The tale of how filters get dirty

Whether long, short, but the filters for the Tion breather with different degrees of contamination (or time of use) have finally reached my playful little hands. This means that it is time to pour a cup of tea and plunge into the wonderful micro-world filtering dust and dirty air.

For intimate details of life filters in real conditions, welcome under cat. Carefully, there will be a lot of photos from the electronic small-scope display.

In the previous article of the corporate blog Tion, the basic principles of operation and the mechanisms for filtering particles on a filter such as HEPA (filter class H11) were described. Filters, even without 100% efficiency, are able to quite effectively capture particles of dirt and dust. Usually, such studies are carried out on model, standard systems, that is, a certain mixture of particles is taken and the filter-pump-filter is chased around until a given amount of air is pumped, then, for example, the mass of the substance settled on the filter is measured.

Below, I will show how the actual filters are contaminated over time using the examples provided by Tion, although, of course, the results can be extrapolated to any modern fiber filters. But we begin, perhaps, with a small lyrical digression.

')

Filters and their manufacturing technology

First , I would like to answer the question of the previous article , given by the user vesper , about which materials are used:

What kind of fibers does the HEPA filter consist of? Not from cotton?

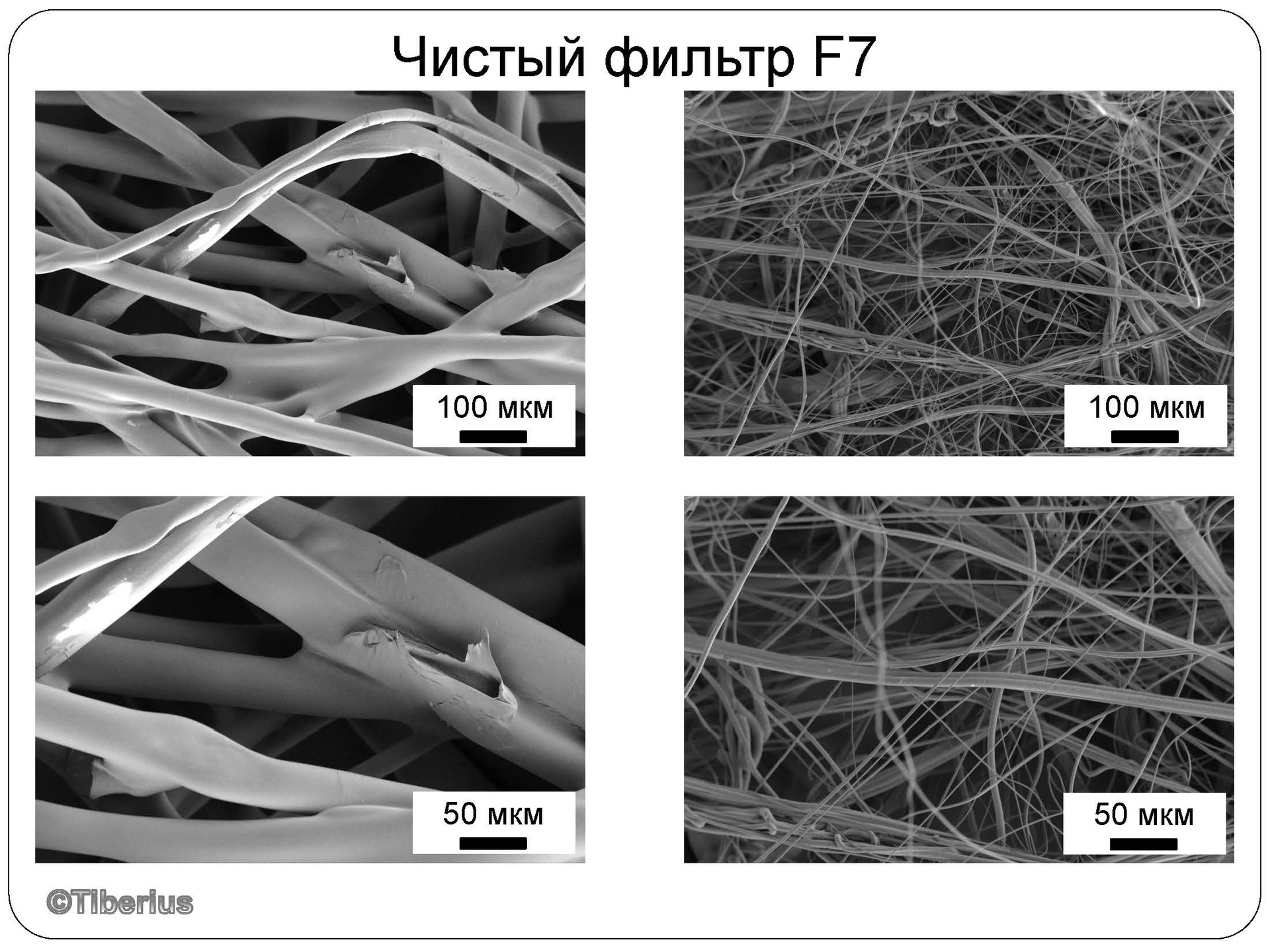

The filter itself consists of two parts; for clarity and brevity, we call them “the base”, which gives the filter rigidity and which practically does not participate in the filtering act, and flexible “filter fibers” with a developed surface (in other words, a large surface area). The difference in the diameters of such fibers exceeds the order and varies from 1 to 10-20 microns or microns (for comparison, the diameter of a standard human hair is about 80 microns)!

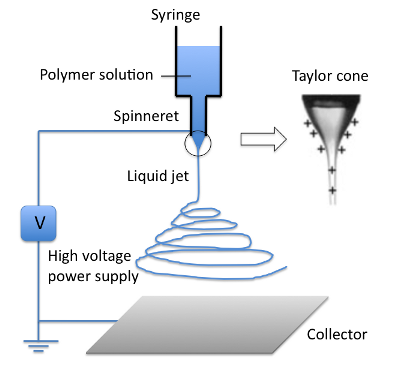

The material from which both parts are made is mainly, of course, polymer or glass fibers, not cotton. The process of obtaining fibers worked out to "automatism" and the most industrialized. Thus, using electrospinning, a polymer or liquid glass that passes through a spinneret (a very thin tube that defines the diameter of a fiber, usually there are many such tubes, thousands or even tens of thousands), is “sprayed” onto the substrate, forming a grid.

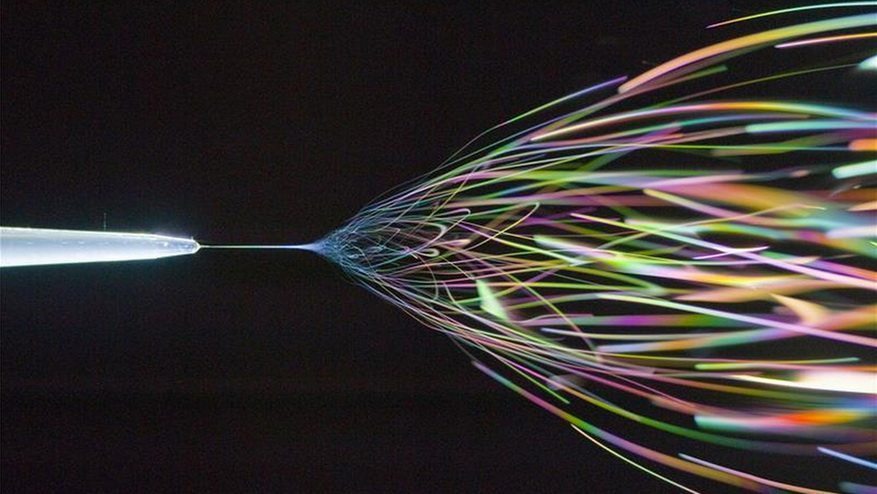

Such a bright and colorful electrospinning. A source

Schematic representation of the process of electrospinning and the formation of a Taylor cone . A source

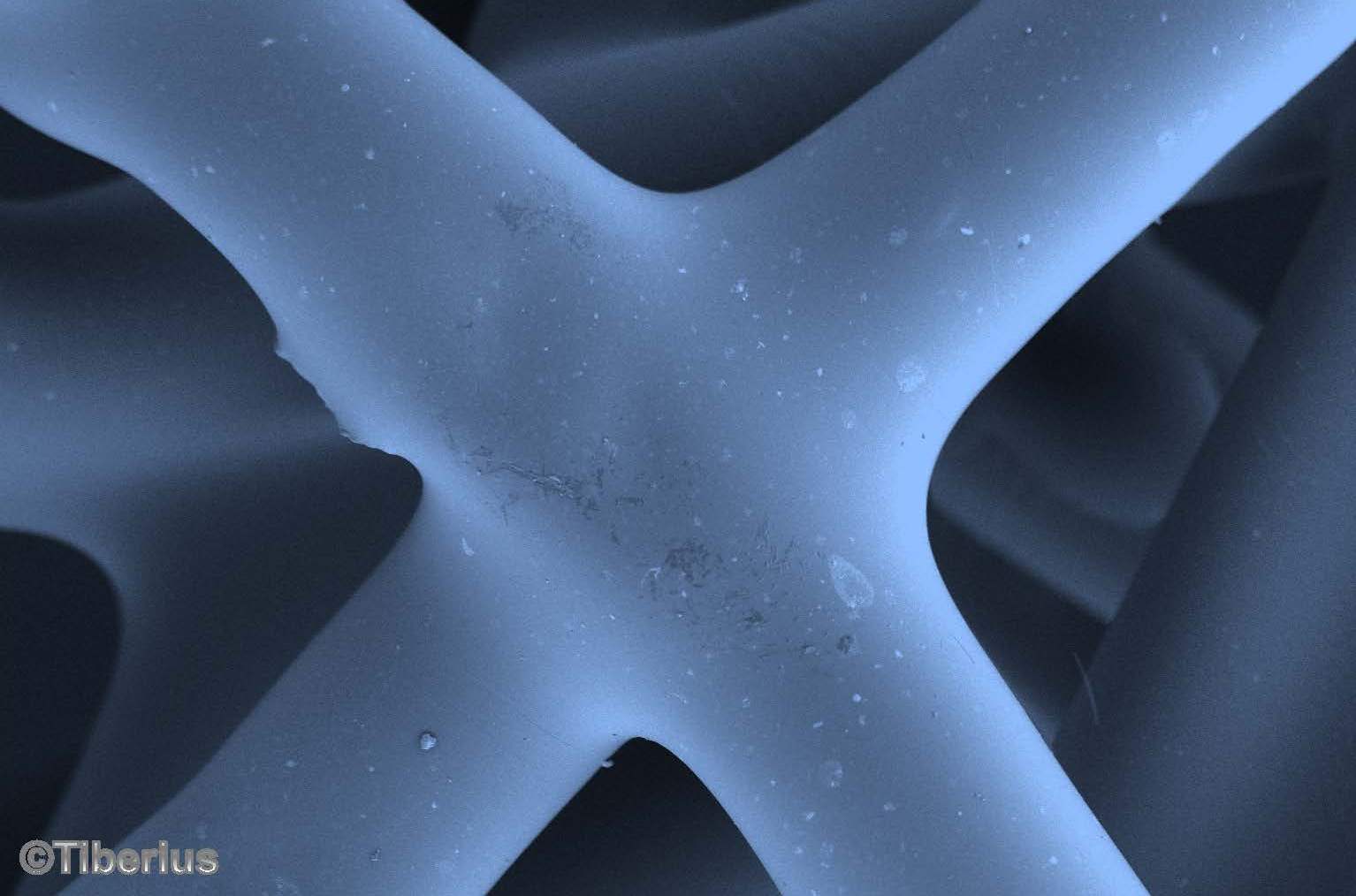

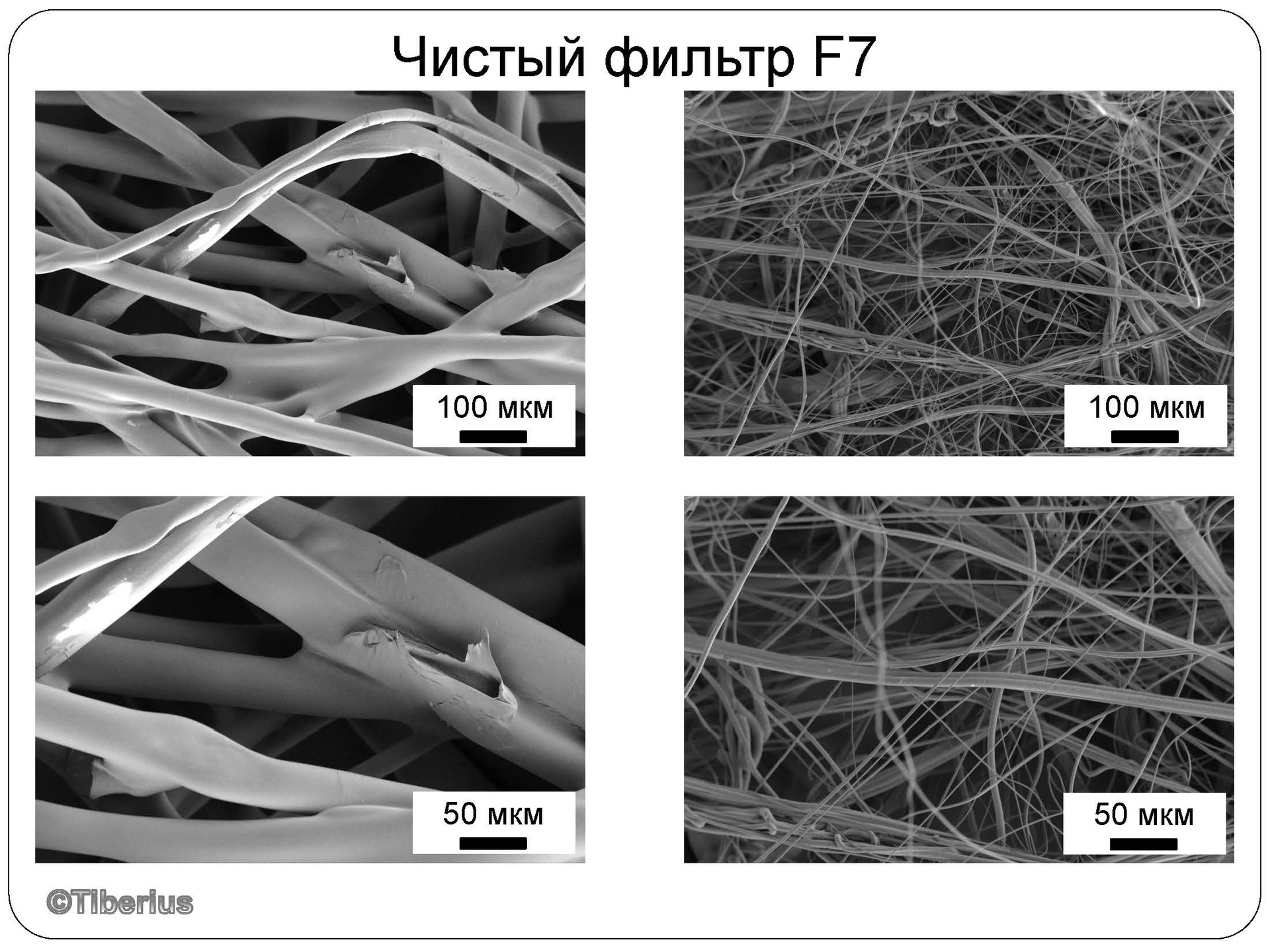

Base (left) and filter fibers (right), obtained by electrospinning

Next, the polymer is cured either by light, or thermally, or in some other way. Hurray filter mat is ready! It remains only to cut and pack.

Of course, the exact composition, parameters forcing through dies and other technological know-how are a trade secret. Although in some ways this process is similar to the creation of heat insulating mats - I happened to somehow visit the Saint-Gobain factory near Yegoryevsk.

Nanofibres and electrostatic forces

Secondly , I would like to make a few clarifications and additions to the material of the previous work.

Why not make nanofibres (increase the area even more)?

If we solve the problem of laminar airflow around an obstacle within the framework of classical hydrodynamics, then we inevitably come to the boundary condition: on the surface of the fibers, the flow velocity should be zero, which creates excellent conditions for the deposition of particles. However, when the size of the obstacle is too small, the so-called effect of slipping appears.

In one interesting work , the hydrodynamics of the process of gas flow around a round fiber is analyzed in detail. The change in the velocity profile or flow mode is described in terms of the Knudsen number . So, for air under normal conditions, the flow slip should be taken into account for fibers thinner than ~ 0.5 micron, which is why the bulk of the fibers for the HEPA filter are made with diameters from 1 to 100 microns. For it is this range of sizes that favors the engagement and deposition of relatively large particles on the surface. However, the efficiency of this deposition mechanism drops significantly for particles smaller than 0.3 microns, which creates certain difficulties.

Profiles of air flow rates near the filtering fiber (a) without and (b) with slippage of incident flow

Slippage is intensively used to create filters with nanoscale fibers, and the filtering mechanism itself changes. Instead of entanglement, particles are deposited mainly at the points of interlacing of fibers, which they are trying to make very, very much.

Tion conducts its own developments in this area, allowing to obtain a very thin mesh of nanofibers to create: “a filtering composite web from a mixture of polypropylene and polyethylene terephthalate with the addition of fiberglass ”. Such a "beast" can even hold the smallest droplets of tar in tobacco smoke.

If electrospinning is used for fiber production, is the fiber charged in the process? Is it worth washing the filter then?

Next, we introduce some clarity in the distribution of forces that arise when dust particles interact with filtering fibers. Since the fibers are formed by the rapid transmission of a polymer melt or glass through dies (often also under the action of an additional electric field), as a result, the fibers bear some excess charge. In addition, an excess charge can additionally be created by processing the material in the plasma. For example, glass and quartz are very often used as natural and inexpensive electrets , in other words, a material with a significant constant charge.

Dust particles flying past charged fibers can effectively “snatch” from the stream due to the action of electrostatic forces (or repel if the fiber and the particle are equally charged). Strange as it may seem, the overwhelming majority of micro and nanoparticles are charged, and even more so dust particles. The charge with ease arises on the surface of the particles due to friction against the air, objects and the corresponding redistribution and separation of charges. Of course, we do not feel this in everyday life, because a few electron charges (1.6 10 -19 pendants) are nothing for us, but for the nanoworld this is a huge amount. For example, on this is built a whole branch of renewable electric power - triboelectricity, about which I wrote earlier (part 1 and 2 ).

Of course, there is a correlation between the fiber charge and the filtration efficiency. Too much charged filtering fiber will simply repel particles that have a charge of the same sign, and the efficiency will drop, but completely neutral filters are not effective enough, therefore the middle ground must be respected.

The attentive reader will notice that there are fully electrostatic filters, which first additionally charge dust particles, and then effectively remove almost all particles with a diameter up to 10 nm! However, this is a completely different story, worthy of a separate article.

Moving from theory to practice: should we wash the filters then ?!

Attempts to return the filter to its original state are doomed to failure, however, some of the contamination can be removed by washing and knocking out, especially large particles or groups of particles. At the same time, such a “restored” filter will serve much less than the new.

I also advise you to read another excellent publication on filters .

The part is experimental. Filters are dirty

So, the following filters were provided for the review: F7 with a duration of 0 and 3 days, 2 weeks and 6 months, which cleaned the fresh taiga air of Novosibirsk, as well as H11 (HEPA) from the northern capital.

Let's start with the primary cleaning filters F7. A noticeable contamination of the filter begins to appear after two weeks of operation in a large city. So dirt, dust and smog metropolis - this is not an empty phrase!

Now take a look at the filters with my favorite electron microscope. Other everyday objects examined at the point of the electron microscope are presented in the articles “The world around us” .

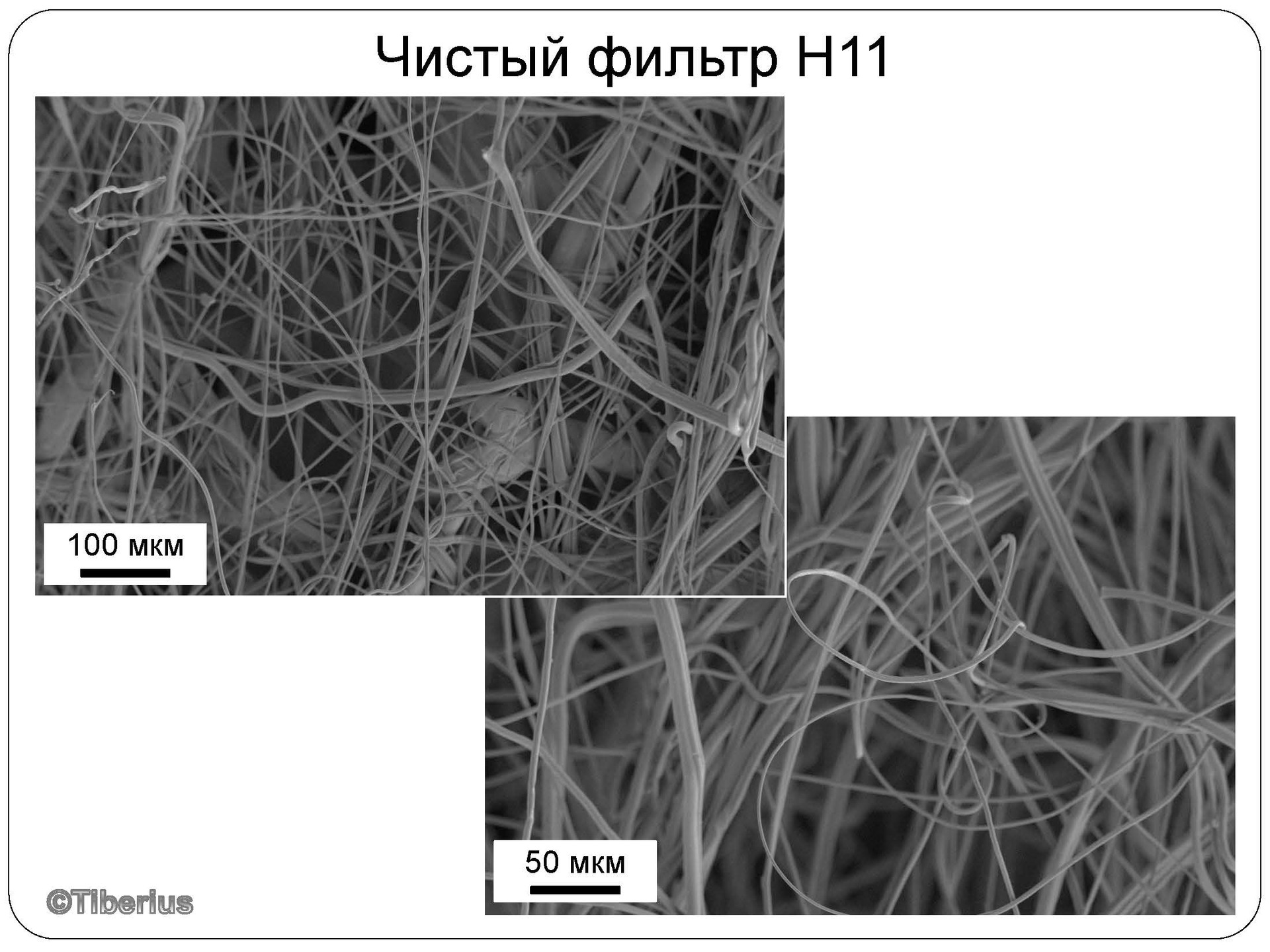

As noted above, the filter consists of two parts - thick base fibers with a diameter of 50-100 microns and fine filter fibers. The fibers themselves are clean and smooth.

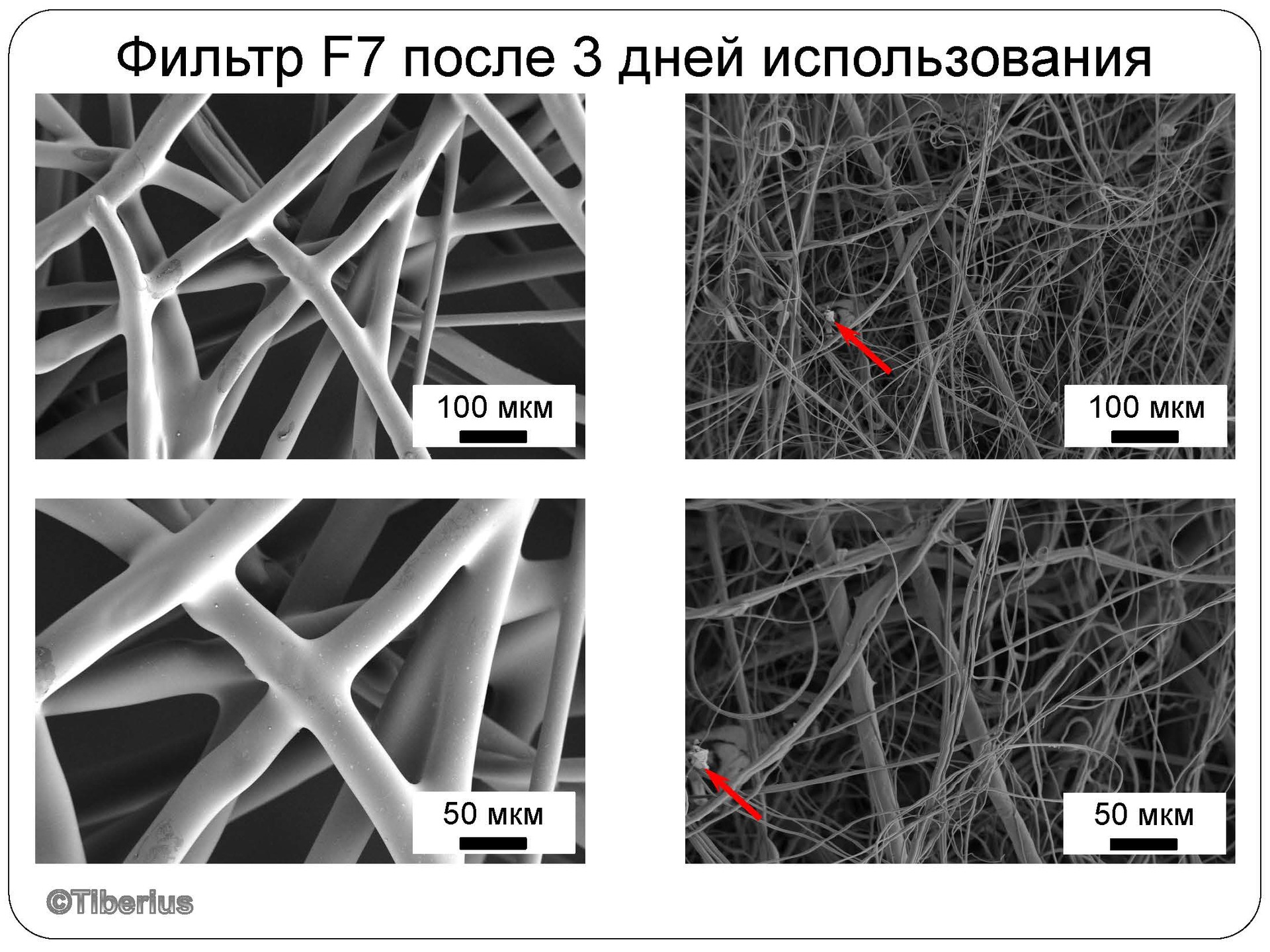

Even after three days of use, it is already possible to notice some large dust particles caught on the fibers (marked with red arrows). Although the base fibers remain relatively clean and, as noted above, do not participate in filtration.

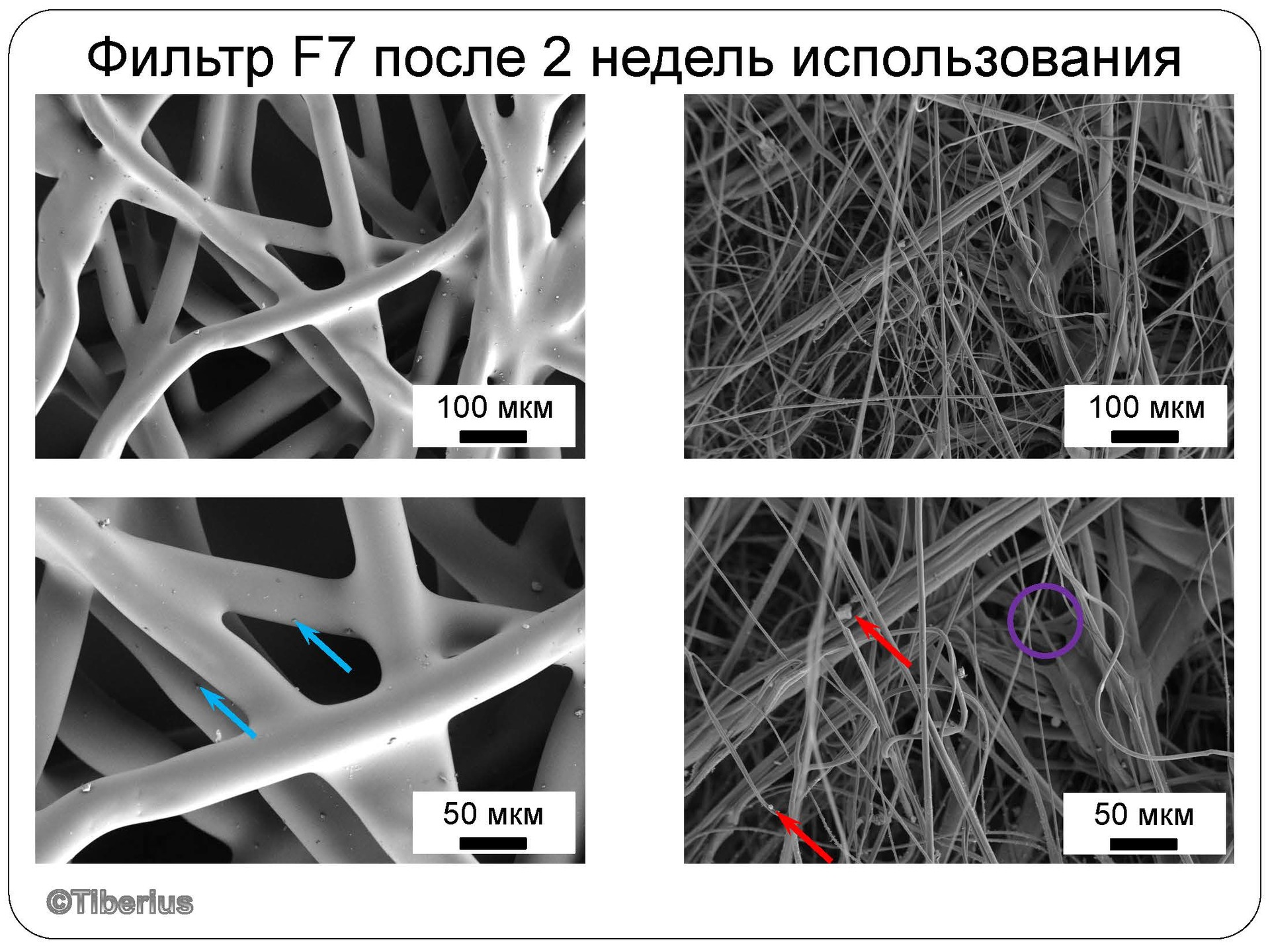

After two weeks, the total amount of pollution increases significantly. Separate fibers are covered with barely visible submicron and even nanoscale particles (in accordance with the IUPAC classification <100 nm, blue arrows), in some places mud "membranes" begin to form (marked with a purple circle).

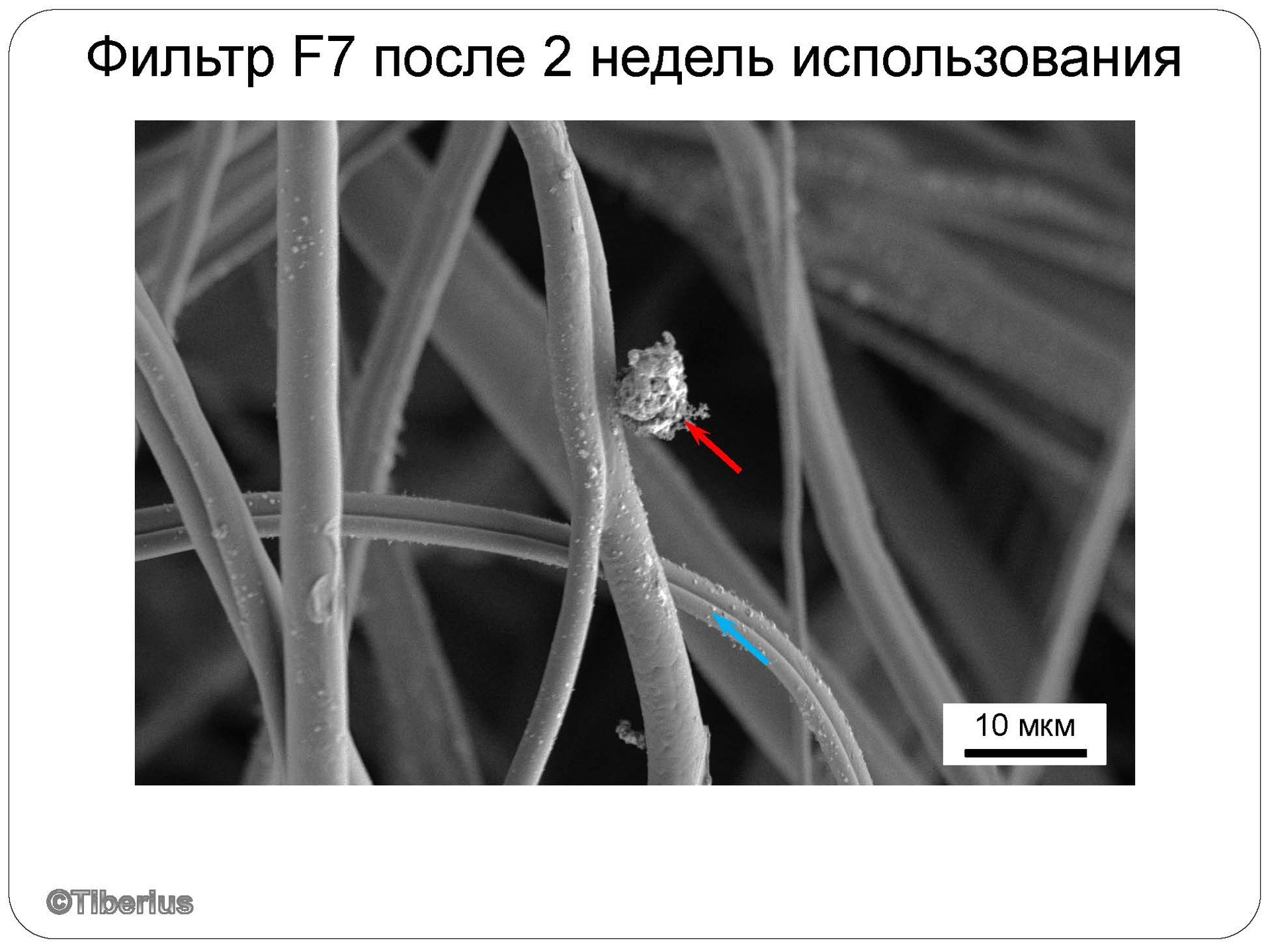

The micrograph below shows this in all black and white details:

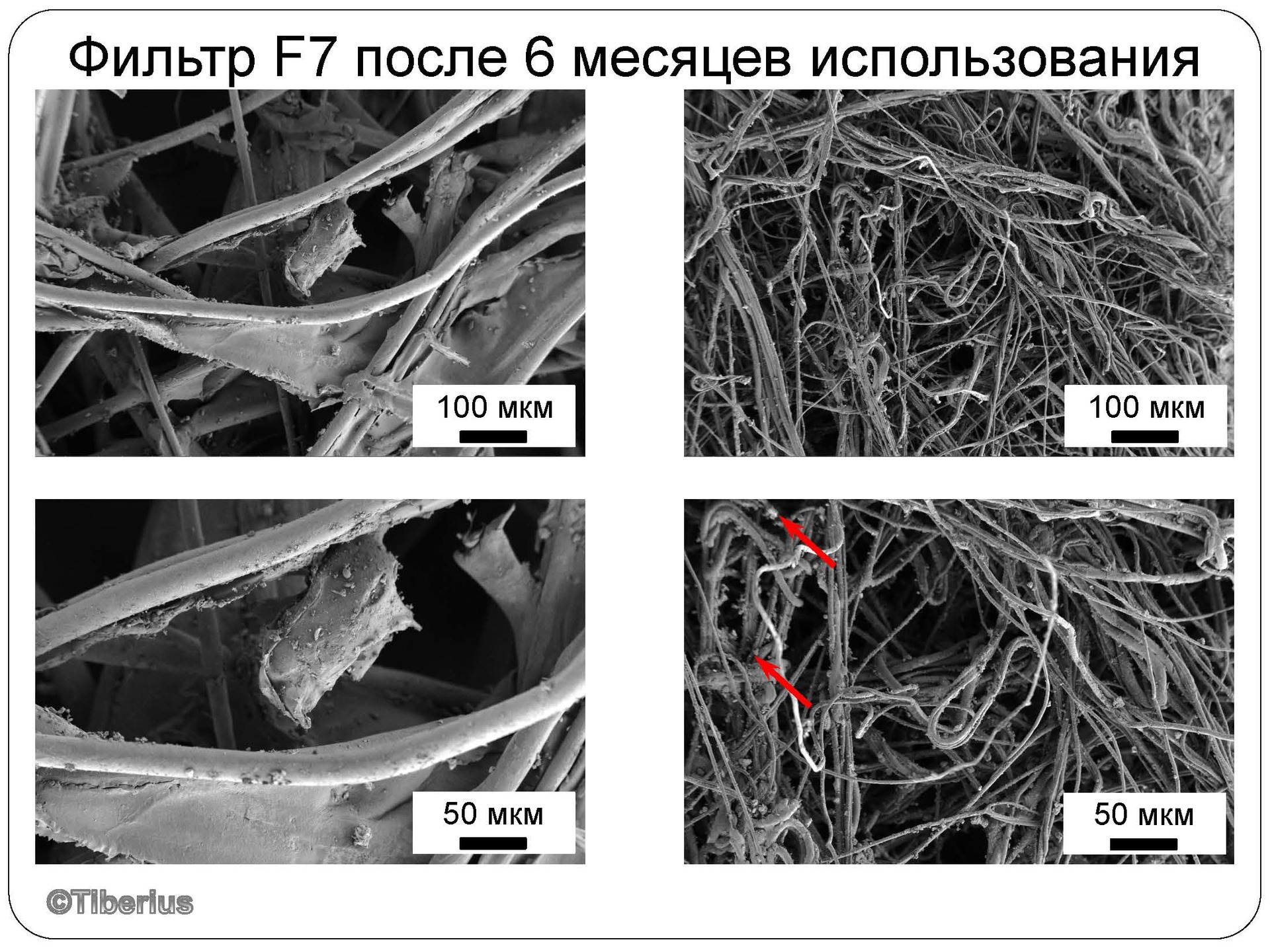

After six months of use, much of the space between the fibers is filled with dust, dirt, and various particles. Films of dirt and dust cover even the thick fibers of the base, not to mention the thin fibers.

Below, in my opinion, is a very representative micrograph showing practically all the mechanisms of particle deposition. Inertia or gearing caused a large particle (red arrow), small particles settled due to diffusion (blue arrow). As a result of the gradual overgrowth of the filtering fiber with such particles, a film is formed on the surface (marked in purple).

In principle, the filter can be shaken out, washed, but it is unlikely that it will be possible to return to a completely new state. It is also worth considering that the charge that was on the surface of the fibers was spent and compensated for by adhering dust particles, and, therefore, the washed filter will still filter and, more importantly, keep the dust worse than new.

Next, we briefly consider the HEPA filter and an example of its operation in real conditions for two weeks.

A clean H11 filter is not much different from the previously considered F7 except for a more dense packing of the filter fiber. That is, HEPA is simply a denser filter with a smaller pore diameter between the fibers.

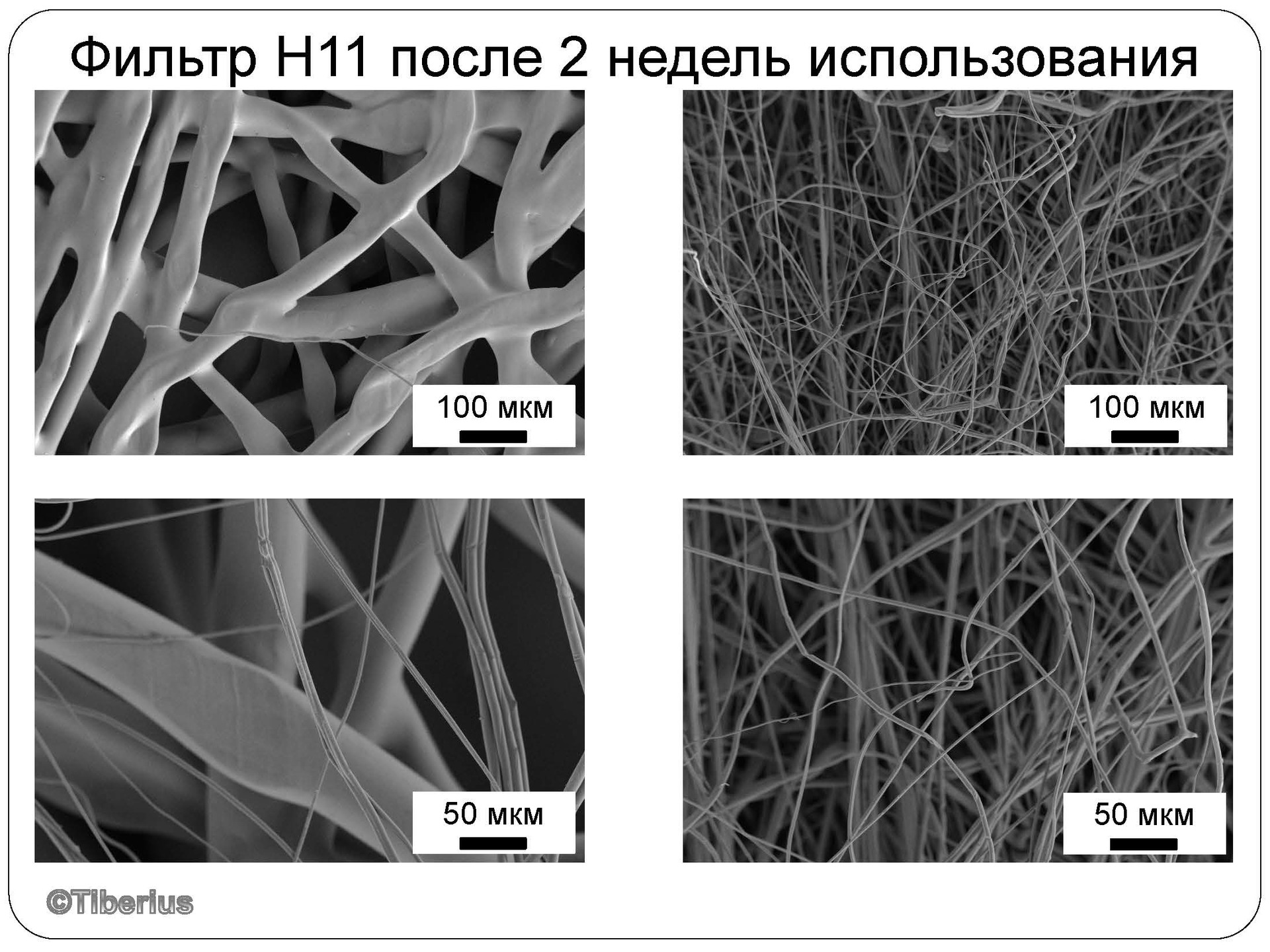

It may seem that after two weeks of using HEPA the filter looks like new, but this is not quite so. Of course, most of the dust and dirt remained on the coarse F7 filter, so large particles are unlikely to be found in large quantities.

However, if we zoom in again at ten, we will easily find that the HEPA filter works by retaining very small particles on the surface of the fibers (blue arrows). As well as the F7 filter, HEPA “grows” over time with a layer of dirt (marked in purple).

Instead of conclusion

It was interesting to trace the evolution of pollution of filters not by model particles on a test bench, but in real operational conditions of a big city (and even two cities!). In fact, it turns out that the filter fibers over time are overgrown with a monolithic layer of dirt and dust, forming "membranes" between the fibers. On the one hand, this is good, as it increases the capture section of new and new particles, on the other hand, the filter material itself becomes less permeable to air, and, consequently, the load on the pump increases.

Answering the question: to change the filter or not to change and wash? - I can answer this way: try, but the washed and / or knocked out one will beat even faster than the new one, again additionally loading the pump.

Text and microphotographs prepared specifically for Tion © Tiberius.

PS: Please report errors and comments on the text through the LAN.

Source: https://habr.com/ru/post/397457/

All Articles