In the laboratory of the University of Stuttgart printed multi-lens with a diameter of human hair

A research team from the University of Stuttgart, using a 3D printer, managed to print a series of one-, two-, and three-lens functional lenses with a complex lens geometry ranging in diameter from 100 to 200 microns. A full description of the research and technological chain published in the journal Nature Photonics, an abbreviated version is presented on the pages of Phys.org .

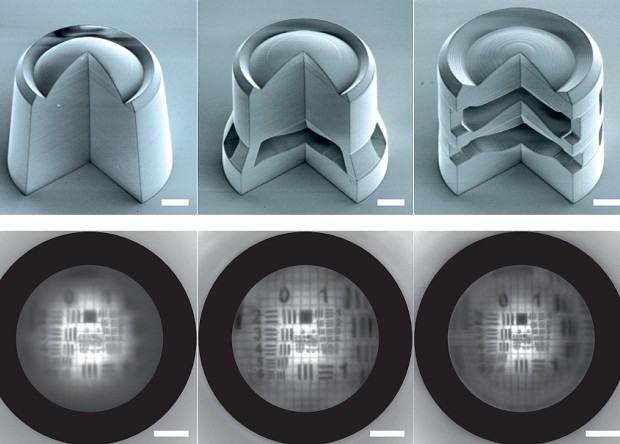

Schemes of lenses and the course of rays falling at different angles. Bottom - simulated photos of the test table

Timo Gissibl et al. / Nature Photonics, 2016

Multi-lenses with non-spherical elements are in demand where high optical performance and effective correction of chromatic aberrations are crucial. The authors of the development were able to present a new concept of micro- and nano-optics with complex lens designs, which they managed to print on a 3D printer. The report on the pages of Nature Photonics describes in detail the full technological chain of creating a multi-lens, starting from the design stage of an optical element - to the production stage using a femtosecond two-photon laser and subsequent testing for specific purposes of combinations of several lenses about 100 microns in diameter.

')

To create lenses, researchers used the capabilities of 3D printing and lithography technology. The future material for the lens was deposited in layers, 100 nanometers in a layer, after which it was exposed to laser femtosecond pulses. Such a sequence of operations made it possible to provide directional changes in the chemical properties of the surface of a material, the elimination of physical defects and the obtaining of a lens of a given geometric shape. In order to improve printing accuracy, researchers used the effect of two-photon absorption .

A series of lenses printed by physicists (above). Images taken on the photosensitive matrix with their help (below)

Timo Gissibl et al. / Nature Photonics, 2016

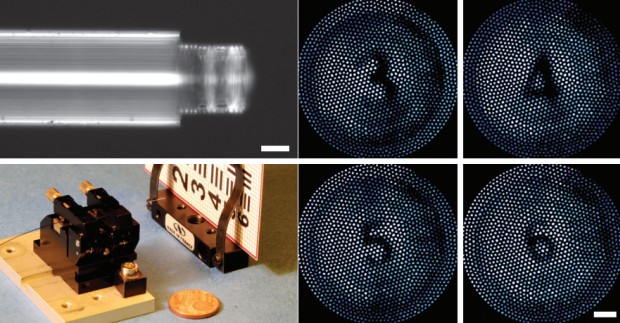

Scientists stressed that the entire technological chain, from the development of the layout to the creation of the lens itself, took only a few hours. In particular, a three-lens “triplet lens” was made, which is located on a fiber-optic cable. This design allows you to focus on objects located three millimeters from the lens and broadcast the image with virtually no loss of quality over fiber, up to 1.7 meters long.

From the bottom left - staging an experiment on shooting using optical fiber. Top left - a snapshot of the fiber profile. On the right - examples of images taken with lenses.

The resolution in the central part of the obtained image, formed using printed lenses, was 400 lines per millimeter during the experiment. At the same time, as computer modeling showed, using the lenses created in the laboratory, this indicator can be increased by 25%. Another way to improve image quality, considered by the authors of the proposed technology, is to apply an anti-reflective coating to the lens surface.

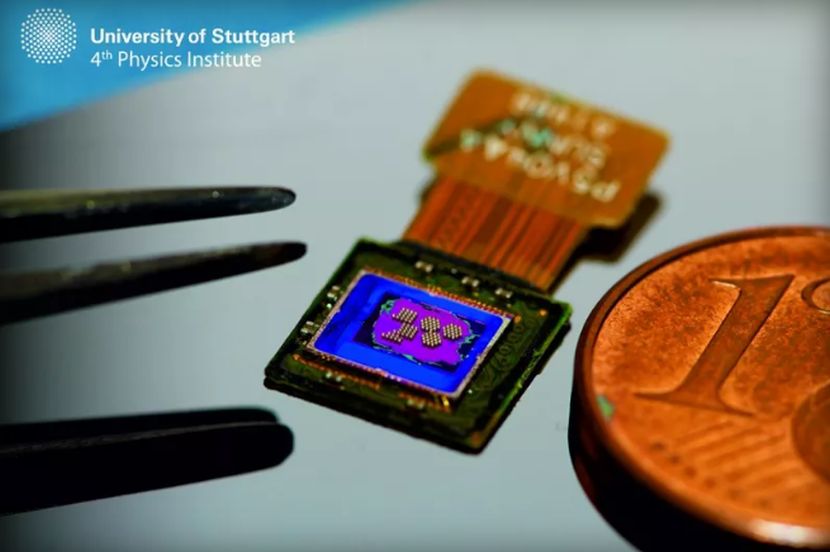

Miniature cameras created by experts at the University of Stuttgart will find application in endoscopic studies, both in the industrial field and in medicine. One of the promising areas of technology application in its further development, according to the authors of the invention, may be the use of mini-lenses in tiny microscopes, which, in real time, will allow to study the activity of groups of neurons.

Printed lens combined with fiber optic cable

Today, when the miniaturization of cameras and lenses with the preservation of image quality took shape in a steady trend, engineers are looking for and finding different technological approaches to solving this problem. So, for example, a group of researchers from Harvard, using metamaterials, created flat lenses that are not inferior in quality to modern lenses of microscopes. Another, more radical approach to solving the problem was the complete abandonment of the use of lenses.

One of the unique advantages of the proposed method is its flexibility, which allows to create miniature optical devices such as endoscopes, optical devices for cell biology, innovative lighting systems, miniature fiber optic traps and tracking cameras, integrated quantum emitters and detectors, miniature UAVs and mini bots with autonomous vision.

That's all with you was Dronk.Ru. Do not forget to return money for purchases in China and subscribe to our blog , there will be many more interesting things.

We recommend:

- Save up to 8% on every purchase on AliExpress and other online stores in China

- Why do online stores give money for purchases?

- Return your money - Choose a cashback service for Aliexpress

- The history of the development of Dronk.ru - from choosing quadcopters to returning money for purchases on AliExpress and not only

- The best cashback service or 5 main criteria for evaluating cashback service

Source: https://habr.com/ru/post/395523/

All Articles