ITER: Diagnostic Builds

Ask yourself, “why is ITER built for so long”? If you honestly read my notes on this project, the first thing that comes to mind is “this is an extremely complicated installation”.

One of two dozen diagnostic assemblies of the ITER reactor, which will be discussed today

The complexity of engineering structures is a hard-to-measure substance, unlike, for example, from algorithms . Historically, humanity has continuously complicated its structures, machines and systems, and has struggled with increasing complexity both by decomposing into smaller works and performing them in parallel, and by standardizing the experience gained. The first approach can be illustrated, for example, like this: a building is designed not by drawing ready-made pieces with all the elements (structure, electrics, ventilation, facades, water communications, etc.), but parallel from the general concept by different people. The second approach manifests itself in the use of standard components, the elaboration of ready-made algorithms and solutions (“for copper wiring wires, the maximum current value is 8-10 amperes / mm2” - no one has to investigate the question of what current will not cause a fire, this is already the norm and rule developer).

However, decomposition and parallelization of tasks of engineering creativity has an obvious downside - the drop in recoil for each person added. Communication, search for errors and synchronization of development processes take up an increasing part of the man-hours spent.

')

It is especially bad where decomposition is not easy, where there are a lot of related problems, and solutions for one pull the need to redo the other. In practice, such difficulties arise where at one point many different disciplines converge, in which different specialists are engaged, who have little knowledge of the “clearing” of each other. For example, if for the development of design drawings, it is necessary to take into account calculations on neutron physics, thermal mechanics and thermal hydraulics, electromagnetic forces and, at the same time, the requirements of a mass of engineering disciplines — vacuum technology, reliability of nuclear pressure vessels, manufacturability and assembly, serviceability of robots ... it seems you understand what installation I say.

Today we will talk about diagnostic assemblies, otherwise known as “diagnostic port plug-ins” - less ambitious than the main ITER systems, but incredibly complex and precision devices.

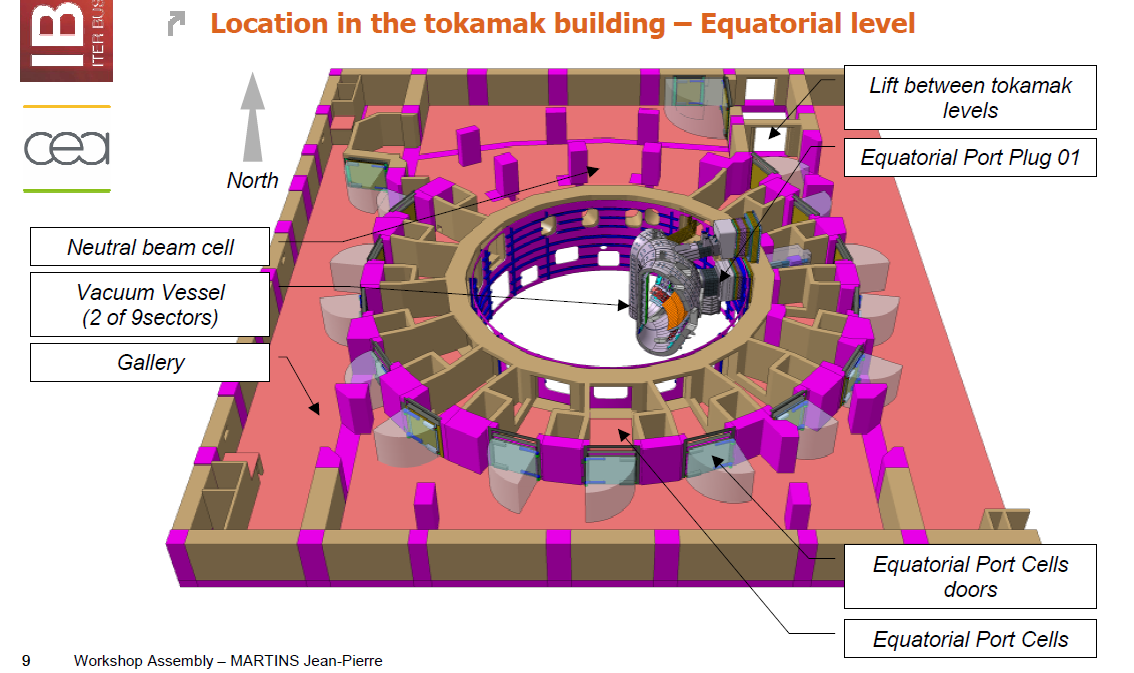

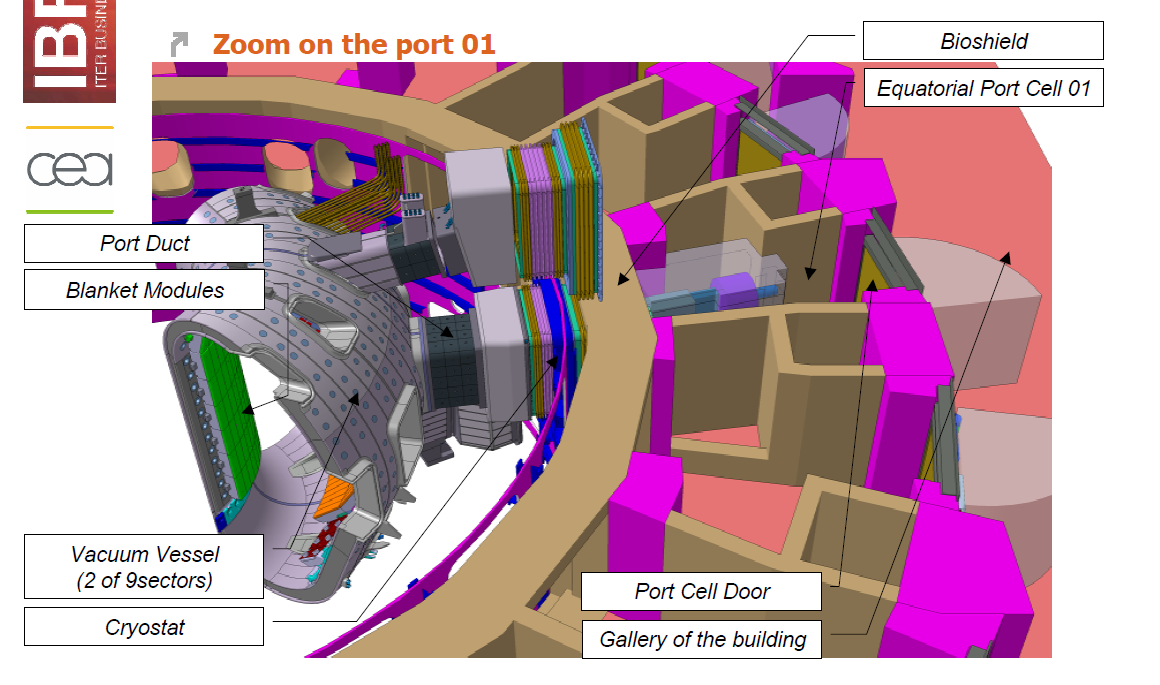

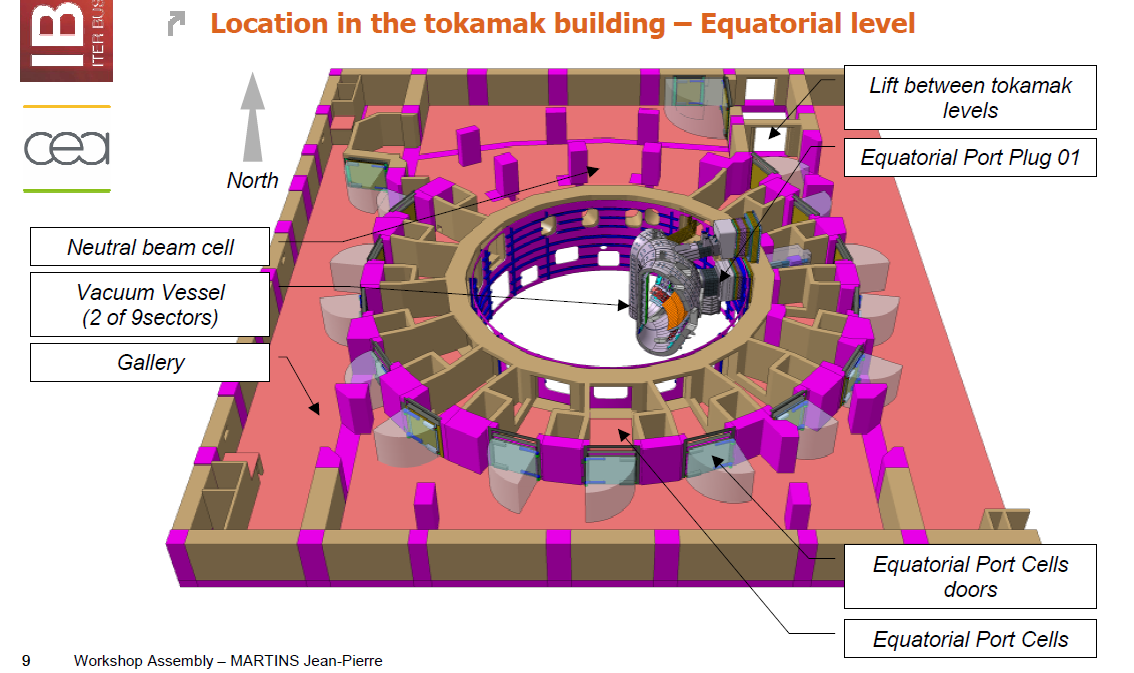

Floor Plan ITER. In the center of the reactor shaft, around it - the port chamber (Port Cells), which can be inserted heating system, test blanket assembly or diagnostic assembly

ITER diagnostics refers to equipment that measures some plasma parameters (namely, plasma, sensors that measure the state of a machine are called “instrumentation”). Those. in fact, these are scientific instruments of the reactor. For example, this could be a neutron monitor measuring the neutron flux from a plasma, which characterizes the fusion power of a reactor. Or a microwave reflectometer that receives the temperature and density profile of the plasma across the plasma cord. In total, 47 diagnostic systems of all imaginable types (and more than ten thousand instrumentation sensors only at the reactor) will be installed on ITER.

Diagnostic systems in the scale of the ITER structure (highlighted in green). The physical parts of the devices are collected in diagnostic assemblies in the ports, and the electronics and servers are moved to a separate attached building.

Since the plasma in tokamaks is surrounded by a vacuum chamber and powerful cell magnets , access to the plasma is possible only through the openings in these two systems. In ITER, the openings are called ports and are organized on three tiers: the lower - divertor, equatorial in the middle and the upper tier is called the upper. A total of 44 ports: 9 divertor, 17 equatorial and 18 upper.

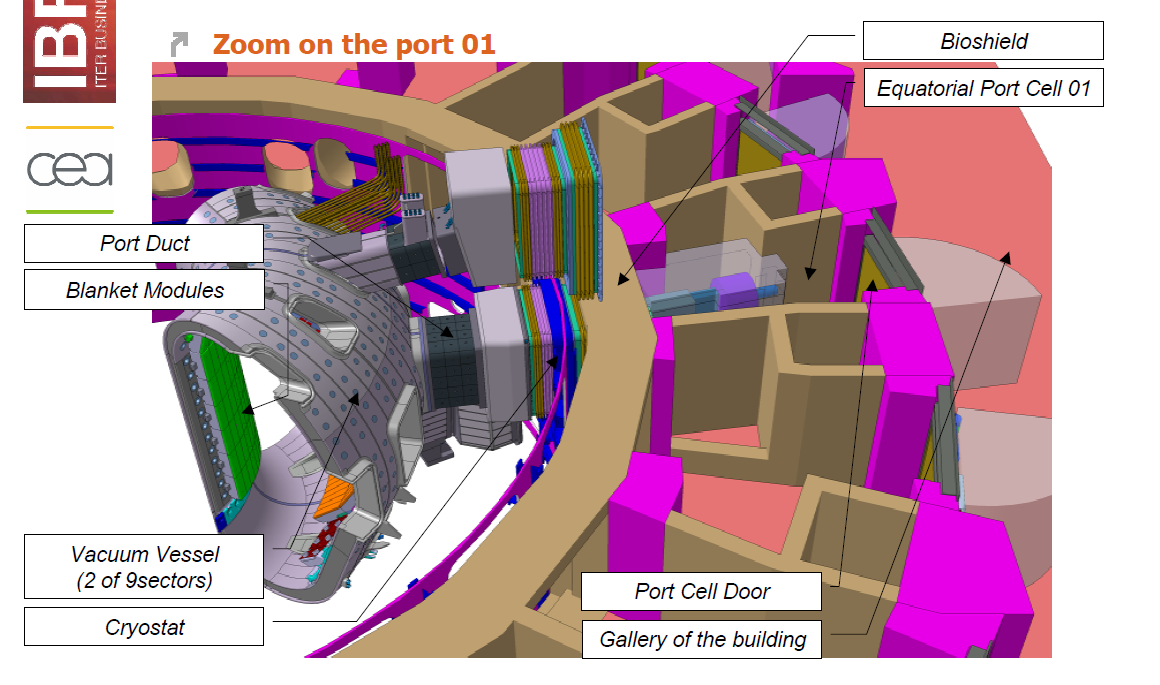

Port cells, connecting pipes, vacuum chamber. By the way, pay attention to the accordions on the connecting pipes - they are needed to compensate for the change in the size of the reactor during cooling down and any movements caused by plasma breakdowns

The ports have different purposes: some of them look at the plasma through heating systems ( radio frequency , for example, IRCH antennas), 4 diverter ports will be occupied by cryo-sorption pumps , some will be accessed by robots inside the torus, 3 equatorial ports will be occupied by experimental assemblies of the propagating blanket (here lithium tritium and evaluation of various engineering variants of such a blanket), finally 6 equatorial and 11 upper ports will be occupied with diagnostics.

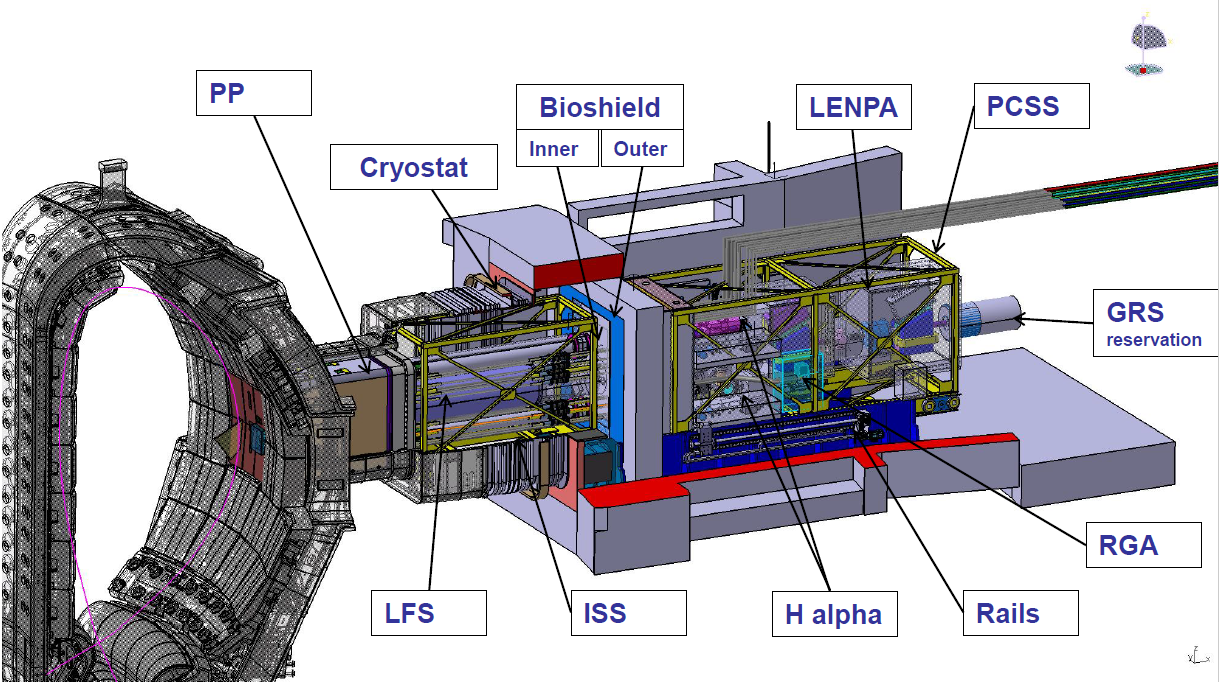

The location of the diagnostic assembly equatorial port number 1. Piece with gray tubes - a radial neutron chamber that receives a neutron image of a low resolution neutron plasma field

An insertion port is made for each diagnostic port - a long assembly weighing up to 150 tons, which can be installed and removed by the ITER robotic service system. This assembly includes up to 10 scientific instruments, their protection and cooling from neutron and electromagnetic radiation from plasma, the necessary communications, etc.

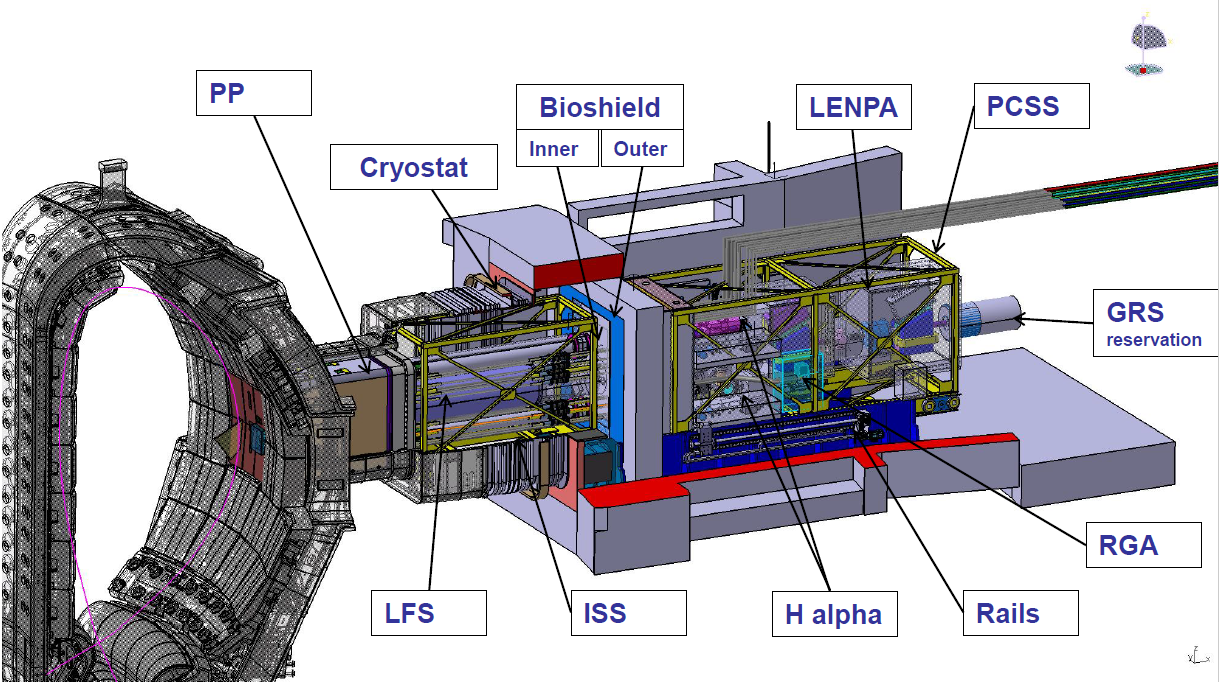

Diagnostic assembly equatorial port number 11, developed in the Novosibirsk INP. Assembly length - about 17 meters.

Because of their location in the port plug, the conflicting demands of many disciplines converge. Let's start by listing them:

The port insert includes the front vacuum part (called the port-plug) and the rear atmospheric part (called the port-camera insert), which means all communications are broken by vacuum-tight closures, windows, etc. At the same time, the vacuum part of the port-plaga should satisfy the extremely harsh conditions of the ITER ultra-high vacuum torus, which means such requirements as a narrow choice of materials, the absence of closed cavities (which can be etched by air residues), for example, deaf threads, the need to clean the entire vacuum unit from organic contamination before installation in the reactor.

Therefore, all optical / microwave paths must be led through such vacuum-tight windows, and electrical connectors must be made with an intermediate cavity with a protective vacuum.

The entire port insert design, including the precision optical systems of scientists, must be assembled by robots with a low accuracy, which means that all systems requiring precise installation must be able to adjust - to have movable mirrors. In addition, the docking of all communications should also be done automatically - it turns out very, very automated system of this type, which no one in the world has yet done.

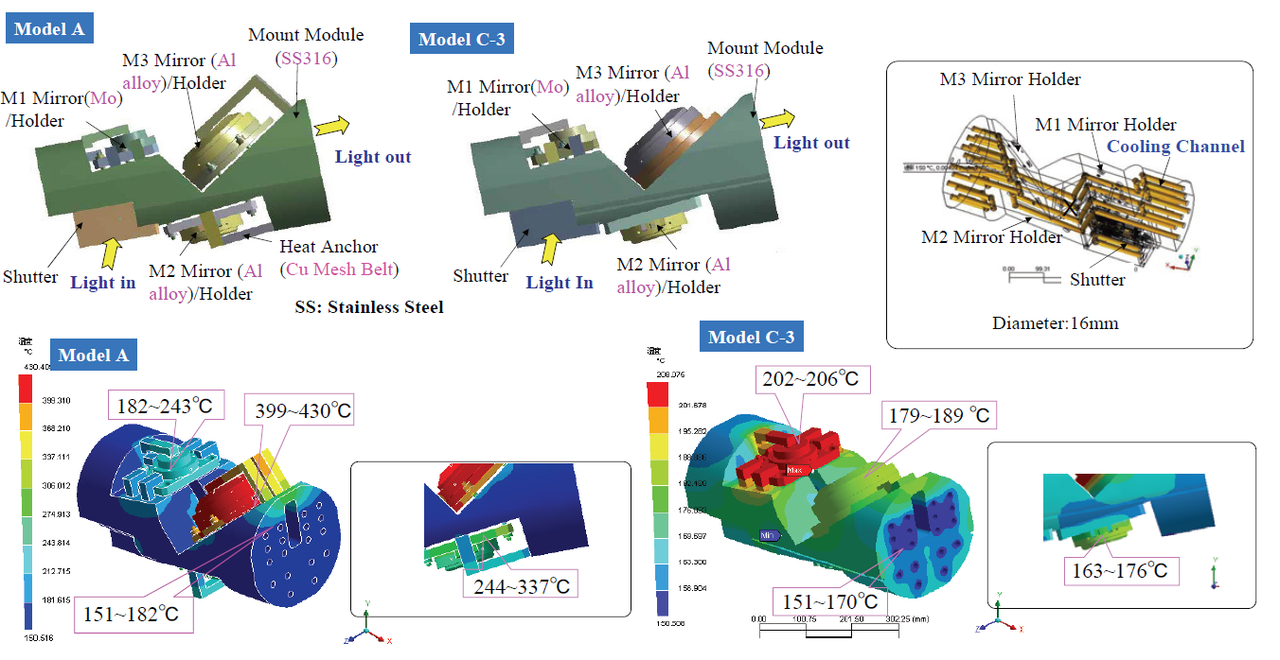

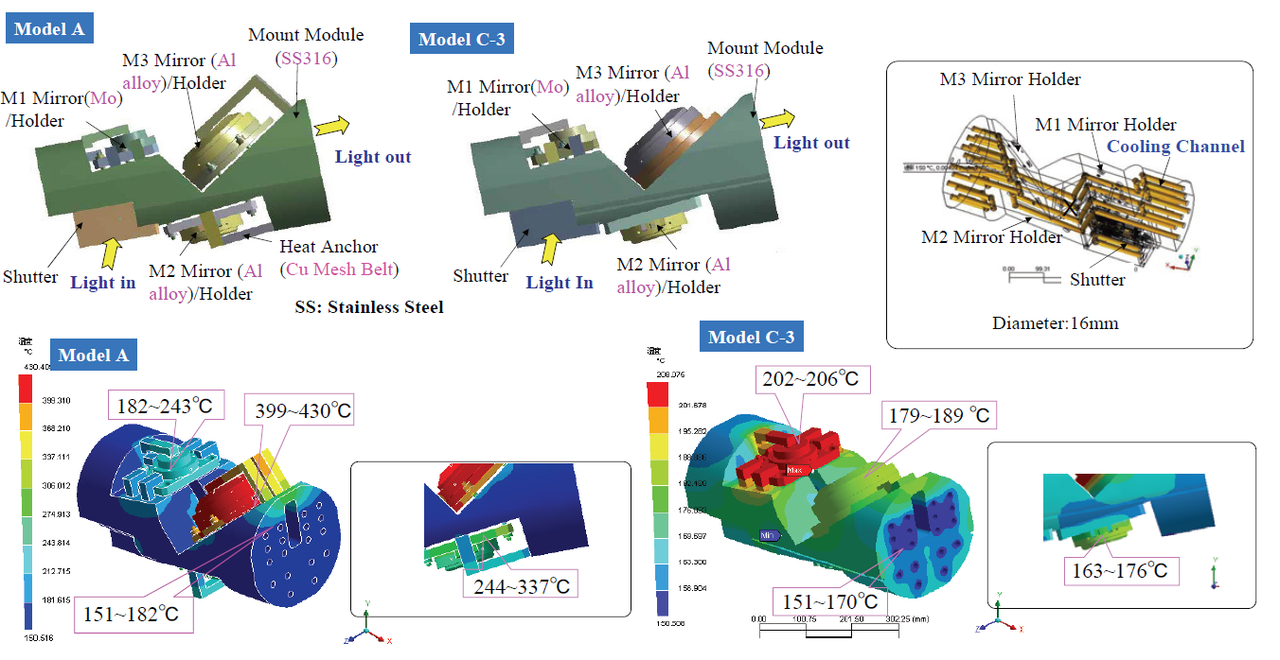

One of the engineering nightmares of ITER are optical systems that transmit plasma radiation to the tail spectrographs removed to the tail. There are problems of thermal deformations, problems of alignment, problems of cleaning optics, and problems of “divorcing” the neutron flux and the light flux.

The whole structure will be subjected to neutron irradiation more rigid than in nuclear reactors, therefore neutron protection from steel, water and boron carbide will be located ahead. In order for the assembly design not to turn into highly radioactive waste, neutron radiation to the rear of the port plug must be attenuated 10 million times. At the same time, it is necessary to bend in defense all the channels of diagnostics, looking at the plasma so that neutrons cannot pass straight back through these channels. If it is impossible to bend the channels (for example, there are no mirrors for X-rays, gamma radiation, neutron radiation), then it is necessary to surround them with separate elements of neutron protection.

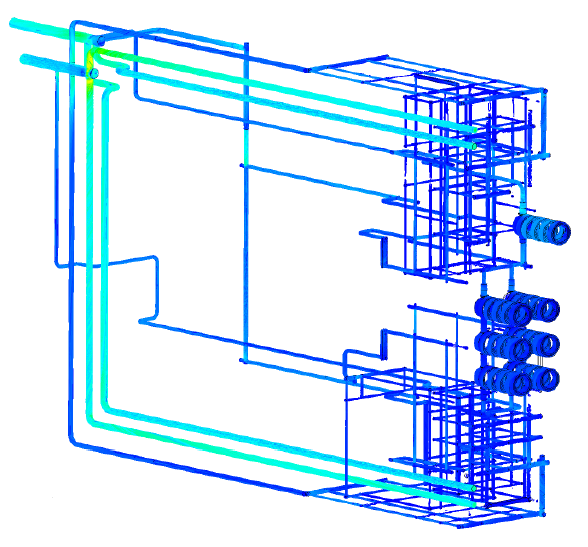

An example of a thermal-hydraulic calculation of the most thermally loaded elements of a portplag (diagnostic protection modules)

Here is an example of optimizing the cooling of an optical assembly.

Protection against neutron and electromagnetic radiation (called diagnostic protective blocks DZM and diagnostic first wall DPS) will be exposed to the most powerful heat flux from a thermonuclear reaction, going a few meters.

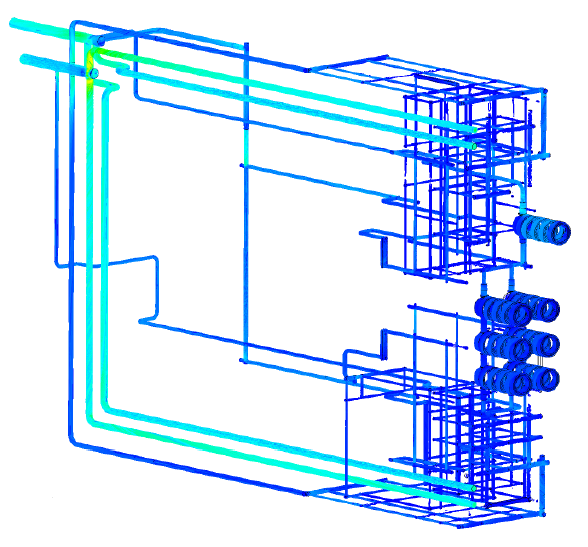

Thermal load can reach units of megawatts, and it is voluminous - it means that all port-plague structures must be penetrated by channels with flowing water for cooling.

In the case of plasma breakdowns, the port-plug structure will induce currents with a capacity of hundreds of thousands of amperes, which causes not only additional heating, but also electromagnetic forces (due to interaction with the magnetic field of the tomak) thousands of tons that need to be calculated, taken into account and designed design so that it can withstand these efforts.

Electromagnetic calculation of the upper port DZM. The current currents, interacting with the ITER magnetic field, create “pulling out” DZM from the nest effort of the scale of tens of tons of force.

Yes, due to the presence of tritium in the port-plug reactor is a non-proliferation barrier. It is necessary to prove to the French atomic inspection that at all possible loads (for example, seismic) the barrier will not be broken.

And also to diagnose all the welds that will be in this design to show that they will not flow. This task is complicated by a puzzling geometry, in which it is almost impossible to get close to some seams from two sides to make X-ray control.

Let me remind you that this construction should work for at least 15 years, and it should be serviced at best by personnel with limited access time and in protective clothing, and better by robots.

Thermohydraulic calculation of DZM cooling channels. Drilling in solid metal through windows with the subsequent welding of windows is a separate topic in the field of blanket and port plug engineering.

Are you a little? Now imagine that the engineering of this installation is done by teams located in France, Russia, India, the USA and South Korea.

As a result, any, even the slightest change in design leads to the need for numerous recalculations, approvals, and most likely - the following design changes.

Russia is responsible for the integration of scientific equipment and the design of the inserts of the equatorial port number 11 (where there will be 8 scientific systems, which we will talk about later) and the upper ports number 2 and 8. “Integration” means the design and manufacture of a structure that combines 8 diagnostics and fulfill all the requirements mentioned above. This work is carried out by the Novosibirsk Institute of Nuclear Physics (INP), about 30 people are involved in it. While the INP team is preparing for the preliminary protection of the project in Cadarache, the actual production of prototypes needed to protect the technical design of the equatorial port equipment number 11 will begin in a couple of years.

Equatorial port number 11 is the first ITER diagnostic assembly, which will be installed on the reactor, and diagnostics, already needed for the first plasma (which is scheduled for December 2025), are collected to analyze plasma behavior in a car. These included:

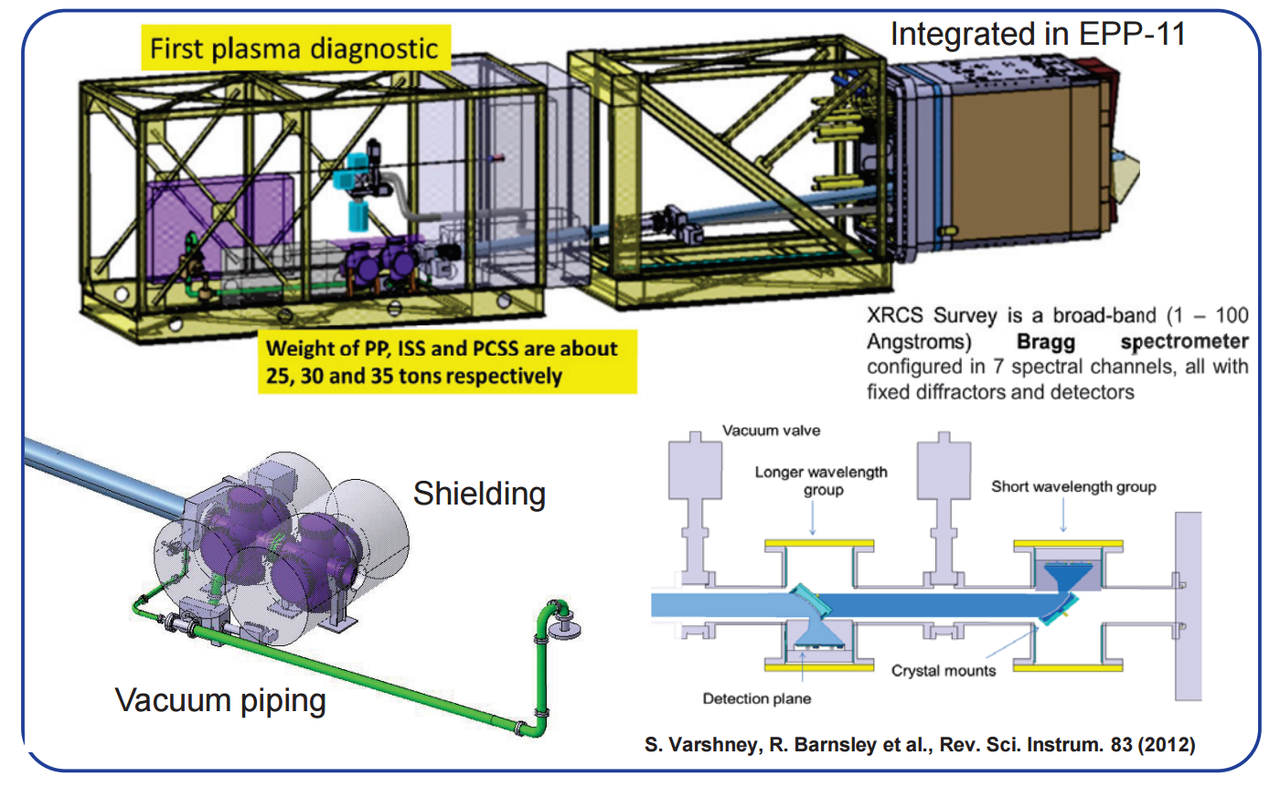

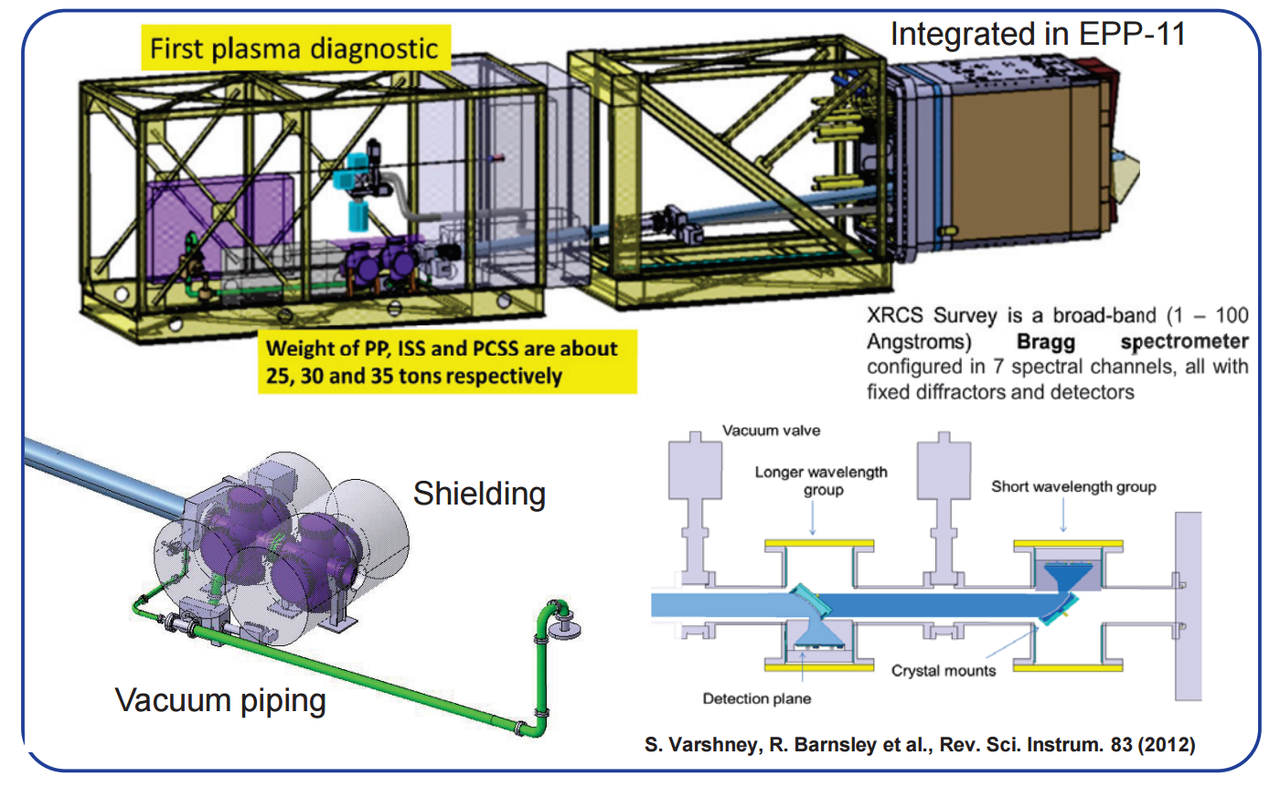

Indian X-ray Crystal Spectrometer

The elements of eight diagnostics are assembled in the form of three blocks, which are joined at the ITER port: the port-plug, the supporting frame in the continuation of the port (OPOP), the supporting frame of the port camera. The most difficult to develop is the port-plug - the vacuum part of the assembly, the weight of which can not exceed 45 tons.

The port-plug consists of a shell supplied by ITER-IO, diagnostic first walls protecting the port from electromagnetic radiation (10 mm of beryllium are located on an intensively cooled copper base) and plasma, and diagnostic protective modules absorbing neutron radiation - structurally port The plug is similar to the protection modules and the first wall of the ITER blanket.

The assembled port-plug is inserted into the port (ideally with the help of robots) and sealed with a bolt flange, and the flange itself is also closed with a protective cover with protective vacuum. The first support frame is connected to the portplag, which connects the continuation of diagnostics paths (as well as cooling pipelines, electrical connectors of port port instrumentation, shafts and rods for adjusting mirrors, etc.) to the vacuum windows on the port plag flange. All these elements are structurally located inside the cryostat, i.e. in the reactor shaft. Behind the first support frame there is a biosecurity plug protecting against gamma radiation of plasma and activated reactor structures, and behind it - the second frame, with the main mass of the measuring equipment.

Port-plag vacuum flange and its docking mechanization of diagnostic paths and cooling piping.

It is interesting that today none of the port integrators fulfilled the combination of requirements at the port-plug of 45 tons of maximum weight and attenuation of the neutron flux by 10 ^ 7 times. These requirements were written into the ITER preliminary draft as feasible, but in practice it turned out that it was impossible to fulfill them with the help of steel-water protection. Now, boron carbide protection is introduced into the port-plug design - although it is not desirable for reactor vacuum (boron releases helium under the neutron flux, which needs to be pumped out, which gives an unplanned load to the ITER vacuum system).

This episode again shows that decomposition and parallel development of such complex systems will always come across a lack of a common understanding at the stage of splitting the task into small ones.

The calculation of the neutron flux and energy release from neutrons in the construction of the port plug EP11. An energy release of 5 W / cm3 means that a cup of water will boil in a minute, and the steel bar will heat up to 250 C.

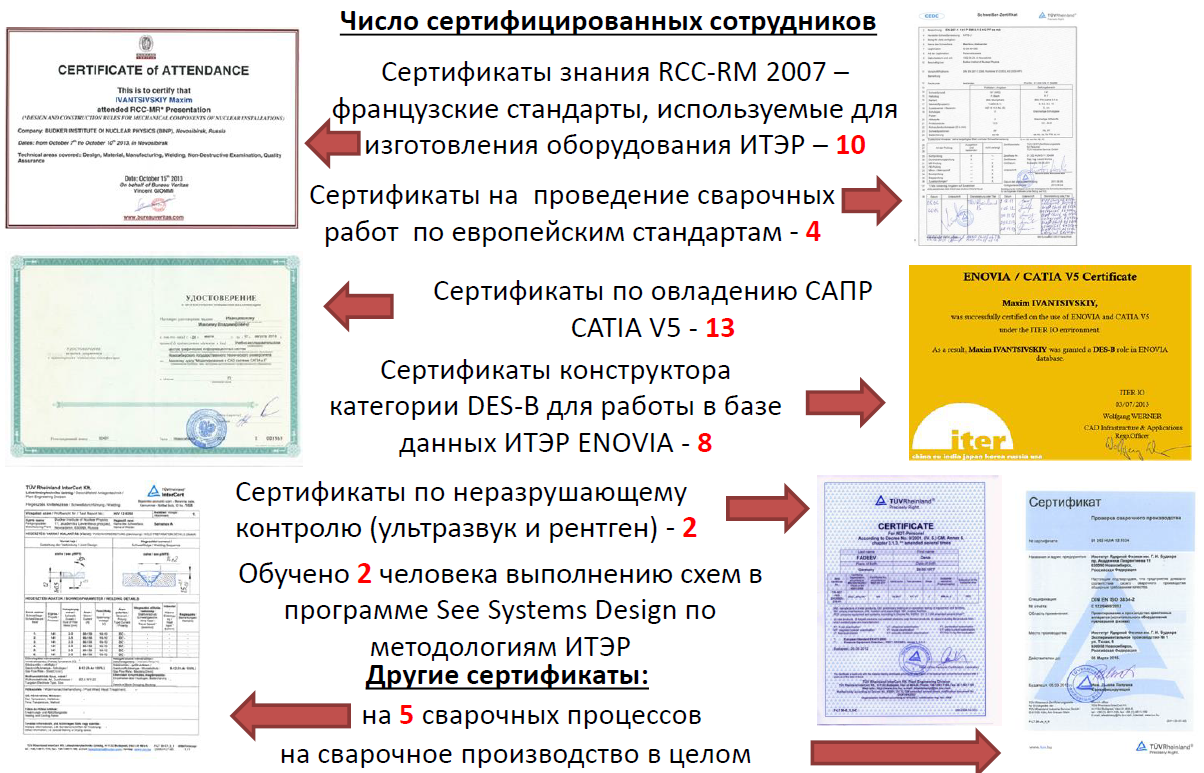

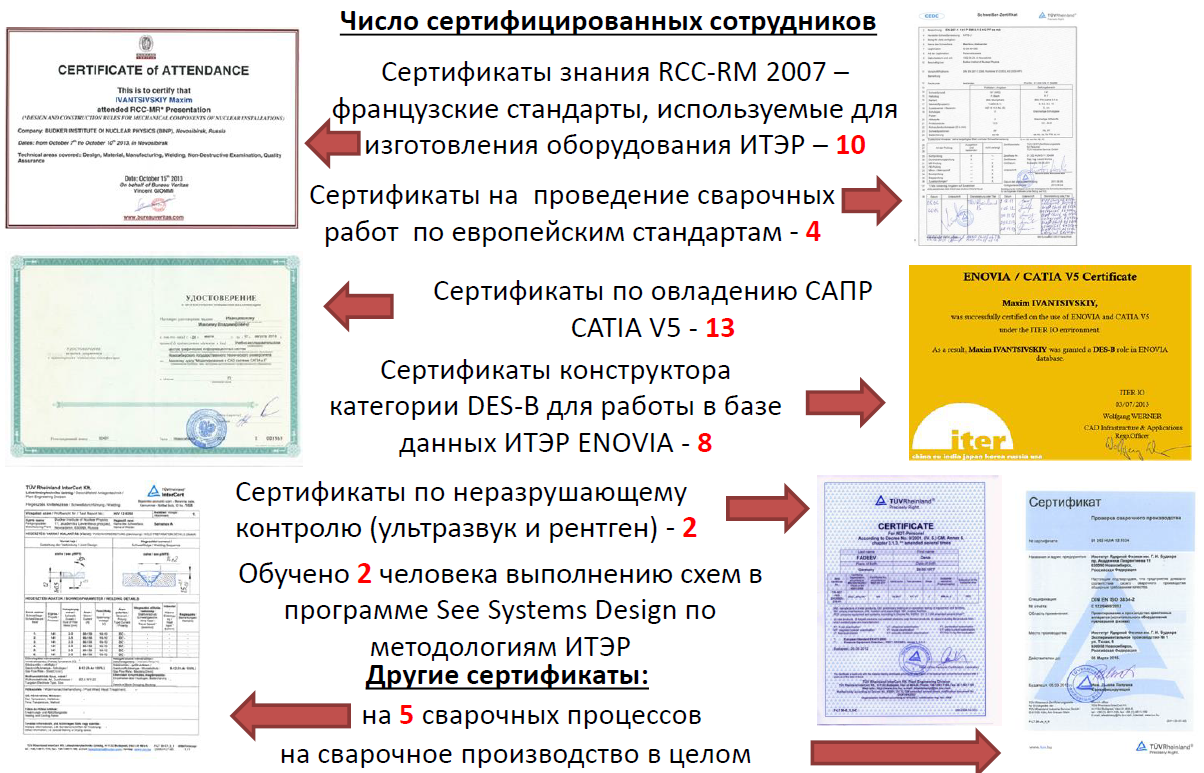

An important story for port plug-in integrators is that ITER is a nuclear installation. It is necessary not only protection against ionizing radiation, but also the organization of nonproliferation barriers from the tokamak vacuum chamber - i.e. after the first thermonuclear campaigns, tritium and radioactive dust from the structures will accumulate inside the chamber. From a practical point of view, this means that the entire structure must be certified according to the French nuclear regulation rules ESPN and RCC-MR 2007. And not only the design, but also the methods, knowledge and skills of the designers, the quality system - the amount of paper work can be comparable to volume of design and development work.

The diagnostic assembly of the equatorial port No. 11 will be assembled partially from the standard components of the ITER-IO supply and from the components that will be produced by the INP in its production. For example, here is a prototype of a basket for boron carbide blocks of neutron protection, which is made for testing.

For this project, INP is modernizing its production, including arranging a rather big assembly and test site - let me remind you that the heaviest components here will weigh up to 45 tons.

I think it would be very interesting to look at the production and testing of iron of similar complexity. I’m not afraid to say that today such developments set new records for humanity in engineering complexity, and set the boundaries of the possible.

One of two dozen diagnostic assemblies of the ITER reactor, which will be discussed today

The complexity of engineering structures is a hard-to-measure substance, unlike, for example, from algorithms . Historically, humanity has continuously complicated its structures, machines and systems, and has struggled with increasing complexity both by decomposing into smaller works and performing them in parallel, and by standardizing the experience gained. The first approach can be illustrated, for example, like this: a building is designed not by drawing ready-made pieces with all the elements (structure, electrics, ventilation, facades, water communications, etc.), but parallel from the general concept by different people. The second approach manifests itself in the use of standard components, the elaboration of ready-made algorithms and solutions (“for copper wiring wires, the maximum current value is 8-10 amperes / mm2” - no one has to investigate the question of what current will not cause a fire, this is already the norm and rule developer).

However, decomposition and parallelization of tasks of engineering creativity has an obvious downside - the drop in recoil for each person added. Communication, search for errors and synchronization of development processes take up an increasing part of the man-hours spent.

')

It is especially bad where decomposition is not easy, where there are a lot of related problems, and solutions for one pull the need to redo the other. In practice, such difficulties arise where at one point many different disciplines converge, in which different specialists are engaged, who have little knowledge of the “clearing” of each other. For example, if for the development of design drawings, it is necessary to take into account calculations on neutron physics, thermal mechanics and thermal hydraulics, electromagnetic forces and, at the same time, the requirements of a mass of engineering disciplines — vacuum technology, reliability of nuclear pressure vessels, manufacturability and assembly, serviceability of robots ... it seems you understand what installation I say.

Today we will talk about diagnostic assemblies, otherwise known as “diagnostic port plug-ins” - less ambitious than the main ITER systems, but incredibly complex and precision devices.

Floor Plan ITER. In the center of the reactor shaft, around it - the port chamber (Port Cells), which can be inserted heating system, test blanket assembly or diagnostic assembly

ITER diagnostics refers to equipment that measures some plasma parameters (namely, plasma, sensors that measure the state of a machine are called “instrumentation”). Those. in fact, these are scientific instruments of the reactor. For example, this could be a neutron monitor measuring the neutron flux from a plasma, which characterizes the fusion power of a reactor. Or a microwave reflectometer that receives the temperature and density profile of the plasma across the plasma cord. In total, 47 diagnostic systems of all imaginable types (and more than ten thousand instrumentation sensors only at the reactor) will be installed on ITER.

Diagnostic systems in the scale of the ITER structure (highlighted in green). The physical parts of the devices are collected in diagnostic assemblies in the ports, and the electronics and servers are moved to a separate attached building.

Since the plasma in tokamaks is surrounded by a vacuum chamber and powerful cell magnets , access to the plasma is possible only through the openings in these two systems. In ITER, the openings are called ports and are organized on three tiers: the lower - divertor, equatorial in the middle and the upper tier is called the upper. A total of 44 ports: 9 divertor, 17 equatorial and 18 upper.

Port cells, connecting pipes, vacuum chamber. By the way, pay attention to the accordions on the connecting pipes - they are needed to compensate for the change in the size of the reactor during cooling down and any movements caused by plasma breakdowns

The ports have different purposes: some of them look at the plasma through heating systems ( radio frequency , for example, IRCH antennas), 4 diverter ports will be occupied by cryo-sorption pumps , some will be accessed by robots inside the torus, 3 equatorial ports will be occupied by experimental assemblies of the propagating blanket (here lithium tritium and evaluation of various engineering variants of such a blanket), finally 6 equatorial and 11 upper ports will be occupied with diagnostics.

The location of the diagnostic assembly equatorial port number 1. Piece with gray tubes - a radial neutron chamber that receives a neutron image of a low resolution neutron plasma field

An insertion port is made for each diagnostic port - a long assembly weighing up to 150 tons, which can be installed and removed by the ITER robotic service system. This assembly includes up to 10 scientific instruments, their protection and cooling from neutron and electromagnetic radiation from plasma, the necessary communications, etc.

Diagnostic assembly equatorial port number 11, developed in the Novosibirsk INP. Assembly length - about 17 meters.

Because of their location in the port plug, the conflicting demands of many disciplines converge. Let's start by listing them:

The port insert includes the front vacuum part (called the port-plug) and the rear atmospheric part (called the port-camera insert), which means all communications are broken by vacuum-tight closures, windows, etc. At the same time, the vacuum part of the port-plaga should satisfy the extremely harsh conditions of the ITER ultra-high vacuum torus, which means such requirements as a narrow choice of materials, the absence of closed cavities (which can be etched by air residues), for example, deaf threads, the need to clean the entire vacuum unit from organic contamination before installation in the reactor.

Therefore, all optical / microwave paths must be led through such vacuum-tight windows, and electrical connectors must be made with an intermediate cavity with a protective vacuum.

The entire port insert design, including the precision optical systems of scientists, must be assembled by robots with a low accuracy, which means that all systems requiring precise installation must be able to adjust - to have movable mirrors. In addition, the docking of all communications should also be done automatically - it turns out very, very automated system of this type, which no one in the world has yet done.

One of the engineering nightmares of ITER are optical systems that transmit plasma radiation to the tail spectrographs removed to the tail. There are problems of thermal deformations, problems of alignment, problems of cleaning optics, and problems of “divorcing” the neutron flux and the light flux.

The whole structure will be subjected to neutron irradiation more rigid than in nuclear reactors, therefore neutron protection from steel, water and boron carbide will be located ahead. In order for the assembly design not to turn into highly radioactive waste, neutron radiation to the rear of the port plug must be attenuated 10 million times. At the same time, it is necessary to bend in defense all the channels of diagnostics, looking at the plasma so that neutrons cannot pass straight back through these channels. If it is impossible to bend the channels (for example, there are no mirrors for X-rays, gamma radiation, neutron radiation), then it is necessary to surround them with separate elements of neutron protection.

An example of a thermal-hydraulic calculation of the most thermally loaded elements of a portplag (diagnostic protection modules)

Here is an example of optimizing the cooling of an optical assembly.

Protection against neutron and electromagnetic radiation (called diagnostic protective blocks DZM and diagnostic first wall DPS) will be exposed to the most powerful heat flux from a thermonuclear reaction, going a few meters.

Thermal load can reach units of megawatts, and it is voluminous - it means that all port-plague structures must be penetrated by channels with flowing water for cooling.

In the case of plasma breakdowns, the port-plug structure will induce currents with a capacity of hundreds of thousands of amperes, which causes not only additional heating, but also electromagnetic forces (due to interaction with the magnetic field of the tomak) thousands of tons that need to be calculated, taken into account and designed design so that it can withstand these efforts.

Electromagnetic calculation of the upper port DZM. The current currents, interacting with the ITER magnetic field, create “pulling out” DZM from the nest effort of the scale of tens of tons of force.

Yes, due to the presence of tritium in the port-plug reactor is a non-proliferation barrier. It is necessary to prove to the French atomic inspection that at all possible loads (for example, seismic) the barrier will not be broken.

And also to diagnose all the welds that will be in this design to show that they will not flow. This task is complicated by a puzzling geometry, in which it is almost impossible to get close to some seams from two sides to make X-ray control.

Let me remind you that this construction should work for at least 15 years, and it should be serviced at best by personnel with limited access time and in protective clothing, and better by robots.

Thermohydraulic calculation of DZM cooling channels. Drilling in solid metal through windows with the subsequent welding of windows is a separate topic in the field of blanket and port plug engineering.

Are you a little? Now imagine that the engineering of this installation is done by teams located in France, Russia, India, the USA and South Korea.

As a result, any, even the slightest change in design leads to the need for numerous recalculations, approvals, and most likely - the following design changes.

Russia is responsible for the integration of scientific equipment and the design of the inserts of the equatorial port number 11 (where there will be 8 scientific systems, which we will talk about later) and the upper ports number 2 and 8. “Integration” means the design and manufacture of a structure that combines 8 diagnostics and fulfill all the requirements mentioned above. This work is carried out by the Novosibirsk Institute of Nuclear Physics (INP), about 30 people are involved in it. While the INP team is preparing for the preliminary protection of the project in Cadarache, the actual production of prototypes needed to protect the technical design of the equatorial port equipment number 11 will begin in a couple of years.

Equatorial port number 11 is the first ITER diagnostic assembly, which will be installed on the reactor, and diagnostics, already needed for the first plasma (which is scheduled for December 2025), are collected to analyze plasma behavior in a car. These included:

- Reflectometer of the weak field (USA) - microwave broadband radar (15-220 GHz) studying the distribution of electron density along the plasma profile. Important diagnostics that measure the density and temperature characteristics of the plasma.

- Residual gas analyzer (USA) - a mass spectrometer that measures the chemical composition of gases remaining in the vacuum chamber after pumping

- Spectrometer of hydrogen lines H-alpha (Russia). One of the most important diagnostics of the reactor, which studies the spatial distribution of hydrogen isotopes for understanding plasma behavior - MHD and ELM instabilities, transition to the H-mode of confinement and other basic plasma physics.

- Neutral Particle Analyzer (Russia) is an analogue of a residual gas analyzer, but performing this work with a neutral (non-ionized) plasma component. Allows independent study of the content of various chemical elements in the plasma. It is interesting because it requires a direct channel from the plasma (without windows, valves and protections) 12 meters long and heavy protection around this channel and the device.

- A gamma-ray spectrometer and a neutron spectrometer combined with the channel of the previous instrument for measuring the properties of thermonuclear plasma combustion.

- Spectrometer of the vacuum ultraviolet of the main part of the plasma (VUV-M) and the divertor region (VUF-D) (Korea). An important tool for studying the concentration of elements heavier than helium in plasma. At thermonuclear temperatures, these elements very quickly cool the plasma with radiation, so the fight against them (and the measurements of concentration) is put on a large foot. In the vacuum ultraviolet light heated ions from beryllium to argon.

- Neutron activation analysis system (Korea). One of the neutron diagnostics, arranged very interesting is actually a pneumatic mail with a small capsule, in which samples of various materials (indium, silver, cobalt, hafnium, chromium, etc.) are located, which are activated by the neutron flux. After exposure to the stream, the capsule is delivered to the diagnostic system, where the content of activated nuclides is measured by a gamma spectrometer and the fluence (power) and the neutron flux spectrum are calculated.

- X-ray crystal spectrometer (India) is another tool for determining the concentration of heavy elements in a plasma, this time mainly tungsten, iron, chromium, nickel, copper, etc.

Indian X-ray Crystal Spectrometer

The elements of eight diagnostics are assembled in the form of three blocks, which are joined at the ITER port: the port-plug, the supporting frame in the continuation of the port (OPOP), the supporting frame of the port camera. The most difficult to develop is the port-plug - the vacuum part of the assembly, the weight of which can not exceed 45 tons.

The port-plug consists of a shell supplied by ITER-IO, diagnostic first walls protecting the port from electromagnetic radiation (10 mm of beryllium are located on an intensively cooled copper base) and plasma, and diagnostic protective modules absorbing neutron radiation - structurally port The plug is similar to the protection modules and the first wall of the ITER blanket.

The assembled port-plug is inserted into the port (ideally with the help of robots) and sealed with a bolt flange, and the flange itself is also closed with a protective cover with protective vacuum. The first support frame is connected to the portplag, which connects the continuation of diagnostics paths (as well as cooling pipelines, electrical connectors of port port instrumentation, shafts and rods for adjusting mirrors, etc.) to the vacuum windows on the port plag flange. All these elements are structurally located inside the cryostat, i.e. in the reactor shaft. Behind the first support frame there is a biosecurity plug protecting against gamma radiation of plasma and activated reactor structures, and behind it - the second frame, with the main mass of the measuring equipment.

Port-plag vacuum flange and its docking mechanization of diagnostic paths and cooling piping.

It is interesting that today none of the port integrators fulfilled the combination of requirements at the port-plug of 45 tons of maximum weight and attenuation of the neutron flux by 10 ^ 7 times. These requirements were written into the ITER preliminary draft as feasible, but in practice it turned out that it was impossible to fulfill them with the help of steel-water protection. Now, boron carbide protection is introduced into the port-plug design - although it is not desirable for reactor vacuum (boron releases helium under the neutron flux, which needs to be pumped out, which gives an unplanned load to the ITER vacuum system).

This episode again shows that decomposition and parallel development of such complex systems will always come across a lack of a common understanding at the stage of splitting the task into small ones.

The calculation of the neutron flux and energy release from neutrons in the construction of the port plug EP11. An energy release of 5 W / cm3 means that a cup of water will boil in a minute, and the steel bar will heat up to 250 C.

An important story for port plug-in integrators is that ITER is a nuclear installation. It is necessary not only protection against ionizing radiation, but also the organization of nonproliferation barriers from the tokamak vacuum chamber - i.e. after the first thermonuclear campaigns, tritium and radioactive dust from the structures will accumulate inside the chamber. From a practical point of view, this means that the entire structure must be certified according to the French nuclear regulation rules ESPN and RCC-MR 2007. And not only the design, but also the methods, knowledge and skills of the designers, the quality system - the amount of paper work can be comparable to volume of design and development work.

The diagnostic assembly of the equatorial port No. 11 will be assembled partially from the standard components of the ITER-IO supply and from the components that will be produced by the INP in its production. For example, here is a prototype of a basket for boron carbide blocks of neutron protection, which is made for testing.

For this project, INP is modernizing its production, including arranging a rather big assembly and test site - let me remind you that the heaviest components here will weigh up to 45 tons.

I think it would be very interesting to look at the production and testing of iron of similar complexity. I’m not afraid to say that today such developments set new records for humanity in engineering complexity, and set the boundaries of the possible.

Source: https://habr.com/ru/post/397611/

All Articles