Created biomaterial for 3D printing of human temporary bones

Several temporary human vertebrae printed on a 3D printer. Photo: Adam E. Jakus

Attempts to create materials for 3D printing of temporary human bones (osteoregenerative biomaterials) have been made repeatedly. Unfortunately, they still suffer from a number of shortcomings. Among them - the inability to quickly and accurately reproduce the new bone, the high cost and limited production capabilities, the complexity of processing during surgery.

The new biomaterial is devoid of all these shortcomings. If all the tests are successful, then in a few years people will be able to get strong, super-elastic and cheap artificial bones that will biodegrade in the body over several years (they are gradually replaced by natural bone tissue). The most interesting thing is that the process of extrusion of material at room temperature, theoretically, allows for the printing of bones, even on home printers.

As the scientists write, the new material HB (from hyperelastic “bone”) is 90% by weight hydroxyapatite and 10% polycaprolactone .

')

Hydroxylapatite Ca 10 (PO 4 ) 6 (OH) 2 is the main mineral component of natural human bones. In most bones, it is about 50% of the total mass, and in tooth enamel - 96%. In medicine, a synthetic analogue has long been used in traumatology, orthopedics and bone surgery as a filler, replacing parts of a lost bone. In dentistry, it is also used in toothpastes, as a remineralizing element that strengthens tooth enamel.

But polycaprolactone (PCL) is absent in biological materials. This is a biodegradable polyester, which is used in industry for the production of polyurethanes. From it make biodegradable packages. In medicine, PCL is also used as a suture material and as a self-resorbable thermal implant of prolonged action (filler), which has the ability to stimulate the growth of fibrous tissue and replenishes volume with its own components. Many tablets come in capsules of PCL, they are absorbed in the body. In addition, PCL is used in mass 3D printing as a prototyping material. By its properties, viscous PCL is similar to natural gum like gutta-percha .

Experiments have shown that artificial bones of this composition can be quickly printed at room temperature at a speed of up to 275 cm 3 / hour by extrusion, that is, by forcing a viscous melt of material or thick paste through a forming hole. To create a viscous mixture that is loaded into the printer, a special solvent is used.

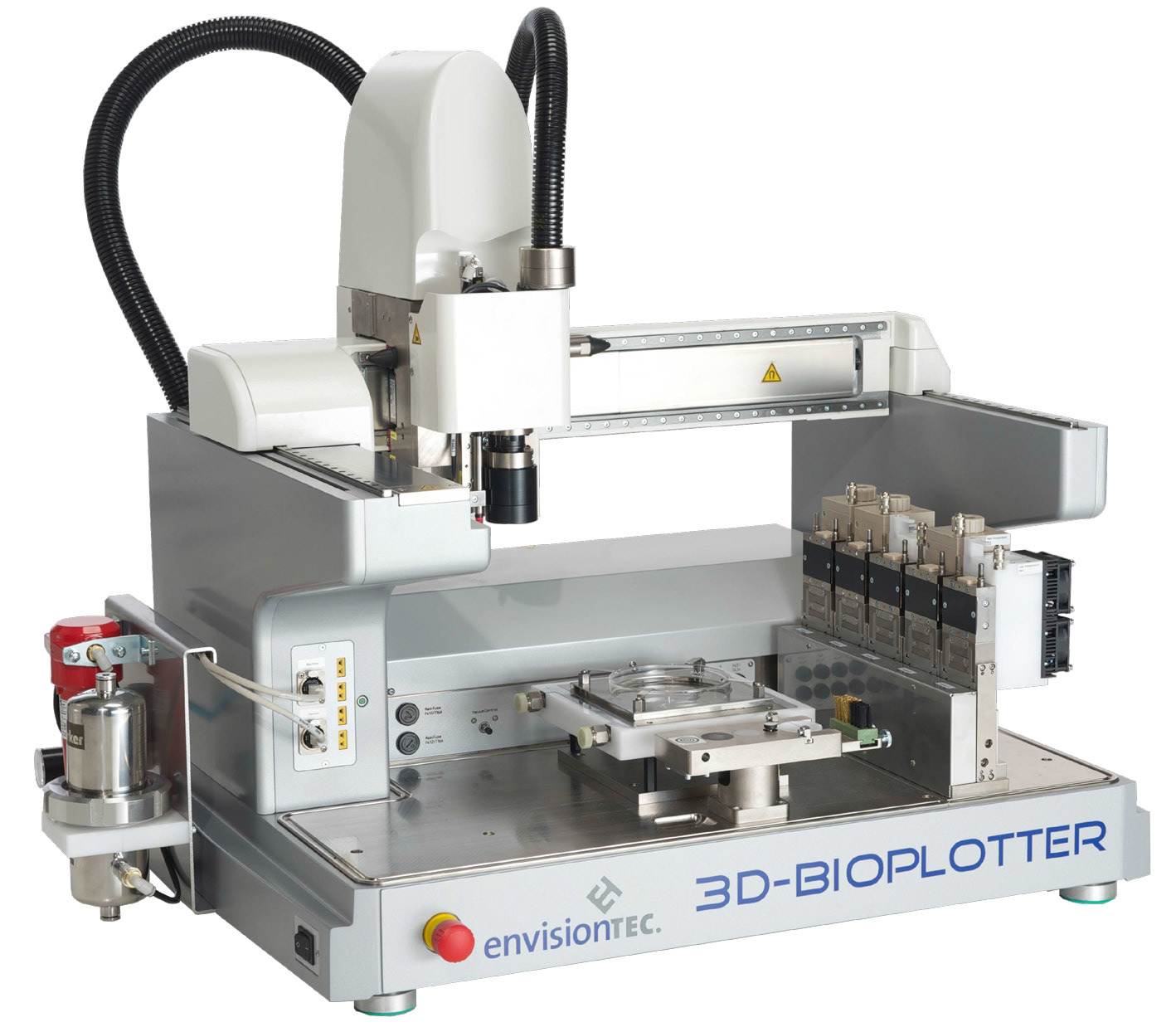

Printing an implant with traditional extrusion at room temperature is a great advantage because other bone implants are created at high temperature using lasers, explains Ramille Shah, lead author of research and team leader at Northwestern University (USA). . The researchers themselves during the experiments used a commercially available 3D-Bioplotter System printer manufactured by EnvisionTec. This device can be purchased for as low as $ 250,000 to $ 300,000.

Of course, in a household, such a printer would be too expensive. But every hospital or surgical center can afford it. In principle, even individuals can buy such printers and print new bones for themselves or pets if necessary (of course, it is advisable to contact a professional surgeon for the operation).

EnvisionTEC 3D-Bioplotter

Artificial bones exhibit good mechanical properties: strain to strain (strain to failure) from 32% to 67%, modulus of elasticity from 4 to 11 MPa. Thus, it is an elastic and durable material. It is also characterized by high absorbency (porosity 50%), supports the viability and distribution of living cells. Tests have shown that the material does not interfere with the formation of bone marrow cells from mesenchymal stem cells.

So far, the biocompatibility of HB has been tested only on laboratory animals, but these experiments turned out to be very promising. Subcutaneous implants in mice did not cause rejection within 7-35 days. In rats, a bone graft was installed in the posterolateral part of the spine (posterolateral spinal fusion) for 8 weeks, the formation of a new bone tissue was recorded. Also conducted an experiment on primate with damage to the skull (4 weeks).

During all the experiments, HB did not cause a negative reaction of the immune system. At the same time, normal vascularization (vascular formation) was noted, the artificial bone quickly integrated into the surrounding tissues, quickly ossified and supported the growth of new bone tissue without additional intervention. It is assumed that, as the material is biodegradated, its place will be occupied by living natural bone tissue with blood vessels.

It is important to note that with all the strength and elasticity of the new material is not fragile and not fragile, like many other implants. That is, the surgeon can cut off a piece of artificial bone without forming fragments - this is a common problem with other implants.

Researchers hope to get permission to start human trials within five years. At the moment in the US, no 3D printing material is approved by regulatory authorities as a regenerative bone material. HB can be the first.

The scientific work was published on September 28, 2016 in the journal Science Translational Medicine (doi: 10.1126 / scitranslmed.aaf7704).

Source: https://habr.com/ru/post/398027/

All Articles