Print a pill for you personally, here and now? Easy

At the National University of Singapore (NUS), scientists are very close to the commercial launch of a new technology for the creation and production of drugs, taking into account the individual characteristics of the patient. The new generation of tablets, as scientists promise, will not only take into account the requirements for dosage, but also, which is very important, implement the individual scheme (profile) of drug release in the required time interval, according to the biological characteristics of a particular organism and the clinical picture of the disease. Thus, the daily dose of drugs can be concluded in one pill, which can be printed on the most ordinary 3D printer in the laboratory of the same clinic where the patient is undergoing examination.

“For a long time, a personalized tablet remained nothing more than a concept, because its translation into a practical plane was too expensive and technologically complex. The method proposed by us, on the contrary, is technically simple, relatively inexpensive and universal. In the future, it may well be used in private clinics for the production of individual pills for patients directly upon the diagnosis, or in mass installations used in the production by pharmaceutical companies, ”explained the head of the group, Professor Soh Siow Ling.

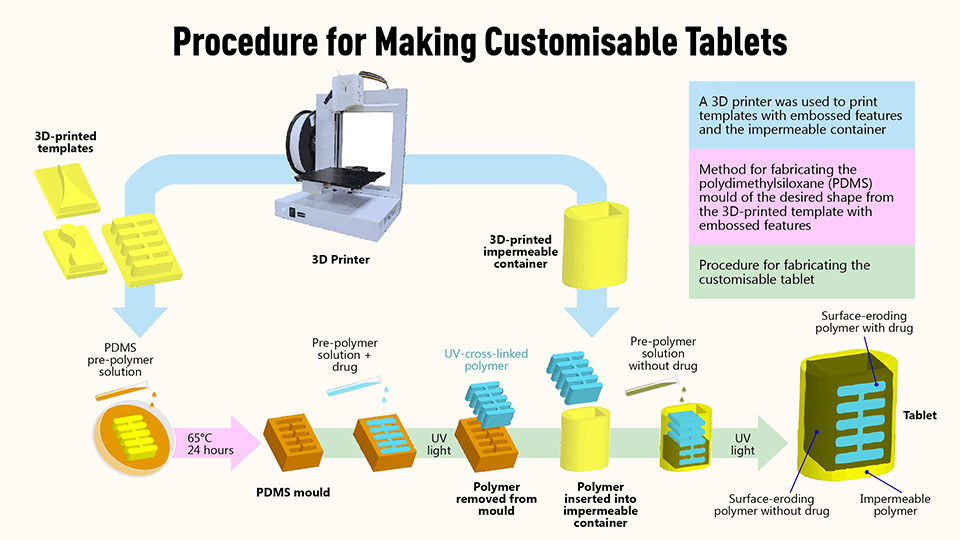

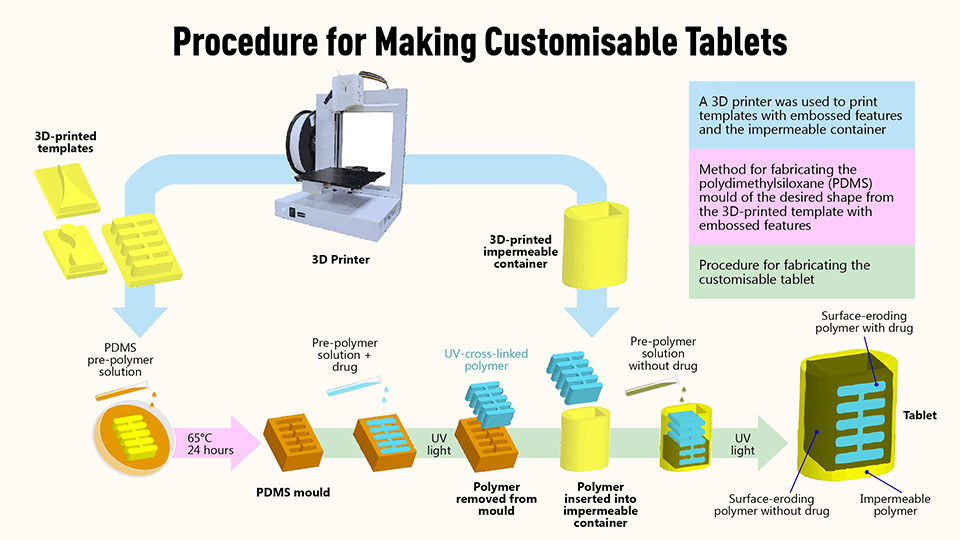

The program, which, based on the data entered into the computer by the attending physician, is capable of reproducing a 3D tablet layout with regard to the recommended daily dosage and a unique time profile for the release of active ingredients has already been created and tested in the NUS laboratory. The file created in specialized software is used by a 3D printer in the process of printing the “frame” of an individual tablet. At the next stage, the printed tablet is covered with a special protective layer.

')

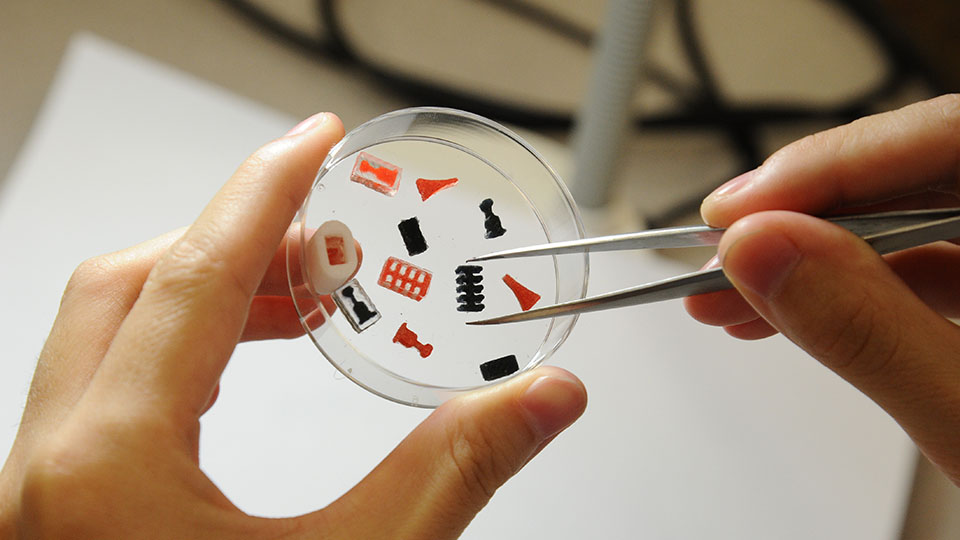

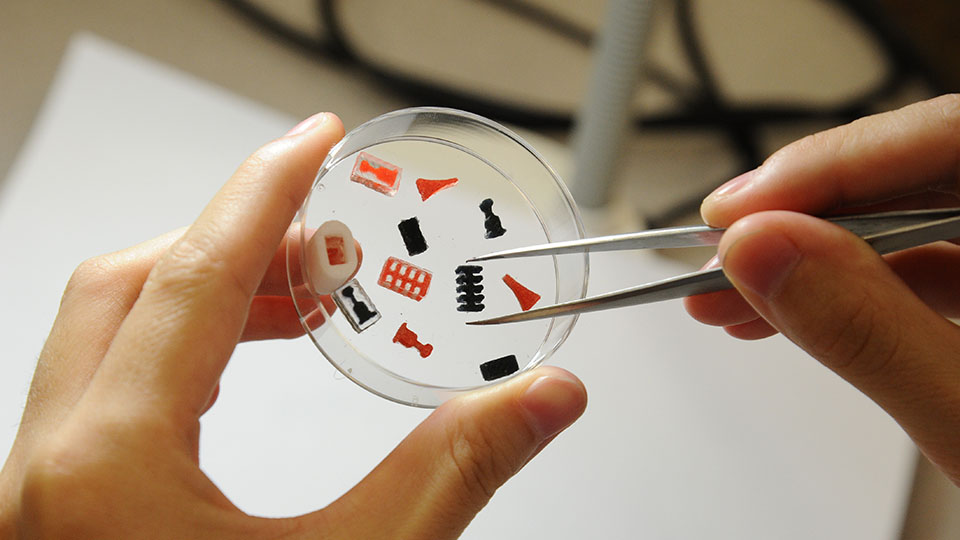

Instead of making a drug tablet, printing layer by layer, the drug developed by Professor Soh and Ms. Sun Yajuan consists of three separate components, including a polymer containing the drug in a specially designed form that will determine the rate of drug release. For example, a 5-prong form will allow the drug to be released by five short-duration pulses over a given period of time. By adjusting the form of the drug containing the polymer, it is thus possible to release the drug at any desired rate and frequency.

Due to the unique shape of the polymer-containing layer, the medicinal ingredients realize individual release profiles. It can be said that the proposed system is completely customizable and capable of reproducing patterns for any release profile.

The process of creating a personalized tablet

Professor Soh explained that the new method is technically simple, relatively inexpensive and versatile. “It can be applied in private clinics, where doctors could produce individual pills on site for patients, or in industrial production conditions by pharmaceutical companies,” he added.

It is very important that the developed program, like the technology itself, is extremely visual, does not need to use complex mathematical or computer algorithms to build tablets of various geometries, while allowing the medical specialist who does not have in-depth knowledge of 3D modeling to create complex therapeutic profiles.

In terms of versatility and flexibility, the method proposed by the team from NUS has unique capabilities. And the fact that the principle of phased controlled release of the ingredients of the drug, implemented in it, is really convenient and effective has already been confirmed by the example of the American team of researchers and their preparation Spritam , used to relieve epilepsy attacks in children. But talking about the personalization of the drug Spritam, even against the background of its clinically proven efficacy, will still be a clear exaggeration. (SPRITAM is right for you).

In the future, clinics, pharmacies and hospitals could deploy this cost-effective technology, thanks to its simplicity and affordable price, researchers are confident. It allows you to use the most common commercial 3D-printers and cost-effective materials. As a result, the use of a commercially available 3D printer as the main unit of production equipment allows you to significantly reduce the cost of the production process, making it accessible at the level of personalized medicine a reality.

Patients suffering from diseases such as arthritis, asthma, peptic ulcer and many others will understand the practical importance of a personalized tablet developed by NUS researchers. Since the proposed method involves the release of the active ingredients of the drug at different rates and dosages, it is possible to significantly simplify complex treatment regimens.

Among those who will be able to appreciate the advantage of this system will be people who take drugs that must flow into the blood with short-term metered pulses. In particular, these are patients taking a course of hormonal treatment, in which the factor of consistency of drug therapy with biological processes and rhythms of the human body takes on particular importance.

Now a team of researchers from NUS is negotiating with one of the largest transnational concerns with the aim of commercializing its development. Along the way, the possibilities of combining various polymer components in order to achieve maximum efficiency indicators are being studied.

Sources:

publication on the website of the National University of Singapore

Press release

That's all, with you there was a simple service for choosing sophisticated Dronk.Ru equipment. Do not forget to subscribe to our blog , there will be many more interesting ...

“For a long time, a personalized tablet remained nothing more than a concept, because its translation into a practical plane was too expensive and technologically complex. The method proposed by us, on the contrary, is technically simple, relatively inexpensive and universal. In the future, it may well be used in private clinics for the production of individual pills for patients directly upon the diagnosis, or in mass installations used in the production by pharmaceutical companies, ”explained the head of the group, Professor Soh Siow Ling.

The program, which, based on the data entered into the computer by the attending physician, is capable of reproducing a 3D tablet layout with regard to the recommended daily dosage and a unique time profile for the release of active ingredients has already been created and tested in the NUS laboratory. The file created in specialized software is used by a 3D printer in the process of printing the “frame” of an individual tablet. At the next stage, the printed tablet is covered with a special protective layer.

')

Instead of making a drug tablet, printing layer by layer, the drug developed by Professor Soh and Ms. Sun Yajuan consists of three separate components, including a polymer containing the drug in a specially designed form that will determine the rate of drug release. For example, a 5-prong form will allow the drug to be released by five short-duration pulses over a given period of time. By adjusting the form of the drug containing the polymer, it is thus possible to release the drug at any desired rate and frequency.

Due to the unique shape of the polymer-containing layer, the medicinal ingredients realize individual release profiles. It can be said that the proposed system is completely customizable and capable of reproducing patterns for any release profile.

The process of creating a personalized tablet

Professor Soh explained that the new method is technically simple, relatively inexpensive and versatile. “It can be applied in private clinics, where doctors could produce individual pills on site for patients, or in industrial production conditions by pharmaceutical companies,” he added.

It is very important that the developed program, like the technology itself, is extremely visual, does not need to use complex mathematical or computer algorithms to build tablets of various geometries, while allowing the medical specialist who does not have in-depth knowledge of 3D modeling to create complex therapeutic profiles.

In terms of versatility and flexibility, the method proposed by the team from NUS has unique capabilities. And the fact that the principle of phased controlled release of the ingredients of the drug, implemented in it, is really convenient and effective has already been confirmed by the example of the American team of researchers and their preparation Spritam , used to relieve epilepsy attacks in children. But talking about the personalization of the drug Spritam, even against the background of its clinically proven efficacy, will still be a clear exaggeration. (SPRITAM is right for you).

In the future, clinics, pharmacies and hospitals could deploy this cost-effective technology, thanks to its simplicity and affordable price, researchers are confident. It allows you to use the most common commercial 3D-printers and cost-effective materials. As a result, the use of a commercially available 3D printer as the main unit of production equipment allows you to significantly reduce the cost of the production process, making it accessible at the level of personalized medicine a reality.

Patients suffering from diseases such as arthritis, asthma, peptic ulcer and many others will understand the practical importance of a personalized tablet developed by NUS researchers. Since the proposed method involves the release of the active ingredients of the drug at different rates and dosages, it is possible to significantly simplify complex treatment regimens.

Among those who will be able to appreciate the advantage of this system will be people who take drugs that must flow into the blood with short-term metered pulses. In particular, these are patients taking a course of hormonal treatment, in which the factor of consistency of drug therapy with biological processes and rhythms of the human body takes on particular importance.

Now a team of researchers from NUS is negotiating with one of the largest transnational concerns with the aim of commercializing its development. Along the way, the possibilities of combining various polymer components in order to achieve maximum efficiency indicators are being studied.

Sources:

publication on the website of the National University of Singapore

Press release

That's all, with you there was a simple service for choosing sophisticated Dronk.Ru equipment. Do not forget to subscribe to our blog , there will be many more interesting ...

|  |  |

| Why do online stores give money for purchases? | How to find the best deal in China and return some of the money for the purchase? | Return your money - choose a cashback service for Aliexpress |

Source: https://habr.com/ru/post/395399/

All Articles