WAZER: the world's first desktop water cutter

3D printers are becoming more common and affordable. Devices of this type can buy not only rich companies, but also students or even schoolchildren. With the help of 3D-printers you can create a lot of useful things for work or at home. In addition to these, laser cutters are also being developed, among which there are miniature desktop systems that can be installed at home or in small workshops.

But 3D printers and laser cutters can work with a limited number of materials. For example, not all desktop cutters can handle thick metal. And if glass or ceramics are needed for work, the laser in this case is not suitable at all. What to do? Now there is an opportunity to process these materials. Wazer can handle them - the first water cutter that fits on the table.

The system's developers are ex-classmates of the University of Pennsylvania, who founded the company for the production of portable water cutters. The developers set a goal to create a portable, productive and not too expensive system that could cope with those materials that are not available to the laser.

')

A water cutter is an apparatus that processes solid types of materials using a thin stream of water supplied under very high pressure. Abrasive particles are also added to the water. Usually such devices occupy a whole room, and their cost is several tens of thousands of US dollars. Here is one example of such systems.

An industrial water cutter works with a jet that exerts a pressure of 414-621 thousand kilopascals per square inch. The creators of the desktop “home” cutter had to reduce the pressure, but this did not really affect anything, the system still works with a large amount of materials without any problems. The materials that Wazer can process include glass and metal. The maximum thickness of the metal with which Wazer works is 4 mm. Cut edges are smooth.

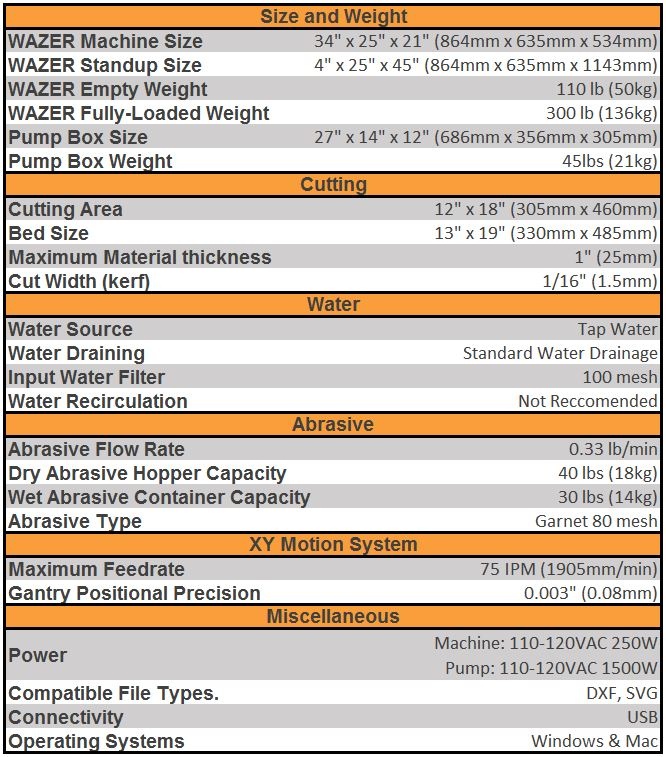

The size of the working platform is only 30 * 46 cm. The supply voltage is 110 volts. The platform is completely closed, so that there will be no splashing or dust on the desktop outside the device during its operation. The advantage of such a system is that it can work with almost any material, the processed particles are collected in a container, and not fly around. No ventilation is required, unlike laser cutters. Plus, the Wazer can work with any material that is afraid of heat.

WAZER comes with its own software. To work with it, you need a ready-made model created in packages such as Solidworks, Adobe Illustrator or Google SketchUp. After the model is loaded and the type of material is set, the software will show how long it takes to process.

Water cutter consists of two parts. Actually, the cutter and the water pump, which can be placed anywhere. If desired, you can change the vertical arrangement of the two elements of the WAZER, to make them even more compact. The main working element of the cutter is the nozzle. Water and abrasive material is supplied here. Garnet is used as an abrasive material. This powder is specially designed for water cutters. It must be used constantly, otherwise the cutter will not work. Such abrasive material can be purchased from both developers and third-party companies. Abrasive is non-toxic.

According to the developers, the portable water cutter works somewhat slower than industrial systems. But at home or in a small workshop, this does not affect anything.

What can be done with such a cutter:

Knife. The processing time of the knife was 118 minutes

Necklace of coins. Processing time was 60 minutes

Rack for baking. Processing time is 95 minutes

Pulley for belt transmission. Processing time 168 minutes

Figure from glass. Processing time 43 minutes

How much it costs?

Now the developers of Wazer are raising funds on Kickstarter . Here you can pre-order it for as little as $ 3,599. In retail, the cost of a water cutter will be about $ 4,500. Customers will receive their system no earlier than August 2017. And sending is not around the world, you need to check the list of countries where developers can send an order.

Now the developers have already collected $ 823264 instead of the planned amount of $ 100000, so the project is likely to be implemented.

Source: https://habr.com/ru/post/397473/

All Articles