How different is printing on 3D printers for $ 2,200 and for $ 200,000

Every year, home 3D printers are becoming easier to use, faster and more functional. Gradually increases the list of materials for printing. The time is not far off when it will be possible to print metal and glass products at home, and not just plastic ones.

Another big revolution 3D printing promises to make in industry and construction. Now, 3D printers are almost universally used for prototyping, and in the future mass production of high-quality products will probably begin.

')

As home “amateur” 3D printers get better and better, the interesting question arises: how much does home print quality differ from industrial ? This is the question asked by an American engineer and 3D printing enthusiast Mike Skrzypczak (Mike Skrzypczak). For the sample, he went to the manufacturing laboratory of Caterpillar, one of the leading corporations for the production of large machinery.

A very expensive Stratasys Fortus 380 MC printer costing about $ 200,000 has been installed in the laboratory. This 2 meter high printer is designed for making durable prototypes that match the characteristics of the final product, as well as various production tools and production parts that withstand high pressure.

Printer Stratasys Fortus 380 MC

Industrial printer prints with seven types of thermoplastic : ABS-M30; ABS-M30i; ABS-ESD7; ASA; PC-ISO material in white and translucent color; PC; FDM Nylon 12. According to official specifications , the layer thickness is 0.330 mm, 0.254 mm, 0.178 mm or 0.127 mm.

For the print sample, Mike took a real part — an auxiliary device for laying loops in the manufacture of electronic equipment. Previously, such forms were made on the press by molding, but now 3D printing is perfect for this.

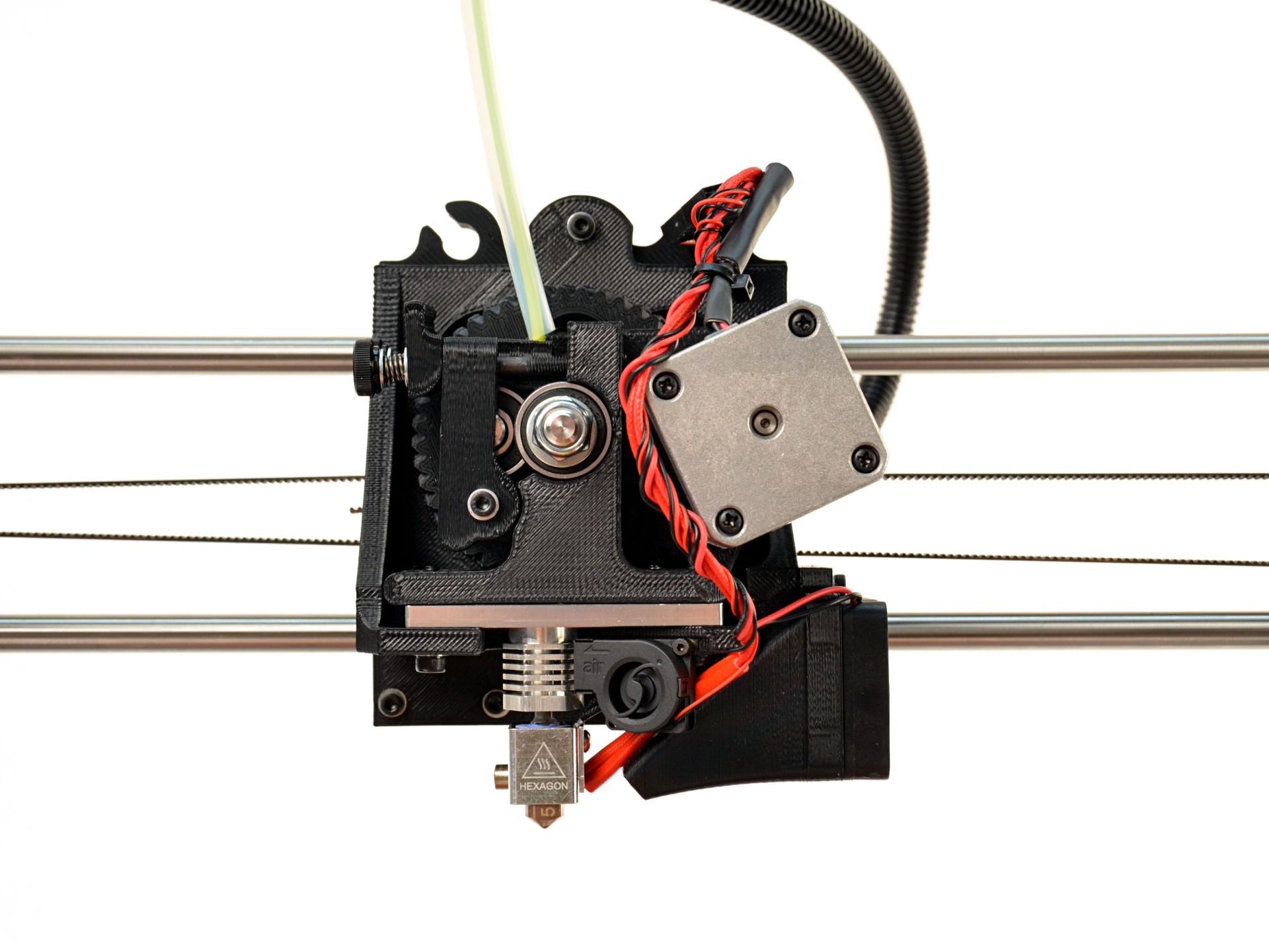

So, Lulzbot Taz 5 3D with a retail price of about $ 2,200 will try to compete with an industrial monster.

Printer Lulzbot Taz 5 3D

Stratasys Fortus 380 MC printed part from ABS plastic, with 100% filling, with standard layer thickness and normal default settings. Mike says that at the factory he was not allowed to go directly to the machine, so he cannot tell in detail about the print settings. The laboratory just made this item at his request, well, thanks to that.

On a home printer, an engineer used a HIPS filament, printing was done with a nozzle with a diameter of 0.5 mm, with a layer thickness of 0.1 mm, 25% filling, with four upper and lower hard layers, a print speed of 45 mm / s and standard acceleration, extrusion temperature of 240 ° C work surface temperature 110 ° C and an extrusion width of 0.6 mm.

It is unlikely that such a test can be called one hundred percent correct. We do not know the exact parameters of printing on an industrial printer. In addition, the engineer for some reason used a different HIPS filament, although the home printer can print the same ABS and fill 25% instead of 100%. In general, this is a very superficial comparison, but still quite curious.

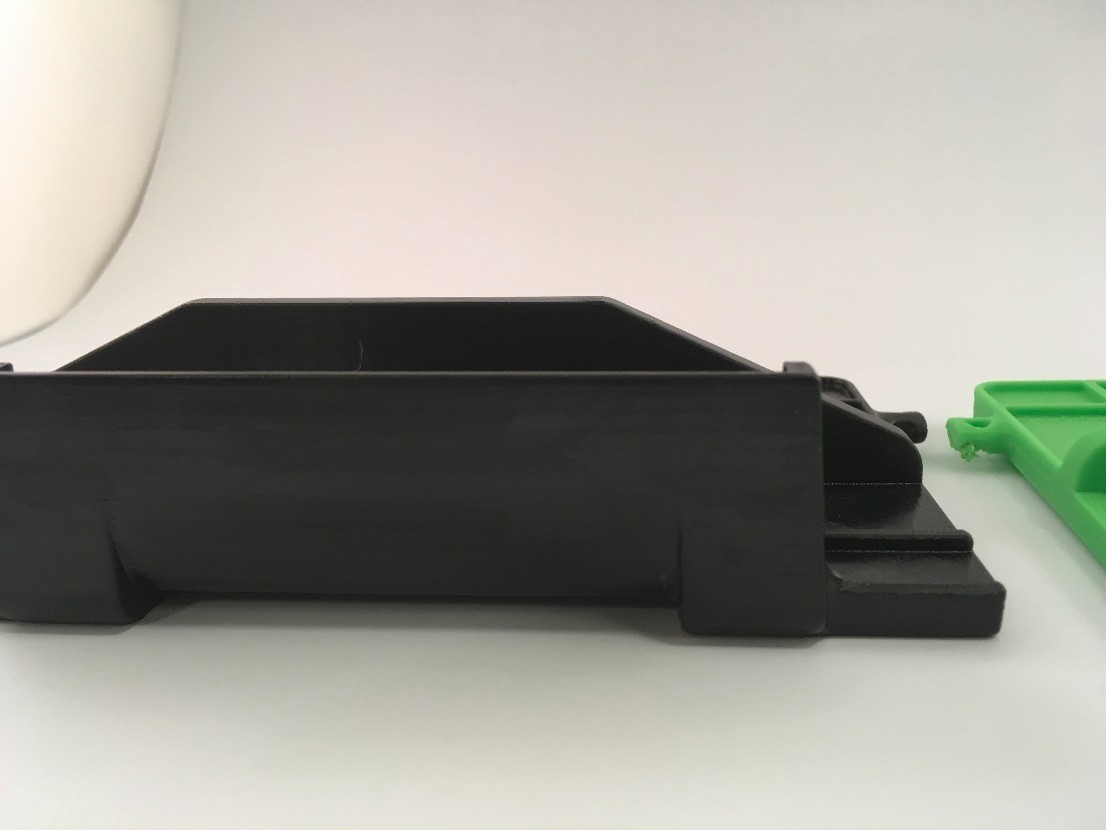

Printing products on both machines took 18 hours. So, what happened?

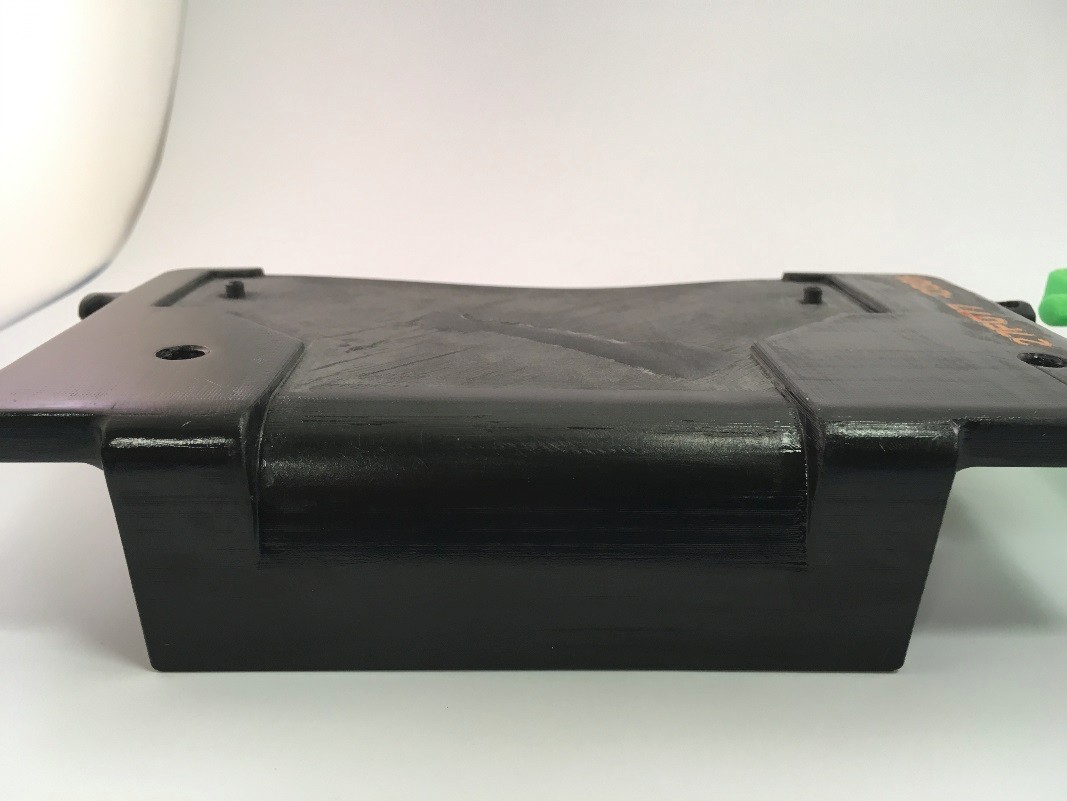

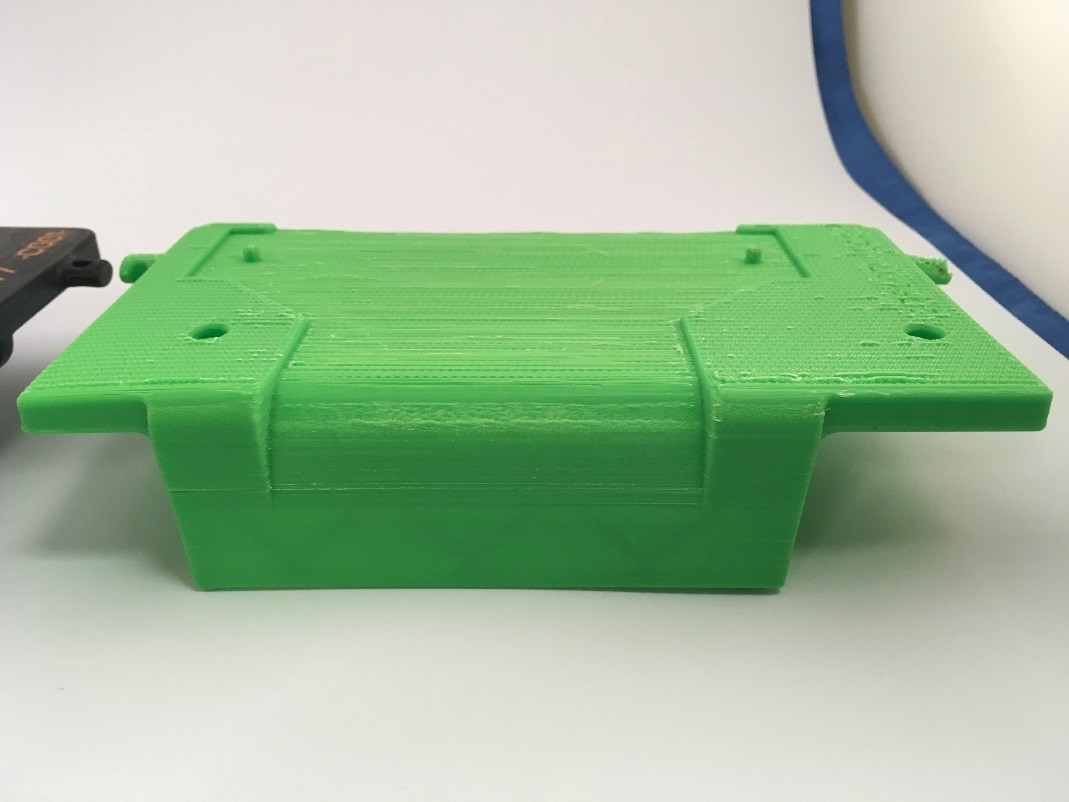

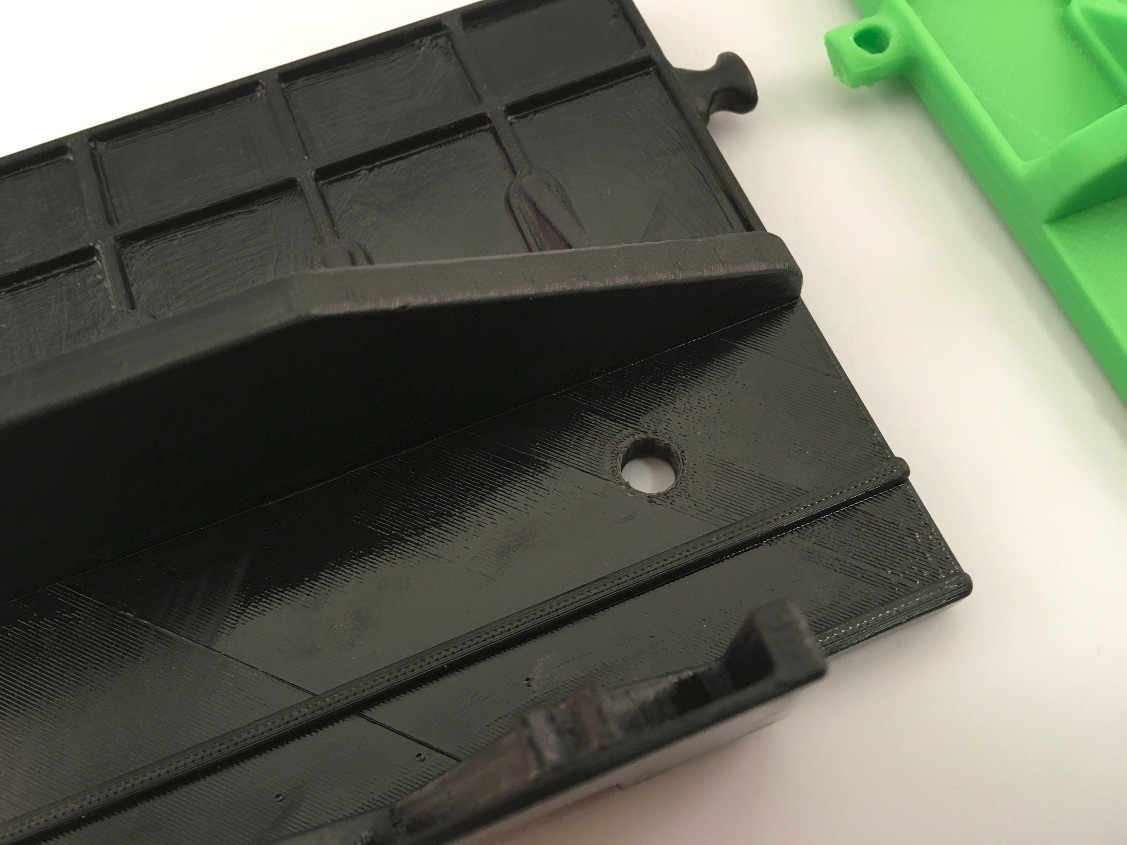

In the photographs, two details are easy to distinguish, because the industrial detail is black. The experimenter cleaned the parts as much as possible from excess materials - and began photographing.

If you look closely, the difference still becomes noticeable. The product Stratasys Fortus 380 MC turned out a little better, but the difference is not as radical as you might think.

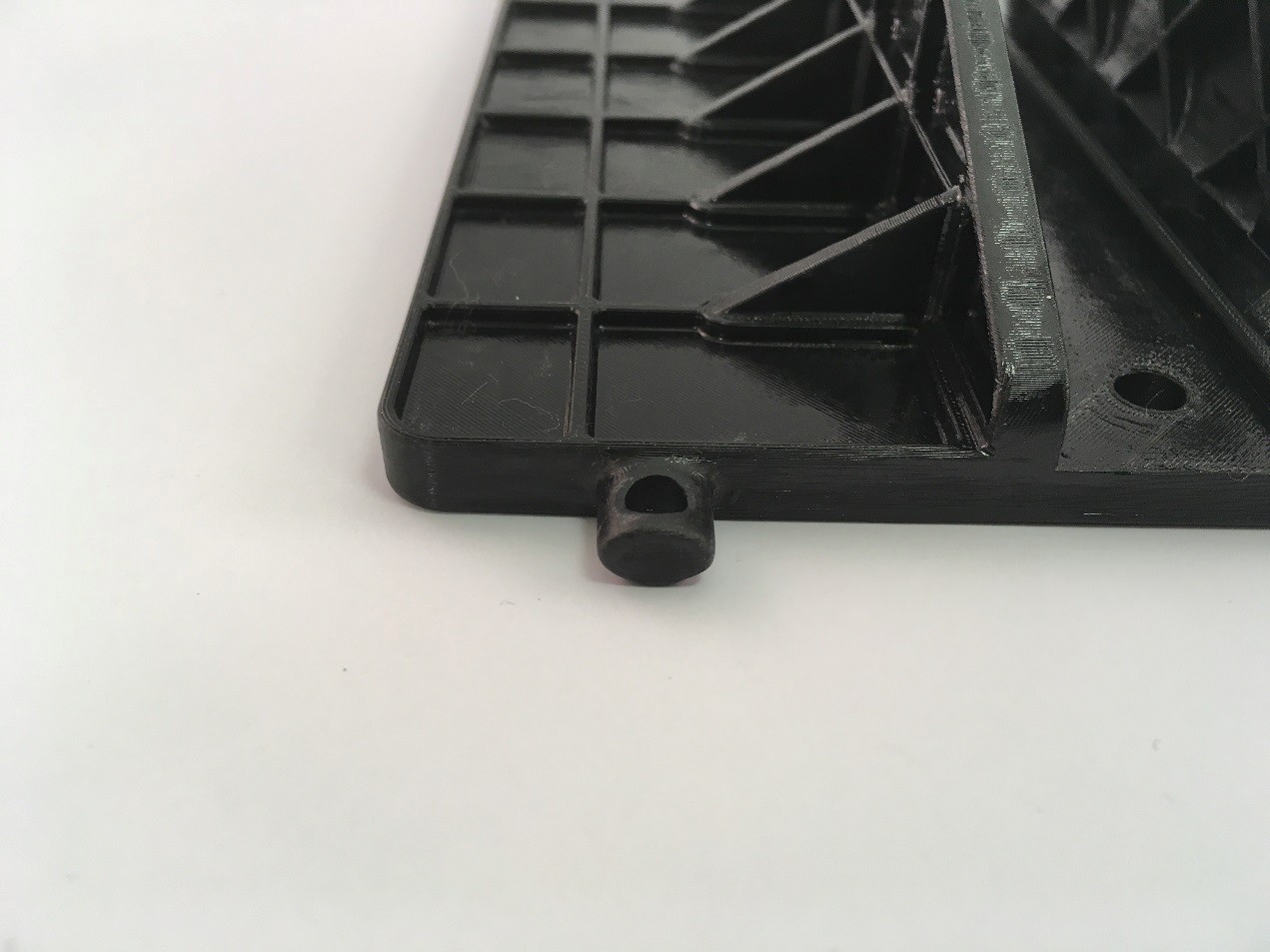

Mike Skrshpchak carefully investigated the individual elements of the two parts. For example, the mounting ledge on the edge of the form. An enthusiast sprinkles ashes on his head, because adequate support is not provided for such protruding parts, which are printed on a home printer. Therefore, the mounting protrusion on the parts from a home printer is not printed completely. But its upper part, which was printed normally, is not inferior in quality to the part from the industrial printer.

Another piece, which he explored in detail - the mounting holes and the surrounding parts of the parts. Here you can see that in the "home" version around the mounting hole there are small tears in the upper layers of the print. He says that if he printed the part again, he would have made twice as many solid upper and lower layers to eliminate this artifact. Just the layers are too thin, so the four, as we see, turned out to be not enough.

In general, in the above photographs, the difference in the quality of parts is not very different and is not critical.

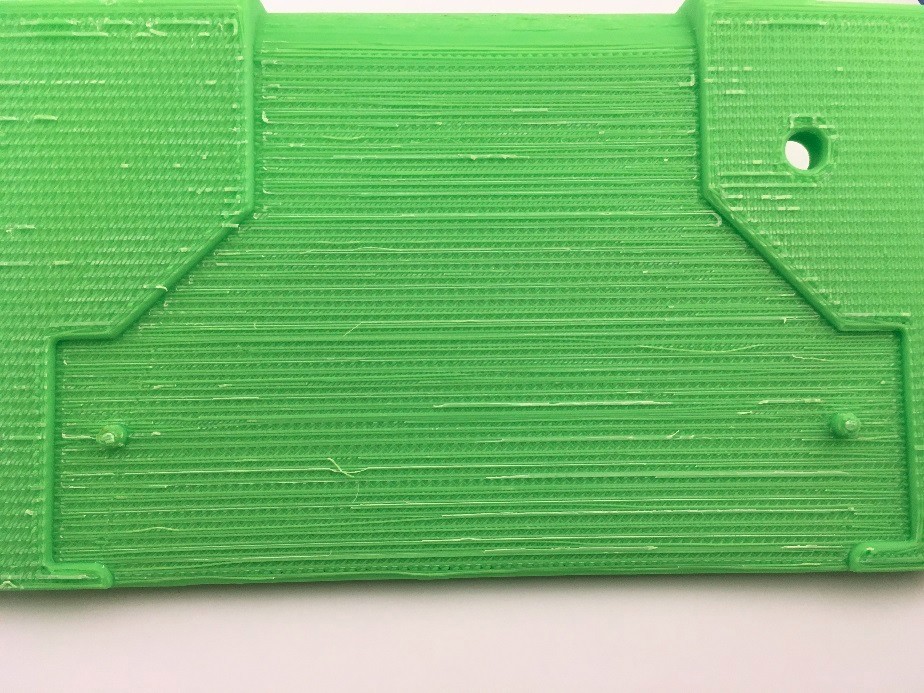

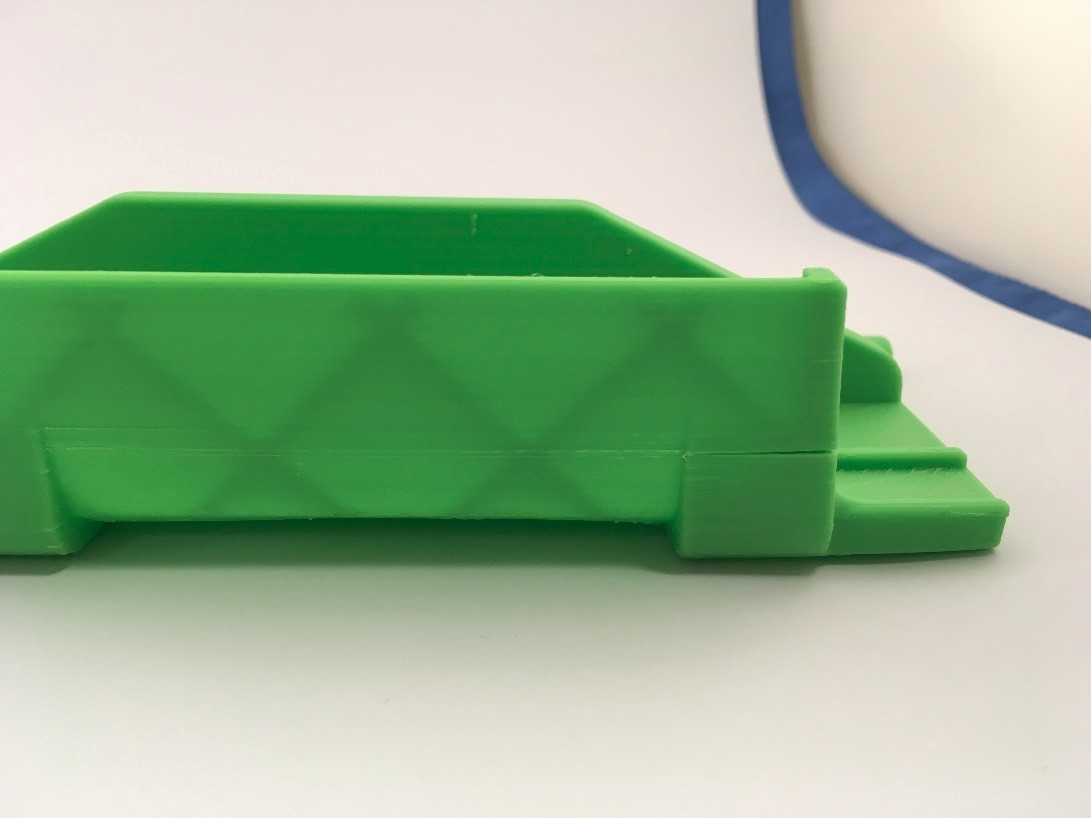

The part of the part where the biggest difference in print quality is the bottom surface that comes into contact with the support. 3D-print enthusiasts are well aware that support spoils the surface that comes into contact with it, so it is advisable to minimize its quantity (see the article “ 10 Rules for Preparing a Model for 3D Printing ”).

So, an amateur printer makes support from the same material from which the part itself is made, with all the ensuing consequences: a lot of burrs and uneven areas that remain on the surface. In a professional printer, the Stratasys Fortus 380 MC support is made from a separate, degradable material. It dissolves in a special saline solution and is simply washed off. Here we see a big difference in the quality of the product.

Regardless of the quality of the print itself, it is the method of chemical removal of support made from another material that provides the best quality on certain parts of the surface of the part.

Detail with an amateur printer, apparently, must be carefully polished to achieve the same quality in these areas. Or make a small upgrade. For a Lulzbot Taz 5 3D printer for about $ 500, you can purchase a printhead, which is also capable of printing support from soluble material. Half a thousand dollars is a considerable amount, of course, but still it doesn’t compare it with $ 200,000 for a professional Stratasys machine.

And on the “amateur” part, the engineer discovered one defect that is missing on an industrial printer. Some fragments of the workpiece did not stick together normally: the horizontal line between them is visible in the photo.

Despite this, both parts can perform their function normally, that is, be used for laying loops in the manufacture of electronic equipment.

Of course, if you look at the photographs of individual fragments, the difference in quality is obvious, and someone can say that a professional printer prints much better. But in practice, these are not such significant differences, says Mike Skshipchak.

It is likely that a more experienced master could print the same part of a much better quality than Mike did .

Yes, he himself admits that if you change the print settings a little and apply a couple of tricks, you could achieve better product quality and eliminate the defects that appeared. That is, here again, much depends not only on the printer, but on the even hands and experience of the master who prints the part. This skill comes with experience.

Although the detail didn’t work out very well, Mike emphasizes that in real work both details are completely identical, that is, he doesn’t have a difference as to which one to use with cables for electronics. Thus, both printers perfectly coped with their task and are excellent for use in work, that is, for the manufacture of original parts. If there is not much difference, it is difficult to come up with an excuse to buy a printer, which is about 90.9 times more expensive.

Now the engineer plans to conduct several more comparative tests on the coordinate measuring machine and check how well the two parts are geometrically accurate. There are suspicions that it is in this test that an industrial printer will show why it costs so much.

In general, even from this experiment, we can conclude that "amateur" printers are not so far behind in print quality from professional industrial machines, a hundred times more expensive. Much depends on the experience and skill of the engineer, who knows how to print a specific part is best, how to avoid the most likely defects.

Source: https://habr.com/ru/post/396043/

All Articles