Valid and unacceptable metal contacts. Popular metric and inch threads

Electronics is often called the science of contacts. Many people know that you can not twist between a copper and aluminum wires. Copper grounding bus or brass rack for the board does not fit well with galvanized screws, bought in the nearest building supermarket. Why? Corrosion can destroy electrical contact and the device will stop working. If this is a protective earth for the case, the device will continue to work, but it will be unsafe. A bare aluminum part in general can gradually turn into dust if even low voltage is applied to it.

Electronics is often called the science of contacts. Many people know that you can not twist between a copper and aluminum wires. Copper grounding bus or brass rack for the board does not fit well with galvanized screws, bought in the nearest building supermarket. Why? Corrosion can destroy electrical contact and the device will stop working. If this is a protective earth for the case, the device will continue to work, but it will be unsafe. A bare aluminum part in general can gradually turn into dust if even low voltage is applied to it.The metals available to us are not limited only to copper and aluminum, there are various steels, tin, zinc, nickel, chromium, as well as their alloys. And not all of them are combined with each other, even in ambient conditions, not to mention harsh atmospheric or sea water.

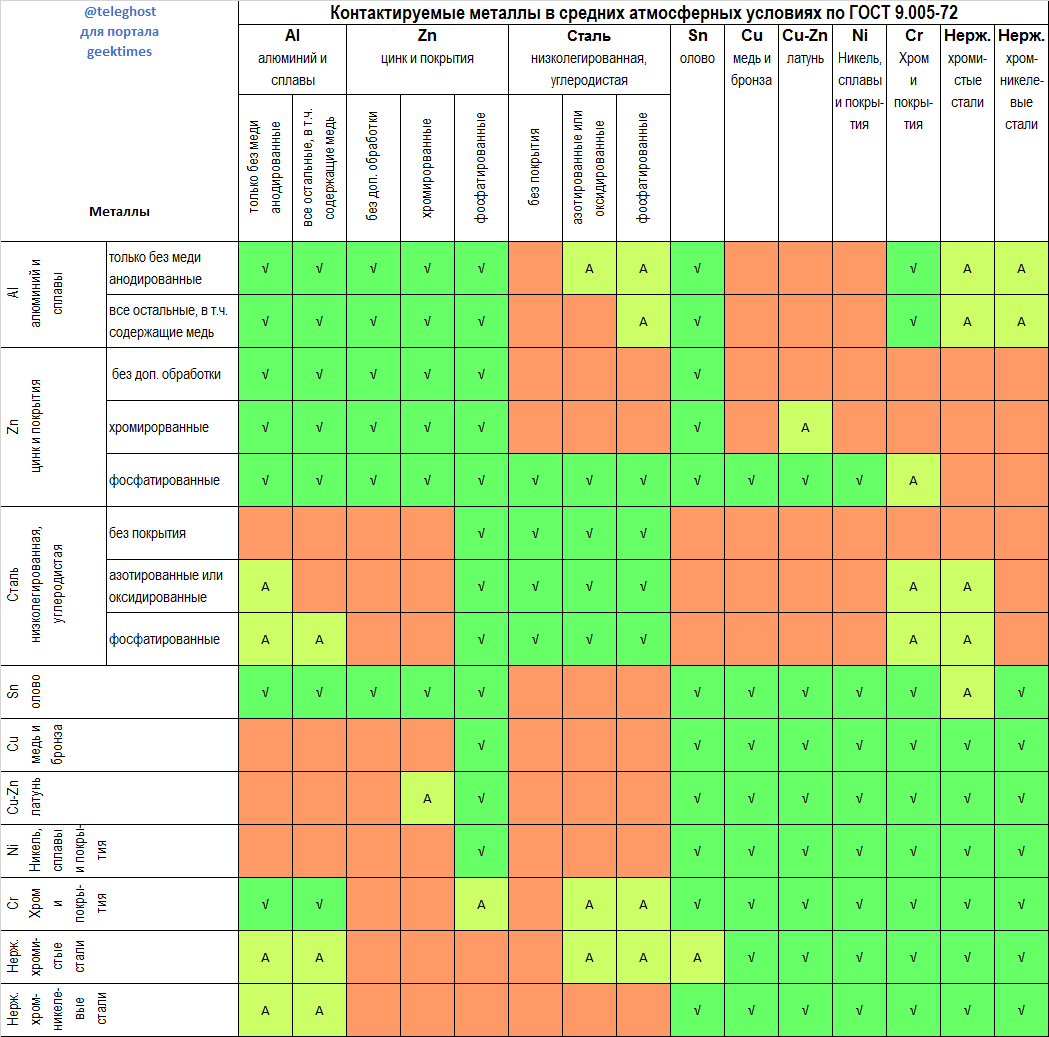

In the Soviet guests almost everything was written about permissible metal contacts, but if studying black and white tables of 1000 cells in small print is tiring, then the correct answer to the “copper” question is stainless steel or nickel-plated steel, from which, by the way, almost all "Computer" fasteners. In the era of black and white television, there were other concepts about the convenience of the interface, so the author prepared a color cheat sheet for dear readers (and for myself at the same time).

')

And, since we were talking about metalworking, the author also brought a table with popular threads in electronics and corresponding drills, selecting from the bulk sources the most relevant topics on the portal. Not everyone here is a metalworker and metallurgists, save your time.

Preamble

Yes, in the age of 3D printing, the popularity of a jigsaw file has somewhat dimmed. But the Faraday cage for CEA is still an advantage, and we don’t forget about protective grounding. Yes, an electrically conductive (ABS) plastic is already available for printing REA cases, but judging by the source , its resistivity is about a million times more than copper. Say, the dust is no longer sticky, but it's still a bit too much for grounding. It’s still impossible to print the steel parts of the PC case at home, and we cannot learn aluminum with tin ...

What to do? Our brother has to act using the method of Michelangelo, using for creativity instead of a stone block, blanks purchased at a DIY store, or generally old PC cases. Working somehow with the case from the old IBM server from smart millimeter steel, the author fell into a stupor, because the existing thread was larger than M3, but smaller # 6-32 (it later turned out that it was M3.5). Why in general it was needed in 2003 to use hardware M3.5, will remain a mystery, but the author did not even suspect the existence of a fractional metric thread.

UPD

For modders , by the way, the market offers new, convenient tools from the home workshop arsenal, and I’m talking about one of them ( oscillorez ) in a separate publication . The arsenal of accessories will perfectly complement the more familiar circular mini-saws (aka “dozeme”), and the absence of the “press-in teeth” effect will simplify the processing of viscous metals such as copper and aluminum. The tool is light, not as clumsy and dangerous as the "Bulgarian". You can cut the metal almost at the level of the nose and without the risk of getting a chop from a wedged or splinter from an "exploded" disc. And this happens in the cases of angle grinders colorfully described by respected readers: a 300-gram pancake "grinder" makes 200 revolutions per second, consuming up to 2 kW of electricity, and requires almost a sapper costume. A working oscilloresis traumatologists put their sawing party directly into the palm of their hands in order to calm the patient who came to the removal of the plaster cast ... But let's return to our metals.

Valid and invalid contacts of metals in accordance with GOST 9.005-72

DISCLAIMER: Provided “as is”. If a respected reader is engaged in modeling, motoring or robotics, the GOST also shows: Table No. 2 for harsh and very harsh atmospheric conditions, Table No. 3 for contacts located in sea water . Below, I offer an excerpt from Table No. 1 for average atmospheric (i.e. room) conditions. The letter "A" means "restrictedly acceptable in atmospheric conditions", details are in the GOST itself.

Clickable (thanks, UFO):

UPD:

More colored cheat sheets (thanks to greatvovan ):

for average atmospheric conditions

for harsh and very harsh atmospheric conditions

Couple words about metals

Metallurgists, correct, if something goes wrong. Corrosion is a very voluminous and complex topic, and I do not pretend to the fullness of its coverage. I just give selective sketches to form the necessary associative rows for the reader.

Galvanized

Galvanized steel is the main workhorse of the national economy. In the form of various hardware, “galvanized” is found in building materials stores much more than, for example, “premium” stainless steel. PC cabinets, process boxes and equipment cabinets are most often made of galvanized cold-rolled steel with a thickness of about 1mm (the cheaper the case, the thinner the sheet). "Galvanized" is strong enough and conducts electricity well, industry requires grounding. If you cut the case, then under a layer of paint of some dull RAL7035 there will be a thinnest zinc coating, and under it, most likely, the same cold-rolled carbon steel. Personally, I have no reason not to trust GOST 9.005-72, so after collective production of factory-made products I do not recommend making electrical contact at the cut point of the steel, better try to save the zinc coating. And cuts and scars can be painted from the balonchik of the same dull RAL7035 (just pay € 10 and try to find it again). I used automobile enamel in neutral white or black (a bottle with a brush, € 2 at any auto shop).

Aluminum

Aluminum and its alloys are anodized (with a protective layer) and ordinary (non-anodized). Aluminum is easy to process at home, but remember about corrosion. Do not use bare aluminum as a conductor even with low voltage, otherwise the current will slowly turn the part into dust. The aluminum and dural details processed in the workshop are shown to be fully equipotential (the currents induced by the fields, seemingly in FIG, can also be grounded). Aluminum is compatible with zinc coating, but for contact with copper, “bare” or nickel-plated steel, tin “gasket” is required. Limited contact of aluminum with stainless steel in atmospheric conditions. For simplicity, it can be assumed that in contact with other metals and coatings, aluminum will corrode by itself, without the aid of external electricity.

Twisted pair of copper-clad aluminum (Copper Clad / Coated Aluminum, CCA) is a separate story, in the home environment the cable is still not produced.

Twisted pair of copper-clad aluminum (Copper Clad / Coated Aluminum, CCA) is a separate story, in the home environment the cable is still not produced.

Copper

Copper is soft and rather unappetizingly oxidized in air; therefore, copper products are enclosed in a hermetic sheath or varnished. The brass plates of soldiers' belts and racks for electronic printed circuit boards are more resistant to oxidation and look more appetizing than green copper, especially if they are polished periodically (I'm talking about metal plates, of course). At the same time, neither copper nor its alloy with zinc (brass) is “friendly” with pure zinc and its coatings. But copper is combined with chrome, nickel and stainless steel. And if you hold in your hands any terminal, then it is surely from tinned (tin-coated) copper.

Tin

The tin is soft, but resistant to corrosion (in room conditions) and electrically compatible with almost all but cast iron, low-alloyed and carbon steels, and magnesium. You should not solder with tin and beryllium, be careful when assembling a domestic nuclear reactor. Tin is used to obtain permissible from an unacceptable electrical contact, i.e. as a "strip". Tinned copper terminals are a great example.

UPD:

It is impossible to make a product in the cold, and at subzero temperatures it is better not to operate at all.

UPD:

It is impossible to make a product in the cold, and at subzero temperatures it is better not to operate at all.

Nickel

Nickel coated shiny "computer" screws. This coating is compatible with copper and bronze, brass, tin, chrome and stainless steel. Nickel is incompatible with zinc and aluminum (for aluminum, contact with stainless steel is better, see below).

Stainless steel

Stainless steel - the queen of metals steels: durable, plastic, resistant to corrosion, electrically conductive, looks cool. Too tight to cut and bend at home on an industrial scale. Chromium and nickel-chrome stainless steels are electrically poorly compatible with zinc and "bare" steel, but they provide reliable contact with copper without the help of tin. Aluminum, as well as nitrated, oxidized and phosphated low alloyed steel are limited compatible under standard atmospheric conditions. Stainless steel grade A2 does not "magnet", but there are stainless steels with magnetic properties. Magnetic properties do not affect the corrosion resistance of stainless steel.

A couple of words about case modding

If you have been assembling a PC, you probably know that the bolts for mounting CD / DVD drives, 2.5 "notebook drives and floppy drives (ha-ha) use M3 metric thread. In the PC cases and 3.5" hard drives inch thread # 6-32 UNC. Why? Soft metal loves a coarser thread, besides adherents inch system while leading the technology market. Rack 19 "uses (you will not believe) inches as the main measure, however for installation of equipment I met only galvanized cage washers and screws with metric thread M6. Inch-metric dualism in technology ...

I started arranging my engineering kitchen by buying protective glasses, a set of high-quality metal drills, a small knob and taps on the threads M3 and # 6-32 UNC, and at the same time M4 and M6. Dies are not needed.

Popular types of carving used in computer technology

GOST 19257-73 recommends using the following drill diameters for metals. It is probably worth considering the number of taps in the set: the harder the material, the greater the need for "preliminary" taps. I have three of them, two "rough" and one "finish". And how correctly, by the way?

UPD

And how correctly - read the comments, the master of plumbing did come to the publication, but I did not manage to sort out all the information. The user golf2109 has kindly brought here right from the workshop the two right-hand columns of the table to indicate how the softness (viscosity) of the metal affects the diameter of the thread hole, thank you for your support.

| Thread diameter | Standard pitch, mm | Diameter of a drill, mm | ||

| GOST | Fe | Al | ||

| M2 | 0.4 | 1.6 | 1.5 * (-0.1) | |

| M2,5 | 0.45 | 2.0 | 1.8 * (-0.2) | |

| M3 | 0.5 | 2.5 | 2.3 (-0.2) | |

| M3.5 | 0.6 | 2.9 | 2.7 * (-0.2) | |

| M4 | 0.7 | 3.3 | 3.2 | 3.0 (-0.3) |

| M5 | 0.8 | 4.2 | 3.9 (-0.3) | |

| M6 | 1.0 | 5.0 | 4.9 | 4.6 (-0.4) |

| M8 | 1.25 | 6.8 | 6.7 | 6.3 (-0.5) |

| M10 | 1.5 | 8.5 | 8.0 (-0.5) | |

| # 6-32 UNC | 0.794 | 2.85 | 2.7 * | 2.5 * (-0.35) |

* I ventured to estimate the calibres of two additional drills for steel and aluminum where I have no data on them in the sources. Please note that # 6-32 UNC thread in outer diameter is between M3 and M4, and the thread pitch is generally closer to M5.

UPD

If you drill something thicker than a millimeter sheet, read the spoiler coolant .

about coolant

Grease and cooling of the parts and tools to be machined is of quite great importance both when drilling and when cutting threads. I strongly recommend not to rush when using the drill and use technical fluids. The cutting edge of the drill overheats easily from the dry part, and a metal break is obtained. Believe me, this leave is not needed: it causes irreversible changes in the structure of the metal and the degradation of its strength properties (the drill will blunt much faster than it should). What to do? Here are some tips that the author has met in different places.

Do not drill with a big drill right away; break the operations by approximately 3mm: i.e. hole 10mm first pass 3mm, then 6mm.

Carefully mark the hole with a core . Borrow plasticine from your child, make a side around the planned hole so that a coin-sized mini-pool is obtained. If you don’t have * anything at all *, mix a spoonful of sunflower oil with a spoon of liquid soap and pour into this mini-pool, it will not be worse. But if you need to drill through, say, a 16kg weight, google the recipe book “Sozh with your own hands”. I wish all beginners a successful penetration: as they say, take care of your drill-taps from your youth, because new ideas and interesting inventions are waiting for them!

Do not drill with a big drill right away; break the operations by approximately 3mm: i.e. hole 10mm first pass 3mm, then 6mm.

Carefully mark the hole with a core . Borrow plasticine from your child, make a side around the planned hole so that a coin-sized mini-pool is obtained. If you don’t have * anything at all *, mix a spoonful of sunflower oil with a spoon of liquid soap and pour into this mini-pool, it will not be worse. But if you need to drill through, say, a 16kg weight, google the recipe book “Sozh with your own hands”. I wish all beginners a successful penetration: as they say, take care of your drill-taps from your youth, because new ideas and interesting inventions are waiting for them!

On the well-known Chinese site, you can buy thumb screws, and on # 6-32, and on the M3. Material and color is different.

On the well-known Chinese site, you can buy thumb screws, and on # 6-32, and on the M3. Material and color is different.Sources

»GOST 9.005-72. Unified system of protection against corrosion and aging. Machines, devices and other technical products. Valid and unacceptable metal contacts. General requirements.

"GOST 19257-73. Holes for cutting metric thread. Diameters

»Unified Coarse Thread ANSI B1.1 (UNC ANSI B1.1 threads).

Source: https://habr.com/ru/post/398957/

All Articles