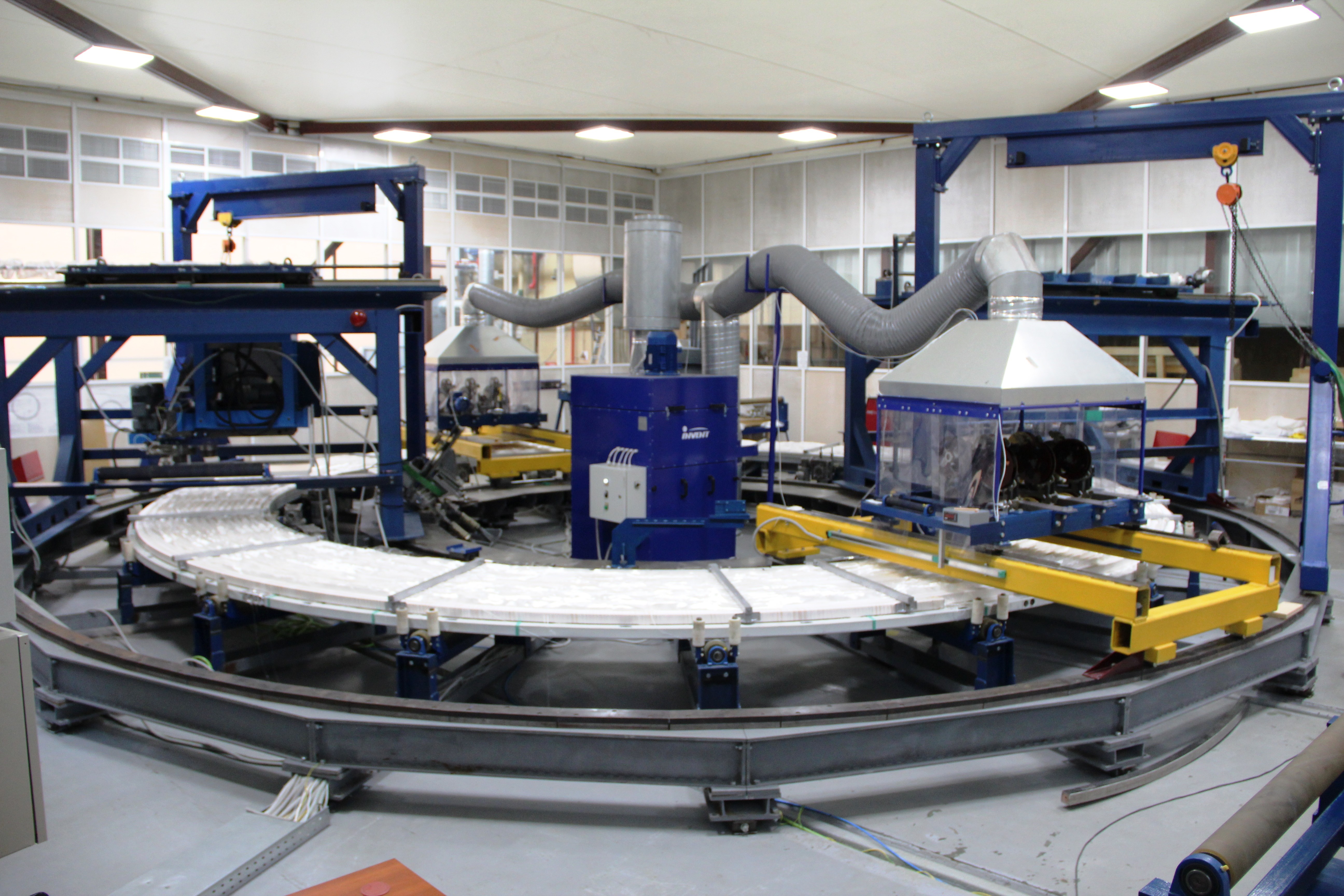

Winding line poloidal coils PF5 and PF2. After manufacturing the coil components, it will be converted to a larger diameter for the manufacture of PF3 and PF4.

One of the 6 lower ITER correction coils is 32 turns of a cable with a current of up to 10 kA.

Winding stand double galeta magnet PF1 in the territory of the Middle Nevsky plant. White - this is a superconducting cable measuring approximately 45x45 mm in fiberglass electrical insulation.

On this, I think, it is worth completing the review of ITER's production successes, although there are still a lot of interesting news, for example, the beginning of the assembly of the first full-scale cryoabsorption vacuum pump. The main conclusion from the review is that, thanks to the new director Bernard Bigo, ITER has overcome the crisis of previous years, and is still making good progress, and the tasks that the construction of an international thermonuclear reactor poses to industry today are a significant source of technical progress in many industries.

Of the minuses, it is worth noting that the real terms that were determined by the Bigo team are very gloomy, and make you think of simpler and smaller alternatives to the classical tokamaks (which will immediately appear in the last years 1 , 2 , 3 ). Nevertheless, in my opinion, ITER continues to be the most interesting engineering and scientific project in the world, offering an incredible interweaving of problems and solutions from various engineering fields. In the coming years, more and more of these “unthinkable solutions” will turn into iron and stand in its place in the most complex machine in the world, and I will continue to follow this as much as I can and talk about it in my blog.

PS For comparison, the results of 2014 and 2015 for ITER.

If 2015 was full of drama and struggle to save the project for a project of an international thermonuclear reactor ITER, then there is nothing special to say about 2016 against it. The construction of 39 ITER buildings and structures, in fact, started precisely in 2015 and continued at a good pace in 2016. The production of components for the future reactor is expanding. The battles in the parliaments of Europe and the United States over the approval of funding for 2017 died down - it was precisely the noticeable progress in project management in 2015 that helped. Everything is going according to plan.

')

However, even at a review level, in 2016 there were several important events that are worth mentioning.

First, in 2016, a detailed plan for the construction of ITER was approved, securing sad news on the landmark project dates. The reactor assembly should be completed in December 2024, the first plasma - in December 2025. Then a ten-year set of reactor capabilities will follow - plasma heating systems, scientific equipment, fuel system, and most importantly - the tritium handling system will be added and the facility will be licensed . And only in 2035 (!) We will see deuterium-tritium burning with a capacity of approximately 100 megawatts, and in 2037 full-launch launches (500 megawatts, up to 400 seconds). In terms of energy, potential ITER competitors clearly have a good temporary odds.

The second important event in the life of ITER managers was the signing of the contract for managing the ITER assembly in the summer of 2016. Gradually, the project shifts from the already annoying construction to installation of equipment - first supporting systems (power supply, cryosupply, water cooling, industrial gases, plasma heating systems, etc.), and from the 3rd quarter of 2019 and the reactor itself (interestingly, installation of the reactor in the mine will take place in the conditions of "clean room").

No less important consequence of the “restart” of ITER was the accession to the project of Australia and Iran. While the conditions of their participation are not clear - but most likely it will be a contribution “cash” in exchange for admission to internal information about the project. This option will somewhat relieve the again increased cost (now the official cost of the project is 22 billion euros).

However, let us go down from the global viewing level to the details: here one can note a lot of interesting and local victories.

Building

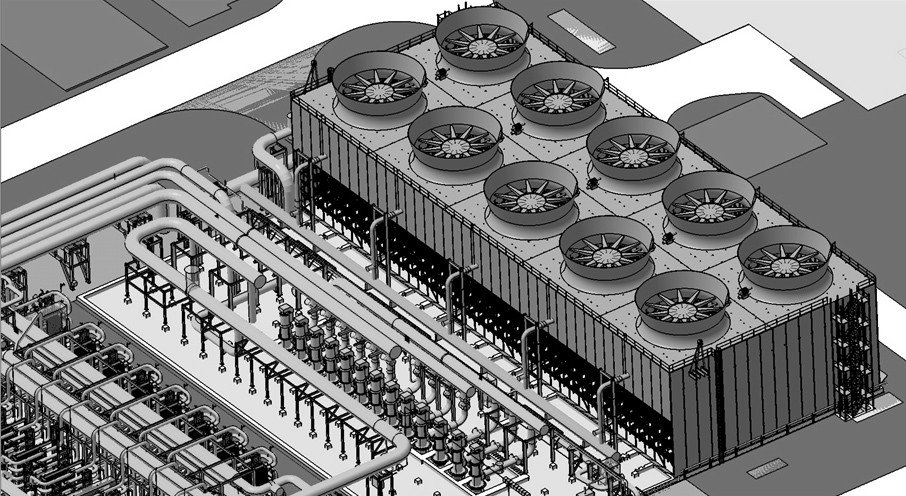

- Three important building complexes have been launched - two buildings of magnetic converters and an excess heat discharge complex for 1 gigawatt with fan cooling towers.

The design image of the ITER heat rejection system with a peak power of 1,150 MW.

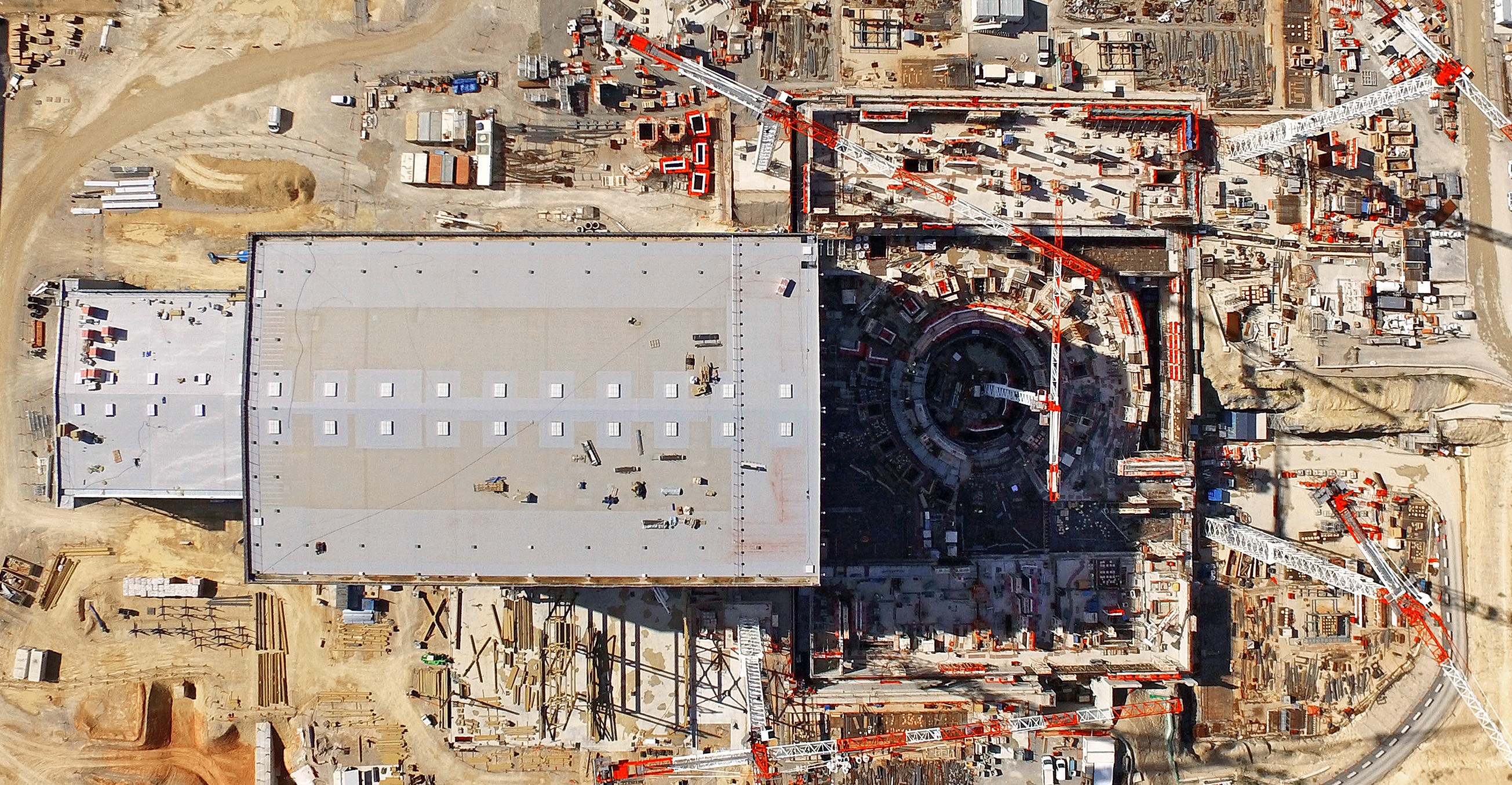

- Tokamak buildings complex - the lower basement floor “B2” is fully completed and 90% of the floor “B2, the construction of the first ground floor L1 has begun (what builders call ground breaking). For the first time in 6 years of the ITER construction history, the design pace of construction has been reached, and it is hoped that in Q2 2019 the tokamak complex of buildings will be commissioned for the installation of the reactor itself. The most interesting thing is that the construction of a tokamak building, which for a very long time was teleping somewhere at the foundation level, is about to overcome the equator - and the diagnostics building has already passed it.

The first floor of the ITER building. At this point through the rectangular windows in front there will be cryofeders of the ITER magnetic system.

- The high-voltage part of the power supply systems of constant and pulsed loads was mounted; in January 2017, it is expected to be set under high voltage. This is quite an important object - commissioning of the cryo-complex and fan-cooled cooling towers will begin in 2018 - these consumers will not be powered by a temporary scheme from two 15 kilovolt lines that are used by the construction site now, therefore a regular system of constant loads with a capacity of 110 megawatts is needed.

- The first building (B61) at the ITER site was completed - before that, all donated facilities were located beyond the formal perimeter. This is an auxiliary building - compressors and cylinders for different gases, water purification and one of the numerous power distribution devices - in general, an auxiliary shop will be based here.

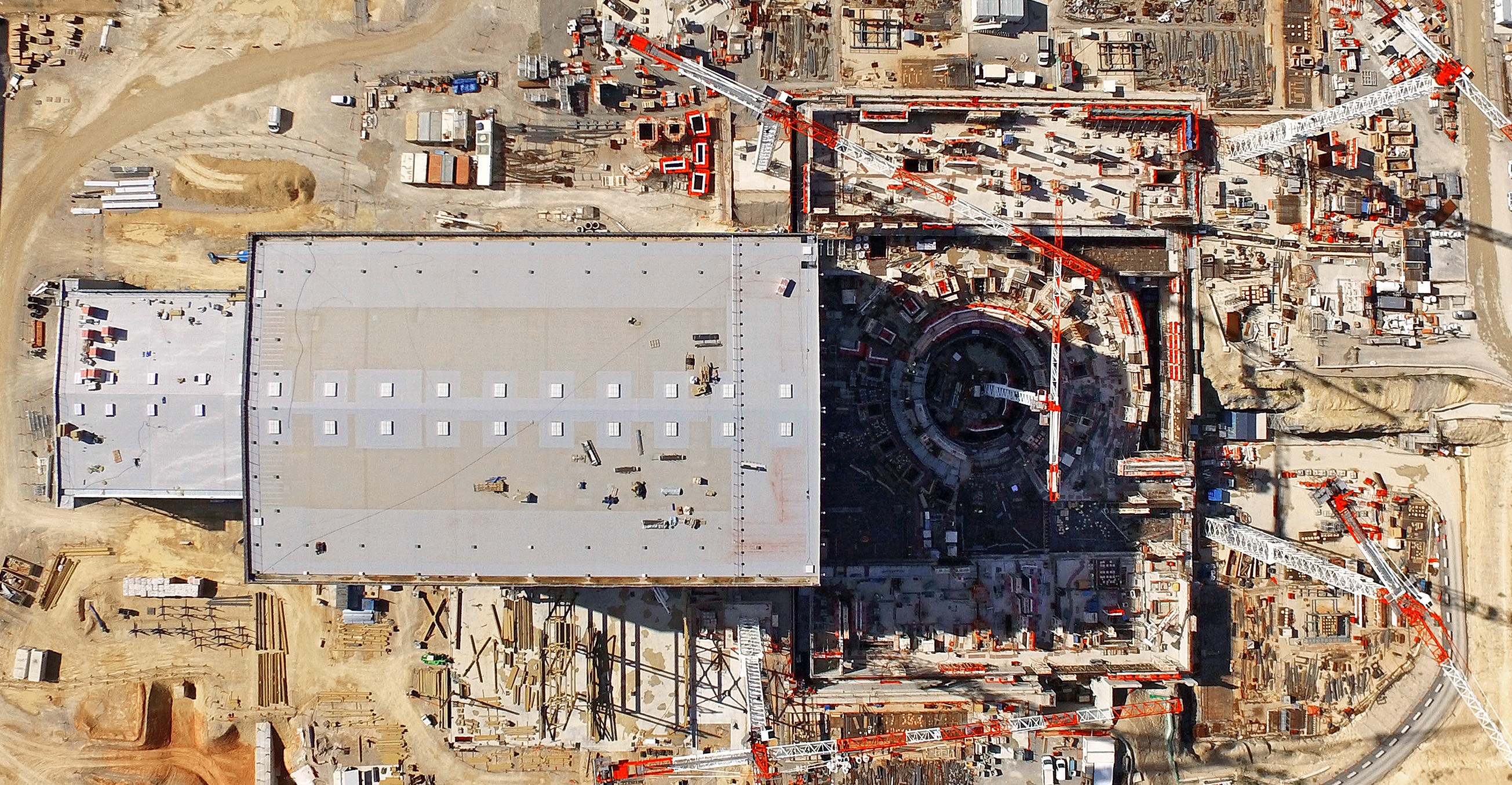

- Almost put under the installation of equipment building pre-assembly with a gateway for cleaning components. This is a giant hangar (50x80 meters in plan and 60 meters high), where tokamak elements will be enlarged in a clean room. In addition to putting the building itself, in 2016, 4 bridge cranes were installed - 2x750 tons and 2x50 tons, and in 2017, installation of ventilation systems, doors and installation of two giant reactor segments assembly stands is expected.

Installation process of cranes in the pre-assembly building in December 2016. The far wall is temporary, when the tokamak building is completed, it will be disassembled and provide a path for the assembled components to the reactor shaft.

- Installation of the first pieces of equipment in the tritium building of the tokamak task complex — water storage tanks with tritium and emergency discharge tanks.

The building is pre-assembled (in the center, in the background), the first above-ground floor of the diagnostic building (to the left) against the background of the foundation of one of the two buildings of magnetic converters.

The coming year 2017 should be the pinnacle of the construction activity of the project - further the scale of construction will gradually fall, but the installation and commissioning efforts should come out on top. In particular, we are waiting for the delivery of buildings of radiofrequency heating systems, a cryogenic plant, laying down plasma diagnostics, building two buildings of magnetic converters.

Component manufacture

In anticipation of the transition to the assembly of the project, the production of ITER components continues to pick up pace. If the unique components of a fusion reactor, such as its vacuum chamber or gyrotrons, are still mostly located in factories, then more standard industrial products like transformers or pipelines are mass arriving at the site, where 16,000 square meters of industrial component warehouses are already running out. Of all these products, we note:

- Pipeline elements: the ITER building will be a real kingdom of pipes belonging to at least 5 systems: vacuum, cryogenic liquids, industrial gases, water cooling, tritium.

- A lot of various equipment for the second in the world in performance cryosystems , compressors, capacitive equipment, distillation columns, gas holders, etc. At the end of the year, for example, 3 helium liquefiers in vacuum vessels arrived at the site - assemblies measuring 4.5 meters by 22 meters and weighing 120 tons each.

Helium compressors of the ITER cryogenic plant at the factory.

- Conduits for the ITER magnetic system. Insulated aluminum tires with a cross section of 200x300 mm for currents up to 70 kA are supplied by Russia - in December the next shipment was made for 70 tons of products (about 500 tons in total will be delivered by 2020).

- Electrical equipment associated with the ITER constant load power supply system - transformers, switchgears and switches for 22 and 0.4 kV. Let me remind you that the total capacity of constant loads will be 114 megawatts, mainly it is a water cooling system (~ 60 MW) and a cryogenic plant (~ 32 MW).

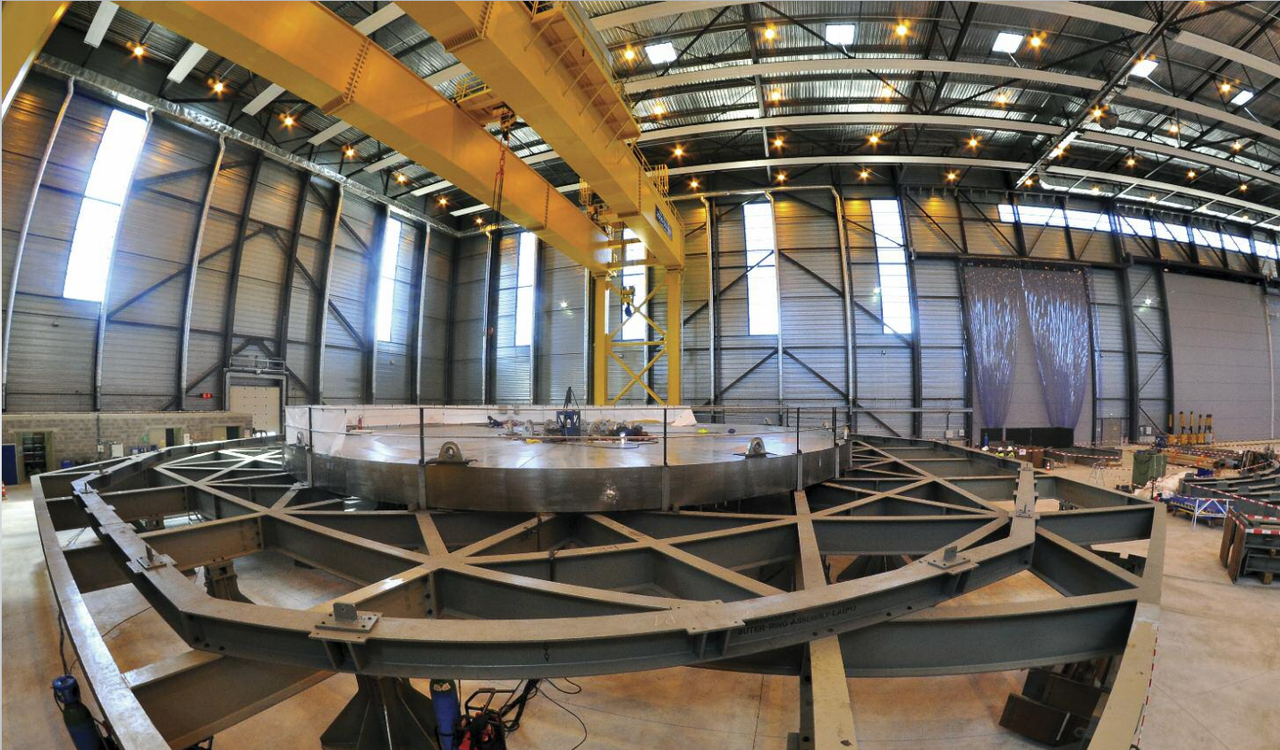

- Separately, on the components of the reactor, I would like to highlight the event that took place on September 8. On this day, the welding began on the base of the cryostat - a giant vacuum chamber with a diameter of 30 and a height of 30 meters, in which the entire tokamak and its magnets will be located. The cryostat base - a part weighing 1250 tons with a diameter of 30 and a height of 5 meters is welded from 18 smaller parts at the ITER site in a workshop specially built in 2014, 200 meters from the reactor shaft.

The 30-meter frame for the cryostat base, the 19-meter bottom and the welder (yes, it is in this photo).

- One of the most technologically challenging topics of the project is the manufacture of a vacuum chamber , where the plasma discharge itself will go. Let me remind you that the chamber with a height of 12 and a diameter of 15 meters will be welded directly into the reactor shaft from 9 sectors, each weighing 350 tons. The main difficulty lies in the fact that these are double-walled stainless steel products up to 60 mm thick, with their size and weight should be assembled into a construction with a tolerance of about 1 mm. Sectors are made in Korea at the enterprise Hyundai Heavy Industries and in Italy at the enterprise Walter Tosto. In 2016, the decision was made to redistribute the last 2 sectors from Europeans who are very badly out of schedule to the Koreans, and also to transfer part of the tasks of manufacturing the Italians to the Spanish company Ensa. According to the schedule, the first sector should be assembled in Korea at the end of next year.

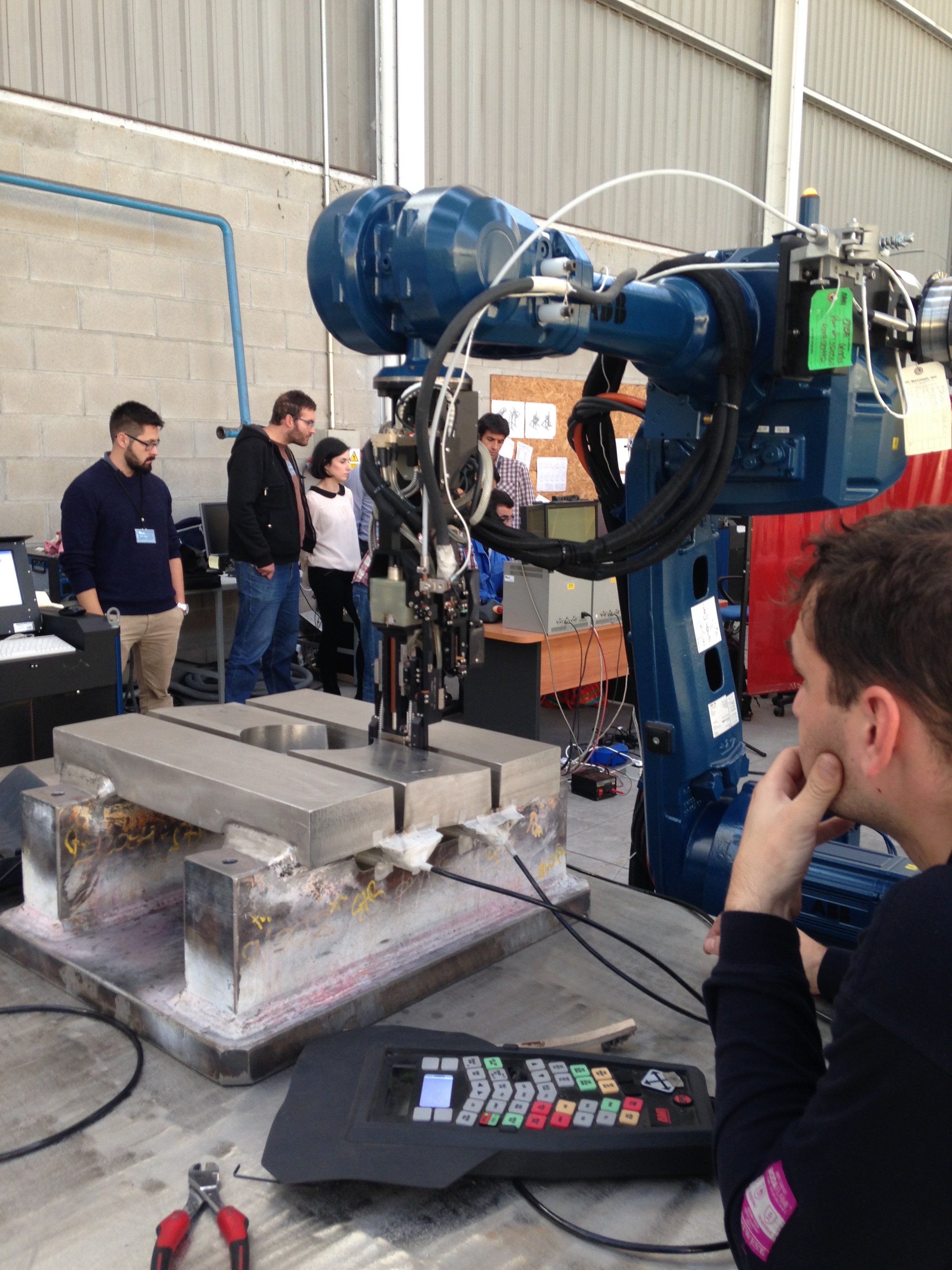

And this is 1/4 of the sector, which Korea should pass next year. In addition to the puzzling geometry, the thick walls of the vacuum chamber are technologically unpleasant by the presence of thousands of fasteners that need to be welded from the inside onto its surface.

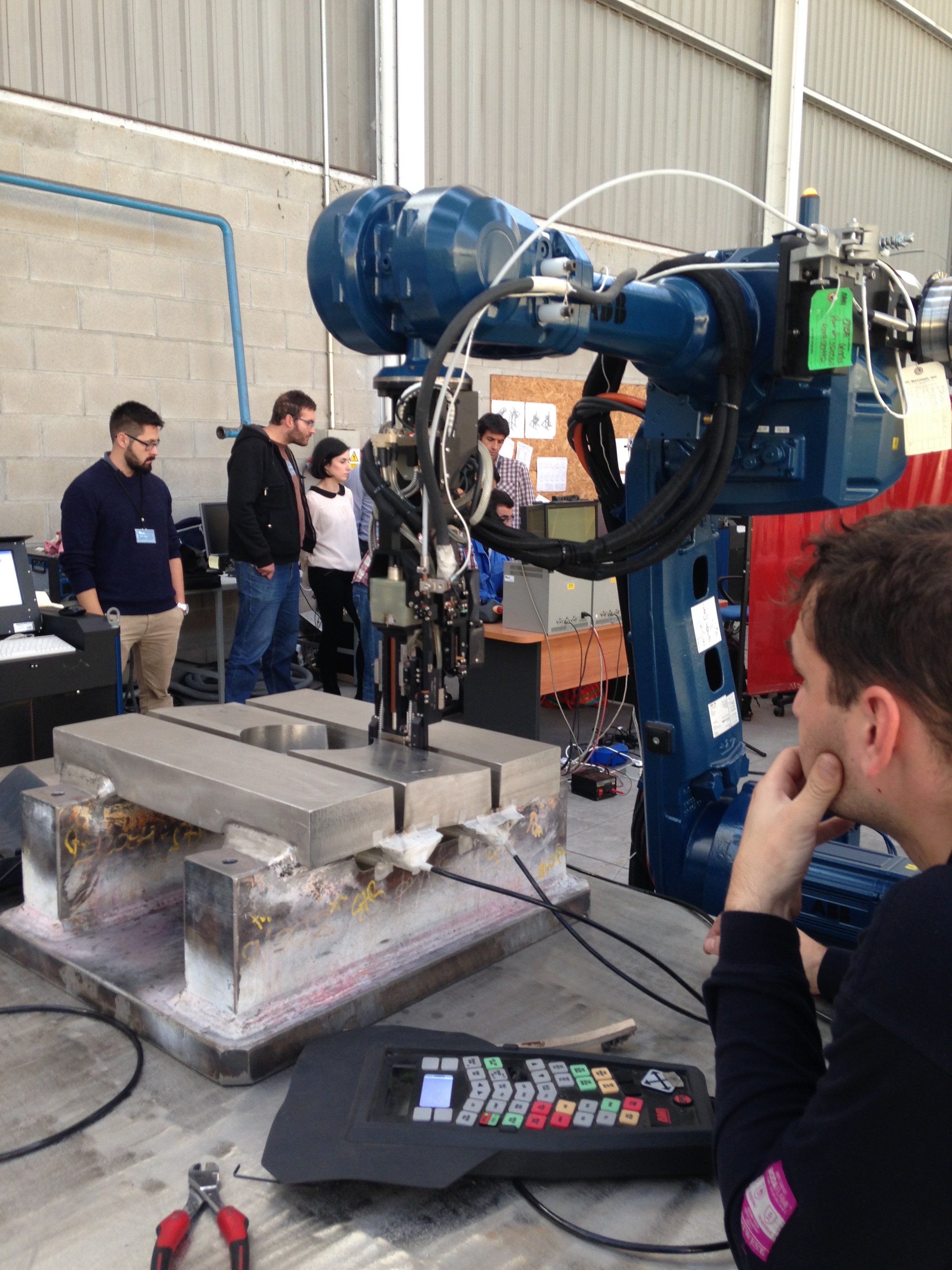

- In 2016, robotic welding heads were also demonstrated on the topic of the vacuum chamber, with the help of which sectors will be closed in the chamber in the reactor shaft.

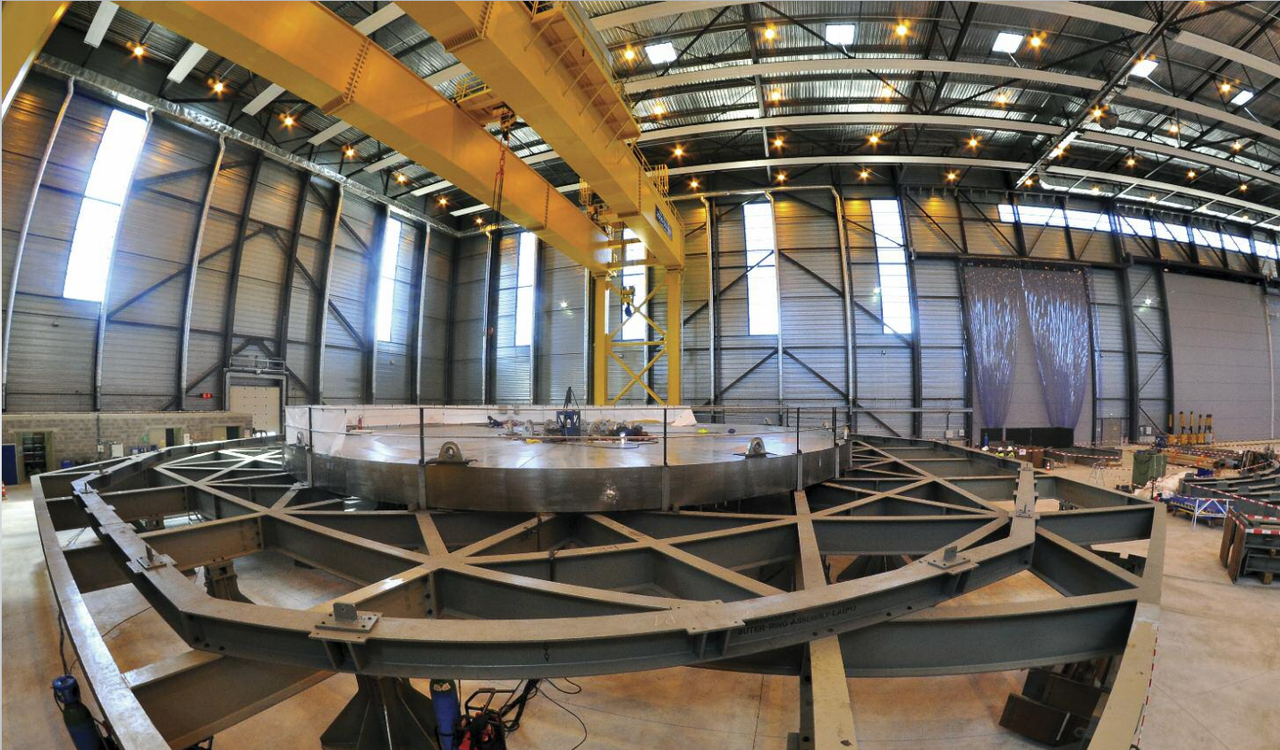

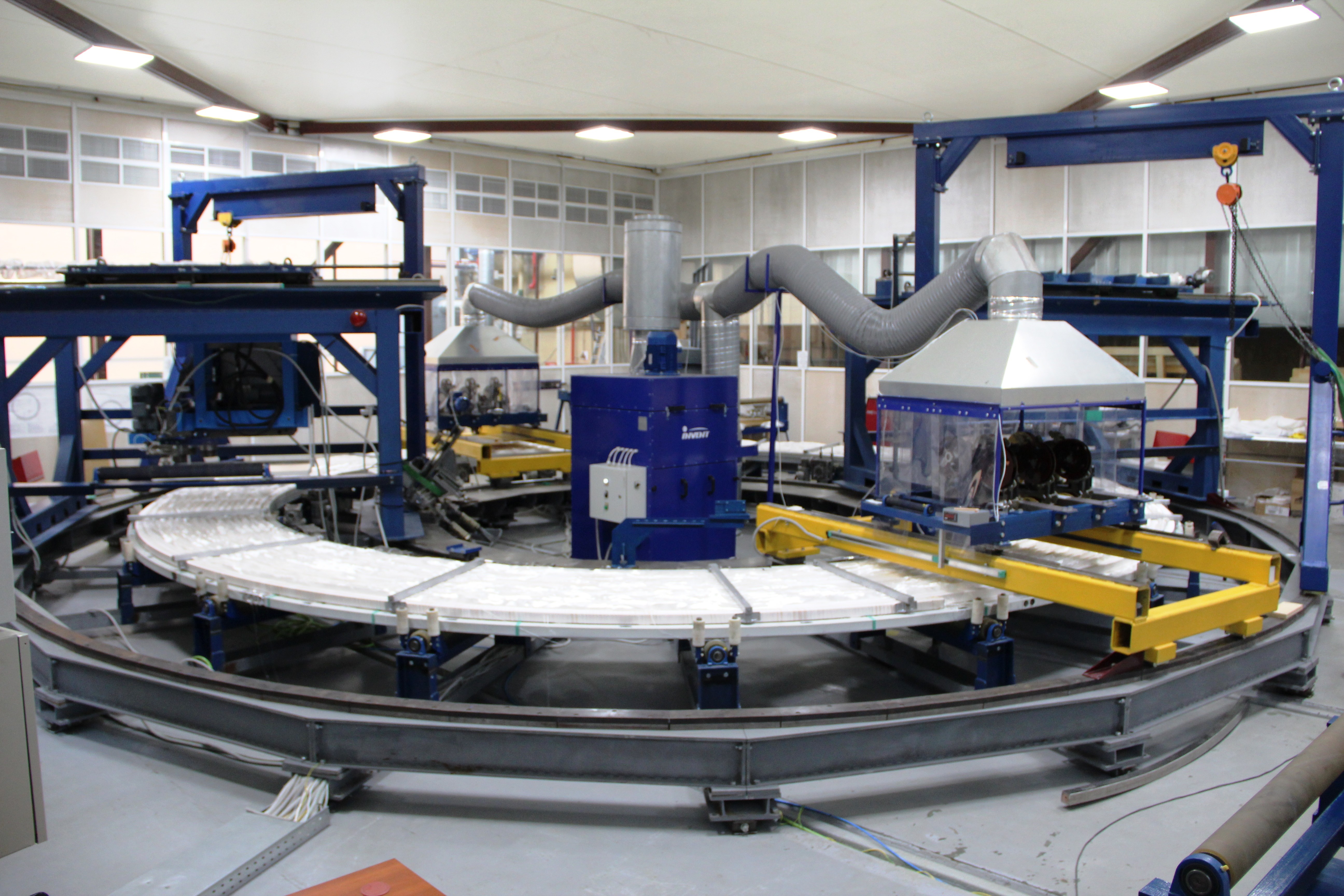

- Another important element associated with the vacuum chamber is the pre-assembly stands, where a segment of the vacuum chamber will be put on thermal cryo screens and then two coils of the toroidal field (each weighing about 320 tons) will be installed on it. The stand has movable platforms (with 6 degrees of freedom) for the correct exhibition of screens and coils relative to the segment, and is a very rather big construction with a height of 22 meters and a weight of 800 tons. These stands are made in Korea and in the spring of 2017 they will arrive in Cadarache for installation in the pre-assembly building.

One of the supporting columns of the assembly stand.

- By the way, thermal cryo-screens that serve to block thermal radiation from the vacuum chamber and the building on tokamak superconducting magnets are also actively manufactured in 2016 in Korea. In general, they are complex, flowing around the geometry of magnets, constructions made of silver-plated stainless steel with a thickness of 20 mm with tubes for supplying cooling helium at a temperature of 80K welded to it.

Heat shield in the process of welding coolant pipes.

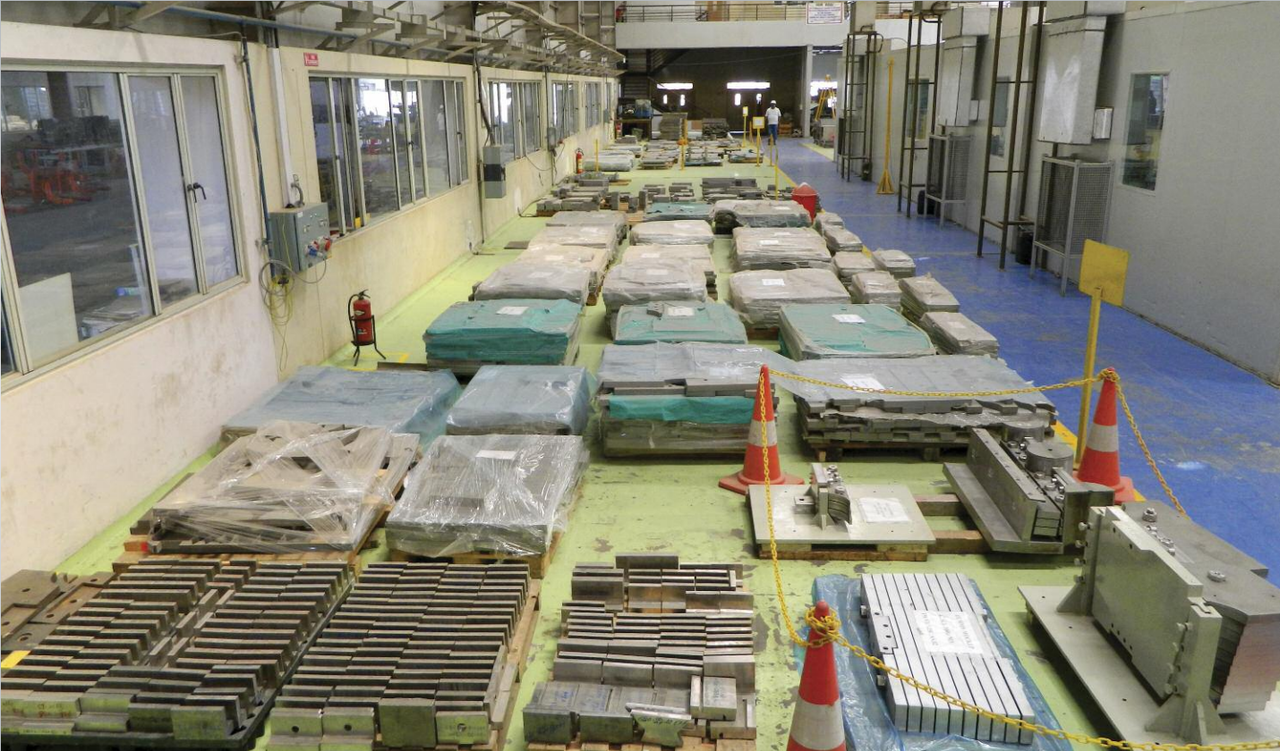

- It is necessary to recall the neutron protection, which is installed between the walls of the vacuum chamber. These are the type-setting steel blocks, made of borated steel. Its total weight will be 1,400 tons, and it will be recruited from ~ 9000 items. In 2016, India has already produced about 40% of the protection, which is sent to Korea and Europe for integration into the manufactured segments.

Steel neutron protection blocks at an Indian plant. Below to the right is an example of the assembled element, how they will look inside the double wall of the vacuum chamber

- Of the three ITER plasma heating systems in 2016, the developers of the electron cyclotron resonance heating system achieved the most progress, which is not surprising, since According to the plan it will be the only heating system installed for the first launch in 2025. Currently, two out of three (Toshiba and JSC “Gikom”) manufacturers of gyrotrons have passed full-scale qualification tests and proceeded to the production of serial 1-megawatt gyrotrons, the first of which can be delivered to the site in 2017.

- Unlike ECRN, which is made immediately by 3 ITER participants (European Union, Russia, Japan), the ion-cyclotron radiofrequency heating system of ISTP is entirely given to India. In 2016, the Indians got the necessary power characteristics for a prototype of one of 8 amplifier modules at the stand - let me remind you that this is 2.5 megawatts of radio frequency power at the frequency range of 40-55 MHz and a wide range of SWR loads. Indian contractors expect to start the production of serial modules already in 2018, and to start the installation at the site in 2020–2021 (although the first ICRN plasma is not planned for use).

The test bench includes power supplies, 3 cascade tube amplifiers with an output power of 1.8 megawatts, a monitoring and cooling system, a load with adjustable SWR, and much more.

- Finally, the third, the most high-tech and powerful heating system - the injector of the neutral beam , while quite far from implementation. In 2016, the assembly of the power source stand SPIDER was carried out in the NBTF laboratory, specially built in the Italian Padua. In addition, the high-voltage power supply system of the future MITICA stand was also being assembled. After launch and testing, SPIDER will be followed by the construction of a full-size ITER neutral beam injector module called MITICA. And only after testing MITICA, Europe will start building two injectors directly at ITER - this will most likely happen no earlier than 2025.

The vacuum vessel of the SPIDER stand, where, from 2017, a 40 amp source of negative hydrogen ions will be tested

- Finally, it is worth mentioning the progress in the production of the magnetic system of the project. Let me remind you that the superconducting magnets of ITER are comparable in terms of the volume of the used superconductor to its many-year global production, therefore, to manufacture a total of 43 magnets of 11 types, it was necessary to create a significant piece of the new industry, including ~ 15 new plants and workshops in 7 countries of the world. The ITER project, as a serious and large-scale event, in fact, began with the solution of the task of producing a magnetic system, and today it is gradually coming to a successful finish. Let me remind you that in 2009-2016, the entire volume of superconducting wire was produced (approximately 600 tons each of NbTi and Nb3Sn), in 2010-2017 the entire volume of superconducting cable will be manufactured (today it remains to perform just a few percent of this task) and efforts are focused on making elements of magnets and assembling them into “flight” products.

Part of the ITER toroidal coil body. 19 hulls should be manufactured in Japan until 2021.

- For example, in the United States, after a one-year qualification of production, the manufacture of ITER central solenoid coils began as well as the manufacture of the mechanical elements of this magnet — for example, 15 meter tension bars, which will have to keep the shape of a CA from deformation to Lorentz forces (I recall that mutual magnetic forces in ITER will reach dozens thousand tons of force).

Mechanical processing of an experienced tension bar of a central solenoid. 24 of these strips surround a magnet with a diameter of 4 and a height of 15 meters.

- In Europe, the manufacture of the first winding package (superconducting winding placed in a solid steel case) of a toroidal coil has been successfully completed. Next year should begin integration into the body, which produces Japan. In Japan itself, which performs part of the work on toroidal coils, progress has progressed even further - the assembly of the first toroidal coil, which should be put on site in 2018, began.

The winding package of the toroidal coil is 134 turns of cable with a current of 68 kA. It must then be installed inside the Japanese case shown above.

- In addition, in 2016, the Europeans assembled and qualified a 300-meter-long poloidal coil assembly building from ITER for the production of poloidal magnets (these are circular magnets with a diameter of 19 and 25 meters that cannot be transported, so they have to be made right next to the tokamak). In 2017, the manufacture of the important PF5 coil should begin - important because it is one of the first products to be installed, and its delivery on time (no later than 3 quarters of 2019) determines the timing of the entire project.

Winding line poloidal coils PF5 and PF2. After manufacturing the coil components, it will be converted to a larger diameter for the manufacture of PF3 and PF4.

- However, the very first magnets to be installed will be PF6 and six corrective magnets, manufactured in China. Production of this part of the magnetic system unfolded in China throughout 2016, and in 2017, according to our plan, we will have the first standard correction coil released and the start of PF6 manufacturing.

One of the 6 lower ITER correction coils is 32 turns of a cable with a current of up to 10 kA.

- Finally, in Russia in 2016, the first two double biscuits (out of 8) of the PF1 magnet were made - it is characteristic that our magnet, which will be put to the last during the assembly, has now broken into the leading ones in terms of production progress.

Winding stand double galeta magnet PF1 in the territory of the Middle Nevsky plant. White - this is a superconducting cable measuring approximately 45x45 mm in fiberglass electrical insulation.

On this, I think, it is worth completing the review of ITER's production successes, although there are still a lot of interesting news, for example, the beginning of the assembly of the first full-scale cryoabsorption vacuum pump. The main conclusion from the review is that, thanks to the new director Bernard Bigo, ITER has overcome the crisis of previous years, and is still making good progress, and the tasks that the construction of an international thermonuclear reactor poses to industry today are a significant source of technical progress in many industries.

Of the minuses, it is worth noting that the real terms that were determined by the Bigo team are very gloomy, and make you think of simpler and smaller alternatives to the classical tokamaks (which will immediately appear in the last years 1 , 2 , 3 ). Nevertheless, in my opinion, ITER continues to be the most interesting engineering and scientific project in the world, offering an incredible interweaving of problems and solutions from various engineering fields. In the coming years, more and more of these “unthinkable solutions” will turn into iron and stand in its place in the most complex machine in the world, and I will continue to follow this as much as I can and talk about it in my blog.

PS For comparison, the results of 2014 and 2015 for ITER.

Source: https://habr.com/ru/post/400389/

All Articles