Universal Testing Machines (Bursting Machines)

Today I want to give general information about the machines allowing to conduct tests and determine the physical and mechanical properties of various materials.

First, let's define what mechanical properties are and what they are. Mechanical properties are the ability of a material to withstand the loads applied from outside. Such loads include compression, bending, impact, torsion, hardness, plasticity, elasticity, abrasion, etc.

In order to artificially reproduce these loads, the produced material (sample) is tested to determine the peak and nominal values of the operation of this sample.

')

Tests are carried out on machines providing a certain type of load, usually in Newtons (N). Explosive machines are generally universal, as they work in tension and compression, and allow you to determine the deformation, elasticity, plasticity and much more. But without exception, all machines receive three parameters from the controller: Load (N), Displacement (mm) and Time (s)

.

For such types of load as torque, a specially designed torsion machine designed to rotate the sample along its axis. The bending forces can be determined both when tested on a classical tensile testing machine and when a sample is tested on a pendulum scraper. Such machines look like a lathe with a torque sensor installed on the torsion axis.

Often, to determine the hardness of a material, a machine is needed as a hardness meter that provides control of hardness after the production of the material (eg, steel). Depending on the hardness of the material, the type of scale is chosen: the hardness of softer products is usually measured on a Shore scale or Brinell scale; for harder products, use the Rockwell scale; for very hard - Vickers scale.

There are still tests for fatigue and long-term strength, they are mainly carried out on classic tensile machines capable of supporting the sample under constant load for a long time, and using climate chambers to recreate the required climatic conditions. The only difference from the classical breaking machine is the load system, made in the form of a set of weights installed through a lever. The number of such machines in the laboratory can reach dozens of pieces, and tests can last from several days to several weeks, months and even years.

There is another class of machines: machines of friction are designed to study the processes of friction and wear caused by friction, the properties of lubricants and friction materials.

Many testing machines are developed and made to order as the serial machine is not suitable for one reason or another (dimensions of the test sample, method of fixing it in the grips, measurement accuracy, measurement parameters ...), the majority of customers are universities (if they have enough funding) , various scientific and production associations and all those who can work not with standard materials.

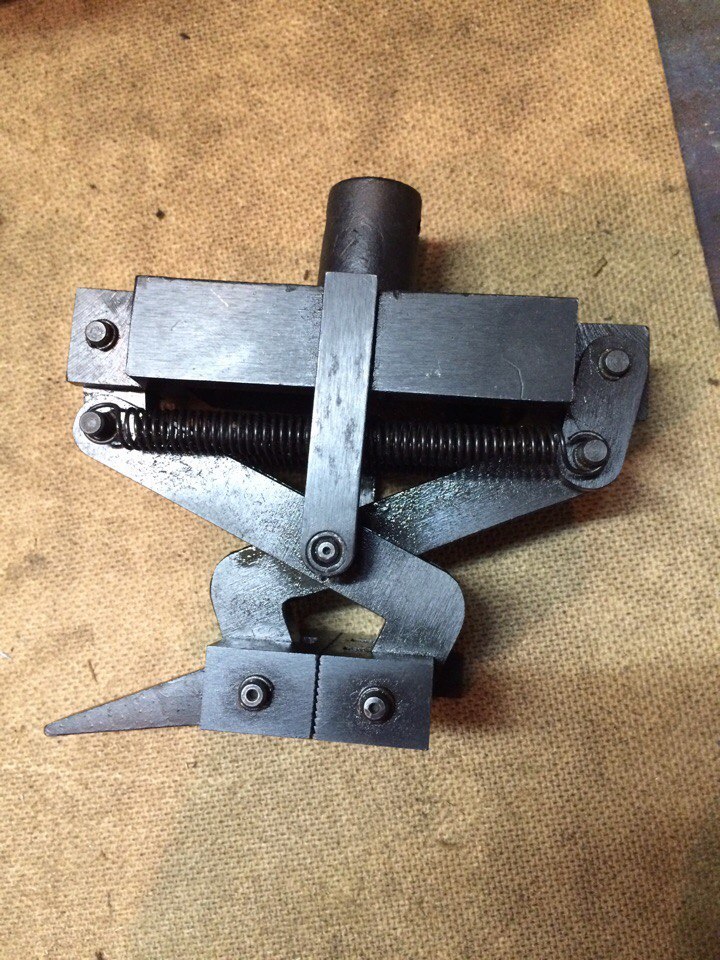

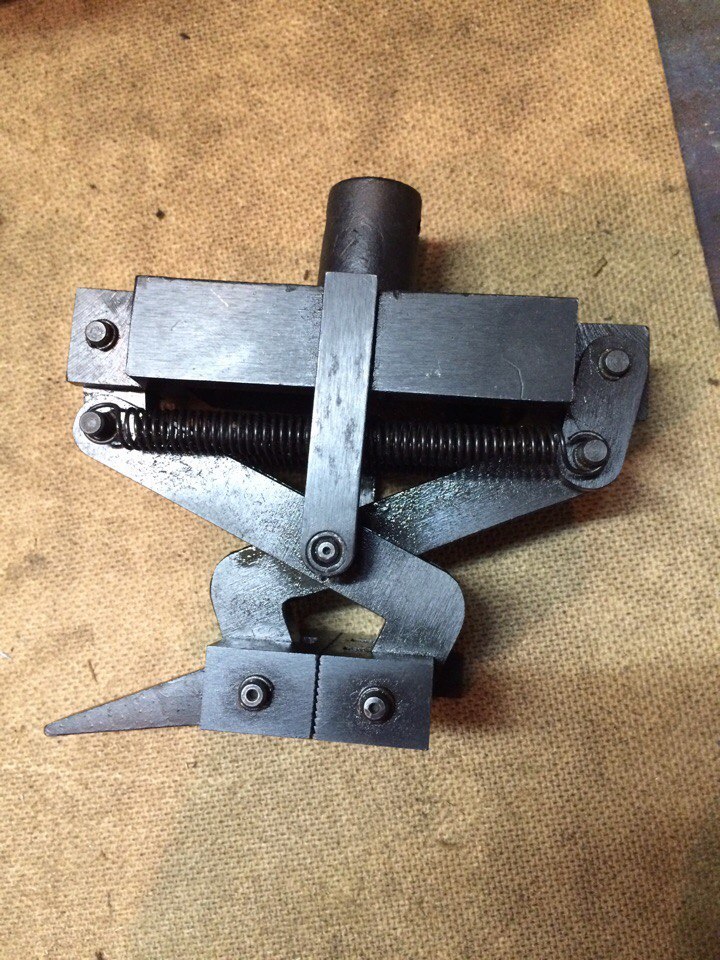

Any testing machine requires grippers to clamp and hold the specimen during the test. There are a lot of types of grippers, I will mention some: Clamping (work and look also like a vice), wedge (self-tightening), clamped (work and look like pincers). All grippers with interchangeable jaws for round and flat samples, and also differ in notch.

Some video testing and operation of machines:

In today's article, I cited several types of testing machines that provide the testing (scientific) laboratory with all the necessary physical and mechanical tests.

This is probably all, but if it is interesting, I can write about the manufacturing process, pricing, and generally answer all the additional questions asked in the comments to this article.

For starters, I can say that one universal machine with a maximum load of 50 kN (5 tons), depending on the version, costs about 1 mil. rub., if not a bad new foreign-made car.

First, let's define what mechanical properties are and what they are. Mechanical properties are the ability of a material to withstand the loads applied from outside. Such loads include compression, bending, impact, torsion, hardness, plasticity, elasticity, abrasion, etc.

In order to artificially reproduce these loads, the produced material (sample) is tested to determine the peak and nominal values of the operation of this sample.

')

Tests are carried out on machines providing a certain type of load, usually in Newtons (N). Explosive machines are generally universal, as they work in tension and compression, and allow you to determine the deformation, elasticity, plasticity and much more. But without exception, all machines receive three parameters from the controller: Load (N), Displacement (mm) and Time (s)

.

For such types of load as torque, a specially designed torsion machine designed to rotate the sample along its axis. The bending forces can be determined both when tested on a classical tensile testing machine and when a sample is tested on a pendulum scraper. Such machines look like a lathe with a torque sensor installed on the torsion axis.

Often, to determine the hardness of a material, a machine is needed as a hardness meter that provides control of hardness after the production of the material (eg, steel). Depending on the hardness of the material, the type of scale is chosen: the hardness of softer products is usually measured on a Shore scale or Brinell scale; for harder products, use the Rockwell scale; for very hard - Vickers scale.

There are still tests for fatigue and long-term strength, they are mainly carried out on classic tensile machines capable of supporting the sample under constant load for a long time, and using climate chambers to recreate the required climatic conditions. The only difference from the classical breaking machine is the load system, made in the form of a set of weights installed through a lever. The number of such machines in the laboratory can reach dozens of pieces, and tests can last from several days to several weeks, months and even years.

There is another class of machines: machines of friction are designed to study the processes of friction and wear caused by friction, the properties of lubricants and friction materials.

Many testing machines are developed and made to order as the serial machine is not suitable for one reason or another (dimensions of the test sample, method of fixing it in the grips, measurement accuracy, measurement parameters ...), the majority of customers are universities (if they have enough funding) , various scientific and production associations and all those who can work not with standard materials.

Any testing machine requires grippers to clamp and hold the specimen during the test. There are a lot of types of grippers, I will mention some: Clamping (work and look also like a vice), wedge (self-tightening), clamped (work and look like pincers). All grippers with interchangeable jaws for round and flat samples, and also differ in notch.

Some video testing and operation of machines:

In today's article, I cited several types of testing machines that provide the testing (scientific) laboratory with all the necessary physical and mechanical tests.

This is probably all, but if it is interesting, I can write about the manufacturing process, pricing, and generally answer all the additional questions asked in the comments to this article.

For starters, I can say that one universal machine with a maximum load of 50 kN (5 tons), depending on the version, costs about 1 mil. rub., if not a bad new foreign-made car.

Source: https://habr.com/ru/post/400043/

All Articles