What you need to know about resistors?

Resistor: a piece of material that resists the passage of electric current. Terminals are attached to both ends. And that's all. What could be easier?

It turns out that this is not easy at all. Temperature, capacitance, inductance and other parameters play a role in turning a resistor into a rather complex component. And it can be used in circuits in different ways, but we will focus on different types of fixed-value resistors, on how they are made and how they can be useful in different cases.

')

Let's start with the simplest and oldest.

Carbon Composition Resistors

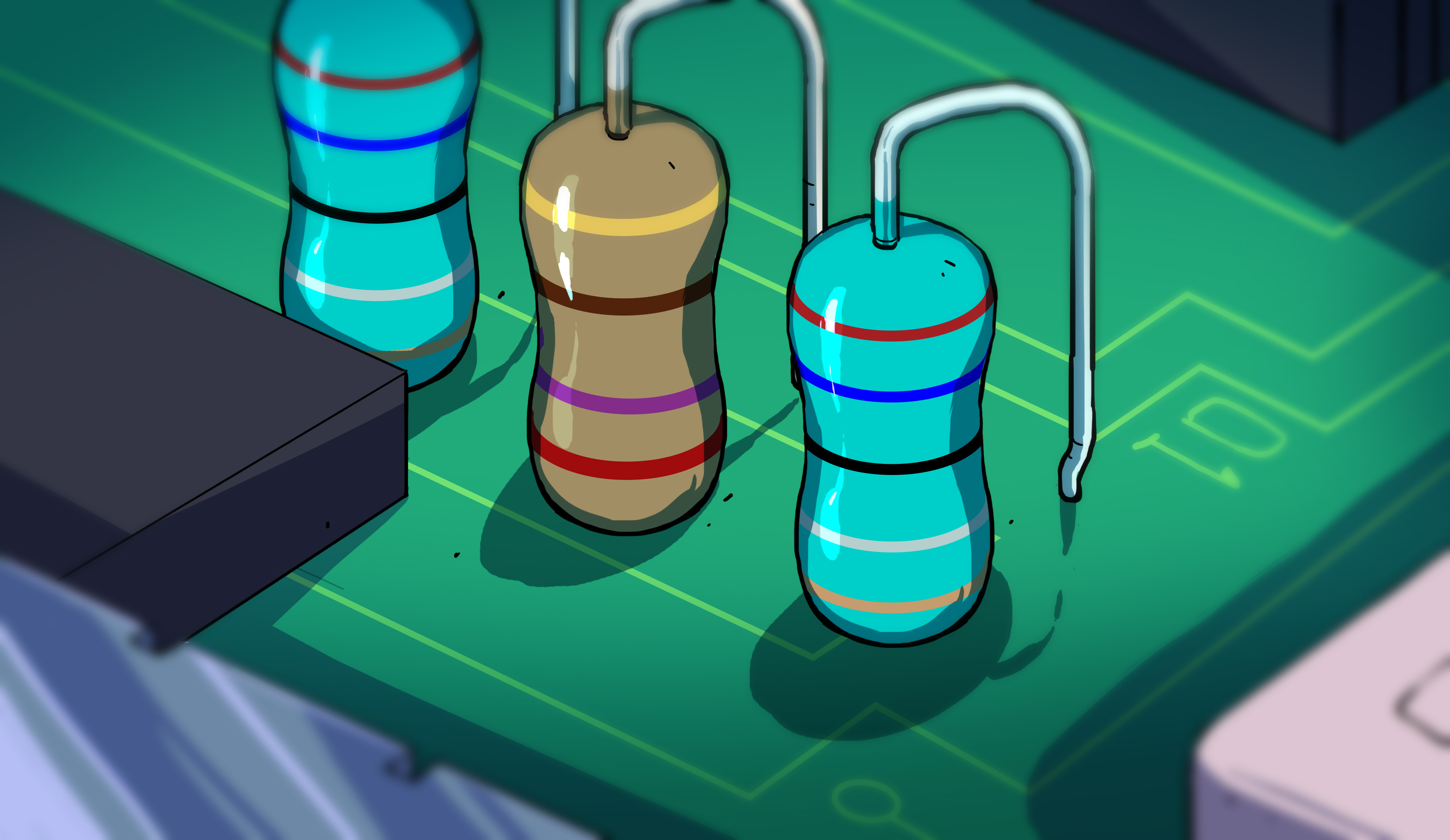

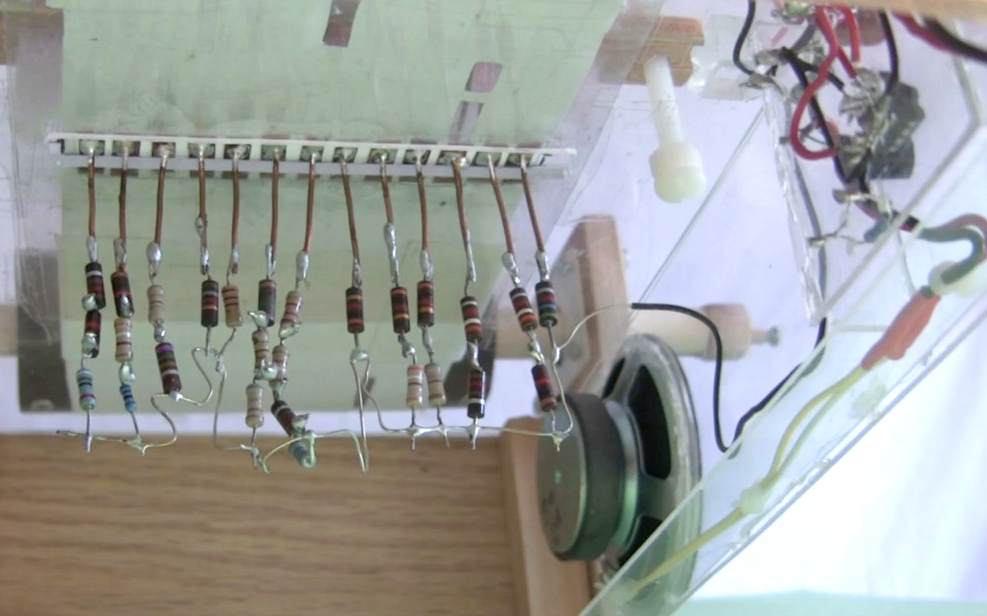

Carbon composite in the player

They are often called "old" resistors. They were widely used in the 1960s, but with the advent of other types of resistors and due to the fairly large cost, their use is now limited. They consist of a mixture of ceramic powder with carbon, bonded with resin. Carbon is a good conductor, and the more it is in the mixture, the less resistance. Wires join at the ends. They are covered with paint or plastic that serves as insulation, and resistance and tolerance are indicated by colored stripes .

The resistance of such resistors can be permanently changed, exposing them to high humidity, high voltage or overheating. Tolerance is 5% or more. This is just a solid cylinder with good high frequency characteristics. They also tolerate overheating, despite their small size, and are still used in power supplies and welding controllers.

However, their age did not stop me from using the bag of such resistors, which I bought in the commission for the purpose of making various resistances that I needed for my musical project. player 555 . The photo is just my work.

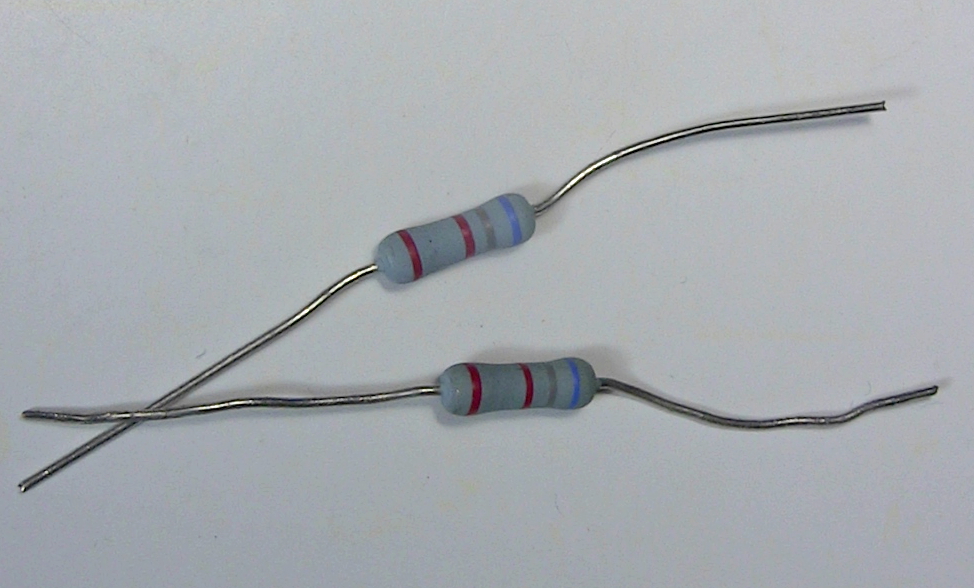

Carbon Film Resistors

Produced by applying a layer of pure carbon on a ceramic cylinder and the subsequent removal of carbon to form a spiral. The result is covered with silicon. The thickness of the layer and the width of the remaining carbon control the resistance, and the tolerance of such resistors is from 2%, better than the previous ones. Due to pure carbon, the resistance varies less with temperature.

The temperature coefficient of resistance of carbon film resistors ranges from 200 to 500 ppm / C - millionths per degree Celsius. 200 ppm / C means that with each degree of resistance will not change more than 200 ohms per MOhm total resistance. As a percentage, this can be expressed as 0.02% / C. If the temperature changes to 80 ° C, at a rate of 200 ppm / C, the resistance of the resistor will change by 1.6%, or by 16 kΩ.

Such resistors are available in nominal values from 1 Ω to 10 kΩ, power from 1/16 W to 5 W and withstand voltages of several kilovolts. Commonly used in high voltage power supplies, X-ray machines, lasers and radars.

Metal film

The metal film is made similar to the carbon image by placing a metal layer (often nickel chrome) on ceramics, followed by cutting out a spiral. According to the documentation from the manufacturer Vishay, after connecting the terminals, the spiral used to be polished, but now lasers are used for this. The result is varnished and marked with color coding or text.

The resistance of metal film resistors varies less than that of carbon film. TCS is in the region of 50-100 ppm / C. 50 ppm / C are similar to 0.005% / C. Using the same example as above with a 1 MΩ resistor, a change in temperature of 80 C in the case of a 50 ppm / C resistor will lead to a change in resistance of 0.4%, or 4 kΩ.

Their tolerance is less than 0.1%. They also have good noise characteristics, low non-linearity and good time stability, and are used for a variety of purposes.

Metal oxide film

The case is similar to a metal film, only commonly used tin oxide mixed with antimony oxide. Such resistors behave better than carbon or metal films, if we talk about voltage, overload, jumps and high temperatures. Carbon film resistors work up to 200 C, metal - up to 250-300 C, and resistors on an oxide film - up to 450 C. At the same time, their stability is very lame.

Wire Resistors

They are made by winding a wire on a plastic, ceramic or fiber glass cylinder. Since the wire can be cut off quite accurately, the nominal value of their resistance can be chosen with great accuracy with a tolerance not worse than 0.1%. To get a high resistance resistor, you need to use a very thin and long wire. The wire can be made thinner for less power or thicker for more power. It can be made from a large number of metals and alloys, including nickel, chromium, copper, silver, chromium steel and tungsten.

Developed with an eye on the ability to work at high temperatures: tungsten withstand temperatures up to 1700 C, silver - from 0 to 150 C. TKS for high-precision wire resistors is about 5 ppm / C. Resistors designed for high power, TKS higher.

Work at capacities from 0,5 W to 1000 W. A few hundred watt resistors can be coated with high-temperature silicon or vitreous enamel. To increase the heat sink can be equipped with an aluminum casing with plates that act as a radiator.

Types of winding

Since these are practically coils, they have inductance and capacitance, which is why they behave badly at high frequencies. To reduce these effects, various tricky schemes of winding are used, for example, bifilar, winding on a flat carrier, and Aerton-Perry winding.

Bifilar winding has no induction, but high capacity. Winding on a flat and thin carrier brings the wires together and reduces induction. Winding Aerton-Perry, due to the fact that the wires go in different directions and are close to each other, reduces self-induction and capacitance, since the voltage at the intersection is the same.

Potentiometers are made on the basis of wire resistors due to their reliability. They are also used in breakers and fuses. Their induction can be increased and used as current sensors, measuring inductive resistance.

Foil resistors

A foil several microns thick, usually made of chromium nickel with additives, is used, which is located on a ceramic substrate. They are the most stable and accurate of all, even though they exist since the 1960s. The required resistance is achieved by foil photo-etching. They do not have inductance, have low capacity, good stability and fast thermal stabilization. Tolerance may be in the range of 0.001%.

TKS is 1 ppm / C. When the temperature changes to 80 C, the mega-ohm resistor will change the resistance by just 0.008% or 80 Ohms. An interesting way in which this accuracy is achieved. As the temperature increases, so does the resistance. But the resistor is made in such a way that an increase in temperature leads to a compression of the foil, due to which the resistance drops. The cumulative effect leads to the fact that the resistance almost does not change.

Well suited for audio projects with high frequency currents. Also suitable for projects requiring high accuracy, such as electronic scales. Naturally used in areas where large fluctuations in temperature are expected.

Thick film and thin film resistors

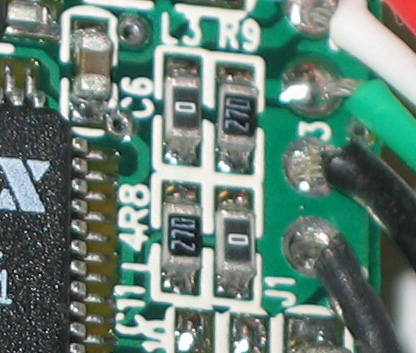

Mainly used for surface mounting. The film in thick-film resistors is 1000 times thicker than thin-film ones. These are the cheapest resistors, since a thick film is cheaper.

Thin-film resistors are made by sputtering nickel-chromium on an insulating substrate. Then photo-etching, abrasive or laser cleaning is applied. Thick films are made by stencil printing. The film is a mixture of binder, carrier and metal oxide. At the end of the process, abrasive or laser cleaning is applied.

The tolerance of thin-film resistors is at the level of 0.1%, and the TCS is from 5 to 50 ppm / C. Thick-film tolerance is 1%, and TKS - 50 to 200 ppm / C. Thin-film resistors make less noise.

Thin-film resistors are used where high accuracy is required. Thick-film can be used almost everywhere - in some PCs you can count up to 1000 thick-film surface-mounted resistors.

There are other types of resistors of constant nominal, but in the boxes for resistors you will most likely find one listed.

Source: https://habr.com/ru/post/397607/

All Articles