Snake robot for laser cutting of nuclear waste

Dozens of atomic reactors of old generations do not meet modern safety requirements, they are morally and technically outdated. Older nuclear power plants around the world now need to be gradually decommissioned and closed, while spent fuel and equipment should be cut, poured with concrete and buried away from people.

Reprocessing and disposal of spent nuclear fuel and other waste is a complex engineering task. First of all, because all operations at nuclear power plants are performed by robots, and not by humans, for safety purposes. The fuel itself and reactor fragments should be cut into small fragments and placed in containers for disposal. For example, at the Chernobyl nuclear power plant, these canisters are only 4444 mm long and 1876.4 mm in diameter. At ChNPP, a stationary circular saw is used, which can cut only rods that are previously placed in the machine.

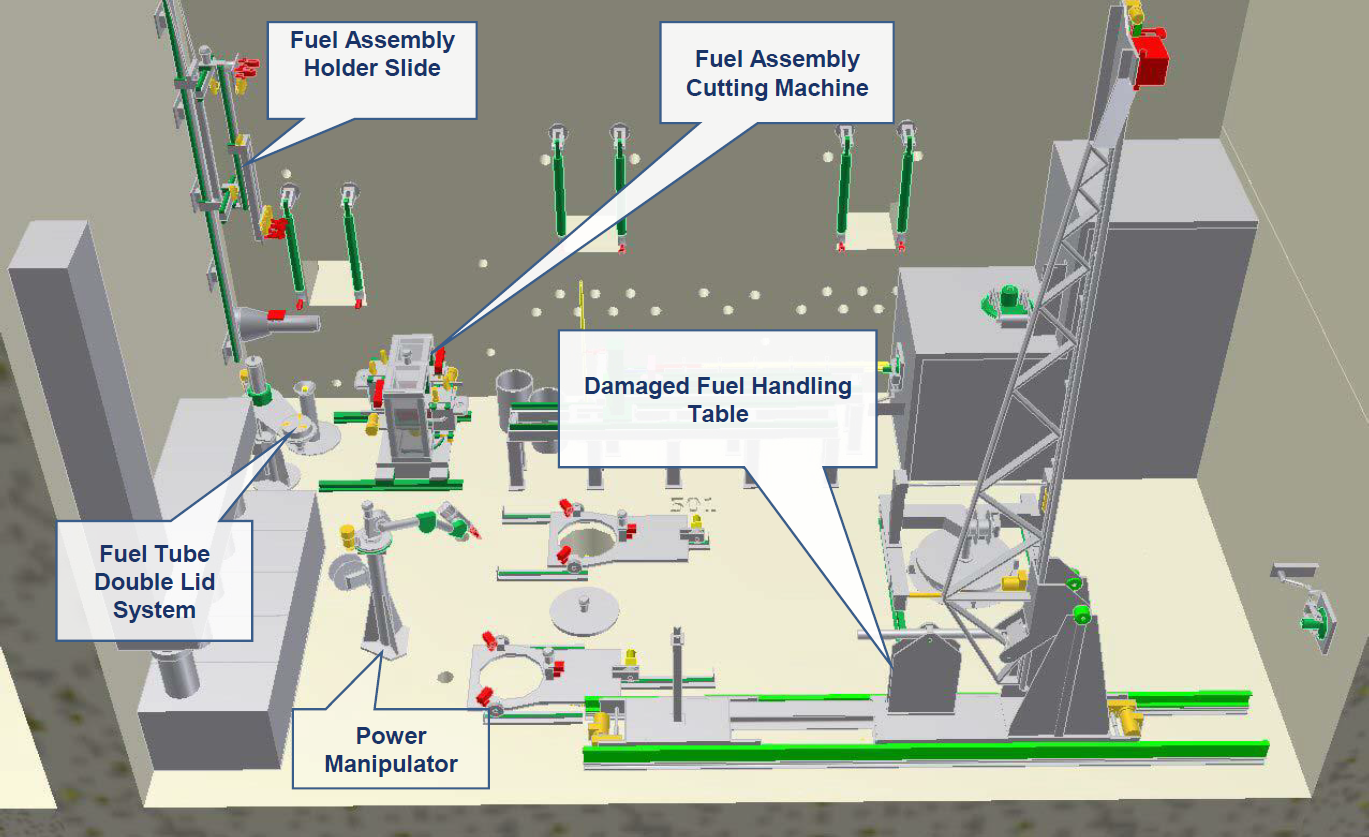

Work on the delivery and cutting of spent fuel at the Chernobyl nuclear power plant are carried out automatically, with remote control. The American company Holtec has built a robotized mini-plant for this, where the spent fuel is prepared for disposal.

')

The scheme of dry spent fuel storage "SNF-2" (Interim Spent Fuel Storage Facility, ISF-2) on the territory of Chernobyl NPP, where cutting of waste occurs before their disposal

After cutting, fragments of rods of spent fuel are placed in double-walled cans, which are poured with concrete and transferred to storage.

Spent Fuel Storage Area at Interim Spent Fuel Storage Facility, Chernobyl Nuclear Power Plant

If it is necessary to cut only the rods and nothing else, as at the Chernobyl NPP, then these are fairly simple tasks. A simple laser cutter is enough.

Cutter with circular saw for cutting rods. The photo was taken during acceptance of the HOYAT-2 plant in operation.

The ChNPP example well demonstrates the challenges that engineers face when developing automated equipment for cutting nuclear waste. Fortunately, science does not stand still, and robotics companies are ready to offer more advanced and versatile equipment for the disposal of nuclear waste. Given the need to decommission old unsafe nuclear reactors, such equipment will come in handy.

The British company OC Robotics has developed an unusual machine that looks like a thick metal snake with a death sting. This is a robotic LaserSnake2 manipulator, which is precisely positioned in all degrees of freedom and equipped with a powerful laser cutter for cutting any material.

The project has been under development since 2013 . He was led by OC Robotics with the participation of TWI, the National Nuclear Laboratory, ULO Optics and Laser Optical Engineering. Funding was provided by Innovate UK, the UK Department of Energy and Climate Change, and the UK nuclear facility decommissioning department.

After a three-year development of the “laser snake” in July-August 2016, the machine was installed and tested at the First Generation Reprocessing Plant nuclear waste processing plant in Sellafield (United Kingdom). This is an extensive nuclear complex on the coast of the Irish Sea. Over the years, weapons-grade plutonium was produced here (since 1950), fuel was produced for nuclear power plants, irradiated nuclear fuel was reprocessed, and nuclear power plants operated (from 1956 to 1983).

Operation LaserSnake2 showed that the machine successfully copes with the tasks. In November 2016, this robot was even awarded the Technology / Innovation Implementation Award from the UK Decommissioning Authority.

The technology of the new generation can be widely used in real conditions of disposal and recycling of nuclear waste. Including stations that are decommissioned.

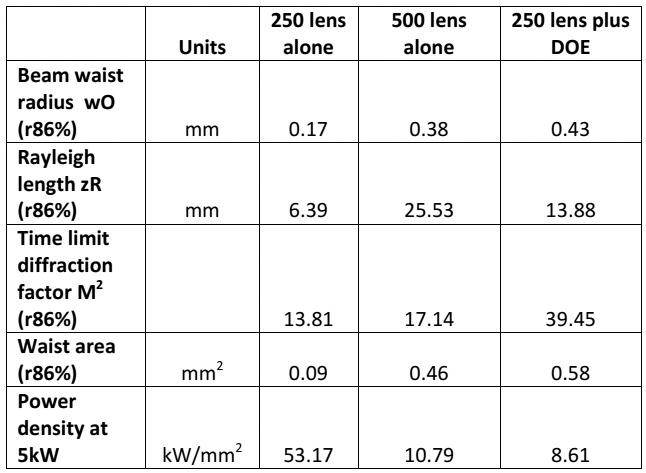

The cutter is designed on the basis of a high-power laser with an optical focusing system (see beam parameters and cutting speed when testing a 5-kilowatt laser and various diffractive lenses).

Cutter LaserSnake2 copes even with thick metal parts.

Remote control cutter provides a group of engineers, which is located in a safe room.

Developers believe that LaserSnake2 can be useful not only for waste disposal, but also to perform laser cutting tasks in any hostile to humans or limited conditions, including under water . In the future, nothing prevents to combine this robot with a mobile platform, providing it with a certain freedom of movement.

In addition to nuclear power, LaserSnake2 is proposed to be used in the oil and gas sector, where such a facility can take part in the inspection and repair of pipes and equipment, in construction and engineering works. For example, in cramped conditions for designing an airliner, during assembly and maintenance of aircraft wings.

Together with the robot comes with software for management. Developers can tailor the design of the LaserSnake2 to perform specific tasks.

Source: https://habr.com/ru/post/399671/

All Articles