Creating a 3D printer by a young engineer - what is it?

Today I will talk about my unique project for creating my own 3D printer model. This article shows how difficult it is to implement projects in our mighty, beloved homeland for young engineers, and just for real techies. I will tell a lot, so I decided to divide my article into several parts.

It all started with a thought: how to create such a printer, in which the constructive shortcomings of 3D printers that exist at the moment will be completely eliminated.

I decided to create such a 3D printer. All open drawings that were posted on the Internet at that time had many different shortcomings (for example: inaccurate dimensions (2.144326… mm), non-orthogonality of lines that had to be strictly orthogonal, excessive refinement of elements, absence of some stiffness elements, etc.) . After studying a number of drawings, the ideal model of a 3D printer has taken shape in my head, and I took it up.

')

As a supporting concept, I took the Prusa i3 project, where I liked the overall concept, but I decided to radically rework it. And he began to create a drawing of his printer in AutoCAD, then simulate it in Autodesk Inventor (most of all, it was funny that a 2D sketch was easier to create in AutoCAD than with the built-in drawing tools).

It took several weeks to develop it. As a result, it was developed. From myself I will say that this is a very difficult task, because from a two-dimensional drawing one should create a kinematically dynamic, three-dimensional construction.

Before my drawing was almost ready for release, I began searching for companies providing laser cutting services. Having sent several requests to different companies, I began to follow the proposals. Only three responded, all the others did not answer. I chose one of the three, because the price for the service was optimal for her, and the staff were quite competent in their work. After correspondence with the performer during the week we agreed on the implementation of the order. A week after payment, I received my order. He weighed according to preliminary calculations about 12 kg. I had to drag all three blocks and then go to the subway (I had to explain to the policemen what I was carrying, because they had a metal detector at the entrance to the subway and for them the contents of the package were strange, and they ran in bewilderment, but in the end missed). He brought all the parts home and the next day began to clean them of chips and oil with ethyl alcohol. After cleaning came the process of painting those parts.

I ordered a new revision of parts from them, but they didn’t do the post-processing after laser cutting (as for the first time), and I had to grind it by hand to paint them later.

Initially, I bought 4 cans of blue and yellow acrylic paint and a can of soil - all this cost about 570 rubles. Before the painting process, I sanded and degreased the surfaces of the parts. I did the painting in an isolated place, at home, because There were no special places that I could provide for painting. At first I grouped the parts in batches, ground them and painted in several layers in turn each batch. Each batch of parts was painted for 2.5 hours (for some it took several days) due to the fact that they had to paint each side.

In some details, there were non-protrasses, which had to be eliminated by additional prokraskoy. Next, a number of parts were replaced with more advanced ones that needed to be painted, before that I bought 2 cans of paint with different colors and primers, all for about 500 rubles. (prices have grown on the primer). Began to paint, but already on the balcony. I painted those parts in 2 days.

As a result of this section, I would like to say that the painting of parts must be ordered from the companies that are engaged in this, since it took a lot of time and effort to paint.

In this section, I will talk about the process of purchasing from us in the city, as I will talk about the process of ordering them abroad later. I just want to say that in the process of delivery of linear bearings they were deployed at customs (as it turned out, 2 weeks after sending) and I had to order them again, but from another supplier. In total, I received the bearings after 4 weeks (from the time of ordering with the first supplier). All other orders reached in 3 weeks.

With the acquisition in our city everything was much more difficult: we had to go to different small shops, to different dirty ends of the city and to purchase other components (heat shrinkage, wires for the necessary sections, fluxes, solders, radio components, etc.). Especially "interesting" was to buy metric fasteners. M3 size was not in large retail building stores and in small ones nearby, I had to search the Internet and go almost to the edge of the city to get them (there were many offers for large wholesalers, but there were very few retail). In the same way were purchased and other types of components.

The following parts of the articles will describe in detail the other steps in creating my 3D printer.

Video of the first 3D printing on my printer:

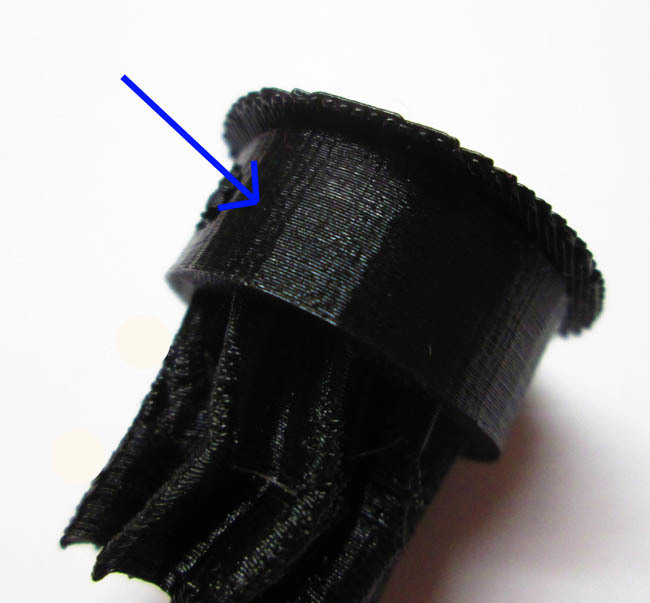

The result of the first 3D printing on my printer (involute chevron gear):

PS: I want to say that it took me a lot of time and effort to create my own printer model (about 5 months), and I also managed to combine my studies at school in grade 11, when the USE was coming soon.

However, such developments, made by a student, are ignored when entering the university. And other persons associated with the education system. In their opinion, the number of balls of the EGE and all sorts of olympiads reflect the child’s intelligence and knowledge. Others are not required to confirm this and are completely ignored.

Idea

It all started with a thought: how to create such a printer, in which the constructive shortcomings of 3D printers that exist at the moment will be completely eliminated.

I decided to create such a 3D printer. All open drawings that were posted on the Internet at that time had many different shortcomings (for example: inaccurate dimensions (2.144326… mm), non-orthogonality of lines that had to be strictly orthogonal, excessive refinement of elements, absence of some stiffness elements, etc.) . After studying a number of drawings, the ideal model of a 3D printer has taken shape in my head, and I took it up.

')

Features compared to peers

- The frame is made entirely of metal, which gives it high rigidity, strength and durability.

- Large print area (real 200 * 300 * 250).

- The design of the printer is resistant to vibrations at all print speeds.

- In the dynamic nodes, the backlash is almost eliminated.

- The design provides for the cooling of engines and a number of other nodes by heat distribution (which is important for long printing).

- The design provides for the installation of all electronics directly on it.

- A light, tough, durable base of a printing table made from a special alloy.

- More durable and rigid guides for the printing table.

History of the idea

As a supporting concept, I took the Prusa i3 project, where I liked the overall concept, but I decided to radically rework it. And he began to create a drawing of his printer in AutoCAD, then simulate it in Autodesk Inventor (most of all, it was funny that a 2D sketch was easier to create in AutoCAD than with the built-in drawing tools).

It took several weeks to develop it. As a result, it was developed. From myself I will say that this is a very difficult task, because from a two-dimensional drawing one should create a kinematically dynamic, three-dimensional construction.

Ordering process for laser cutting

Before my drawing was almost ready for release, I began searching for companies providing laser cutting services. Having sent several requests to different companies, I began to follow the proposals. Only three responded, all the others did not answer. I chose one of the three, because the price for the service was optimal for her, and the staff were quite competent in their work. After correspondence with the performer during the week we agreed on the implementation of the order. A week after payment, I received my order. He weighed according to preliminary calculations about 12 kg. I had to drag all three blocks and then go to the subway (I had to explain to the policemen what I was carrying, because they had a metal detector at the entrance to the subway and for them the contents of the package were strange, and they ran in bewilderment, but in the end missed). He brought all the parts home and the next day began to clean them of chips and oil with ethyl alcohol. After cleaning came the process of painting those parts.

I ordered a new revision of parts from them, but they didn’t do the post-processing after laser cutting (as for the first time), and I had to grind it by hand to paint them later.

Painting process

Initially, I bought 4 cans of blue and yellow acrylic paint and a can of soil - all this cost about 570 rubles. Before the painting process, I sanded and degreased the surfaces of the parts. I did the painting in an isolated place, at home, because There were no special places that I could provide for painting. At first I grouped the parts in batches, ground them and painted in several layers in turn each batch. Each batch of parts was painted for 2.5 hours (for some it took several days) due to the fact that they had to paint each side.

In some details, there were non-protrasses, which had to be eliminated by additional prokraskoy. Next, a number of parts were replaced with more advanced ones that needed to be painted, before that I bought 2 cans of paint with different colors and primers, all for about 500 rubles. (prices have grown on the primer). Began to paint, but already on the balcony. I painted those parts in 2 days.

As a result of this section, I would like to say that the painting of parts must be ordered from the companies that are engaged in this, since it took a lot of time and effort to paint.

The process of purchasing components

In this section, I will talk about the process of purchasing from us in the city, as I will talk about the process of ordering them abroad later. I just want to say that in the process of delivery of linear bearings they were deployed at customs (as it turned out, 2 weeks after sending) and I had to order them again, but from another supplier. In total, I received the bearings after 4 weeks (from the time of ordering with the first supplier). All other orders reached in 3 weeks.

With the acquisition in our city everything was much more difficult: we had to go to different small shops, to different dirty ends of the city and to purchase other components (heat shrinkage, wires for the necessary sections, fluxes, solders, radio components, etc.). Especially "interesting" was to buy metric fasteners. M3 size was not in large retail building stores and in small ones nearby, I had to search the Internet and go almost to the edge of the city to get them (there were many offers for large wholesalers, but there were very few retail). In the same way were purchased and other types of components.

The following parts of the articles will describe in detail the other steps in creating my 3D printer.

Video of the first 3D printing on my printer:

The result of the first 3D printing on my printer (involute chevron gear):

PS: I want to say that it took me a lot of time and effort to create my own printer model (about 5 months), and I also managed to combine my studies at school in grade 11, when the USE was coming soon.

However, such developments, made by a student, are ignored when entering the university. And other persons associated with the education system. In their opinion, the number of balls of the EGE and all sorts of olympiads reflect the child’s intelligence and knowledge. Others are not required to confirm this and are completely ignored.

Source: https://habr.com/ru/post/395255/

All Articles