Containers of the two-phase immersion cooling system

Liquid cooling systems, though not new, are not widespread. The reasons I would call two: scary and expensive. Water, as a heat sink fluid, conducts electricity and can kill both a personal computer and a data center. Other liquids can either be expensive by themselves, such as fluoroketones, or require complex and expensive hardware solutions, such as oil.

I want to talk about our experience in creating a liquid cooling system.

We fell under the charm of “dry water,” as flutecetons are sometimes called colloquially. We quickly assembled the first liquid-cooled computer from scrap materials.

')

The impression of being immersed in the “water” and working computer was so strong that we immediately collected the next more decent layout.

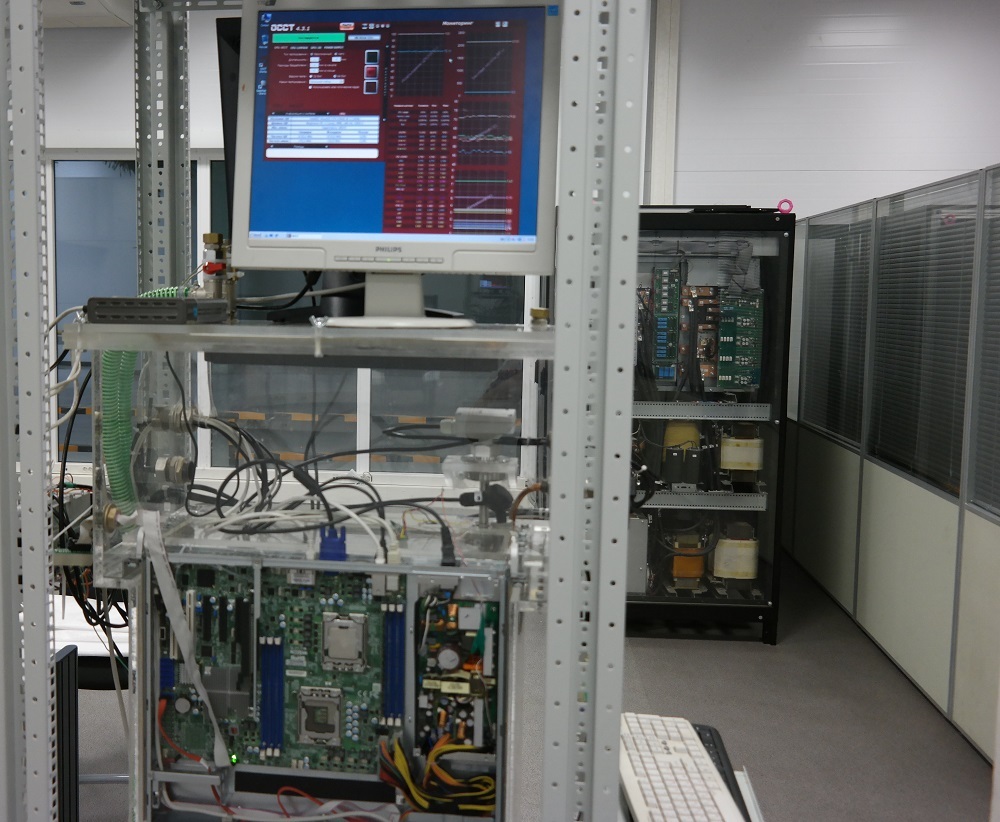

We didn’t stop at this either and quickly made a big box where you can drop a standard 19-inch server. Yes, we understand that it was made for air cooling and our submersible cooling is too redundant for it. Such a server can be cooled with a glass of "dry water"!

Plastic box turned out to be easy to use. And although it was made for the server, most of the time it was immersed in a regular kettle. We inserted the server into the plastic box mainly for demonstration and for the collection of MTBF statistics.

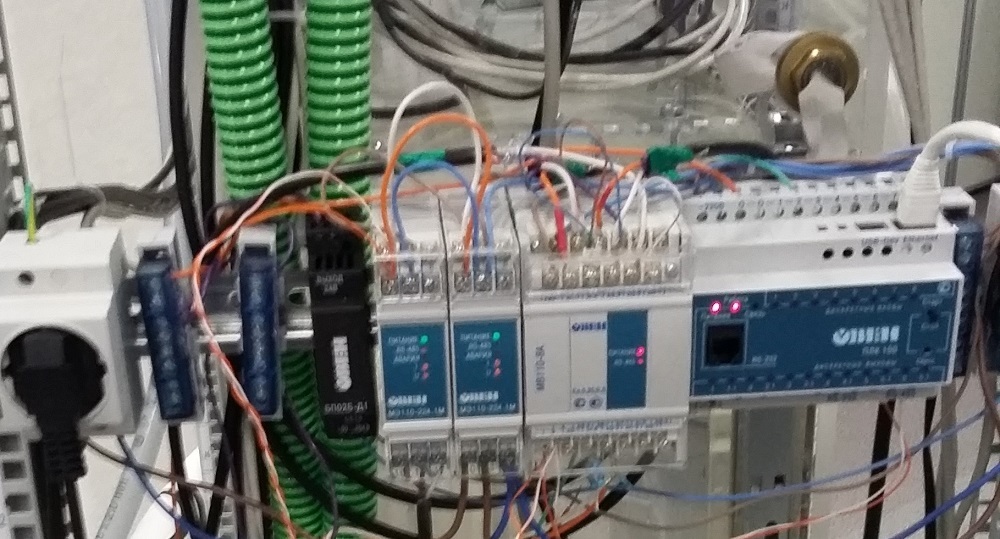

We spent a lot of time experimenting with different modes; an industrial controller was used to collect data.

The knowledge gained was turned into a regular box or as we now call it a container. This is still a prototype and serves mainly for demonstration, but this time it is made of steel, because we are torturing it already in the field, together with the customer.

A microprocessor unit is used to control the container and control its internal parameters. This unit constantly monitors the parameters of the internal environment of the container, such as pressure, temperature, temperature of the coolant at the inlet and outlet of its velocity. Power supply parameters are controlled - voltage and current consumed by the load. Separate sensors monitor the fluid level, the status of the opening and closing of the container lid for access control is monitored. The received data is transmitted in real time to a dedicated server. Information is available for further processing, both by machine methods and for visual assessment in the form of graphs that are easy to understand. Implemented access from mobile devices.

What have we learned and what have we achieved today?

So the fluid system is virtually silent. If you were once in a data center, or at least entered the server room, then the sound of a plane constantly taking off is not new to you. It's not like that with liquid. Liquid transfers heat up to 3500 times better than air. Accordingly, the selection of the same amount of heat from a heated processor requires 3500 times less, so the volumes pumped through the server are much less, and therefore quieter.

Another advantage may be that the liquid not only draws heat well from the servers, but also gives it well. It is technically difficult to recycle many cubic meters of warm air, but it is much easier to find the use of warm water, it is pleasant to wash your hands.

Another advantage of the use of fluoroketones is their “natural” fire safety. Some time ago, the network flashed photos of a burned-out mining for bitcoins. In our case, this is completely impossible. The available amount of liquid will suffice to extinguish a decent pioneer bonfire.

A separate benefit becomes apparent when you get the server out of the bath. It looks as if it had just been taken out of the plastic packaging of the manufacturer and is not at all like a roasted piece of iron.

Most often we are told about the high cost of the heat dissipating fluid. Responding to it, I would like to note that this liquid is already already present in any data center in the gas extinguishing system. Yes, there it is hidden in cylinders, but even here it is poured into containers and does not circulate. To minimize evaporation losses during load fluctuations, we use a cold trap. The second argument is the cost of the IT stuff you want to cool. In comparison, liquid is not expensive at all.

The immersion system is good in that it does not depend on the specific configuration of the cooled equipment. We do not remake it to change the server board or another video card. We have no fans, cold plates, individual radiators, pumps, tubes, quick disconnects, manifolds, hoses, fittings, sealed connectors, controls, there is only one container.

Circulation occurs naturally through evaporation and subsequent condensation, without unnecessary equipment and additional energy costs. There is no temperature difference between the devices. There is no advective resistance, the same temperature on all elements of the immersed device.

Containers are highly mobile equipment. Raise it under the power of two or four people. For its operation, it is only necessary to cool the coolant to the boiling point. The liquids tested by us boil at + 34, + 49, + 61, + 76, which allows using a dry cooling tower or even just pumping water from a stream with a pump.

The container is hermetically closed, which prevents the ingress of moisture, sand, dust and dirt. He can work in any place, even if he is not equipped at all.

Containers we produce can remove 1, 5, 10 kW of heat. Under the order we can make more powerful containers.

Using containers you retain full control over your information. You do not transfer your data either to the data center or to the "cloud". You yourself ensure the physical security of your own data.

Now, about why we do it. We want to give people the opportunity to independently manage their data, no matter how big they are.

Source: https://habr.com/ru/post/400133/

All Articles