Silkworms ate graphene and made a silk thread that conducts electricity

Unsuspecting silkworms eat mulberry leaves sprinkled with a 2% graphene slurry

The silkworm is a relatively large domesticated butterfly that the Chinese have been using for at least 5000 years to produce silk (probably after several centuries or millennia of selection). For a long time, China was a world monopolist, supplying a beautiful fabric to Europe along the trade route, which was called the Silk Road. Then the Byzantines stole the silkworm eggs, and then the Europeans produced them through crusades.

However, this is not about cunning Chinese with their thousands of years of business plans, but about the unique material, which is silk itself. This is a natural protein, one of the most durable in nature. The fiber consists of 75% fibroin and 25% of sericin. Under the microscope, there are two parallel filaments of fibroin with lumpy sericin deposits. In addition to them, waxes and fats are present in silk, as well as minerals. The width of the silk thread is 32 microns, the length can reach 1.5 kilometers. Breaking stress of about 40 kgf / mm 2 .

')

Silk is an outstanding material, and scientists have made repeated attempts to improve silk fiber with various functional components, such as dyes, fluorescent proteins, antimicrobials, metal / semiconductor nanoparticles, and electrically conductive polymers.

Two main strategies are used to modify the silk fiber: modification of the finished yarn and enrichment of the material during its production (digestion) inside the silkworm. The first of these technical processes is rather complicated, multi-step and requires the use of toxic reagents. For comparison, the recently invented method of silk enrichment inside the silkworm is quite environmentally friendly and relatively simple process. It is only necessary to plant silkworms on a diet.

Scientists from the Faculty of Chemistry and the Center for Nano-and Micromechanics at Tsinghua University (Beijing) have proposed a new way of enriching silk fiber with carbon nanotubes and graphene.

Carbon nanotubes and graphene have excellent mechanical properties and are widely used in the production of high-strength materials. There have been several attempts to add carbon nanotubes to silk by modifying the finished yarn or adding silkworms to the diet. Similar experiments were carried out with spiders. In the past experiment, multi-walled nanotubes with a diameter of about 30 nm were fed to silkworms. Now Chinese scientists have logically assumed that silkworms and the introduction of fibroin into the structure of the fibroin will not be much more acceptable than single-stage nanotubes with a diameter of about 1-2 nm. Looking ahead, they were not mistaken.

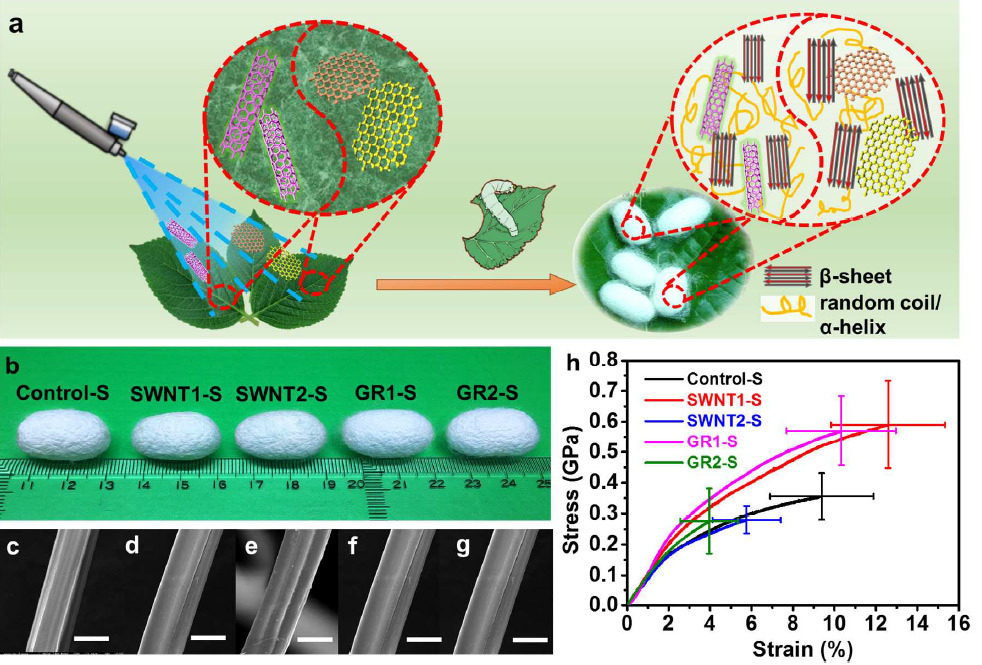

In addition to single-walled nanotubes, the scientists decided to feed the silkworm more and graphene, also a potential hardener. To feed materials to animals, scientists used a simple method: they sprayed the suspension with single-stage nanotubes and graphene onto mulberry leaves that feed the silkworms - and then they collected the product from the cocoon.

The experience was a success. The diet of silkworms with the addition of single-stage nanotubes and graphene resulted in a silk thread with improved properties. The thread is obtained in a natural, natural way from a cocoon, like a regular silk thread.

Scientists have studied the spectra of Raman scattering of silk fiber and silkworm excrement - and in both cases confirmed the introduction of carbon nanotubes into silk fiber. They also checked how the properties of the fiber changed after the introduction of carbon nanotubes.

The illustrations show the experimental scheme, photographs of cocoons obtained after feeding silkworms with mulberry leaves coated with a suspension of nanotubes with a concentration by weight of 0.2% and 1.0% and a suspension of graphene with a concentration of 0.2% and 2.0%. Pictures from a scanning electron microscope are shown for each sample of the silk thread and a diagram with the characteristics of the stretchability of the thread

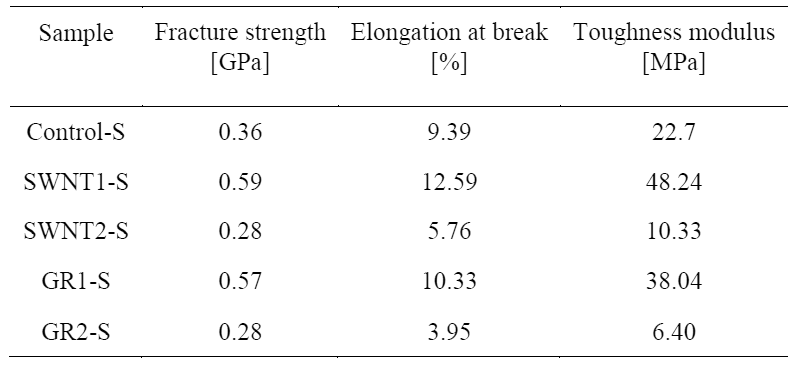

Other mechanical characteristics of the improved silk fibers are shown in the table: breaking stress, maximum tensile strength and modulus of elasticity.

As is clear from the table, there is still a series of experiments to be carried out in order to find the optimal concentration of carbon nanotubes and graphene in the silkworm diet, so that they will have higher strength yarns. We see that a diet with a lower concentration of SWNT1-S and GR1-S led to the production of fiber with much better properties than a diet with a higher concentration of SWNT2-S and GR2-S.

It is not surprising that after adding graphene and carbon nanotubes, the silk thread became a conductor of electricity. In the best sample of silk with graphene particles, the electrical conductivity amounted to a rather high 120 siemens per centimeter. Such silk can be used in electronics. Conveniently powered by wearable gadgets that are sewn right into silk clothing. Actually, the glowing fabric is quite simple to make.

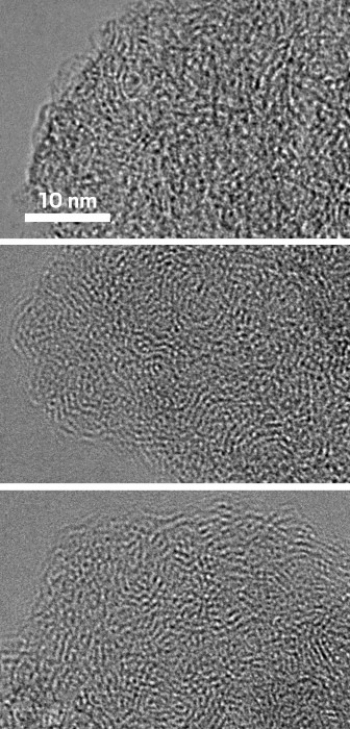

The photographs from the transmission electron microscope clearly show that silk fibers with glorode nanotubes (in the middle) and graphene (below) are much better structured than ordinary silk (above).

The scientific article was published on September 13, 2016 in the journal Nano Letters (doi: 10.1021 / acs.nanolett.6b03597).

Source: https://habr.com/ru/post/398343/

All Articles