How to make paper money

Last time on Geektimes the article about the history of paper money was published . The Chinese were the first to use cellulose fibers for the production of a lighter analog of metallic money. Paper is used for the same purpose now. Of course, the complexity of the paper money production process has increased many times, modern money paper is not at all what was used in China or any other country 100-200 years ago.

Usually, flax and cotton are used to make money paper. Cellulose content in the final product is about 95-97%. The production process begins with the loading of cotton (we are talking about several tons of cotton fibers) into the boiler. Here the source material is kept under very high pressure. After that, the finished mass of fibers is drained into the tank, where clarification and cleaning is carried out. After that, the mass is pressed, placed in softeners. The next step is to add a special ink that changes the shade of the still wet paper. At this stage, the creation of recognition watermarks is going on (more on these are discussed below).

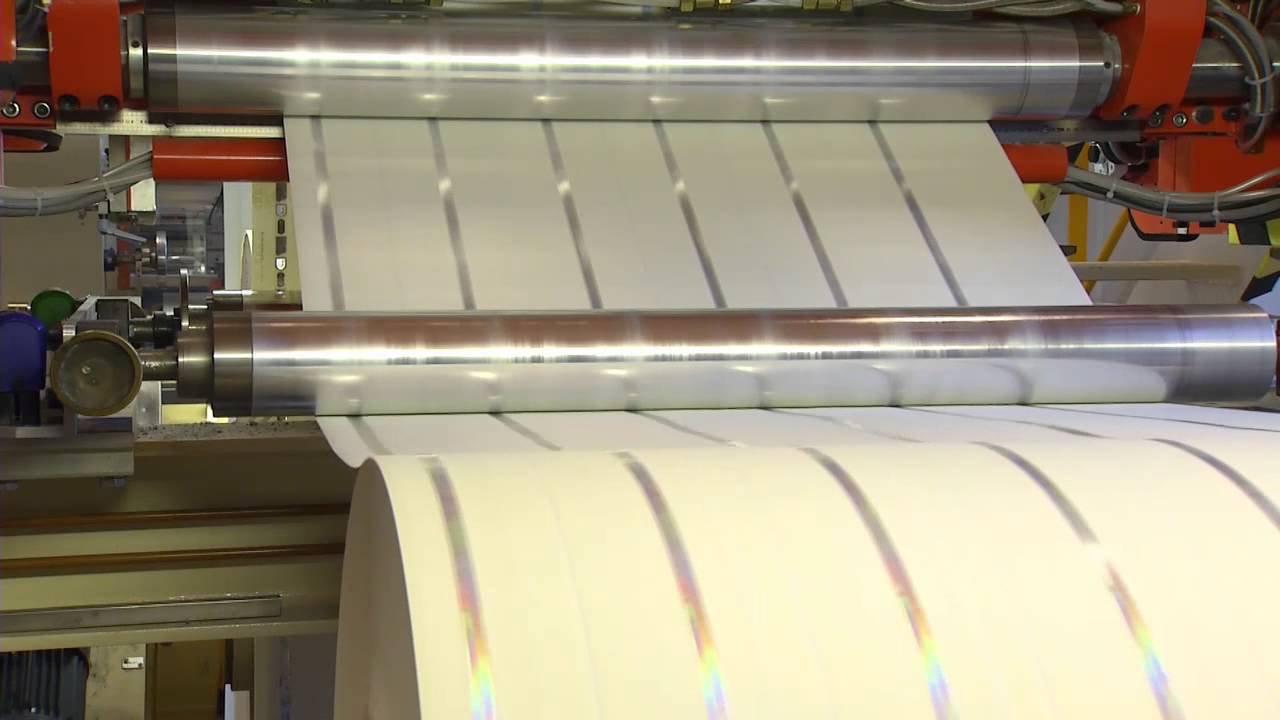

Sheets with protective fibers and watermarks are sent for drying, after which the paper is rolled into rolls. The weight of each roll can be several tons.

')

In addition to paper, paper dyes need special dyes, chemical compounds, and sophisticated equipment. Ink for banknotes domestic "Goznak" buys from the Swiss company SICPA (makes special protective printing inks, ink for sealing products, develops systems for coding excisable goods). According to representatives of Goznak, due to the growth of the Swiss franc, the cost of producing domestic banknotes is growing quite rapidly.

But Swiss paint has always been considered the highest quality. The cost of buying paint in the manufacture of banknotes in Europe and the world averages about 60% of the total cost of the purchase of components and the production of banknotes.

Interestingly, there are several ways to produce paper money, not all countries print money using the same method.

As for paper, one of the basic requirements for this material is wear resistance. Money must be durable so that it does not become worthless too quickly. The main indicator of durability of money - resistance to fracture and rupture. Paper bills constantly fold and unbend, they pull the corners and other parts. Therefore, they should not be torn. Tensile strength is determined on a dynamometer. This characteristic is expressed by the estimated length in meters of a strip of paper, with a break from its own weight. For money paper, this indicator is thousands of meters (more than for ordinary paper).

In order to ensure the high quality and durability of the printed image, the money paper must possess the necessary degree of whiteness, opacity, smoothness and light resistance. This paper should not change its color under the influence of external factors (sunlight, for example).

In Russia, paper for money is supplied by only two enterprises. These are the St. Petersburg Paper Mill of Goznak and the Krasnokamsk Paper Mill of Goznak.

Paper protection

Paper money usually has several levels of protection. Among others, watermarks are used, which can also serve as a peculiar decoration. Create watermarks even at low tide paper. The pattern is obtained by changing the thickness of the fiber layer along the plane of the bill. It is not easy to create a beautiful and clear watermark, for this you need precise modern equipment. In some cases, the watermark is combined with the pattern of the bill itself.

In the production of money paper there is usually a watermark workshop where a large number of highly qualified specialists work. In particular, these are engravers who transfer the artists' drawings to stamps and a metal grid of the so-called shaft-de-bald. Sometimes the drawings are transferred to the grid of the cylinder of the machine. A dendirol is an equalizer that is installed on a machine’s grid and, when rotated, forms an imprint of its watermark on a paper sheet. This method is commonly used to create paper with a common watermark. If you need an art local sign, you can get it by hand or by using a cylindrical boom machine. In this case, on the grid of the cylinder, stamps of the sign are stamped, and when forming a sheet of paper, all conditions are created that allow to obtain a multi-tone artistic sign. Bills of many countries have special protective (often - colored or metallic) fibers.

The watermark should be clearly visible on all bills, and be absolutely identical for all bills of the same circulation. Forging a watermark is not easy, especially for portraits.

Throughout the circulation of paper money, their identity must be ensured. In practice, this means that if a bill, a sample of a banknote has been in force for several decades, then the money that was made in the last years of the bill’s validity must be identical with the money that was issued at the very beginning of the period. However, during this period some changes may be made - for example, new security features are added. The decision to modify the appearance of bills is made by special bodies, all changes are recorded. In Russia, such control is exercised by the Bank of Russia.

Banknote development

The creation of banknotes is a very complicated and rather long process in which specialists from different fields are involved. These are financiers, artists, and Goznak specialists (in the case of Russia) who are actively involved in the process of creating new money. After the customer (the state) has outlined all the necessary criteria for the manufacture of notes, artists and engravers begin their work.

The first is a sketch - it is developed taking into account all the criteria of the technological capabilities of production, with the help of which future money will be printed. One of the main requirements for paper bills is the demonstration of the ownership of the developed banknote to the state-manufacturer. This is done by introducing elements of the unique symbols of the state. They can be state symbols, text, portraits of famous people in this state. Typically, large denominations of banknotes have a much more complex pattern and number of degrees of protection than small ones.

After the sketch is ready, the specialists create a print design with special printed forms that allow you to replicate the notes in the future. Specialists of the highest class take part in it, including photographers, engravers, painters, etgers, stampmakers, designers. In the case of Russia, only Goznak prepares these frames. The modern process of making money includes mandatory and computer technology. As soon as the first printed draft of the new banknote is ready, it is sent to a special commission for study and approval. If the received option is approved, then production of special forms for replicating money begins.

Printing money

The process of printing paper money uses four basic printing methods. This is offset, metallographic, typographical and Orel printing. The most popular and used are metallographic and Orel printing methods. Interestingly, the Swiss company KBA-NotaSys SA produces about 90% of all printing and press machines for making banknotes on the world market. These machines, in particular, are used on Goznak.

Oryol seal

Despite the fact that this printing method was developed in 1891, it is still used today. The name of the printing process comes from the surname of the Goznak specialist Ivan Orlov, who developed this method. Then, for printing banknotes in the typographical way, it was necessary to prepare a separate form of printing for each of the colors of the banknote pattern. Each form was imprinted on a piece of special paper. The coincidence of lines and borders of paint when using this method was not ideal, because even the use of computer and industrial systems does not give an ideal result, not to mention the technologies of the end of the 19th century.

Ivan Orlov managed to introduce a special elastic cushion with a soft structure and intermediate shapes. Each form has its own pattern for each of the colors on the original. When printing such a template, it transfers its own fragment to the desired place of the assembly shaft, and from the shaft, the full palette of colors is transferred to the collective overall form, where the entire drawing of the original is displayed in full.

The advantage of the method is that it allows you to put a picture on the banknotes with almost jewelry precision, with the coincidence of all the borders of the patterns and lines. In addition, the method allows, in the course of a single sheet pass through the printing unit, to create the necessary pattern fragment, which corresponds to the original with almost 100% accuracy. Repeating this accuracy for a counterfeiter - is difficult, although, of course, there are experts of the highest class.

Offset printing

With the help of offset printing, a so-called background grid and a number of additional elements are usually created. In small banknotes with the help of offset printing is sometimes applied and the main figure. Since the transfer of ink from the printing form to paper is done through an intermediate blanket cylinder, the image itself on the printing form is made straight, not mirrored.

Interestingly, with this method of printing, ordinary and whitespace elements of the form are in the same plane. But the surfaces of the elements have different physicochemical properties. So, the printing elements are hydrophobic, they hold the paint well, repelling moisture. But the hydrophilic spacing elements, they absorb water, but repel the paint.

Colors for banknotes are usually divided into three color groups. This is a blue group, red and yellow. For each group, a special form is made by means of a photo-method. The paint from the plates is transferred first to the rubber coating of the cylinder, and already the cylinder prints the design on paper.

Here is how the US dollars are printed:

Metallographic printing

This is another common method of printing bills. It has been known for a long time, and for the money bills it was used for the first time in 1887. For printing in this case, specially made forms of steel or nickel are used.

These forms are almost perfectly polished plates, which bear the desired pattern with a special press. The original form is made by hand by engraving. In Russian there is a special term for the original form. This is the "original stamp." When printing banknotes in this way, details of the engraving units create complex patterns for banknotes. These patterns consist of a large number of lines. After the etching process, an element of the overall image appears, which is placed on the bill.

These forms are almost perfectly polished plates, which bear the desired pattern with a special press. The original form is made by hand by engraving. In Russian there is a special term for the original form. This is the "original stamp." When printing banknotes in this way, details of the engraving units create complex patterns for banknotes. These patterns consist of a large number of lines. After the etching process, an element of the overall image appears, which is placed on the bill.Such elements, combined with hand engraving and printed font, form a single image of a banknote. This image after manufacture is replicated for the printing process. True, this requires high-precision equipment, as a rule, it is a high-frequency machine and automated galvanolines.

According to experts, the main advantage of the method of metallographic printing is that it can be used to reproduce a wide range of bright colors for printing. If you use different depth and width of the application of the pattern, you can achieve a variety of colorful effects, often volumetric.

When printing on printing plates using prepared rubber patterns, paint is applied. She enters the engraving and whitespace elements. After these elements, the paint is erased, and the form is ready for printing on paper. The drawing is applied during the application of the form to the paper under high pressure. Metallographic printing is divided into two types. This is an intaglio printing, when images are transmitted from a printing form, on which the printing elements are significantly deepened in relation to the whitespace. And high printing, when the printing elements on the forms are located above the whitespace. Letterpress is used for drawing on large banknotes, serial numbers and a number of important elements of notes of small and large denominations.

After bills are printed, uncut sheets are sent to a special workshop, where they are cut into individual bills. After that, the money is considered with the help of the machine and packed, they are sent to the "free floating" in the country and abroad.

Source: https://habr.com/ru/post/398989/

All Articles