How will digital production change the future?

Progress, as you know, goes in a spiral, each turn of which is marked by a fundamental change in the approach to production, which immediately affects the volume of production, its quality and availability to the consumer.

Sometime - the use of steam engines in factories, then - the beginning of the mass use of electricity, and even later - the invention of conveyor production; at each of these stages, the production culture made a sharp breakthrough in the desire to satisfy the growing needs of consumers. Nowadays, such a factor that has given new impetus to progress has been the spread of digital technologies - 3D modeling, 3D scanning, volume printing and robotization.

Digital technologies are changing the very concept of production, making it cheaper, more accurate, faster and more convenient. How is this happening now and what will change in the future? Consider a few examples.

')

1. Medicine

Nothing is more important than health, and today digital technologies are literally irreplaceable in this area. 3D modeling and 3D printing have already been successfully applied in an area where an individual approach and strict compliance with the created subject of the patient's anatomy are especially important.

Already now, implants are produced in this way, replacing the affected bones and joints.

Scanning the area of intervention and combining the data with computed tomography, physicians can model and print the desired implant to within a fraction of a millimeter. After that, the correctness of the geometry of the obtained implant is checked and preparations are made for an operation on the patient’s 3d model printed on tomography.

Such technologies have been used all over the world for several years now, and now with us .

Also, for several years now available bionic prostheses have been created that provide new opportunities for people with amputees.

Moreover, not only for people.

Doctors print out individual tires, orthoses and splints, which fix limbs in the treatment of fractures - they are much more convenient to use and comfortable for the patient than traditional gypsum.

One of these domestic projects - www.zdravprint.ru

Apply new 3D technologies also in dentistry and maxillofacial surgery. They allow you to plan and carry out treatment with amazing accuracy, as well as to design and create individual prostheses and temporary crowns of both individual teeth and entire jaw fragments.

How does this happen:

- A 3D scan of the patient's jaw is combined with computed tomography data for highly accurate planning of the placement of the implant, taking into account the patient's bone quality, nerve location and artery.

- The size and shape of the implant and the required angle of its installation is determined.

- According to this data, a surgical template is printed on the 3d printer , which allows you to avoid a medical error when installing the implant during surgery.

- A temporary crown is printed or milled for proper healing of soft tissues for the postoperative period.

- A permanent metal-ceramic crown made of biocompatible metal (titanium or cobalt-chromium) is printed or milled.

3D printing is also used in orthodontics - to create aligners - bite correction devices that have replaced uncomfortable and traumatic bracket systems.

Moreover, this method is now quite rapidly gaining momentum around the world, and I decided to test one of these solutions on myself. As you can see, the aligners are almost invisible, but they do correct the position of the teeth and really work.

But the most anticipated in medicine remains, of course, the printing of living organs. The ear printed on a 3D printer is widely known, and work is underway on muscle, liver and skin cells. In the future, such technologies will completely restore damaged or lost tissues and organs.

By the way, when Skolkovo, there is a startup known in medical circles 3D Bioprinting Solutions, which managed to print a mouse thyroid gland. This is the first step to the manufacture of living organs for human transplantation.

2. Jewelery

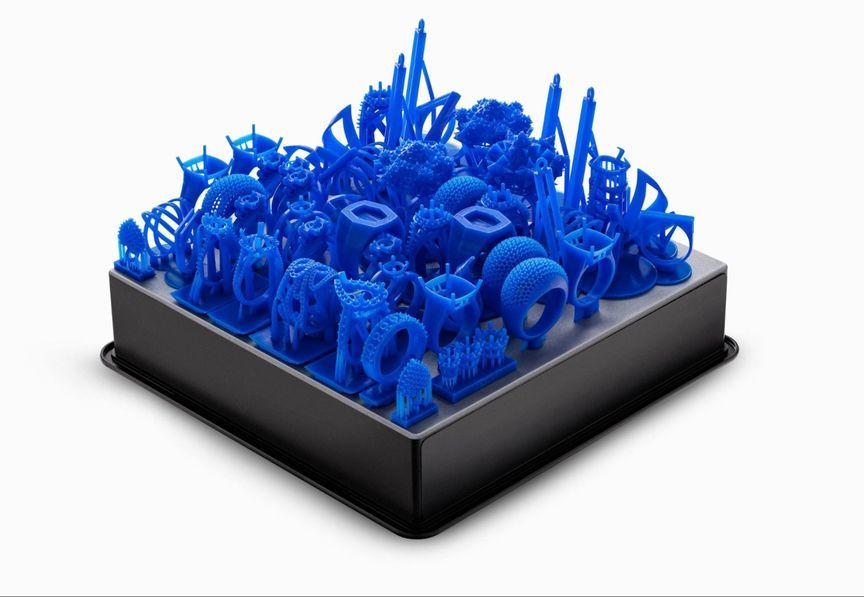

Digital technologies are already widely used in the manufacture of jewelry, jewelry and accessories. Three-dimensional modeling allows you to create an accurate digital layout of the future product and print first a prototype, giving the master the opportunity to hold it in his hands and modify the product in advance.

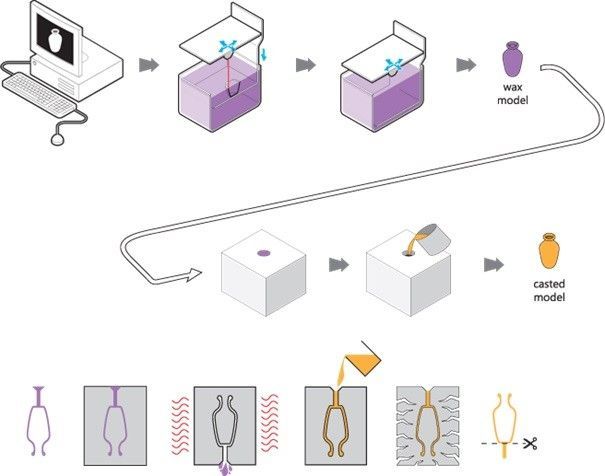

After that, the model is printed or milled from the wax or photopolymer melted or burned out, which is filled with gypsum to obtain a mold and burn out (is smelted) during the casting process, allowing the metal to fill in the form and accurately repeat the slightest nuances of the future product.

The process itself looks like this:

In addition, there are already 3D printers that print directly with precious metals, but so far the price of powder for such machines is too high for continuous use.

3. Engineering production

In engineering, modern digital technologies, such as CAD 3D modeling , 3D scanning and 3D printing, have long been widely used.

The new trend of these technologies - as applied together with automation elements - as part of industrial robots and automatic machines .

For example, 3D scanning is widely used in quality control, and 3D printing, together with automated milling and turning machines, in production workshops.

There are already industrial printers capable of creating three-dimensional forms of very impressive size. The 3D printer shown in the presented photo can print objects with a diagonal of several meters.

The day is not far when the project created in digital form by engineers will be fully implemented by industrial robots, without direct further human participation.

4. Automotive industry

First of all, this is the creation of CAD 3D-models and prototyping.

Now this symbiosis has reached a new level - from the design bureaus fell into production.

Global robotization begins just with the automotive industry and an army of robots, while it is not without the help of people, it is already assembling cars in factories. This is how it looks at Tesla Factory:

There are already examples of creating frames and bodies that are fully printed on a 3D printer.

This also applies to tuning - moldings, spoilers, decorative elements, wheel caps.

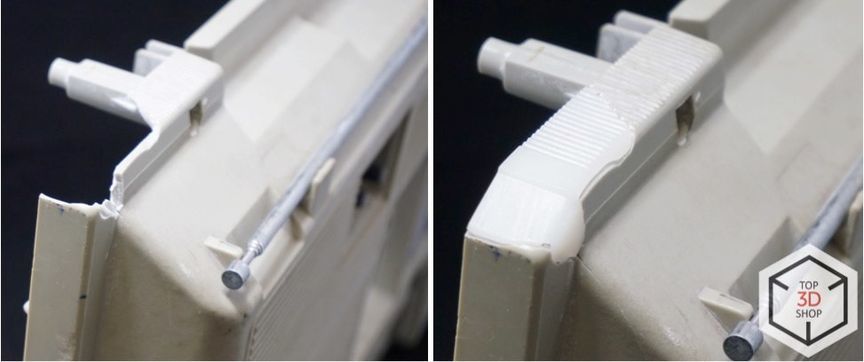

What to say about the individual small elements - functional details and design details, many of which are not difficult to print on a small home printer.

3D scanning is also used in repairs, it allows to diagnose deviations in the body geometry with high accuracy and to easily create models for the subsequent printing of replacement elements.

With the development of three-dimensional printing technology, allowing you to print complex functional parts from many different materials, fully 3D-printed cars can appear, each detail of which will be created by a 3D printer.

5. Construction

All over the world, experiments are being conducted on the use of 3D printing in construction. In this area, technology is used both in the design, where industrial 3D-scanners and special programs are very useful, and directly in the creation of objects.

Special construction 3D printers print modular blocks and whole buildings of concrete. In Russia, Spetsavia has become one of the pioneers of building 3D printing, which has already built several objects using this method.

Construction 3D-printing allows you to create objects of unusual and non-standard forms that are not available for conventional serial construction, while production comes from standard mixtures using reinforcement.

In the future, perhaps - in the coming decades, we will see in the work units capable of printing, for example, a small cottage in a few hours - from the foundation and communications, to the weather vane on the roof.

We, too, have already managed to participate in this, having recently installed the first 3D construction printer in Kazakhstan.

6. Architecture and Layout

The times go down in history when architects, when creating layouts for buildings, had to get their hands dirty with glue and breathe in the fumes of polystyrene cut by hot wire. A growing place is occupied by software and technical devices allowing much more convenient and faster, and most importantly - to more accurately create layouts of future objects.

3D printers are capable of printing, depending on the size, parts or entire layouts, with an accuracy that nobody had ever dreamed of. The smallest architectural elements are visible on them as clearly as on the already constructed buildings, and the cost of the models themselves becomes lower and the production speed is higher.

There are technologies that allow printing in color at once, not only from plaster or paper, but also from multi-material plastic, which allows printing with gradients with varying degrees of transparency.

These technologies are also used by amateurs whose hobbies are the creation of miniatures, for example, large-scale models of various techniques, both poster and functional; and lovers of auto and aero modeling.

Everything leads to the fact that soon, regardless of the scale of the layout or model, it will be impossible to distinguish them from the real object. Not counting the obvious difference in size, of course.

7. Education

Not so long ago, a new subject appeared in schools - Technology. In this discipline, students learn digital production. Including - 3D printing and scanning, the creation of 3D-models.

FabLab's student technology centers, invented by Neil Gershenfeld for students of Massachusetts Technology, are laboratory and production centers for older students, students, and young entrepreneurs, where they can learn new technologies, develop their own projects, create or order prototypes.

In Moscow there is a FabLab at MISiS, created in cooperation with the same MIT, in St. Petersburg there are two of them: FabLab Politech and FabLab Spb. CMITs (Youth Innovation Creativity Centers) - similar formations that are not directly related to the FabLab network, there are even more.

All these educational institutions take full advantage of the latest achievements of 3D technologies - 3D printers and scanners, 3D pens and other equipment .

In the near future, the network of TsMITs will grow and they will become an integral element of education. We can expect the emergence of such organizations in every locality and every district of a large city, which will ensure the growth of technical education of the population and the earliest development of technologies and business segments related to this area.

8. Life and service

3D printing is ideal for creating all sorts of useful things for the home.

It is good for printing spare parts for broken household appliances, furniture fittings and much more.

You can create a toy for a child from scratch, or download a 3D model from the Internet and make it unique in an editor program.

At the same time, such a toy at cost will be cheaper than the purchase and much more interesting for the child, since he will be involved in the process of its creation.

Buying a tool such as a 3D printer, home, parents can print at least a few different toys per day: from simple ones to the most complex and developing ones, thankfully, thousands of models are already available for free download .

You can decorate your home with a figurine of a loved one or yourself - the service of scanning and printing a 3D portrait, both bust and full-length, is already available. Including full color.

Constantly developing new and new materials for three-dimensional printing, with all sorts of mechanical and aesthetic properties, and 3D-printers and consumables are constantly getting cheaper. After a few years, such a device can become an integral part of almost every home, as it is now - TV. And no wonder - the usefulness of this device in everyday life is difficult to overestimate.

9. Food

There are already several commercially available, and quite popular with this, food 3D-printers. Some of them print candy of any given shape from a special consumable material. Such devices, in addition to consumables, are almost indistinguishable from conventional 3D printers. There are more specialized.

For example, the English Choc Creator prints with chocolate both flat pictures (for example, for decorating cakes) and volumetric objects.

The Universal Foodini printer is designed to print food from fresh products.

The design allows you to load it with several different ingredients and get at the exit a variety of dishes.

Fish n chips, for example:

Or useful vegetable dinosaurs:

There is also a special printer for pancakes, allowing you to print pancakes and pancakes of any given shape. He, by the way, and is relatively inexpensive, and in circulation is simple.

In the photo - Pancake Bot is preparing a pancake in the form of an astronaut and our logo.

By the way, here we have prepared a full review of this printer.

The technology of creating food 3D-printers is being improved. We can assume that in the near future there will be inexpensive and widely available 3D kitchen printers, both specialized and universal, ideally combined with a food processor and / or oven.

Total

As we see, digital production technologies have already spread to all areas of human activity. This is not surprising, given their usefulness and relative ease of working with them.

The market for devices for 3D printing and scanning is constantly growing, and with it the variety of models and materials for printing. The quality of work of 3D-printers is increasing all the time - printing speed and resolution, the range of applicable materials and the size of work areas. Prices are getting lower.

In the coming years, this technology will become even more widespread and will radically change the ideas about the production of things, making them more accessible and unique. And this, if you think about it, will affect the culture of production and consumption, inevitably changing the face of a person’s daily life.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/399537/

All Articles