Review of current 3D materials

Material in 3D printing, as in any creative activity, is one of the most important things. Not only the mechanical and chemical properties of the future product, but also its aesthetic value depend on the material.

All those involved in 3D printing have long known materials such as ABS and PLA. These are the most common and used, the most famous filaments with well-studied properties. But not all - there are materials that are known to most printers only by name, and some of them do not even know about them. Meanwhile, they also have many useful properties that you should know about in order to apply them if necessary.

Before turning to the main topic of the article, I would like to say a few words in defense of PLA. Many people mistakenly believe that ABS is stronger and better than PLA, but this is not entirely true. Recently conducted tests of plastics have shown that PLA beats ABS in all strength indicators.

')

The only thing ABS is better at is longevity - PLA is biodegradable, and ABS products will pollute the planet hundreds more years after they are no longer needed.

Here, now back to our exotic.

Prices are approximate and better to specify when buying.

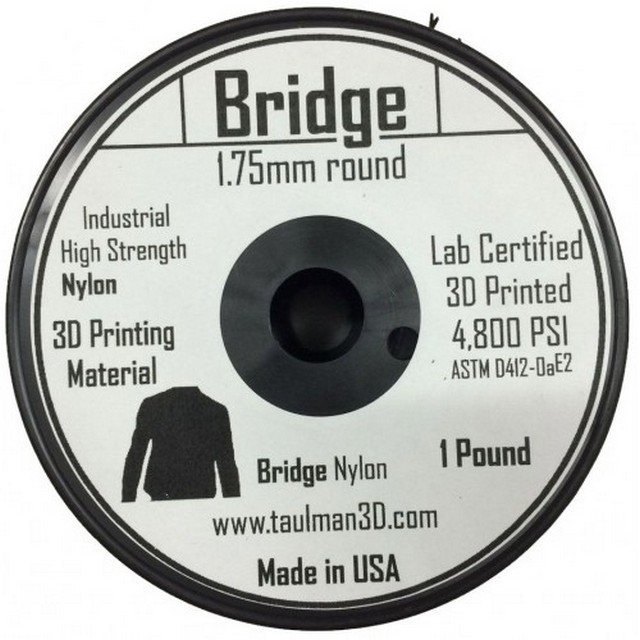

NYLON

NYLON is distinguished by its high strength and wear resistance - it is these properties that allowed it to take a long time and firmly its position both in the production of fibers for clothing, and among industrial plastics. They also brought him to 3D printing. From this material is printed a wide range of various products, from toys and household items, to the details of equipment, clothing and medical orthoses.

Examples of filament with nylon :: Taulman 3D Nylon Bridge for 2580 rubles (0.45 kg), Nylon M1 Print Product for 1300 (0.75 kg), Nylon Super Natural U3print for 2500 (0.45 kg).

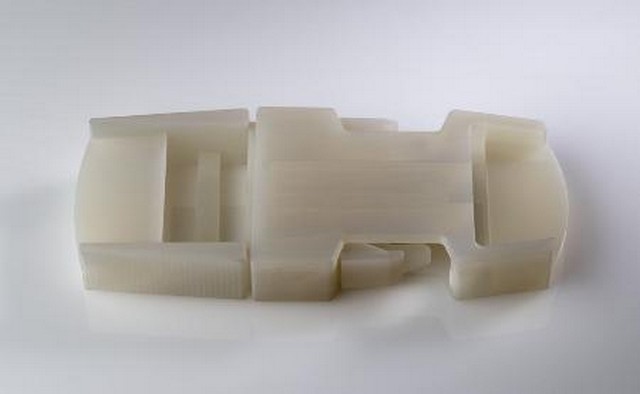

PP

Polypropylene, like nylon, is also well known for a long time. It is difficult to list at least a small part of the things that make him. What is characteristic of PP? - it is non-toxic, wear-resistant material, well-tolerated contact with aggressive media and having good strength. In addition - it is quite inexpensive and very common, which increases its availability.

Of the minuses: it becomes brittle at temperatures below minus five Celsius. It does not tolerate direct sunlight.

Examples: PP polypropylene FL-33 costs 4300 per 1 kg, PP Print Product plastic is white - 1,500 rubles per 0.75 kg.

Flex

Relatively new, still popular industrial elastomer. Differs in high mechanical characteristics. It has good wear resistance and elasticity. Used for the manufacture of decorative products, protective coatings, soles, etc.

- Good adhesion to surfaces.

- Elasticity.

- Wear resistance

- Durability.

- Application at temperatures from -60 to +80 ° C

- Good sintering.

There are also disadvantages: resistance to common reagents is rather low - it is not recommended to use it in contact with gasoline, acetone and acetic acid.

On the market are represented by different manufacturers producing materials in different colors and slightly different mechanical properties.

For example, REC's material is distinguished by proven environmental friendliness — it is designed not to emit toxic gases when printing. Its cost is 2176 rubles per pound.

FL-33 filament is characterized by its original color solutions. It costs 4500.

Print Product TiTi FLEX SOFT from , for 1550 rubles (0.5 kg), is characterized by its special softness, and Flex 1.75 from the same company, for 2300 (0.75 kg), besides its outstanding mechanical properties, it is also interesting for its transparency - from it you can print many beautiful objects with interesting optical properties.

FLEX is used for printing elastic objects. For example, you can print an unbreakable pencil cup, of any shape - an original gift to a colleague.

Hips

HIPS is a material that does not possess any outstanding mechanical properties, but it is absolutely indispensable for printing two or more extruders, as a material for creating soluble supports and adhesions. It is thanks to him that it is possible to create arbitrarily complex objects, especially those where one object is inside another.

It is also widely used in prototyping, since it retains well-defined dimensions when printing — it does not creep and warp.

- High-quality transfer of the specified sizes

- Solubility

- The possibility of use in food contact products

- Non-toxic.

The choice of materials like HIPS is also quite wide: these are HIPS FL-33 for 2090 rubles (1 kg), HIPS PrinProduct for 1220 (0.75 kg), HIPS SEM for 1300 (1 kg), HIPS Bestfilament for 1450 (1 kg), HIPS REC for 1606 (0.75 kg) and HIPS ESUN for 2600 (1 kg).

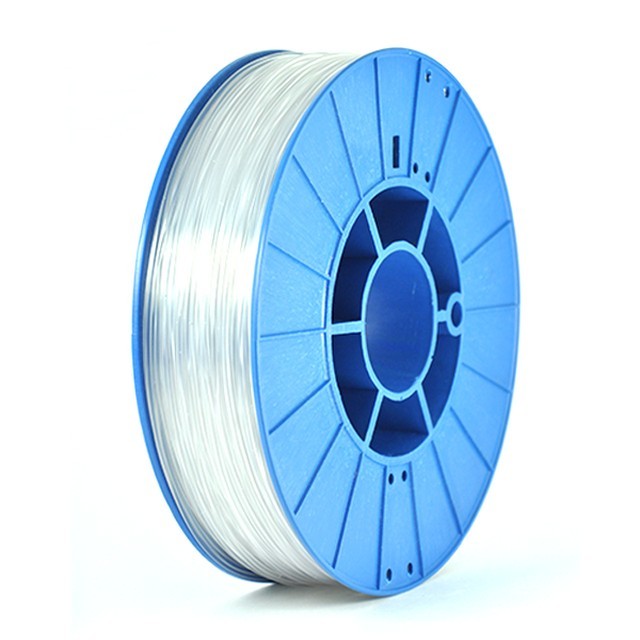

GLASSFIL

Glassfil is a transparent thermoplastic with unique properties: it transmits ultraviolet and X-rays, but reflects infrared radiation. It is not destroyed by ultraviolet radiation, it is also resistant to moisture and to bacterial action. Able to withstand low and high temperatures without damage. Environmentally friendly and has dielectric properties. The advantages also include: transparency or partial transparency of the material, resistance to shock loads and good workability.

It can be used to create products intended for medicine, agriculture, for printing all kinds of household items.

Examples of materials of this type: GLASSFIL Print Product for 1500 rubles (0.75 kg), Ninjaflex for 3500 (1 kg), Zortax Z-Glass for 5700.

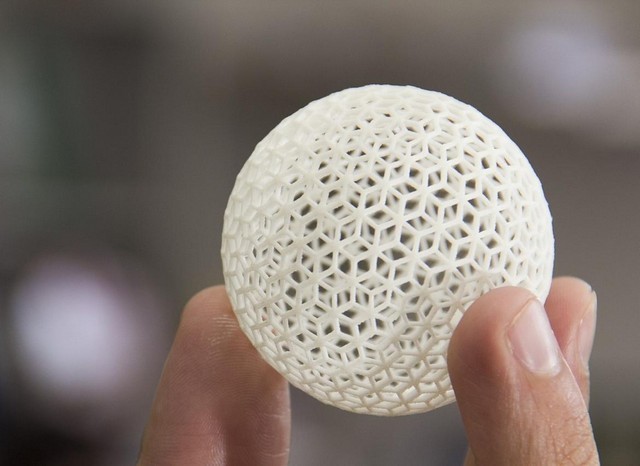

Ceramic

The material is interesting in that it contains natural ceramic particles. When printing creates the effect of ceramic or stone surface. It is used for printing products imitating ceramics or stone.

Examples of such a material: Print Product CERAMIC worth 1,500 rubles (0.75), Filamentarno Pro Ceramo and Pro Ceramo-tex at 2,200 for 0.75 kg.

Filamentarno plastic is also interesting in that it can be used when printing dishes and toys - it does not contain toxic substances and does not smell, like all plastics of this company. And Pro Ceramo-tex foams when printed, giving a completely indistinguishable structure from real untreated ceramics.

Laybrick has properties similar to ceramics, for 2500 per quarter kilogram, characterized in that its texture depends on temperature and printing speed - it can be both rough and textured, and glossy. Another feature is the lack of the need to heat the table, and the only drawback is the need to wait some time before removing the finished model, because it doesn’t freeze immediately (the waiting time, like the texture of products from Laybrick, depends on the temperature conditions of printing).

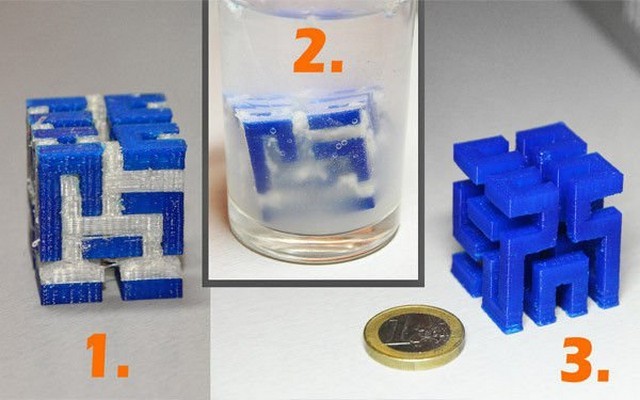

PVA

PVA plastic - created to be dissolved. Like HIPS, this material is best suited for supports and intermediate structures that are necessary during printing, but should be removed after. Its advantage over HIPS - PVA is soluble in ordinary water. This is the most suitable option when you need to print complex parts, and there is no limonene on hand.

- The diameter of the thread, mm 1.75

- Temperature of the press is 180 - 220 ° C

- Water soluble

Examples of PVA :: Esun PVA for 2945 (0.5 kg), PVA U3print for 2800 (0.45 kg) and PVA REC for 3,800 rubles (0.5 kg).

PVD

PVD is a synthetic polymer with good plastic and thermal properties. Essentially - specially treated polyethylene. Lightweight, durable, wear resistant. Does not pass water, but is easily permeable to gases. Widely used in the manufacture of packaging material.

You can easily print, for example, a mini-greenhouse for indoor flower or a container for sandwiches, as it is non-toxic in everyday life and can come into contact with food.

- The diameter of the thread, mm 1.75

- Operating temperature 230 ° -260 °

- Print speed: 10 mm / s to 70 mm / s

- Natural color

Example material: Print Product PVD , 1550 rubles for 0.75 kg.

PETG

PETG material is quite durable. The material is usually transparent or translucent, even with the addition of coloring pigment. It has a beautiful glossy look.

Among other advantages: it has no smell, does not absorb moisture, is easy to print - low shrinkage.

Cons - demanding temperature printing.

Examples of such a material: PETG Natural U3Print for 1000 rubles (0.45 kg), PETG FL-33 transparent for 3990 (1 kg), PETG plastic ESUN for 2300 (1 kg).

POM

- High strength

- Printing temperature of about 210 ° - 250 ° (may vary slightly from manufacturer to manufacturer)

- Print speed from 10 mm / s to 70 mm / s

- Odorless

- Nontoxic

Polyoxymethylene. The strength characteristics of the material are such that products made from it are used in engineering to replace metal parts. It is also biologically neutral and can be used in medicine and food industry.

Examples of filaments: FL-33 engineering POM for 3,610 rubles per kilogram, POM Natural for 2,800 for 0.75 kg.

PC

PC - polycarbonate. Products made of PC are highly resistant to shock loads and withstand short-term heating to 153 degrees, and can function normally in the range from -100 to +115 degrees Celsius.

- It is printed at a temperature of 230 - 280 degrees Celsius

- Freezes at 130 degrees

- Table temperature preferably 100 degrees

Examples of filaments with PC: PC polycarbonate SEM for 1,700 rubles and PC polycarbonate FL-33 for 4180 are transparent, and PC polycarbonate FL-33 is black with dye added, 4180 for 1 kg.

WOOD

Ceramics in our review was already, now it is a turn of not less interesting material - wood. That tree is contained in this filament and gives it its texture and color, tactile characteristics and warmth. Even the smell. Like any wood, products made from this material are very hygroscopic, that is, they absorb a lot of moisture.

It is used to create original products imitating wood and possessing, in many respects, its properties.

- The diameter of the thread, mm 1.75

- Operating temperature 190 ° -220 °

- Print speed from 10 mm / s to 70 mm / s

Examples of materials: COOL WOOD for 3500 rubles (0.75 kg), Colorfabb WoodFill for 4800 (0.75 kg), Laywood Fl-33 light wood for 4703 (1 kg) and Laywoo-d3 for 2500 (0.25 kg) .

ANTISTATIC

ABS Antistatic - almost normal ABS, but also with a surprise, like the rest of the materials in the review. As the name suggests, this filament contains antistatic agents to help get rid of the static characteristic of most 3D printing materials.

It is used to create parts and housings of electronics, where static discharges are completely inappropriate, packaging for storing chips and other sensitive components, rugs for precise measuring equipment, etc.

Also finds application in the fashion industry, when printing fabrics.

- The diameter of the thread, mm 1.75

- Platform temperature 100 ° C

- Extruder temperature 210 - 240 ° C

Example material: ABS ANTISTATIC for 1600 rubles (0.75 kg).

GLOW

The material accumulates light, and in the dark gradually gives it away. The glow time of products from such a filament is up to 14 hours.

It can be used for the manufacture of toys, original souvenirs, dashboards and dials, cases and buttons switches, and much more.

- Extruder temperature depends on specific filament.

- FDM printing technology

- Different colors

Examples of such plastics are: PLA Lumi for 1990 rubles (0.75 kg), ABS FL-33 for 1995 (1 kg), ABS plastic ESUN for 2200 (1 kg) and PLA MakerBot for 5900 in darkness (1 kg).

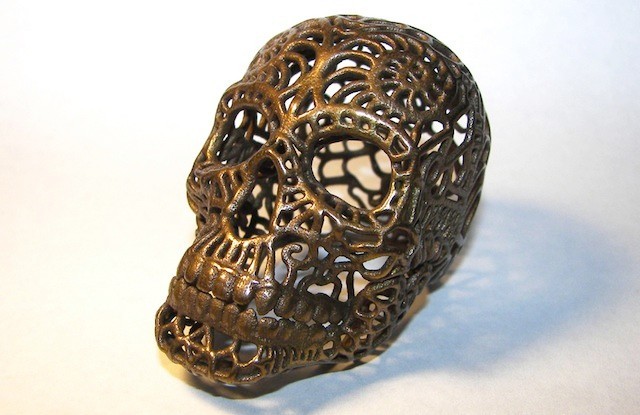

METALLIC

Materials containing metal particles and imitating things created from it. Externally, by weight and to the touch it turns out very similar.

Products from these materials are easily processed and polished, taking the form of these metal things.

Examples of such materials: Bronze ESUN for 2300 rubles (0.5 kg), Colorfabb Bronzefill for 3900 (0.75 kg), Bestfilament Bronze .

COLORFUL

If you are bored with monotonous, as in a child's set of felt-tip pens, filament colors, then it is time to switch to an adult palette. For convenience, you can choose one manufacturer with such an assortment so as not to re-adjust printing every time and have a stable result. For example, among the products of the company Filamentarno there are many beautiful plastics of different shades.

Another advantage of this company's products over many others (and like-minded RECs in Filamentarno) is the safety of all materials, all of them can harmfully contact food, which means they are suitable for the manufacture of food dishes and children's toys.

Examples of plastics: Bottle Green , Bottle Olive , Bottle Brown , Yellow , Orange , Red . This is not all, there are dozens of them. Plastics of this line are worth 1200 rubles for 0.75 kg.

This is not a complete list of current modern materials, only a small part of them, but one cannot grasp the immense. However, we have scheduled reviews in other segments of this area. Keep for updates.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/400377/

All Articles