Construction ITER ahead of schedule. The first plasma is scheduled for 2025

In France, construction continues on the first full-scale fusion reactor ITER. The reactor is built by the efforts of 36 countries (this year Iran was added ). Key project participants are China, the European Union, India, Japan, Russia, Korea, Switzerland and the USA. The project has a long history: the first agreements on it were reached by Mikhail Gorbachev when he was General Secretary of the CPSU and US President Ronald Reagan.

Until 2015, construction was very slow. Constantly failing deadlines, it seemed that the project is just about to close. But after the project was headed by the Frenchman Bernard Bigot, the work was succeeded in intensifying.

What has been done?

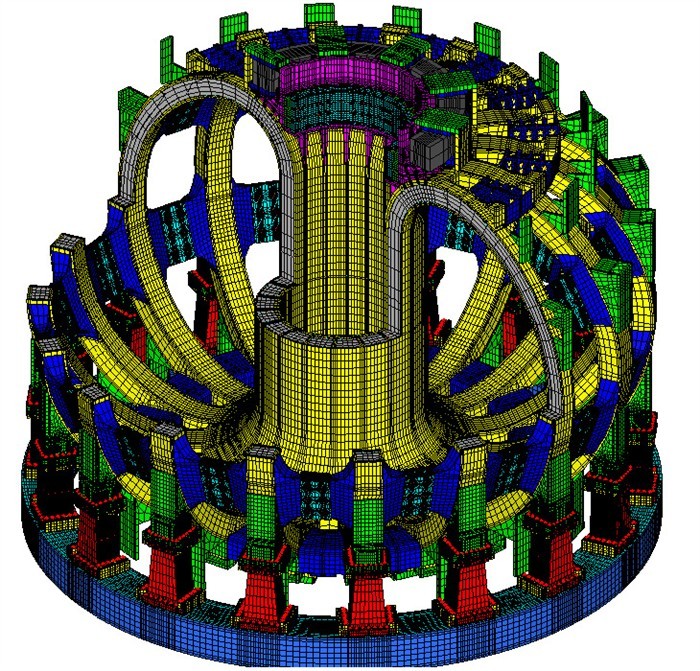

In March of this year , the first winding package was manufactured for the toroidal coil of the ITER superconducting magnet. This magnet will hold a plasma with a temperature of about 150 ppm, inside the toroidal field. Each of the packs measuring 14 by 9 meters and 1 meter thick weighs about 110 tons.

')

Toroidal electromagnet

The radial plates of the toroidal electromagnet are going according to plan. Components of the second coil are ready for assembly. Last year, Chepetsky Mechanical Plant supplied a superconductor for the toroidal magnetic field coils. Superconducting strands contain about 10 thousand superconducting fibers with a thickness of 2-6 microns. At another Russian enterprise, superconducting cables encased in a steel sheath were woven from these strands.

When all the elements are ready, engineers will assemble a cryostat - in the case of ITER this will be the world's largest steel chamber with a capacity of 16,000 m 3 and a weight of 3,850 tons. The temperature of the cryostat will be maintained at -269 ° C, which will ensure the superconductivity of the whole structure. Last year, Russian partners manufactured parts for the bottom of the cryostat.

In the USA, a factory has already been built to create individual elements of the world's most powerful magnet — the central solenoid.

For the manufacture of superconducting strands for project magnets, a huge amount of Nb3Sn superconductor is needed - as many as 500 tons. If not for ITER, such a volume would have been made in about 37 years. After the start of the project, it was possible to increase the global production of this intermetallide six times.

Drainage tanks for the water cooling system, water storage tanks with tritium and power conductors (they were created at the St. Petersburg Scientific Research Institute of EEFA) have already been placed on the site.

Turbine assembled for testing (test passed successfully)

On July 4 of this year, turbines for the cryogenic system of the reactor were manufactured. These turbines will be used to maintain the ultra-low temperature of liquid nitrogen. Turbines will be installed on the ITER site this fall.

At the construction site there are two largest cranes with a combined capacity of 1,500 tons. They were produced in sections of 47 meters each.

To transport crane components by sea, we had to hire a huge barge, and then carry all this 104 kilometers overland at a speed of 5 km / h. The road through which the cranes were transported had to be further strengthened. Cranes were carried at night so as not to interfere with road users in the daytime.

Goes on its way and the assembly of buildings. For example, the assembly shop looks like this now.

The brilliant lining of the building is temporary . It is necessary to maintain the microclimate in the shop. After the reactor is installed, the cladding will be removed. The poster, by the way, depicts a reactor on a scale of 70% of the actual size (poster size 25 * 50 m).

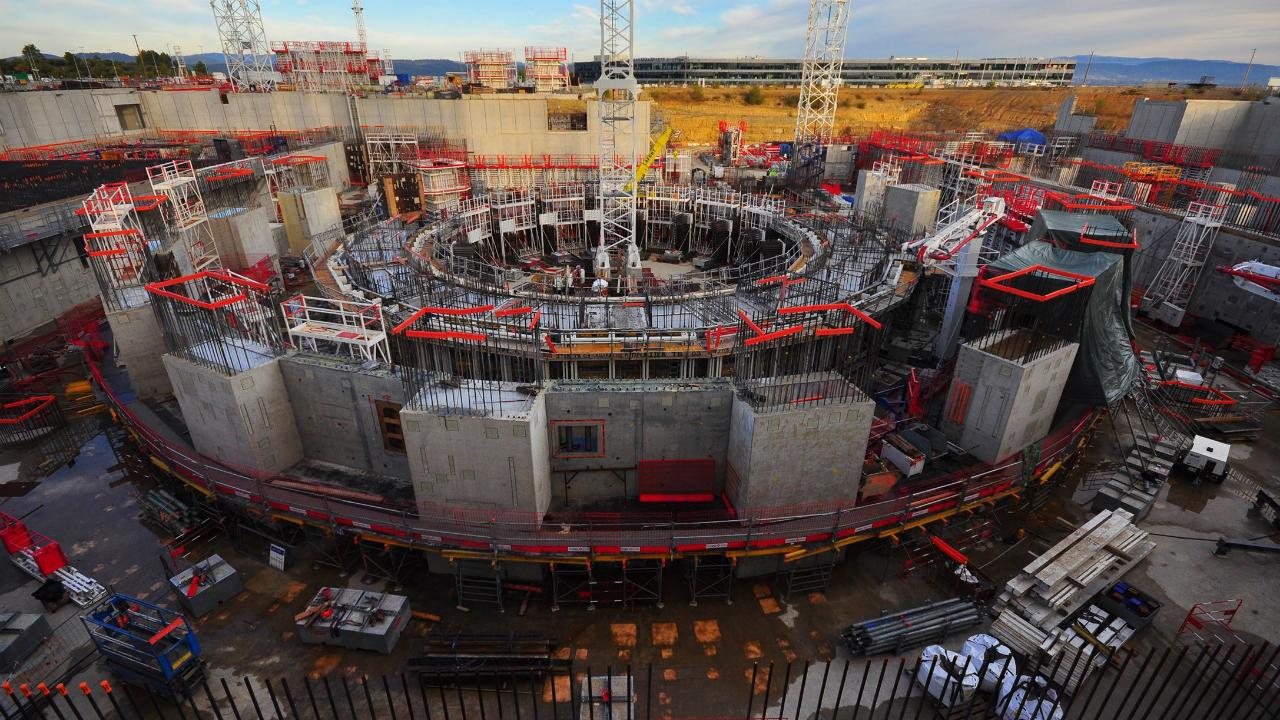

And here will be located the reactor itself.

Another view of the reactor assembly site

An example of a biological protection section. It is a concrete barrier 3.5 meters thick that protects people and equipment from radiation. Rebar diameter - 50 mm

What's next?

At the end of June, the partners approved a new plan , which implies the first launch of the reactor in 2025. Plasma should get in December 2025. The ITER Council recognized that the plan is complex but technically feasible. So far, the construction of the reactor is even slightly ahead of schedule.

The updated schedule offers the best technically feasible way to obtain the first plasma, which will mark the completion of the key stages of the assembly and commissioning of the ITER tokamak and support facilities. Specific construction phases for the coming years are as follows:

Source: https://habr.com/ru/post/395887/

All Articles