What should we build a spacesuit? Interview with spacesuit developer Nikolai Moiseev, part 4

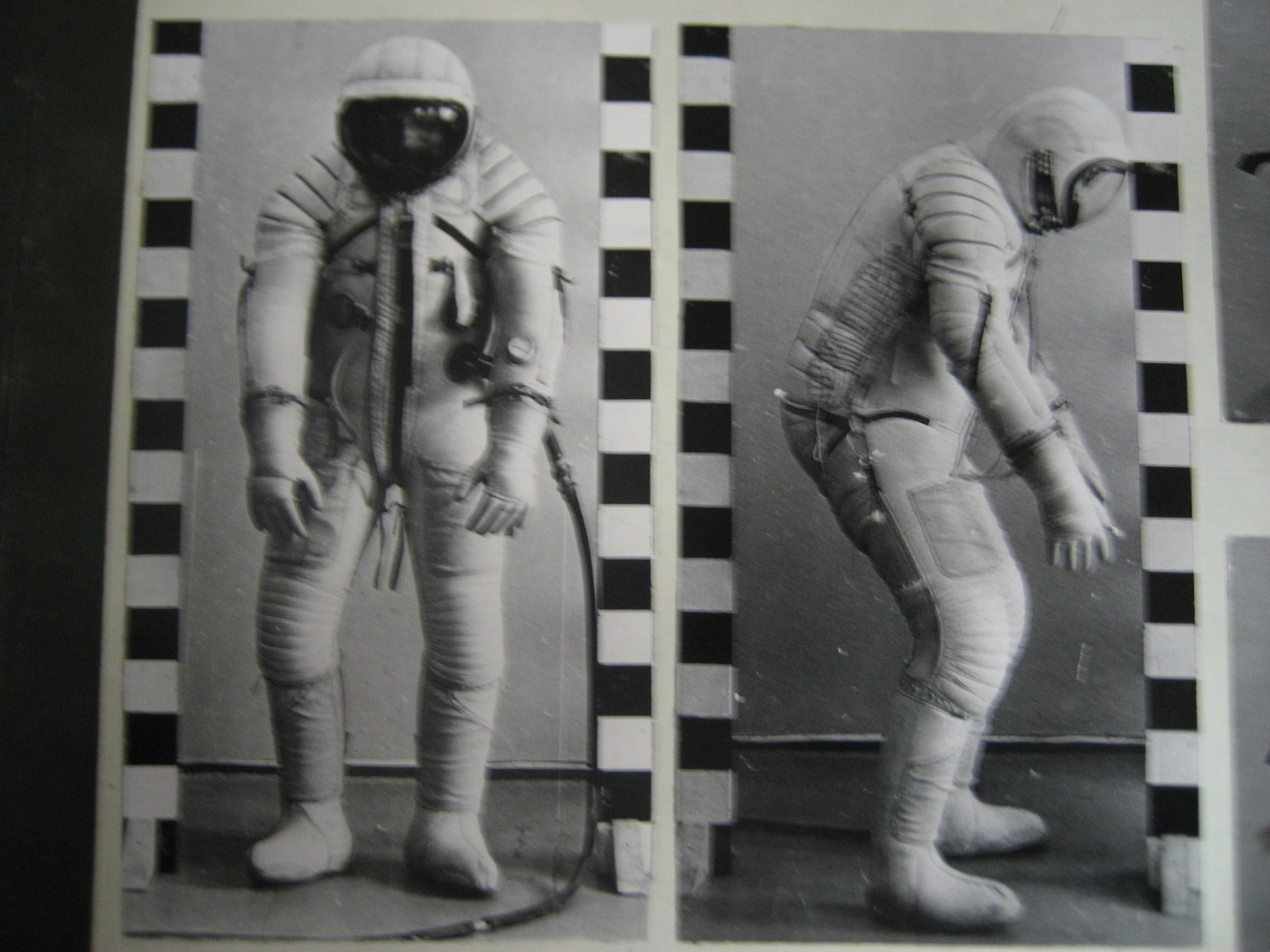

The suit from FFD (left) and the Russian "Falcon" (right). Along the edges are Nikolai Moiseev (left) and Ted Southern (right)

It is already the fourth interview on Geektimes with Nikolay Moiseev, the developer of spacesuits, whose experience in this field totals more than 30 years. Last year, he talked about his company , Nikolai also analyzed the spacesuit from the Martian , in which the hero Matt Damon traveled around Mars. This year, we learned how a spacesuit can be used to land on planets and satellites, what an ideal spacesuit is and how difficult it can be to create a single glove for a “space suit”.

Let me remind you that Nikolai previously worked in the Zvezda Scientific and Production Enterprise. He now works for several years as a lead designer in the American company Final Frontier Design. I was already interested in Nikolai about how a spacesuit could be for landing on Mars or Europe. Today he talks about how the move to the USA happened at the same time with the creation of a company developing space suits there. Most recently, the company passed one of the projects, which was described in an interview - a new type of glove for NASA. Now this glove passes a lot of checks. As far as one can understand, the agency is quite satisfied with the results. Final Frontier Design is developing other projects. All this is explained in the sequel.

Nikolay, hello! Half a year has passed since the last interview, and now we would like to touch on the issue of making a spacesuit. That is, it is not a production by itself, but to find out how it happens in your company, Final Frontier Design (FFD). We have a few questions and we will be very grateful to you for the answers to them.

')

How did you get the idea to create a spacesuit company?

My partner Ted Southern, the president of FFD, and I decided to try a new type of spacesuit in 2010. Initially, and worked together. We had an interesting creative “fusion” of an engineer with an artist. My partner has an education: an artist, a sculptor, a materials scientist.

First, we created an ordinary spacesuit, and then an innovative one. What's new in it? It is two times easier. Perhaps due to the fact that we work together, people with very different experiences, we managed to create such a spacesuit. The fact is that only engineers work at NASA and Roscosmos, there are no artists. The suit is high art, technological art. All this is connected with the human body, which in itself is a work of art. A human body can be described by an engineer, or an artist can be recreated. And it will be different visions of the same object.

When did the last revolutionary turn of development take place in space-building?

For many years, spacesuits have not changed. For example, in the Soyuz spacecraft, astronauts are wearing the Sokol KV-2 spacesuit. In principle, it was created in the 70s, and its design was designed even earlier. After the disaster with the death of the crew of the Soyuz-11 due to the depressurization of the cabin, they decided to return the spacesuits. They took the Sokol aviation spacesuit, modernized it a bit, the same materials were used. And this spacesuit flies for 40 years. Aviation spacesuits for high-altitude flights were created 25 years before the creation of a spacesuit, i.e. before the second world war.

And how much time passed from idea to the first spacesuit?

I developed the templates for 2 weeks and another 2 weeks was spent on manufacturing. Of course, I already had a lot in my head, we did not do everything from scratch. I flew to New York, we said hello, I sat down at the table, designed the plan, and we made the spacesuit on time. Geriet Reisman, a senior SpaceX employee, NASA astronaut, flew to us and we showed him our spacesuit.

How much money was spent on the whole project of creating the first model of the spacesuit?

I want to divide the costs into two parts. The first part is the payment for materials, finished items (safety valve, pressure regulator, hoses). The second part is implicit. For example, my job. The first time I worked for free. This includes the cost of transportation costs, rental apartments, and more. Almost immediately, it was decided to obtain a visa, received it in the category of "outstanding scientists", and then applied for a green card in the same category. Received a green card surprisingly fast - in just two months. All of these expenses are included in the development, but they are really invisible.

If you only count the materials, the costs amounted to only 600 dollars. We started to work together, and our work is the work of two people for a month.

If you gather specialists from other areas, and set the task to develop and fabricate a spacesuit in a month, they most likely will not be able to do this, because without experience nothing will work, even if they are capable engineers.

Spacesuit for high-altitude flights, developed in the USSR in the 30s

And how much money would it take to create such a spacesuit from NASA?

This is hundreds of millions. I will give an example. NASA is currently developing a new spacecraft to fly to asteroids and beyond. And even with their huge budgets, they decided to use space suits, which were developed for the Space Shuttle program, but with some modifications. Imagine - NASA decides not to make new spacesuits for the new ship because it is expensive for them.

Russia also needs many millions for the development, testing and certification of the spacesuit of a new generation. Here, time is of decisive importance, it takes a lot of time. Those novice engineers will not be able to make an improved spacesuit, they need time to understand the specifics.

You say your spacesuit turned out to be easier. Tell me, please, what model is it easier?

Well, if we take the Russian Sokol KV-2 for comparison, then ours is twice as easy, the input-output is much easier, the adjustment range for height is about 35 centimeters, the new hinges provide outstanding mobility under pressure. Of course, in many respects the creation of such a spacesuit is due to the wide choice of various materials in the USA: durable, heat-resistant, elastic, whatever. But also the design plays an important role, new original design solutions were developed.

My teachers Isaac Pavlovich Abramov and Anatoly Stoklitsky said that if you make a spacesuit 10-15% easier, this is an achievement. And we made the spacesuit two times easier. I have been working on spacesuits for 30 years, I have 4 patents, dozens of publications. I can say that our spacesuit is a jerk, it is, in fact, the next generation of spacesuits. We made an innovative spacesuit in 2011, and then another 6 spacesuits for different customers. These are different modifications of the same model. There has been a growing up of our new technologies. Now we no longer modify our spacesuit, because we have reached a certain level of perfection.

We have eliminated all the shortcomings in the design and technology at this stage, lengthened something and added, conducted many tests, only according to the program of trainings and tests at Embry-Riddle Aeronautical University 76 people experienced our suits.

Have you ever thought about creating spacesuits to work on other planets and their satellites?

Recently we were approached by a group of game developers from Russia. They are now working on modeling the exploration of Mars, and then they want to begin the virtual exploration of Enceladus and Titan. And they asked us to advise on the creation of a spacesuit that would allow traveling on the surface of these Saturn satellites.

First of all, it is worth saying that these small planets are very, very different. Titan, for example, has a dense atmosphere of methane and ammonia. Atmospheric pressure at the surface of Titan is 1.46 times the Earth's atmosphere. The atmosphere of this small planet is not at all suitable for humans. Here it is required to create a spacesuit without excessive pressure as for divers, but with ensuring the supply of breathable air, with heating and with thermal insulation.

At Enceladus, there is no atmosphere, it requires a completely different spacesuit, about the same as it is now on the ISS - one that can ensure the normal functioning of the astronaut in an airless space with a number of features. That is, it must be inflated, ensure the flow of the mixture suitable for breathing in conditions of practically open space. The atmosphere of Enceladus is very rarefied. In it, 91% is water vapor, 4% is nitrogen, 3.2% is carbon dioxide, 1.7% is methane. The gravity of this small satellite is not enough to keep the atmosphere, therefore, there is a constant source of its replenishment. Such a source is powerful geysers and cryovolcanoes.

When a spacesuit is created, it is necessary to work out requirements, perform design work, scientific and technical research.

Another pre-war spacesuit for flights in the stratosphere, as the predecessor of the space suit "Falcon"

You can go the other way. If you have your own company, then you can go to bed, and the spacesuit can just dream. I had this several times - the solution comes in a dream, with all the technical details, with the solution of a certain circle of technical contradictions. For example, as in the case of aircraft designers, the aircraft must be durable, but at the same time it must be light to take off and fly.

When a person just goes to work, without interest, even if with a good salary, he often does not burn with an idea. This person, of course, solves the problem, and by the set date he will provide something. But it is not necessary to speak about revolution, breakthrough in this case.

Usually the development of technology is an evolutionary way. And a revolution occurs when there is some kind of accumulation and when someone who is ready to do it appears.

Tomorrow we fly to Enceladus. How much time and money will you need to develop a spacesuit?

This is five years - I will not take less. After all, it is necessary not only to develop and assemble such a spacesuit, but also to conduct thorough tests. You also need to make several modifications to choose the best.

When I was still working at Zvezda ( Scientific Research and Production Enterprise Zvezda named after G.I. Severin , - ed.), And we worked with the European Space Agency (ESA) in the 1990s, they ESA, planned to make only 2 prototypes of spacesuits before the transition to the flight of the product, and the leadership of "Stars" did not agree to a smaller number of prototypes than six. The production of prototypes is necessary for carrying out comprehensive tests, which makes it possible to prevent emergency abnormal situations. And this is the “Star”, which has created dozens of spacesuits directly for flights into space.

Before Gagarin, 18 spacesuit models were created from 1953 to 1961. It is worth noting here that before the Gagarinsky spacesuit there were aviation high-altitude space suits. They were taken as the basis for the development of a space suit.

How much money would it take for a new spacesuit for Enceladus? For example, for $ 10 million, it’s perfectly realistic to take on the creation of a spacesuit fit for work on Enceladus. Need to hire professionals for computer modeling. Materials in the United States are not so expensive, but the labor of workers is expensive. For an employee, 3,000 per month clean is the bare minimum. A year for six people with a salary of $ 3,000, $ 216,000 is received and these are only working specialties, excluding equipment, computer systems, test benches and everything else, including taxes. We bought all our stands and made a lot of original contract gloves for NASA.

What tests need to be carried out in order to check the performance of the spacesuit?

Tests are divided into two types. This is a trial with and without human participation. It is necessary, for example, to measure pressure, to conduct a test for pressure testing and other tests. We start with individual elements. For example, gloves for a spacesuit. We tested gloves for breaking pressure several times. Some exploded, some no longer. We did the same with the sleeves of a spacesuit.

Now NASA helps us to verify and certify our spacesuit for free. This is a great achievement for us.

Tests, in particular, need to spend on overload. Ideally, this requires a capsule, with real chairs. The corpse of a man is placed inside the spacesuit - this is exactly what NASA is doing during its tests. And the spacesuit with the corpse is located in the chair. In the US, many people will bequeath their bodies after death for scientific research. Even the coolest mannequin with a bunch of sensors will not show the whole picture of the effects of overloads. It is necessary to load the corpse, and already carry out tests with him to drop the capsule. After that, the body is examined for MRI (tomography). As a result, we learn what happened to the body as a result of a simulated landing. Sensors give an extra picture.

As for certification, it is necessary to pass tests of our materials on the release of toxic substances. NASA helps us with these challenges.

And tell me, please, how are helmets for spacesuits being tested? How strong are they?

There are several tests for impact resistance and one of them is a test to simulate the impact of micrometeorites flying at cosmic speeds. A special gun accelerates the grains of sand that hit the helmet's glazing. Obtain objective data. Polycarbonate is a very durable material. You can create helmets from acrylic glass, it is not scratched, but any hole in acrylic will lead to the destruction of the helmet. A polycarbonate - a viscous material and more durable compared to acrylic plastic. It is very difficult for a person to destroy a polycarbonate glazing by himself, well, very difficult, even if you hit the helmet with the same hammer with all your strength.

And what about the "Martian" - he had broken glass. This is real?

This is very difficult to do. This is a move by Hollywood directors. In my opinion, breaking a helmet with double-glazed polycarbonate against stones is unlikely when it falls on Mars.

An acrylic helmet can be pierced, so that Soviet tester Peter Dolgov died in 1962 due to damage to the glazing of the helmet, trying to set a world record for jumping from a great height. When he and his partner went up to a predetermined height in the balloon, the partner jumped first. The gondola began to weigh less and jumped up sharply. Debts as the second room stood at the edge of the hatch, and, most likely, hit some glazing on the protruding bolt. A small hole formed in the helmet, only a few millimeters. He fell out and flew down, the parachute automatic worked, the parachute opened at a predetermined height and landed. But at the beginning of his fall, he was already dead, killed by decompression.

New materials for helmets have been developed in the USA, more durable than polycarbonate and not scratchable, but they are still expensive.

What temperatures does the astronaut suit protect? What degree of thermoregulation will the spacesuit provide?

Modern materials for spacesuits are heat resistant. Now space suits are being developed with an airgel interlayer for thermal insulation. Specialists from the United States learned how to make airgel flexible 2-3 years ago. We used it in 2015 to create thermal insulation for the Martian spacesuit glove. A thin layer of airgel will protect the astronaut from extreme temperatures in future missions.

A cooling system is also needed, respectively, energy is needed to maintain around + 20 / + 23 degrees Celsius inside the spacesuit. When outside about minus 125 degrees Celsius, inside plus 20, a specific thermal control system is required.

Modern materials that are used for space construction, will withstand the temperature on the surface of Venus. But, of course, the spacesuit needs to be cooled, and this is difficult to implement on Venus.

What are your future plans for the company?

We have reached the end of the contract with NASA. We have created for them a new glove suit. And soon we should begin testing our gloves. This is a complex process involving dozens of people. We are waiting for the results of these tests. Among the other advantages of our gloves, you can highlight the mobility of fingers, which is increased compared to conventional gloves for space suits, and the volume and weight of gloves is reduced. NASA at the conclusion of the contract put forward 30 criteria and requirements for gloves. All conditions were met by us.

Negotiations are underway with a number of companies to purchase our spacesuits. We are also working on a new type of spacesuit that can be used in various conditions.

Source: https://habr.com/ru/post/399631/

All Articles