Available 3D milling machines with CNC, from 250,000 to 1,000,000 rubles

There is a choice. If you have a relatively large-scale production, or you want to close the issue of equipment for a longer time, it makes sense to get a frezer at once more powerful - with greater speed and work area, with additional functions and a fair amount of resources.

Roland SRM-20

Roland SRM-20

- Size of the working field: 203.2 x 152.4 x 60.5 mm

- Spindle power: 20 W, 7000 rpm

- Number of axles: 3

- Application: Design, Education

- Price: 270 660 rubles.

Ultra-precise Japanese CNC milling machine for office, design studio or institute. Works with materials: wood, wax and plastic to create models and patterns, plexiglass, solid ABS plastic, PCB and printed circuit boards.

')

The machine is used in jewelry, for prototyping samples of wearable consumer electronics and creating unique parts for piece production. The speed of passage of the curves by the mill in it is up to 1800 mm / min.

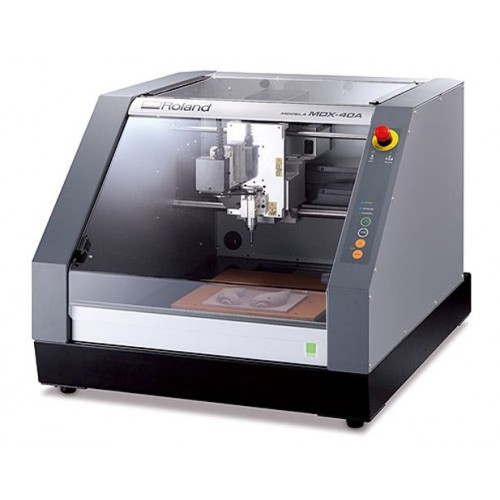

Roland MDX-40A

Roland MDX-40A

- Size of field: 305 x 305 x 105 mm

- Spindle power: 200 W, 150000 rpm

- Number of axles: 3+

- Application: prototyping, press forms

- Price: 437 220 rubles.

Works with materials: plastic, ABS, acrylic, wood, model wax, magnesium, brass, aluminum, copper, bronze and other similar materials.

It is used to create realistic models, existing prototypes, molds. When equipped with an optional scanning nozzle, it can also perform 3D scanning with a resolution of 0.04 mm.

Fully closable housing helps to reduce the noise level in the room and protects the manufactured product from external influences.

Roland JWX-30

Roland JWX-30

- Size of field: 305 x 205 x 100 mm

- Spindle rotation speed: 6000 - 30000 rpm

- Number of axles: 4

- Application: jewelry production

- Price: 895,000 rubles

The machine works with a wide range of materials applicable in jewelry, one of them and the main one is model wax, which is even available in original equipment. Used by jewelers in the process of creating jewelry.

A feature of this machine is the most simplified in the application, but having the widest range of functions software, which includes the development and visualization mode with the calculation of the volume and mass of the future product.

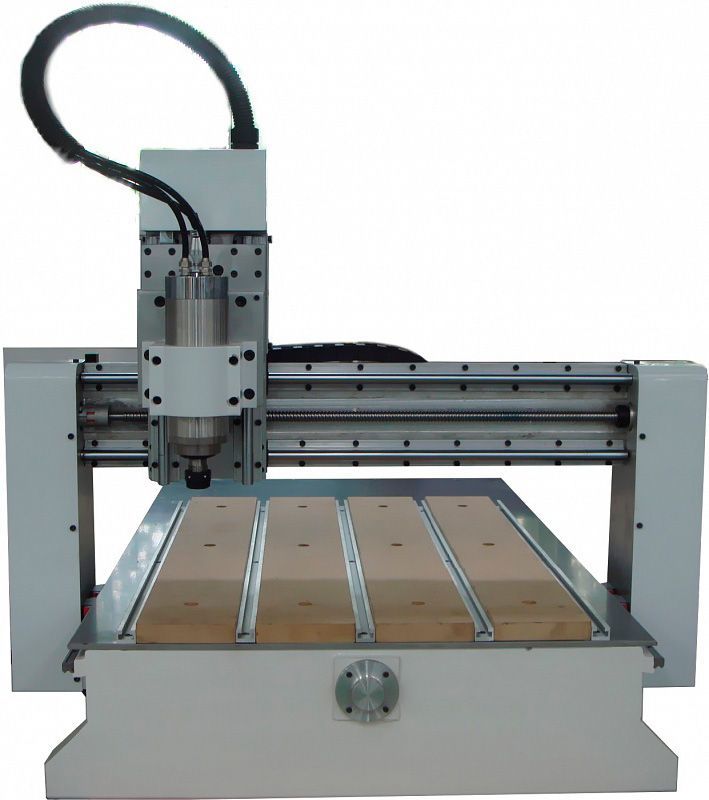

Advercut K6090T

Advercut K6090T

- Size of field: 600 x 900 x 150 mm

- Spindle power: 2.2 kW, 24,000 rpm

- Number of axles: 3

- Application: furniture, advertising production

- Price: 318,000 rubles

Used mainly in furniture production and advertising. Ideal for creating signs and furniture decoration.

Differs in the big size of working area and the increased power. It takes up quite a bit of space - it literally fits on the table, and its performance and resources far exceed those of the previous price category. It works with all traditional furniture materials, as well as with Plexiglas and PVC, with plastics and soft metals (duralumin, aluminum, brass, copper).

Advercut K6100A

Advercut K6100A

- Size of the working field: 600 x 1000 x 150 mm

- Spindle power: 2.2 kW, 24,000 rpm

- Number of axles: 3

- Application: industry, multipurpose, advertising production

- Price: 433,000 rubles.

Compact frezer-CNC for a small company, creative workshop or office Technology or Labor at school.

Engraves, mills (including in 3D), drills and cuts wood, furniture composites, a wide range of polymers and non-ferrous metals like aluminum (aluminum alloys, copper, brass). Optional desktop to choose from - with a vacuum capture of the workpiece or t-slots.

Advercut K30MT / 1212

Advercut K30MT / 1212

- Size of the working field: 1200 x 1200 x 120 mm

- Spindle power: 3-7.5 kW, 24,000 rpm

- Number of axles: 3

- Application: advertising production, woodworking, interior and decorative elements

- Price: 664,000 rubles.

The machine is distinguished by increased power and speed of work, a large work area, and the convenience of the operator during long continuous work.

Perfect for small productions, design bureaus and workshops with advertising agencies.

It easily processes all traditional furniture materials, as well as plastics, plexiglas and non-ferrous metals (aluminum, aluminum alloys, copper, brass).

Advercut K45MT / 1325

Advercut K45MT / 1325

- Size of the working field: 1300 x 2500 x 200 mm

- Spindle power: 3.5-7.5 kW, 24,000 rpm

- Number of axles: 3

- Application: advertising production, woodworking, interior and decorative elements

- Price: 943,000 rubles.

Due to the size of the working area, Advercut K45MT / 1325 is widely used for the manufacture of wooden wall panels in bas-relief style, furniture parts made of composite materials such as chipboard, fiberboard, MDF and hardboard, as well as advertising structures.

Used in workshops advertising agencies. Differs in the increased power and reliability.

Advercut K45MT / 1520

Advercut K45MT / 1520

- Size of the working field: 1500 x 2000 x 200 mm

- Spindle power: 3.5-7.5 kW, 24,000 rpm

- Number of axles: 3

- Application: door manufacturing, advertising production, woodworking, interior and decorative elements

- Price: 966,000 rubles

Processed materials: brass, aluminum, duralumin, copper, wood and derivatives (plywood, chipboard, etc.), plastic and other polymers (plexiglas, PVC and the like).

From the previous model (K45MT / 1325), the Advercut K45MT / 1520 differs in the size of the surface to be treated. The working area of this machine is ideal for the manufacture of entrance and interior doors of the most interesting and sophisticated forms. That does not prevent him, of course, successfully work on any other, often - even more interesting products.

Router 9565

Router 9565

- Size of the working field: 990 x 670 x 150 mm

- Spindle power: 1050 W

- Number of axles: 3

- Application: small industry, multipurpose

- Price: 305,000 rubles.

Due to the fact that the speed of the cutter is up to 3000 mm per minute, the accuracy of movement is up to 0.0025 mm, and the repeatability accuracy is up to 0.1 mm, this machine is able to reproduce highly detailed objects in the shortest possible time.

It works with wood, plastic, plexiglass and many other materials, including aluminum.

It is used in joinery and for prototyping objects in engineering production.

With a power of 1050 watts, the Router 9565 easily cuts thick hardwood into pieces of wood.

Router 3020

Router 3020

- Size of the working field: 300 x 200 x 120 mm

- Spindle power: 800 W

- Maneuverability: swivel mechanism included

- Application: decorative applied

- Price: 395,000 rubles.

High vibration resistance and reliable fixation of the workpiece. Rotary mechanism for cylindrical machining of parts. Work with wood, light metals and plastics, plexiglass and PVC, etc. Used for the production of decorative products and functional parts of various objects.

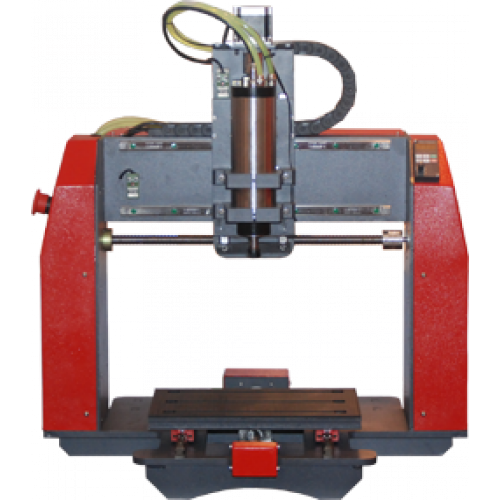

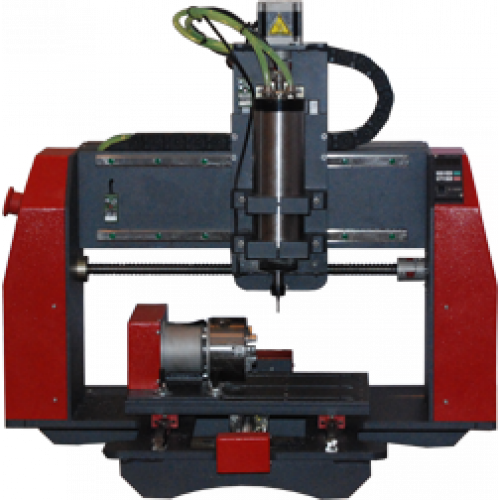

Router 4030

Router 4030

- Size of the working field: 400 x 300 x 137 mm

- Spindle power: 1050 W, 10,000-29,000 rpm

- Number of axles: 3

- Application: industry, multipurpose

- Price: 415,000 rubles.

The router 4030 is a 3D milling machine with a CNC, featuring high precision and speed.

Designed for use in a production environment. Closed construction. A wide range of materials used: plastics, polymers, wood and derivatives, non-ferrous metals (aluminum, aluminum alloys, copper, brass).

Router 3020 BZ

Router 3020 BZ

- Size of the working field: 300 x 200 x 120 mm

- Spindle power: 800 W

- Number of axles: 3

- Application: carpentry production

- Price: 445 000 rub.

The machine easily copes with solid wood grades, textolite and hardboard, various types of plastic and light metals. Used in carpentry production and for prototyping in engineering developments. The open design allows you to secure workpieces significantly exceeding the size of the working area.

Router 3020 VZKM

Router 3020 VZKM

- Size of the working field: 300 x 200 x 120 mm

- Spindle power: 800 W

- Number of axles: 3

- Application: industry specialized

- Price: 555 000 rub.

The model was created specifically for the production of EDM electrodes of any desired shape, but can be used in other areas, such as jewelry manufacturing or dentistry. The case with double doors reliably protects the process from external influences and looks aesthetically pleasing. Regularly works with copper, brass, aluminum and any softer materials.

Router 4030 PS and 4030 PS Servo

Router 4030 PS

- Size of working field: 400 x 300 x 160 mm

- Spindle power: 1100/1300 W

- Number of axles: 3

- Speed of movement of a mill to 6000 mm a minute

- Application: universal

- Price: 710,000 rubles.

And faster analog:

Router 4030 PS Servo

- Size of working field: 400 x 300 x 160 mm

- Spindle power: 1100/1300 W

- Number of axles: 3

- Speed of movement of a mill to 20 000 mm a minute

- Application: universal

- Price: 910,000 rubles.

Ultra-precise universal 3D milling machine with CNC. Spindle stroke accuracy up to 0.0025 mm.

Works with light metals and all less rigid materials, i.e. - from aluminum to plywood. Designed for use in manufacturing, where accuracy and speed are important.

The Servo modification is distinguished by the presence of servo drives along the spindle movement axes, which ensures an increase in the speed of work more than three times. There are no other differences.

Router 6040S

Router 6040S

- Size of field: 600 x 400 x 200 mm

- Spindle power: 2000/4200 W, 3000 - 24000 rpm

- Number of axles: 3

- Application: industry

- Price: 920,000 rubles.

The cutter moves at a speed of up to 6000 mm / min, the torque is 46 kg / cm, the displacement accuracy is up to 0.0025 mm.

The model has a stable platform and increased protection from vibration, can be used conditions factory workshops.

Work with rigid materials, up to titanium, various types of steel and ceramics is permissible.

It can be used for the manufacture of various parts from anything, the restriction is only in the size of the working field.

As we can see, the range of available CNC milling machines, with a price within a million rubles, is large enough to satisfy the demands of not only a small business or a freelance artist, but also a developing enterprise that claims more.

It is not necessary to spend tens of millions to get a functional milling machine at your disposal that can solve many emerging production problems.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/399655/

All Articles