Palace for Hakko T12, or what is common with a soldering station with a hedgehog

Good day to you, dear geeks and sympathizers! Read carefully these lines of the great poet:

I knew only one power of thought,Mikhail Yuryevich was able to accurately describe the mental agony, overwhelming many radio amateurs in search of a powerful, fully automatic, accurate, versatile, reliable and inexpensive soldering station.

One but fiery passion:

She, like a worm, lived in me.

Gnawed soul and burned!

')

Thanks to the hardworking Chinese comrades, the above described (as, indeed, many others) dream may well come true at relatively low financial costs. It will be a question of a kit for assembling a soldering station on Hakko T12 tips. This kit costs less than 18 euros on Aliexpress and contains all the necessary details, except for the power supply and case. In the network you can find many reviews of this set.

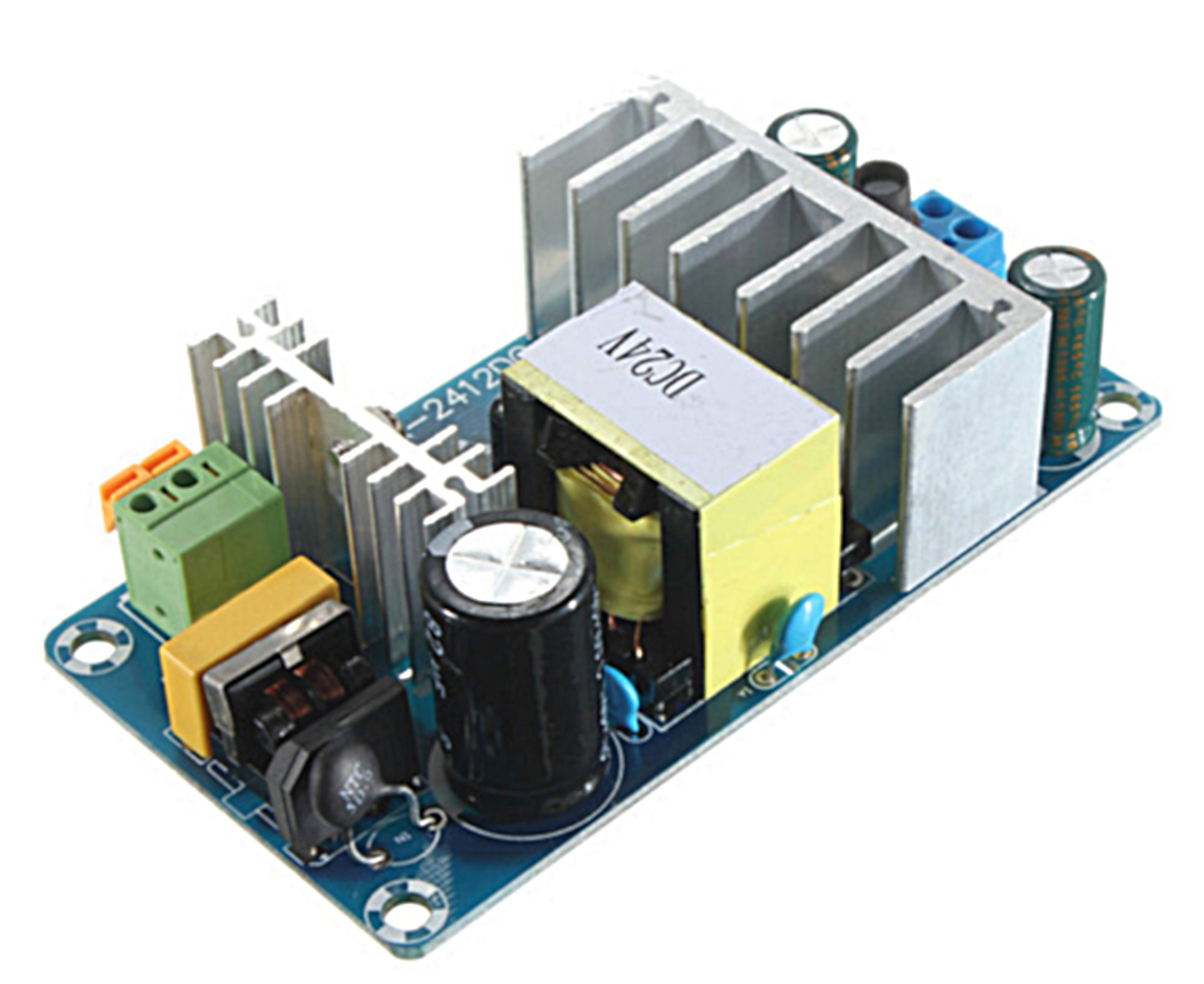

A compact stovattny (in fact, no) power supply for 24 volts costs about 8 euros with shipping.

The problem of this power supply in significant heat with a load of more than 75 watts. Since the soldering station consumes significantly less power, this power supply unit can be considered a suitable candidate with a clear conscience.

Let us turn to the body: this is where the maximum scope for creativity opens up and considerable difficulties lie for radio amateurs who do not have a 3D printer for personal use. As you know,

Some of the above parts have combined the following wonderful device:

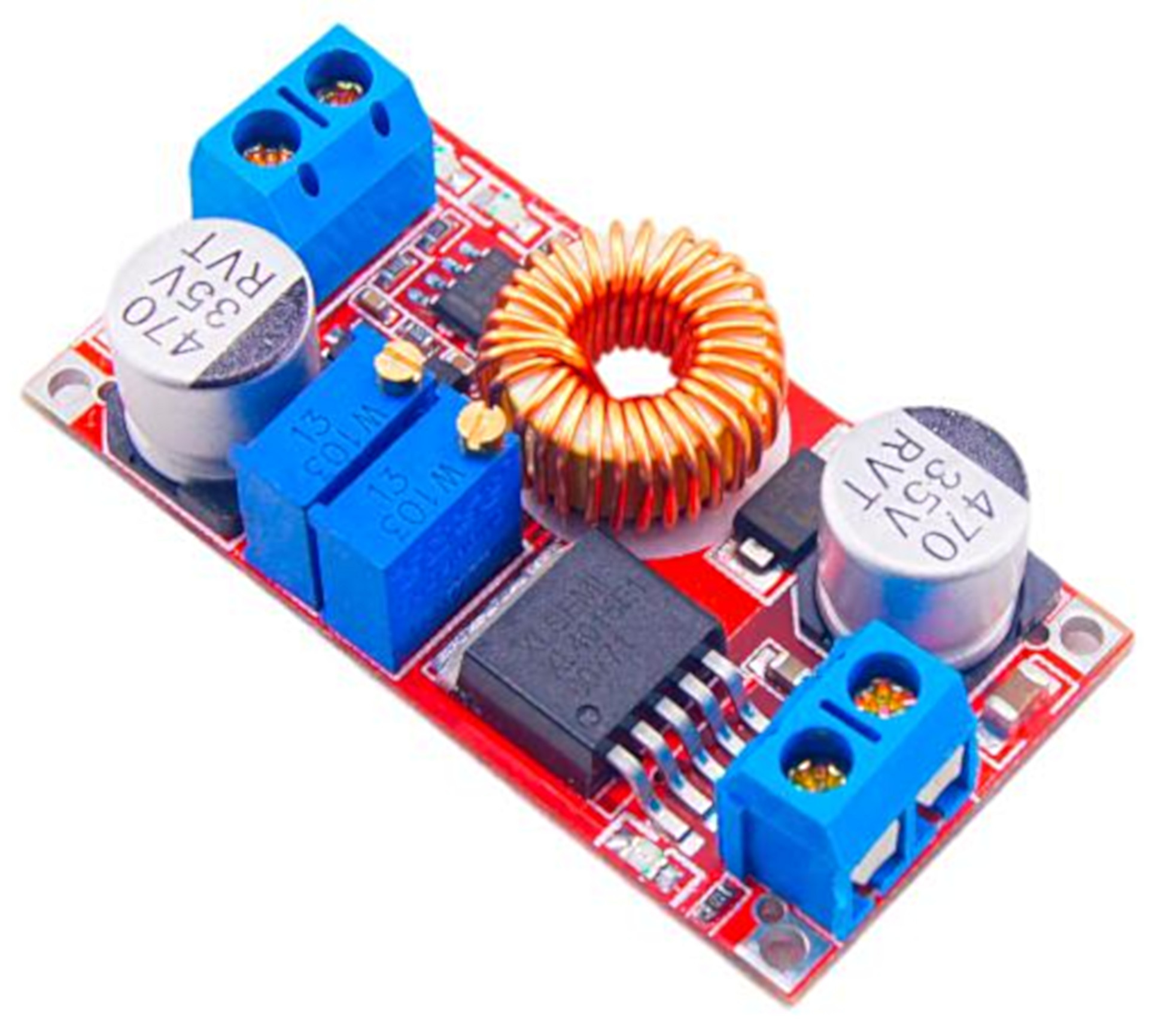

The only problem with this device is a thin and poorly routed cable to power the LED backlight. This cable is best to replace immediately. Since LED lighting requires a 5 volt power supply, we will also need to purchase a voltage converter from 24 volts to 5 volts. The Chinese comrades will part with the necessary device for a symbolic 1.8 euros.

Note: this converter is built on the basis of the XL4015 microcircuit. Despite the stated output current of 5 amperes, this converter operates without overheating only at a current of less than 2.3 amperes. Since this converter has an adjustable output current, for reliable operation, you can simply set the maximum current to 2.2 amps and forget about the problem.

As you know, there is no such tube with toothpaste, from which it would be impossible to squeeze out another drop. This highly scientific observation prompted me to take the resulting voltages of 24 and 5 volts to the external terminals and use the soldering station as a power supply. Naturally, two USB sockets and asked for the front panel. The Germans call this the “Eierlegende Wollmilchsau” (egg-laying whelp dairy).

It remains to purchase a power cable with rubber insulation (soft and does not melt), a power switch with light indication, some installation wire in silicone insulation (soft and does not melt), a pair of USB connectors, a four-pin terminal block (these are used to connect speakers), 20 self tapping screws M3 and 8 M2 screws.

My fakeQR home 3D printer has earned the honor of manufacturing the case. The material for the hull was chosen PETG filament of the Chinese manufacturer Winbo (Chinese with Chinese in Chinese, or else there will be). PETG has a lot of advantages over other materials: excellent interlayer adhesion, no warping (“shrinking”) when printing large objects, high strength and resistance to environmental factors. For example, Coca-Cola bottles are made from this material.

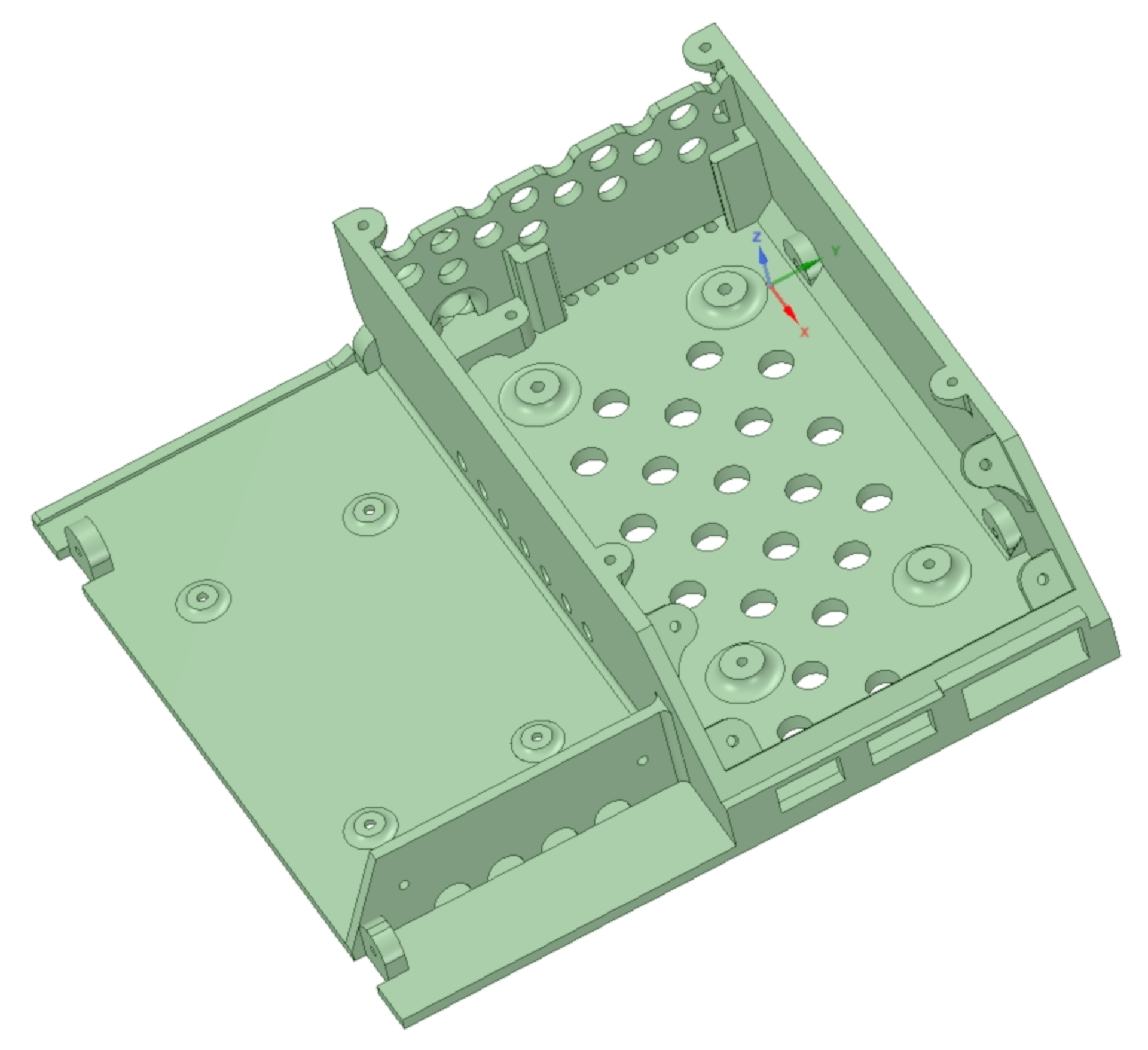

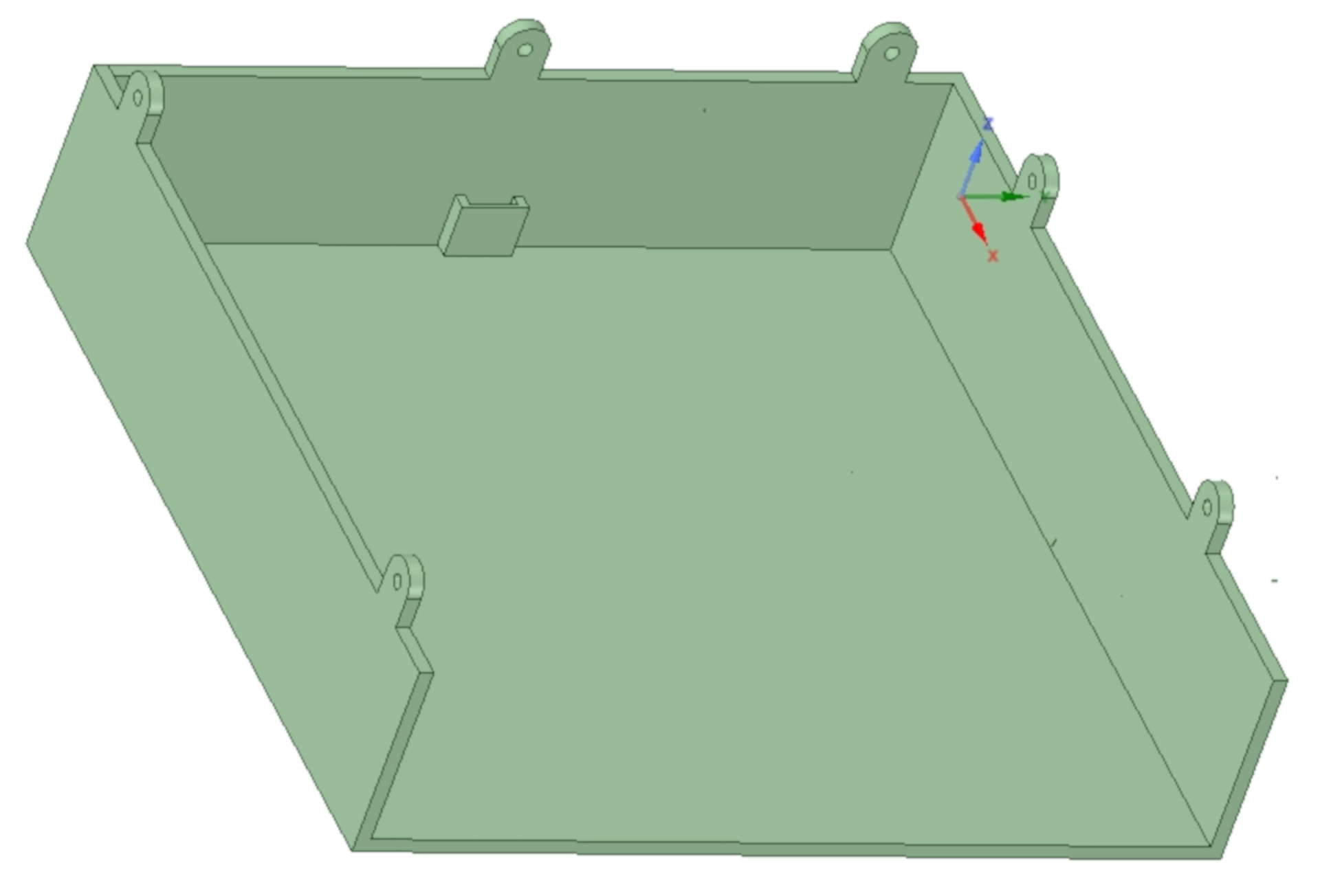

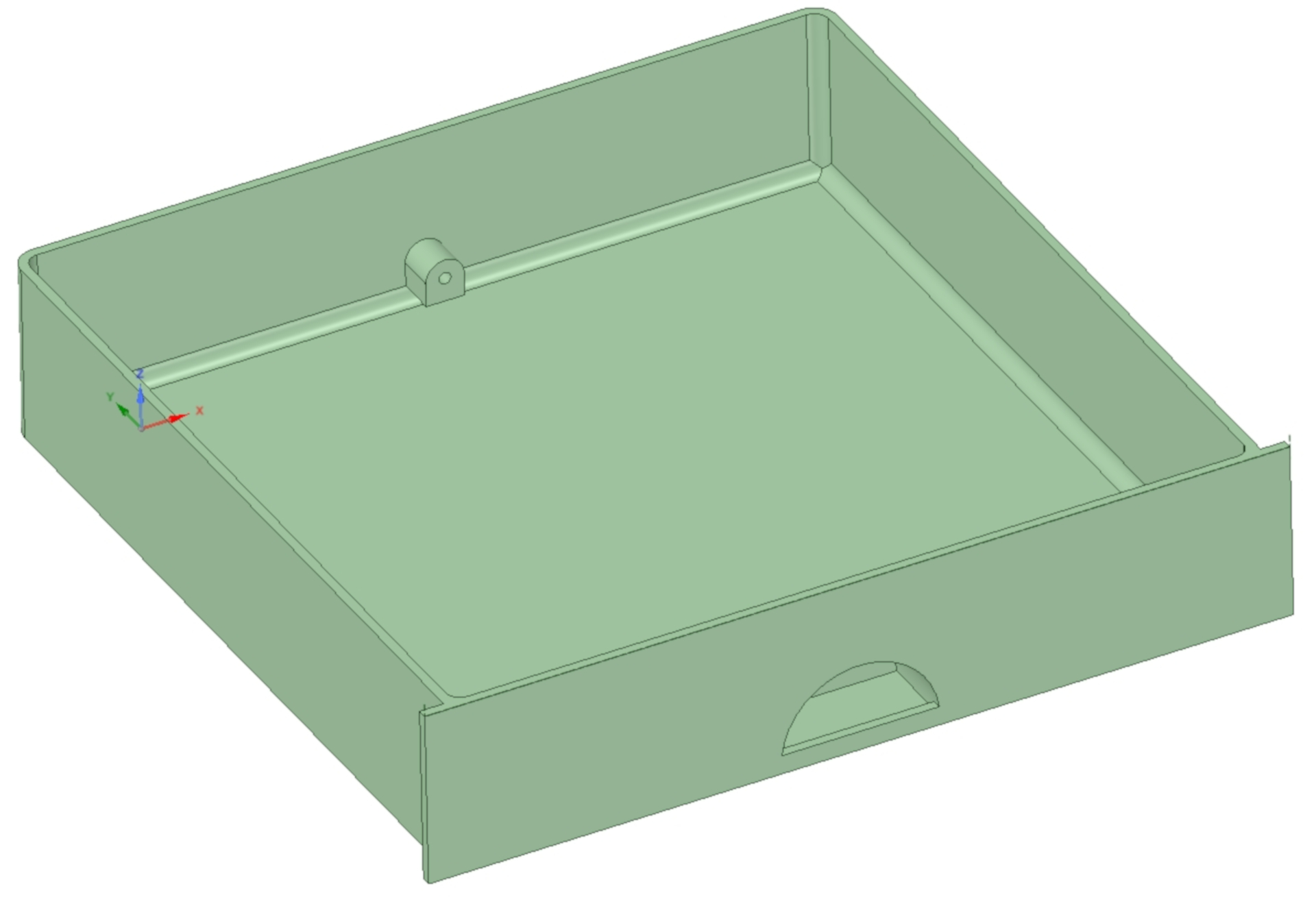

After a short fuss in a wonderful free CAD DesignSpark Mechanical, parts of the future mega-corps of the super-soldering megastation were created.

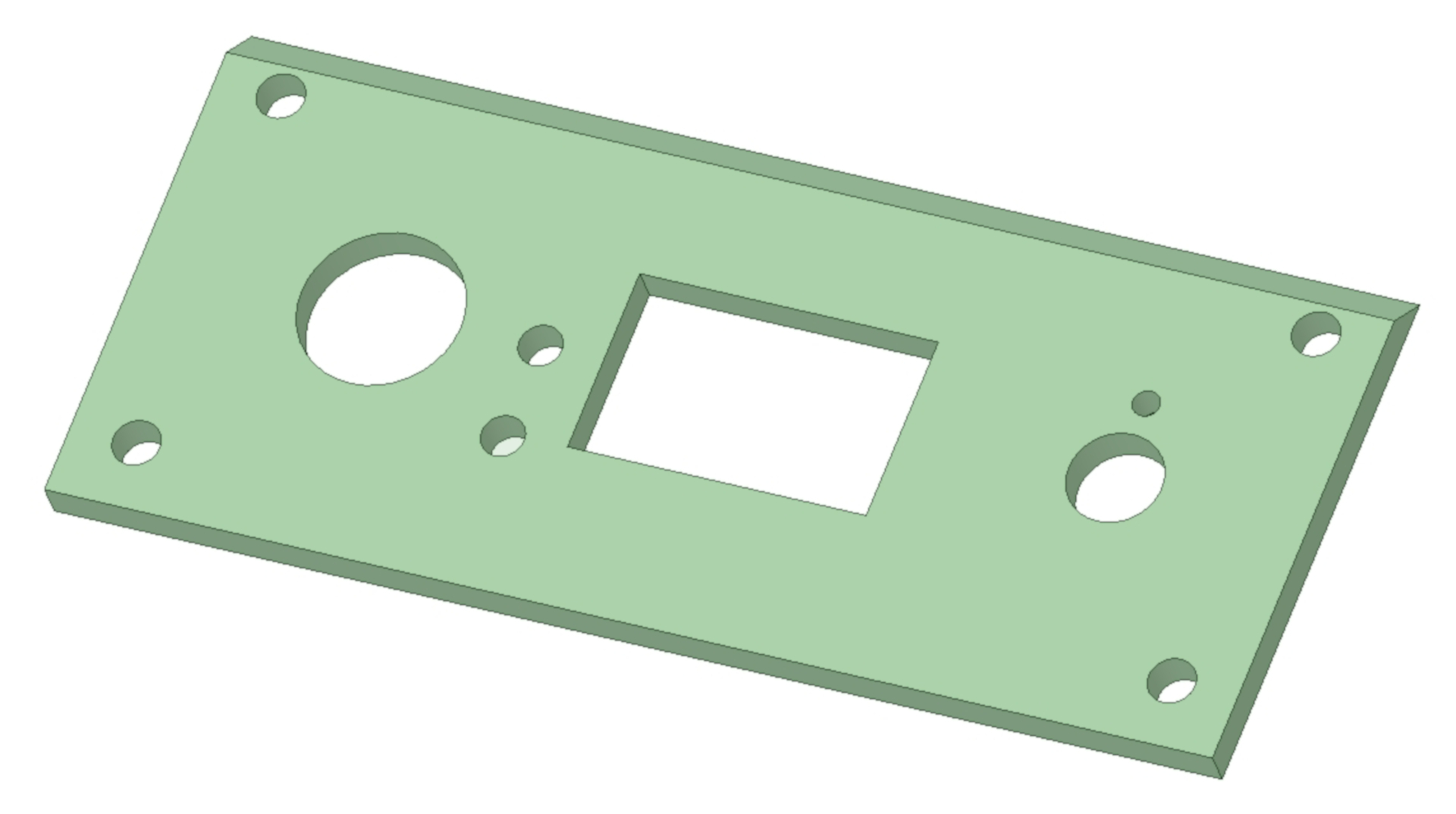

Front panel. Serves for fixing the electronic control unit of the soldering station on the main part of the housing

Main part. All other parts of the case and electronic components are screwed to it.

The following elements are located on the front wall of the main part: two USB sockets. the power switch (the switches on the rear panel are something of a crime against humanity, in my opinion), ears for fixing the front panel with the electronic unit. On the back wall is a pocket for the voltage converter and ventilation holes. The hole for the power cable outside has a funnel shape to prevent the cable from breaking. The power supply is located at a certain height from the bottom wall to ensure free access of air through the lower ventilation openings.

The cover of the electronics compartment is made in the form of a bath in which you can fold different things. The body is made so that not a drop of tin, nor any small objects can get into the electronics compartment.

Lower part and pull-out drawer. On the inside of the back wall of the lower part there is a magnet pocket, in the corresponding place of the box there is an opening for a screw made of magnetic material. Holding the box with a magnet is a cheap, safe and easy solution, in my opinion.

After assembly, the soldering station looks exactly like a hedgehog from the famous Ushinsky fairy tale. (the animal was "wrongly tailored, but firmly sewn" and avoided so many misfortunes).

After the first version was assembled, the 3D models were corrected, improved and simplified, you can download them here . Published under the WTFPL license.

Well, and traditional: Have fun!

Source: https://habr.com/ru/post/397919/

All Articles