Created a flexible solar panel that can be used as a blinds or wallpaper

Solar cells, which convert light into electrical energy, play a big role in stimulating the production of solar energy throughout the world. However, researchers still face constraints that prevent the spread of this technology from increasing. Improving battery efficiency remains an urgent task. Scientists around the world are not trying to create a compact, easy-to-use and inexpensive technology that everyone could use. Some researchers promise that in the very near future, the processing of light energy in your home will become a simple and routine procedure. Led by Priash Shashank, a team of mechanical engineers and chemists from the Virginia Polytechnic University produces flexible solar panels that make window blinds or wallpaper to capture solar energy and sources inside buildings.

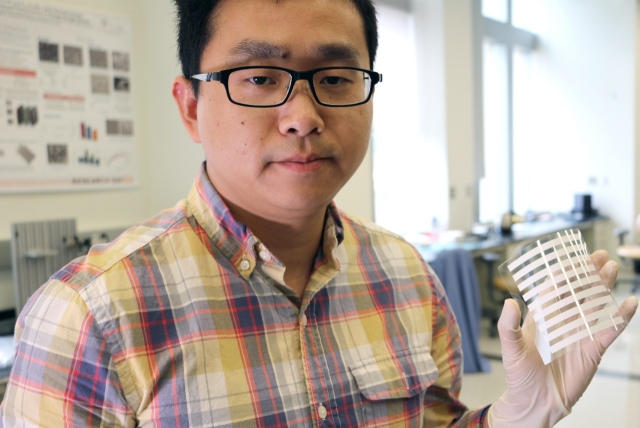

Solar modules less than half a millimeter thick are created using screen printing at low temperature. Part of the flexible five-layer structure of the material is paste-like titanium oxide. The result is thin, flexible panels that look like tiles in the bathroom. These tiles can be joined together and cover large areas with them. One panel about the size of a human palm provides about 75 milliwatts of power. Scientists suggest that from a panel the size of an ordinary A4 sheet is enough to easily charge a smartphone.

')

The work of Priya and his team is described in detail in an article published in the June issue of ACS Energy Letters. Engineers promise that their panels capture a wide spectrum of light waves, which will allow extracting energy by installing special blinds. Other work demonstrating the stability of the plates will be published later in the same journal.

To date, flexible panels are a little inferior in their performance to heavier and harder silicon, and Priya says that more research is needed. Nevertheless, it is likely that the new flexible panels will soon catch up with their tougher “brothers”.

Conventional silicon cells that have been advertised in terms of efficiency as the industry’s gold standard for more than a decade are relatively cheap. The efficiency of conversion of sunlight into electricity is 15-20%. Priya panels give about 10% efficiency in a standard size. The smaller the size, the greater the efficiency, so scientists see the potential for much more efficient energy collection.

The world record of efficiency for multi-junction solar cells belongs to two French companies, Soitec and CEA-Leti, which, together with the Fraunger Solar Power Systems Institute, achieved 46% in December 2014. The previous achievement in this field (44.7%) also belongs to the union of institutions and companies, with the participation of the Helmholtz Berlin Center .

Most silicon panels can only absorb sunlight. Flexible panels are designed to absorb ambient light, such as from LEDs, incandescent lamps and fluorescent lights.

The technology is attractive for several reasons. First, the manufacture of modules does not require high temperature, and the equipment for their production is relatively inexpensive and easy to use. Secondly, it is possible to create both miniature panels, from which various devices in the house will be charged, as well as whole sheet rolls, with which you can glue the entire room and use it for energy supply and heating. The panels produce blinds or curtains that will absorb light through the windows. The properties of the panels are such that they really have very few restrictions in terms of light sources.

Since flexible panels are close to the conversion efficiency of solid silicon and glass, they can be used where the old technology cannot be competitive. For example, in military uniforms and backpacks. Now Priya's laboratory collaborates with the Research Center for Electronics and Communications of the American Army ( CERDEC ). If you add flexible panels to these things, the soldiers themselves will be a walking station for recharging. This will help reduce the amount of wearable logistics equipment and reduce the weight of what each individual soldier carries on his back.

“Right now we are at the forefront of this technology. We are able to produce large area modules with high efficiency and are actively working to bring our product to the market. We see a wide range of applications of this technology: from clothing to windows in smart homes, from unmanned aerial vehicles to mobile recharging stations, ”says Priya.

DOI: 10.1021 / acsenergylett.6b00457

Source: https://habr.com/ru/post/398827/

All Articles