Available 3D milling machines with CNC, part 1: up to 250 thousand rubles

For many years, program-controlled milling machines have been used in countless areas, from the manufacture of souvenirs and piece craft items, to full-scale industrial operation in factories. In this review we will present the reader only some of them, for the most part - not requiring expensive installation and sold at a relatively small price - 100,000-1,000,000 rubles. That is, it is the price segment that may be of interest to small and medium-sized businesses; those samples, with the acquisition of which it will be interesting to begin acquaintance with the exciting world of CNC machine tools.

')

Easy to buy, just place

Compact 3D CNC milling machines, worth up to 250,000 rubles

If you do not have large-scale production, then you should pay attention to these samples - these are small program-controlled milling cutters, which can be called desktop ones. And indeed - it is not necessary to allocate a special place in the workshop or workshop for them, most of them can be installed on almost any workbench.

Corresponds to the form factor and the price is within 250 thousand rubles.

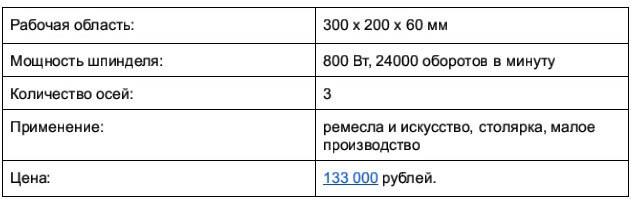

AMAN 2030 200w

And the same model, but with a more powerful spindle:

AMAN 2030 800w

One of the most inexpensive models on the market, from having such capabilities.

The working volume of this router and the power of the spindle make it possible to easily process not only plastics, wood and composite materials like chipboard and textolite, but also some metals - aluminum, aluminum alloys, copper, brass.

Differs low price while maintaining good quality.

It is widely used in advertising production and small workshops.

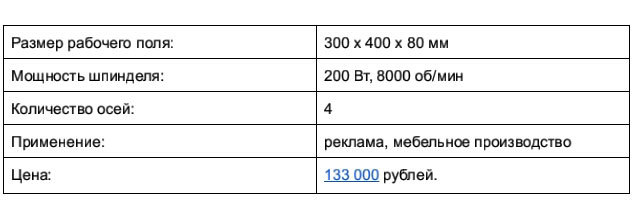

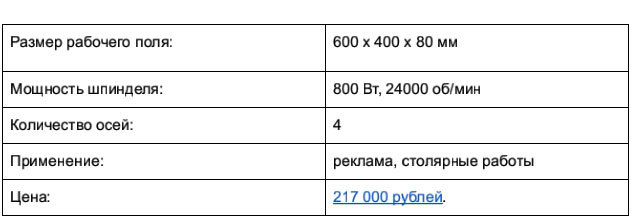

AMAN 3040 4axis

There are two similar models in the line, which are distinguished by the presence of a rotating device in the kit and an increased size of the working area - 30x40 cm. Well, at the price, of course.

If your field of activity is not limited to the creation of plates and engraving of inscriptions and bas-reliefs, then you should pay attention to two modifications AMAN 3040 4axis - these are AMAN 3040 4axis 200W and AMAN 3040 4axis 800W.

From each other, they differ only in power, 200 and 800 W, respectively.

AMAN 3040 4axis 200W

AMAN 3040 4axis 800W

These machines are used in the production of plates, jewelry and advertising products, handicrafts and art, souvenirs and much more of wood, plastic and other materials with similar characteristics.

They can work with metals, provided they are not too high stiffness. With such as aluminum, for example.

Used in the advertising and furniture business.

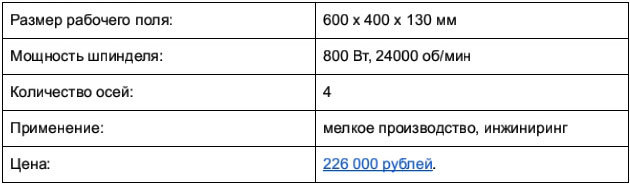

AMAN 3040 4axis 800W Z13

Increased along the Z axis, i.e., vertically, the area of work in which this machine differs from AMAN 3040 4axis 800W, together with the complete rotary device, allows to process large rotating billets and billet of great height.

The machine is compact enough to be installed in not too spacious rooms.

Ideal for small workshops, home craftsmen and theater requisites.

The range of materials processed is standard: non-ferrous metals (aluminum, aluminum alloys, copper, brass), plastics and other synthetic materials, wood and composites based on it.

AMAN 4060 800W and AMAN 4060 800W Z +

The AMAN 4060 4axis 800W has the most extensive work table in this series of machines and an 800-watt spindle.

The machine can engrave, cut, mill volume objects.

It works with the usual assortment of materials: wood, chipboard and fiberboard, plywood, plexiglas and plastic, non-ferrous metals (aluminum, aluminum alloys, copper, brass).

AMAN 4060 800W Z + (Z13)

The AMAN 4060 4axis 800W Z + differs from the AMAN 4060 4axis 800W by the Z-axis, which is increased to 13 centimeters, and the rotary axis for processing workpieces from all sides, which allows you to process larger vertical objects.

The combination of high power and relatively compact size makes it possible to use it both for production and for private purposes: engineers and inventors, advertisers and artisans, service workers and furniture makers, as well as artists and amateurs making original products will appreciate the effectiveness of such an acquisition.

It can process the same materials as AMAN 4060 800W - plastics and plexiglas, plywood and wood, aluminum and non-ferrous metal alloys.

The machine does not require specialized computing equipment and can work with a conventional consumer computer running Windows.

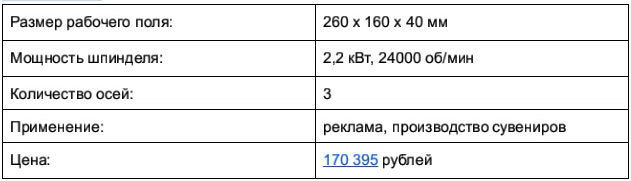

Suda SD 2616

Designed for the manufacture of decorative products by milling, drilling, sawing and engraving wood, plywood, plastics and hardboard. It copes well with aluminum and light alloys such as brass and dural.

Easy to use and does not take up much space.

High spindle power gives great performance

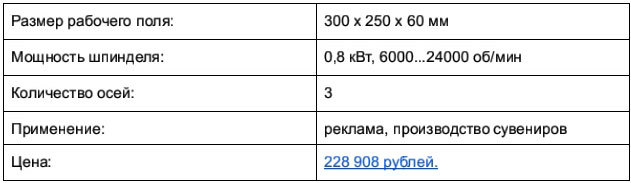

Suda SD-3025

Materials to be processed: Plexiglas, various types of plastic, wood and wood composites, non-ferrous metals (aluminum, brass, copper, decorative alloys).

Used in the manufacture of decorative products and information plates.

It has variable spindle speed.

Suda SD 3025 S

Powerful machine for serious tasks. It differs from Suda SD-3025 by a much more powerful spindle and a slightly smaller size of the working area along the Z axis (vertical), due to which it works more efficiently with metals.

The 3D CNC milling machine Suda SD 3025 S, although it has the capacity of the AMAN 2030 800w, doesn’t have a much larger working surface size (30x25 cm versus 20x30), and is even less than 20 mm in height of the workpiece, but has a different design feature. - massive cast-iron frame, which houses the spindle drive. This bed gives stability to the whole structure (the portal is fixed relative to the bed, the working table itself moves), which allows you to precisely control the movements of both the spindle and the working surface, and protects against vibration and random shocks.

Designed to create a variety of functional parts and decorative elements of various forms.

It can process the whole range of materials, except for especially hard (stone, tool steel, ferrous metals, glass).

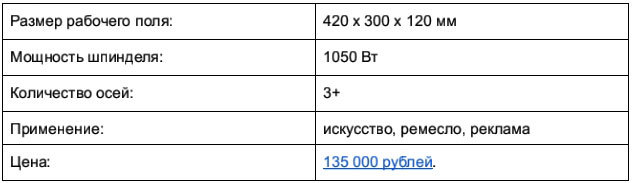

Router 4230

A compact desktop 3D milling cutter with program control is intended for the manufacture of parts up to 42x30 centimeters in size and up to 12 cm high.

It can work with plastic, wood and other materials, with hardness up to the corresponding aluminum and brass, in the manufacture of various souvenirs, advertising and decorative products, toys and art objects, furniture accessories and much more.

The device is three-axis, but can be improved by an additional turning mechanism.

Router 7846

Router 7846 is a multifunctional milling machine with a wide scope.

The working space of the 7846 Router is 780x460x150 mm, and the spindle power is 1050 W, which makes it possible to process very large parts of fairly solid materials, and at a decent speed (spindle travel up to 3000 mm per minute) and accuracy (0.0025 mm).

Works with wood and plastic of various compositions, with various composites and aluminum.

Most often used to create various products from wood and plastic.

Like AMAN machines, the Router 7846 has the ability to upgrade to a four-axle, which further increases its capabilities.

In the next review, we will look at 3D CNC milling machines in a category worth up to one million rubles.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/399541/

All Articles