Mega constructions. German stellarator Wendelstein 7-X

Wendelstein 7-X is the world's largest thermonuclear reactor, the type of stellarator , which performs controlled thermonuclear fusion. A bizarre experimental setup was built at the Max Planck Institute for Plasma Physics in Graiswald to test the use of this type of device as a fusion power plant. According to some forecasts, by 2100, energy consumption on Earth will increase about 6 times. Some experts believe that only thermonuclear energy is able to meet the growing energy needs of mankind.

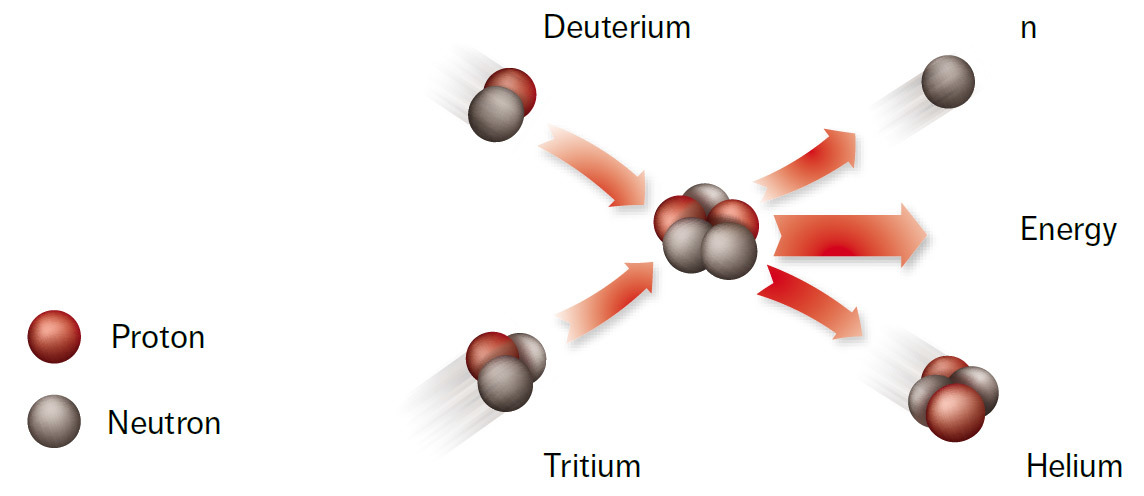

1 gram of hydrogen fuel (deuterium and tritium) in such an installation produces 90,000 kWh of energy, which is equivalent to burning 11 tons of coal.

Thermonuclear energy

According to economists and futurologists, mankind urgently needs a reliable and powerful source of energy. Hydrocarbon reserves in the world are limited. If energy consumption grows six times by the year 2100, then the energy system needs to be reformed and restructured, and the sooner the better. Thermonuclear energy seems to be a good solution to the problem.

')

Atomic nuclei are composed of nucleons (protons and neutrons), which are held together by a strong interaction. If you add nucleons to light nuclei or remove nucleons from heavy atoms, the difference in the binding energy will be released. The energy of motion of particles passes into the thermal motion of atoms. Thus, nuclear energy manifests itself in the form of heat. Changes in the composition of the nucleus is called nuclear reaction. Nuclear reaction with a decrease in the number of nucleons in a nucleus is called nuclear decay or nuclear fission. A nuclear reaction with an increase in the number of nucleons in a nucleus is called a thermonuclear reaction or nuclear fusion.

Nuclear fusion

Controlled thermonuclear fusion differs from traditional nuclear power engineering in that the latter uses a decay reaction, during which lighter nuclei are produced from heavy nuclei. In the synthesis of light nuclei synthesized heavy. Unlike a nuclear chain reaction, nuclear fusion is manageable.

The issue of controlled thermonuclear fusion on a global level arose in the middle of the 20th century, at the same time the concepts of the first reactors for controlled thermonuclear fusion, including tokamaks and stellarators, appeared.

Until recently, scientists have failed to overcome technological problems to prove that controlled thermonuclear fusion can actually be used in practice and such power plants will be cost-effective. Experimental reactors ITER and Wendelstein 7-X should prove this fact.

Stellarators

Wendelstein 7-X

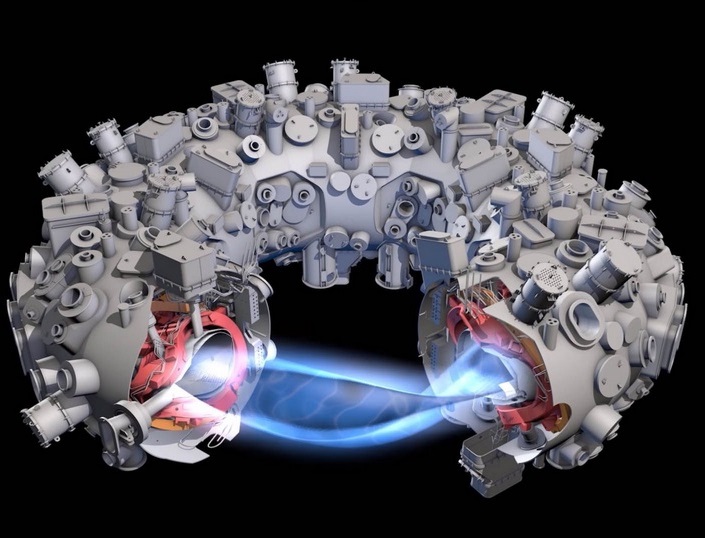

In a thermonuclear reactor, the fuel is placed inside a magnetic field and heated to a temperature of about 100 million degrees Celsius, at which a stable controlled nuclear fusion reaction takes place.

Stellarator is a type of reactor for controlled thermonuclear fusion. The name comes from lat. stella is a star, which should indicate the similarity of the processes occurring in the stellarator and inside the stars. Invented by American astrophysicist Lyman Spitzer in 1958. The first sample was built under the leadership of Spitzer in 1959 under the secret project Matterhorn, which in 1961, after declassification, was renamed the laboratory of plasma physics at Princeton University .

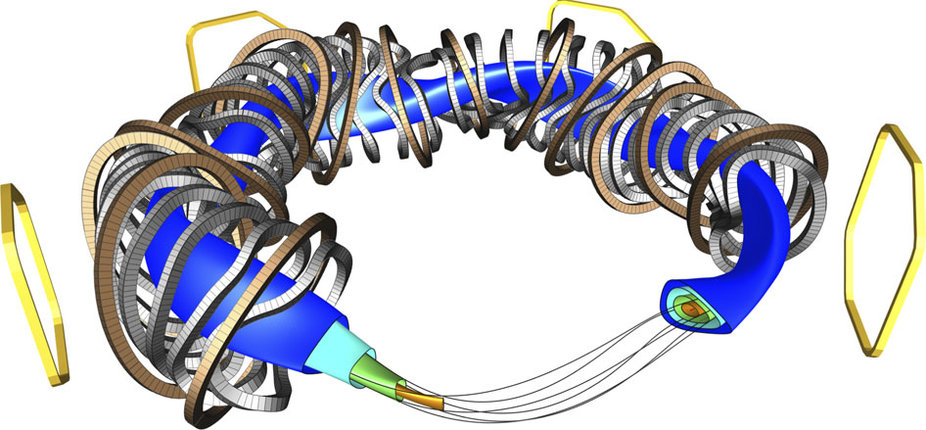

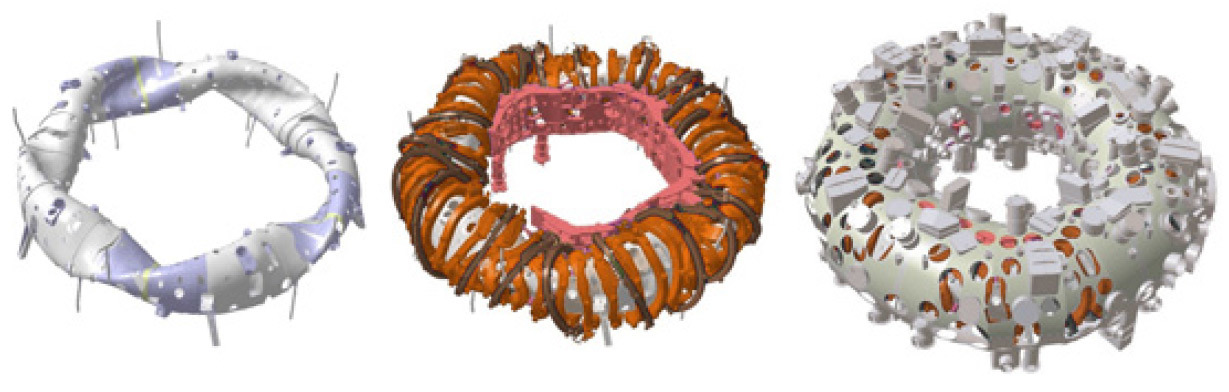

Stellarator is a closed magnetic trap for confining a high-temperature plasma. The principal difference between the stellarator and tokamak is that the magnetic field for isolating the plasma from the inner walls of the toroidal chamber is completely created by external coils, which, among other things, allows it to be used in continuous mode. Its lines of force undergo a rotational transformation, as a result of which these lines repeatedly bypass along the torus and form a system of closed toroidal magnetic surfaces nested in each other.

Stellarators were popular in the 50s and 60s, but then the attention of the scientific community shifted to tokamaks, which showed more encouraging results. Everything changed in the 21st century. In connection with the powerful development of computer technologies and computer graphics programs, the magnetic system of the stellarator was optimized. As a result, a completely new configuration of the rotational transformation appeared, not with two windings, as in all previous designs of the stellarator, but with only one winding . True, this is a very tricky winding form.

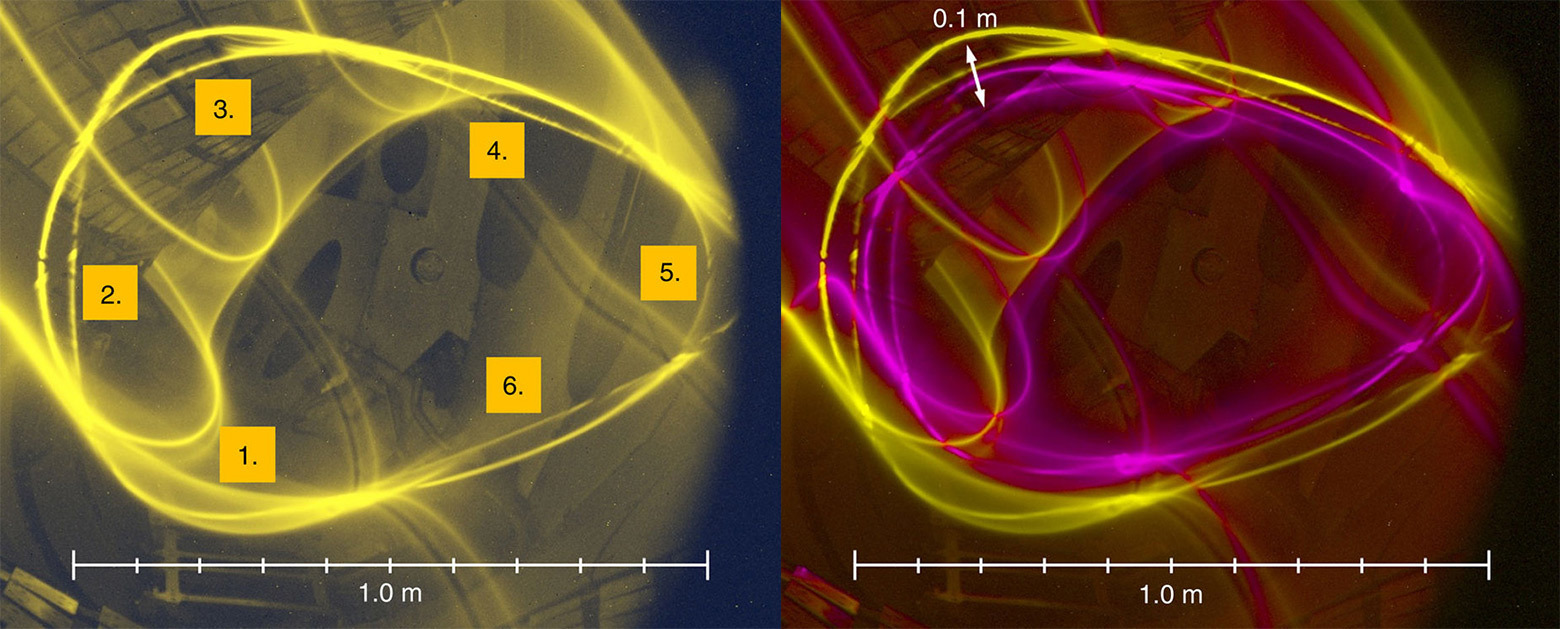

Topology of the Wendelstein 7-X stellarator in a computer simulation program with magnetic field lines. Planar (flat) winding coils are marked in brown, non-planar coils in gray. Some coils are missing on the renderer to show the structure of the nested structures of the stellarator (left) and Poincare sections for these structures (right). Four of the five outer filter coils are shown in yellow, the fifth should be on top. Source: Scientific paper "Confirmation of the topology of the Wendelstein 7-X magnetic field to better than 1: 100,000" , published November 30, 2016, Nature Communications magazine, doi: 10.1038 / ncomms13493

Why does the stellarator have such a bizarre form?

Hedgehog combing theorem

The hedgehog combing theorem states that it is impossible to choose a tangent direction on a sphere at each point, which is defined at all points of the sphere and continuously depends on the point. Informally speaking, it is impossible to comb a hedgehog coiled up with a ball so that it doesn’t have a single needle sticking out - hence the mention of a hedgehog in the title of the theorem. The theorem is a consequence of the fixed point theorem , which was proved in 1912 by Brauer.

It follows from the theorem on combing a hedgehog, among other things, that on the surface of the planet there is always a point at which the wind speed is zero.

Aware of the hedgehog combing theorem, German engineers designed a specific form of a stellarator in which magnetic induction vectors are “combed” in such a way that nuclear fusion (helium formation from hydrogen) continues along the entire closed contour in the center of the chamber. Enough to turn on the machine - and begins a continuous process with the release of energy.

The form of the stellarator is derived precisely from the mathematical equations of the hedgehog combing theorem.

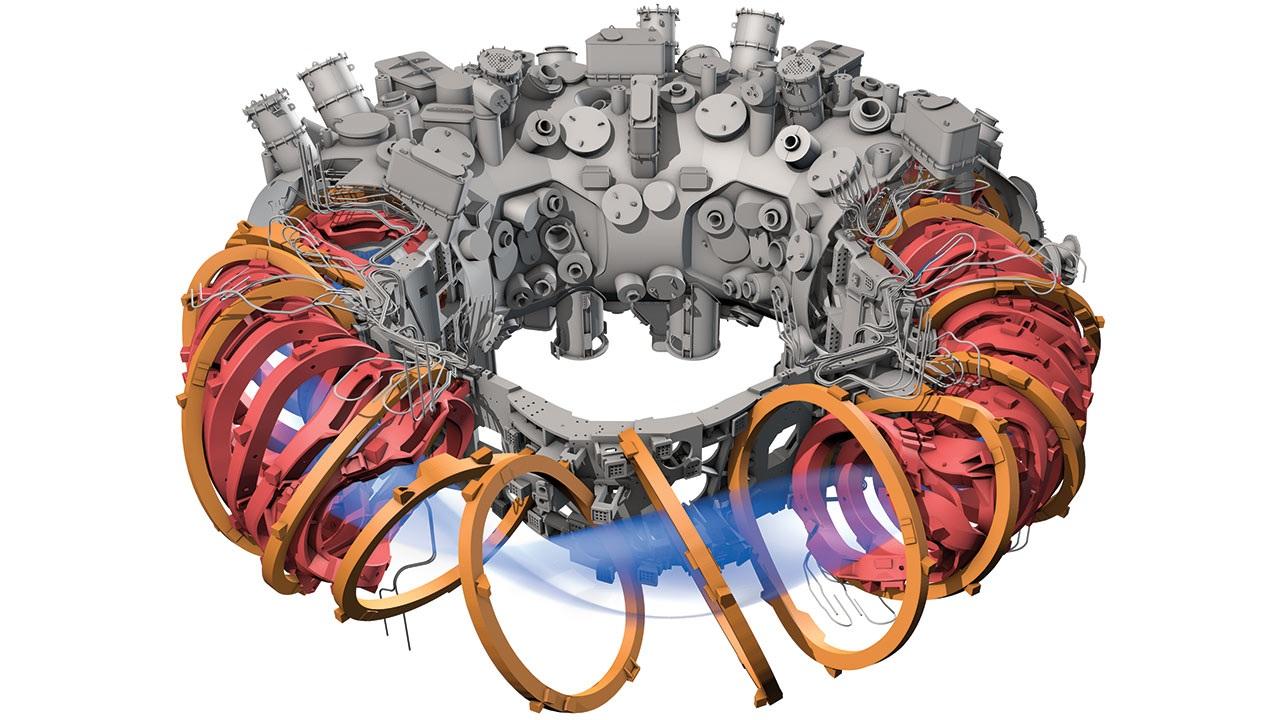

Wendelstein 7-X Stellarator Concept

The form of the stellarator was modeled on a computer, all vectors were calculated and verified. The only question that remained was whether the engineers could bring the theory to life - and in fact pour out the metal stellarator of such an unusual shape. It immediately became clear that the project would be very expensive (according to the results, the construction of the stellarator itself cost 370 million euros, and together with the building, salaries and other expenses - 1.08 billion euros; 80% of financing was assumed by Germany, 20% - by the European Union) . But the stakes are high: a source of energy from thermonuclear fusion promises a revolution in the global energy industry. Therefore, the engineers set to work.

Wendelstein 7-X Stellarator Assembly

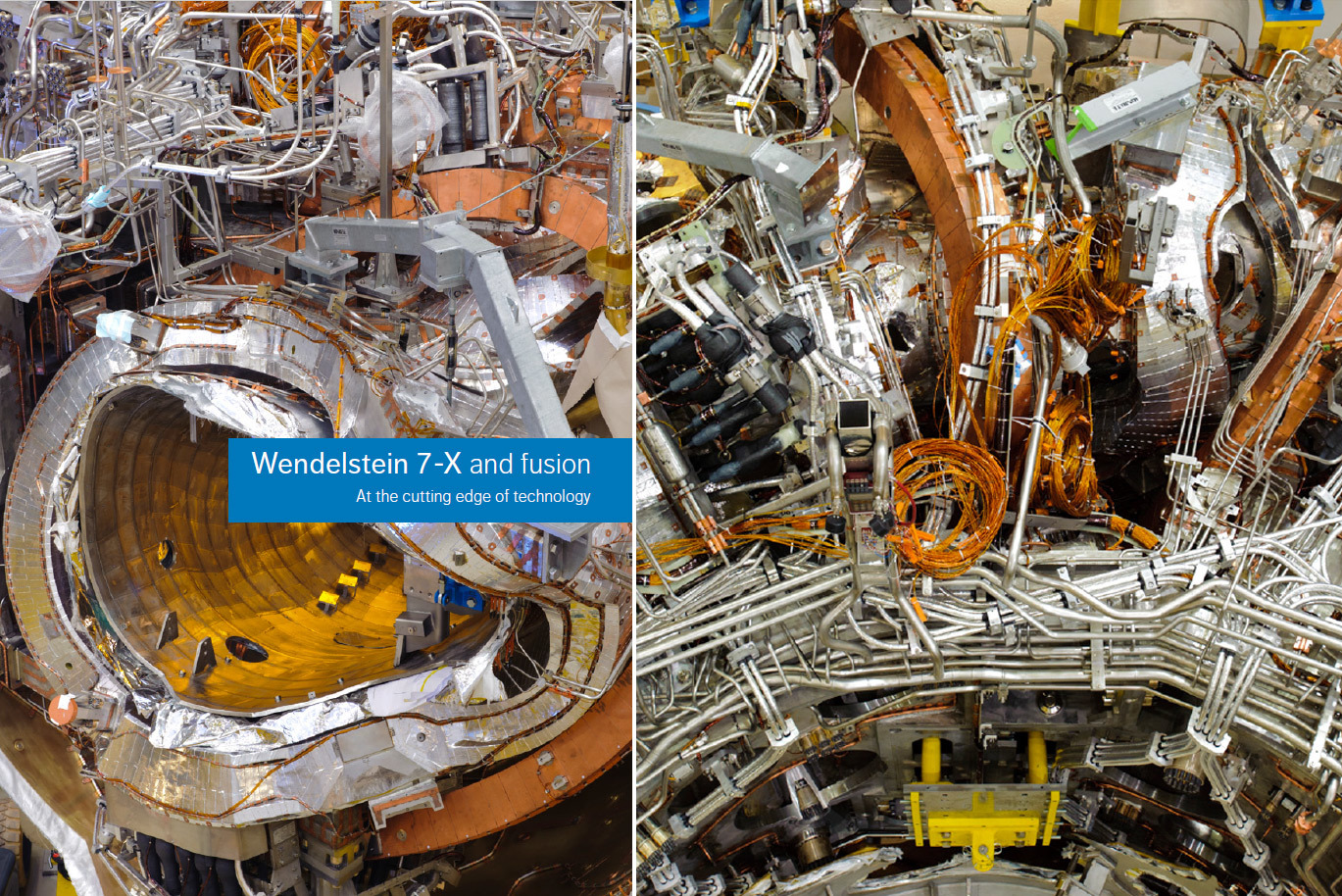

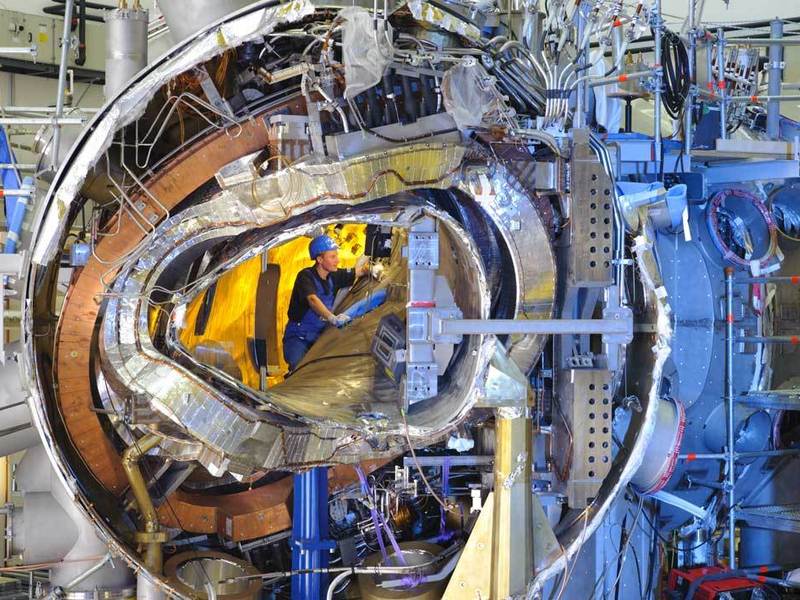

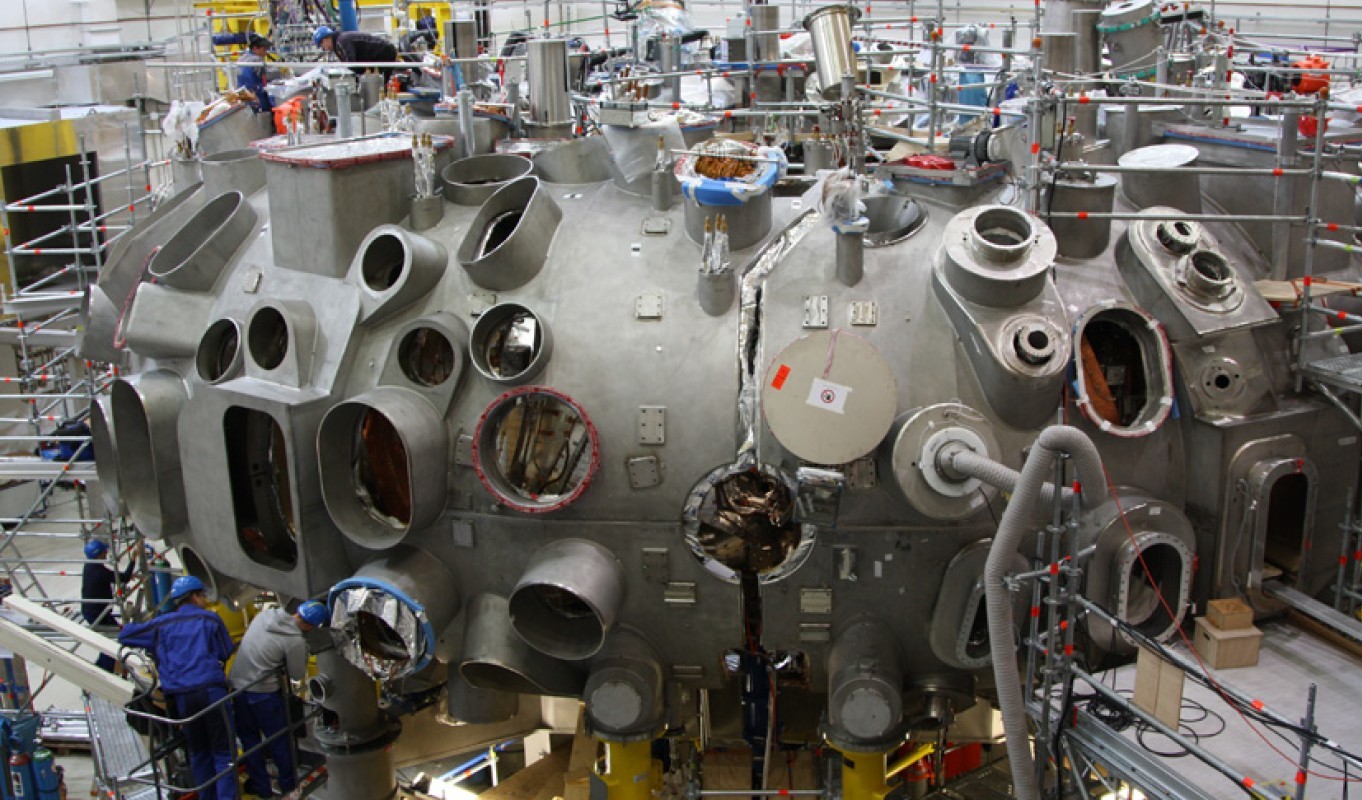

The stellarator was assembled from April 2005 to April 2014. During the nine years of construction, the facility took 1.1 million man-hours of work. Then began the technical preparation for the experiment. Each technical system was tested: vacuum vessels, cooling system, superconducting coils and their magnetic field, control system, as well as heating devices and measuring instruments.

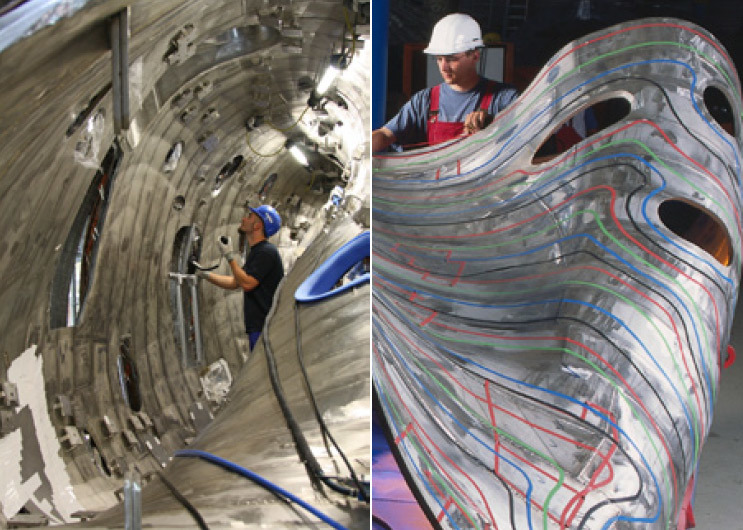

Assembly of the Wendelstein stellarator 7-X, November 2011. Photo: IPP, Wolfgang Filser

The winding of the Wendelstein 7-X stellarator consists of 50 non-planar and 20 planar superconducting magnetic coils. They are circulating a magnetic field in which the hydrogen plasma is heated to 100 million degrees Celsius. The coils used are niobium-titanium conductors. This material enters the superconducting state when the temperature drops below 9.2 ° K. Standard magnet cooling with liquid helium at a temperature of -270 ° C. Due to the need for continuous cooling, the coils are installed inside a cryostat, having an inner and outer shell, isolated from each other by a vacuum. For the study and heating of the plasma used 254 holes in the shell.

Technically, the Wendelstein 7-X stellarator consists of five almost identical modules. In each of them there is a plasma shell, thermal insulation, 10 superconducting non-planar coils, 4 connected planar coils, a system of tubes for liquid helium, a segment to support the central ring and an outer shell.

Plasma is heated by three methods: microwave heating with a generator power of 10 MW, heating with radio emission of 4 MW, and heating with a beam of neutral particles of 20 MW.

When all five modules were installed in place at the base of the stellarator, work began on their welding, connecting the systems for heating and monitoring the plasma.

Companies from all over Europe were attracted to build the stellarator. One of the main contractors was the company MAN Diesel & Turbo, which was involved in the manufacture of steel segments of the plasma chamber. In general, it has an external diameter of 12.9 m and a height of 2.4 m. They had to solve many technical problems. For example, steel plasma chambers have a fancy shape and should be poured with a tolerance of +/− 2 mm. Each chamber consists of 200 rings, and each ring consists of several 15-centimeter steel strips, bent in a special way in accordance with a complex geometry calculated in a computer simulation program in accordance with the formulas of the hedgehog combing theorem. The modules were manufactured at the MAN Diesel & Turbo plant in Düsseldorf.

The same accuracy and specific scientific requirements were imposed on the cooling circuits for the coils.

Assembly of thermal insulation of the outer shell

The organizers believe that participation in the project gave each company invaluable technical experience and was in itself prestigious. For example, MAN Diesel & Turbo specialists had to master specific 3D design programs and electronic laser tools for geometry estimation. Since then, these tools have entered the company's ongoing production process.

The plasma heating system was manufactured by Thales Electron Devices (France), Element Six (UK), Diamond Materials (Germany) and Reuter Technologie (Germany).

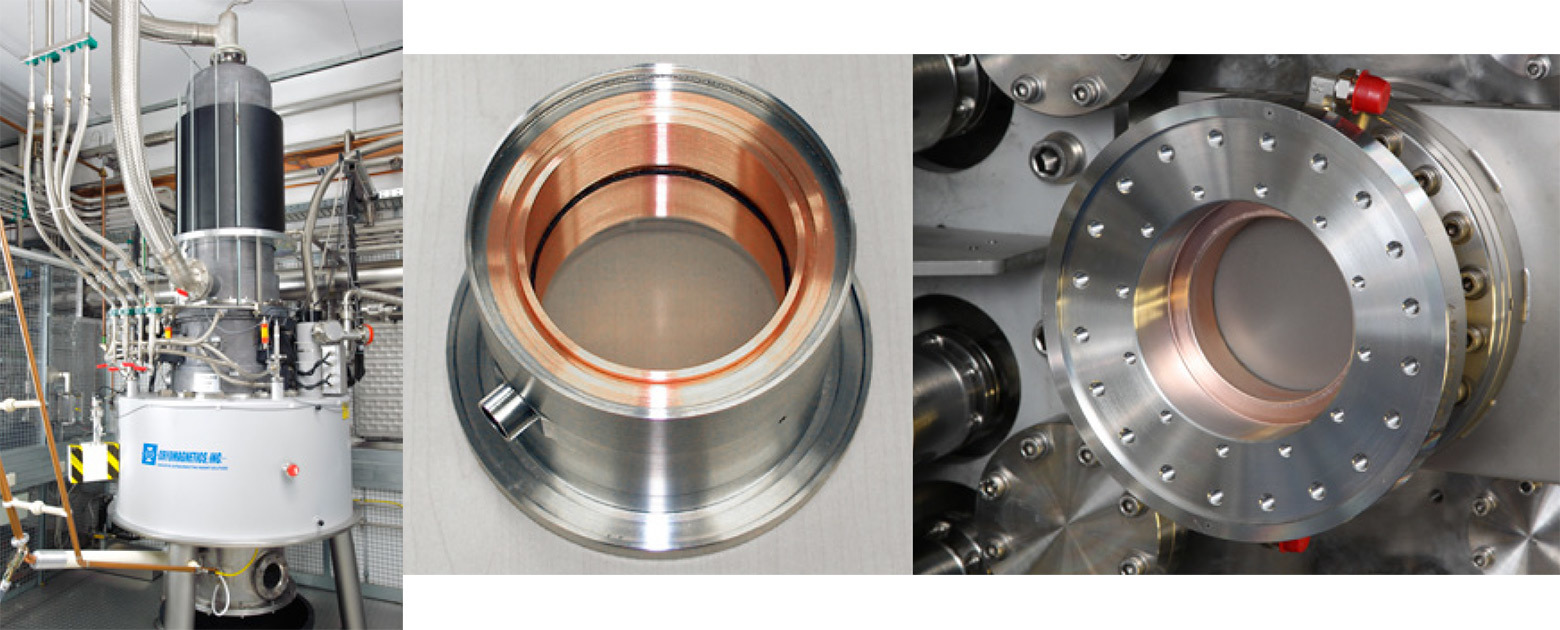

Thales Electron Devices was engaged in the manufacture of key plasma heating devices - gyrotrons - in close cooperation with German physicists.

A gyrotron is an electrovacuum microwave generator, which is a kind of cyclotron resonance maser. The source of microwave radiation is an electron beam rotating in a strong magnetic field. Radiation is generated at a frequency equal to the cyclotron frequency in a resonator with a critical frequency close to that generated. Gyrotron was invented in the USSR at the NIRFI in the city of Gorky (now Nizhny Novgorod).

Left - One of the 1 MW Wendelstein 7-X gyrotrons for continuous microwave plasma heating, center and right - a window between the gyrotron and the outer shell of the stellarator, made of artificial diamond, parts were made at the Diamond Materials plants in Freiburg and the Element Six in the UK

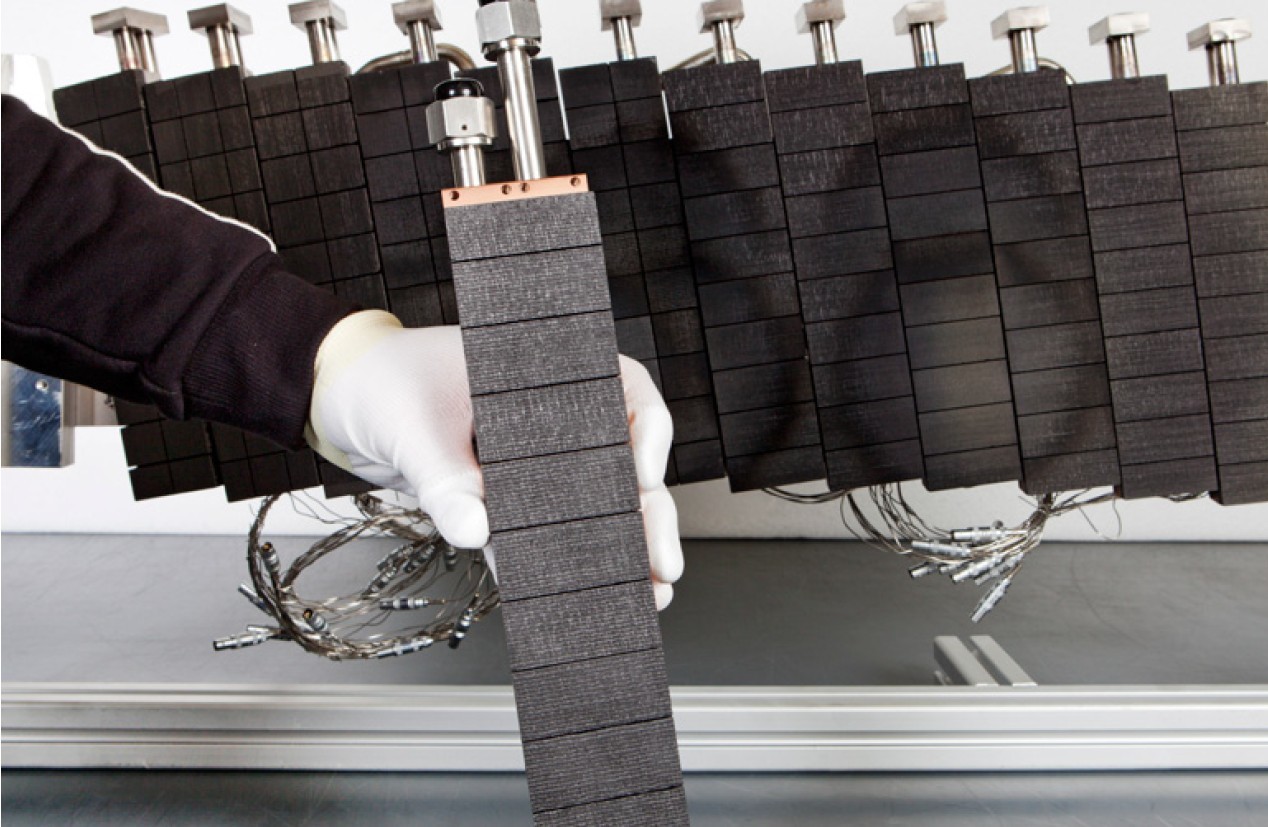

The plasma inside the reactor is held in a magnetic field, but it still cannot avoid its contact with the inner shell. Although at the same time the temperature of the plasma drops to only 100,000 ° C, it is still necessary to cover the inner side of the steel chamber with heat-resistant material that simultaneously removes heat. The manufacture of such diverter engaged Austrian company Plansee. Engineers have created structural elements from new materials: carbon blocks reinforced with carbon fiber (carbon-graphite composite) and water-cooled metal. In total, the stellarator required to make 890 elements of the divertor from 18,000 blocks. The new material is already patented by the inventors under the name EXTREMAT .

Plansee Heat Exchanger Diverter absorbs 10 MW per square meter in continuous mode

The superconducting coils from a niobium-titanium alloy of complex shape for a stellarator were manufactured by Babcock Noell (Germany).

During the ten years of construction, it was possible to solve all technical problems and put into operation the mega-structure of the stellarator.

Creation of a stellarator at the Max Planck Institute for Plasma Physics

A historic event took place on December 10, 2015: the Max Planck Institute for Plasma Physics (IPP) in Graiswald was the first to launch the experimental stellarator Wendelstein 7-X .

Wendelstein 7-X: First Plasma

The operators of the stellarator gave the command to generate a magnetic field and launched a computer control system for the experiment. They applied about one milligram of helium to the plasma compartment, turned on microwave heating for a short 1.3-megawatt pulse — and the first plasma was detected by installed cameras and measuring instruments. The first plasma maintained a stable state for 0.1 seconds and reached a temperature of about a million degrees Celsius.

Project leader Professor Thomas Klinger (Thomas Klinger) said that the plan was to start with helium, because it is easier for him to get the state of the plasma. In 2016, experiments with hydrogen plasma began.

Magnetic field metering

Heating the plasma to a million degrees and more is good, but the main question that remained open was whether the scientists really managed to assemble a stellarator of the correct form, in accordance with the hedgehog combing theorem. Is the result of a mathematical model? This is the most important question, because no one has ever assembled such a fusion reactor before. Is there really going to be thermonuclear fusion with the given parameters?

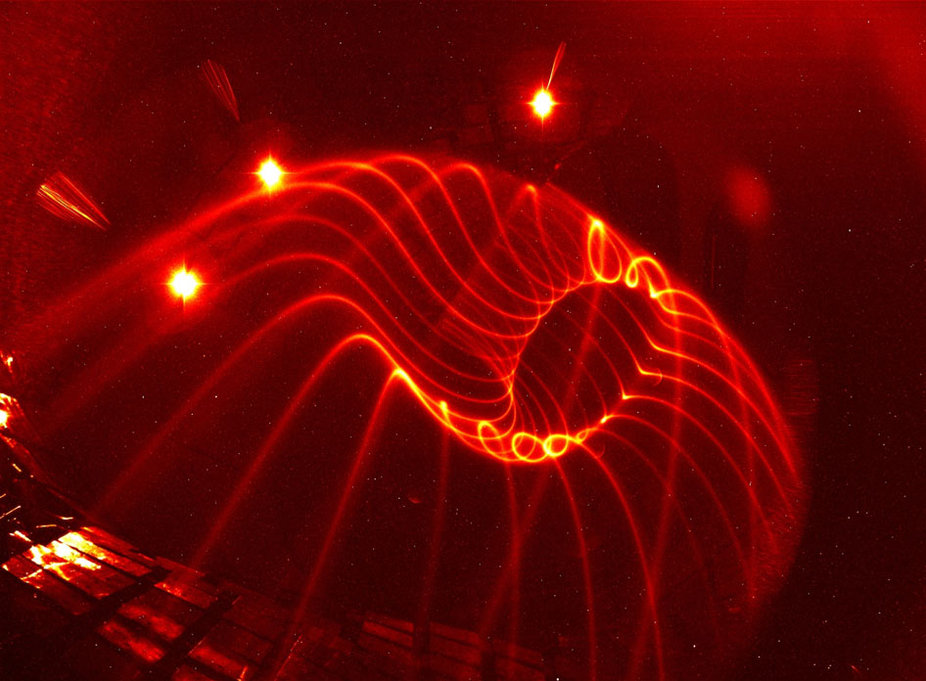

On November 30, 2016, we received an answer to this question. On this day, the journal Nature Communications published a scientific article "Confirmation of the Wendelstein 7-X magnetic field to a better than 1: 100,000" (open access). It presents the results of measurements of the magnetic field inside the toroidal chamber, which confirm the actual operability of the Wendelstein 7-X stellarator in accordance with the calculated parameters. The measurements were made before the plasma was heated up, but they show that the engineers at the construction site did indeed succeed in assembling the mega-design, which fully complies with the calculated parameters. The magnetic topology of the machine is made by German engineers with the required accuracy.

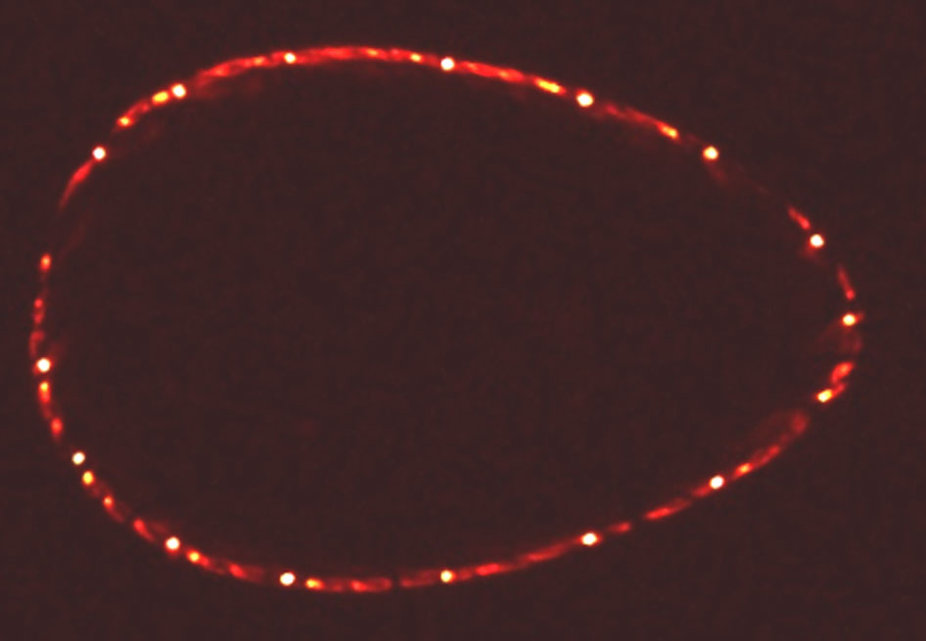

Visualization of the magnetic field in the stellarator using neutral gas (a mixture of water vapor and nitrogen). Three bright spots - calibrators for the camera

Poincare section of a closed magnetic circuit. The electron beam passed through it more than 40 times, that is, more than 1 km

Minor magnetic field shift due to deformation of superconducting magnets

So, the world's largest stellarator really works.

Source: https://habr.com/ru/post/399993/

All Articles