DIY mini-desktop. 3.0

A little more than a year has passed since the publication of my second article on the design of the PC case in the UCFF PC form factor. During this time, I managed to launch the first batch into production and start online sales not only of cases, but also of configurations based on it. It is especially joyful that the project for the most part took place thanks to the support and interest of the Habrahabr community.

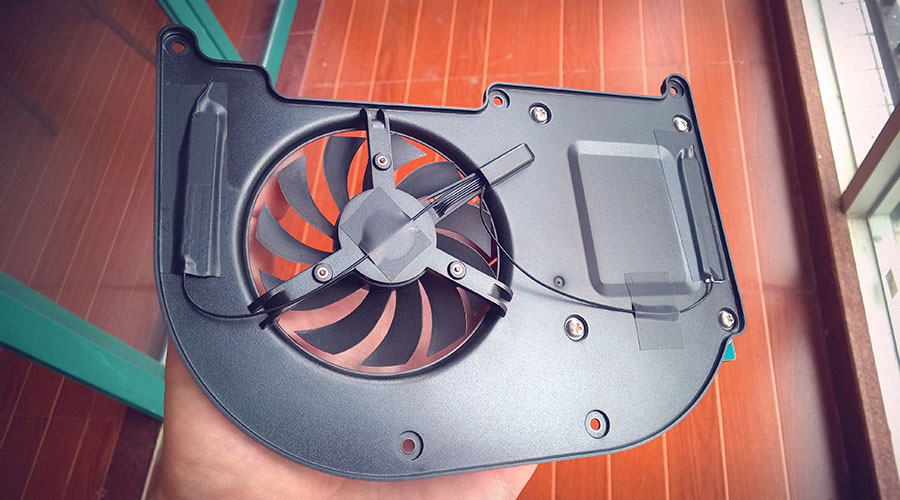

First of all, the project is interesting for its non-standard approach to the cooling system, as well as for the construction of the hull design itself and the placement of the main system components. I had to literally turn everything upside down. This applies to the air blowing in the opposite direction, the inverted motherboard, the fan blowing from the radiator, a clear separation of incoming and outgoing air flows. Due to this, we managed to place and cool the power supply in such a compact case, and install sufficiently powerful desktop processors, which distinguishes this solution from nettops and other Mini-computers based on Ultra Low Voltage (U-Series) processors.

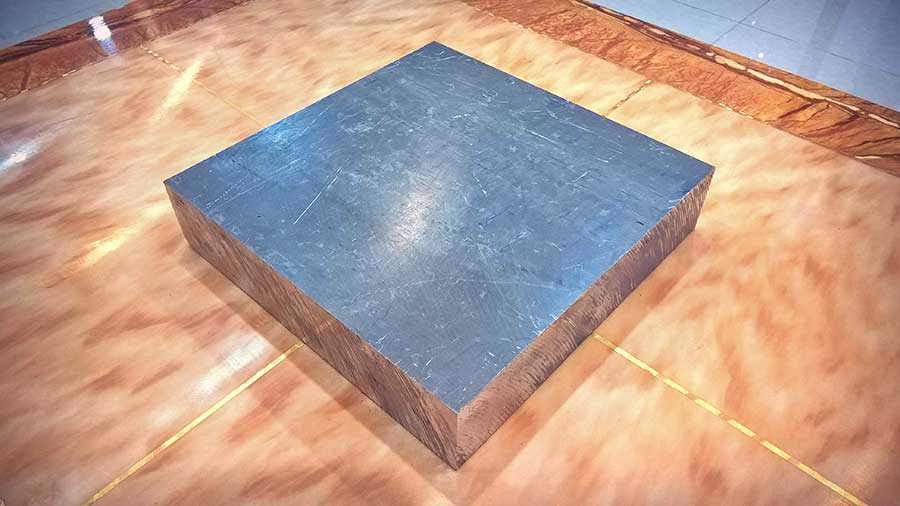

Many of those who followed the first publication were disappointed that a plastic version of the design was included in the series. From the beginning of this year, I began work on updating, and thanks to a successful platform, it was enough to add just one detail to update the appearance. I didn’t want to do flexible, stamping or metal welding at all. This would violate the integrity of the appearance and contradict the basic concept of design - solidity. Therefore, I decided to return to the only right way: milling on CNC machines from a single piece of aluminum. It is from these bars weighing 5.5 kg that the updated design will be produced:

')

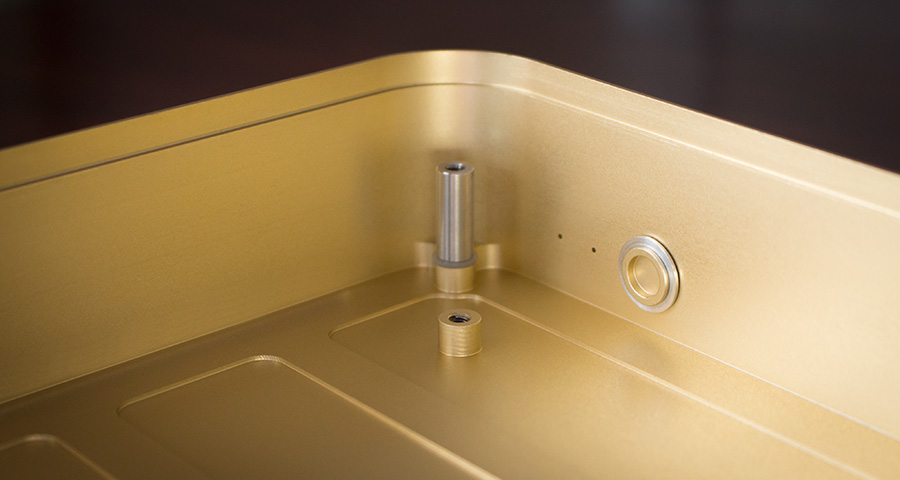

At the moment in the industry of cases for self-assembly of computers, a similar approach simply does not exist. Basically, this is extrusion of aluminum with further boring on CNC machines, or more simple operations on metal bending. A variant of injection molding with subsequent finishing treatment was considered, but this option did not guarantee a flat surface on the entire part and the possibility of further beautiful anodizing due to the composition of aluminum used in casting. Aluminum 5052-T32 was chosen as the material for milling. This composition is used in most housing products, computers, tablets and phones because of its optimum strength and more predictable anodizing results. Also, 747 vents in the upper part of the part have not been forgotten. Their task is to expel the heated air under the motherboard, thereby cooling the upper part of the case. These holes will be drilled by a separate high-precision machine.

Usually, electronics manufacturers save on finishing the internal surfaces of parts. In the case of proprietary solutions, this may be justified, but in the case when there is an opportunity to assemble the system yourself - this is unacceptable. And this is not from the field of design. This is from the realm of mood. It's like a beautiful jacket with a terrible lining. Everyone sees what's outside, but you know what's inside.

Not so long ago, I conducted a survey among buyers, both in Russia and abroad. The average feedback on the graphs below. As you can see, the main complaint was reduced to the noise level. And here there is one very interesting feature: buying a computer in such a small size, we, of course, want quiet operation from it. Even despite the fact that there is a desktop Core i7 processor installed. However, this trouble must be corrected.

The updated version will use Akasa fans with an optimized rotational speed curve and Enter Bearing technology (in simple terms - a sleeve) with up to 40,000 hours of life. In the previous version of the design, slide bearing fans were used, which created a certain level of noise that could be heard in the evening or at night. And at maximum speed - a characteristic buzz. Enter Bearing technology is free from these disadvantages. Another plus is that the aluminum part transmits much less noise from the fan than the plastic one. That is, even with powerful desktop processors, it was possible to achieve noise characteristics at the level of Nettops, built on the basis of Ultra Low Voltage processors. Subjectively, at maximum speed, the noise decreased by almost 2 times.

Internal dual-band antennas for M.2 wireless adapters have been added to the new design. And so that the aluminum cover does not serve as a screen, the antennas are placed at the bottom of the case. Connections at 2.4G / 5G frequencies are supported.

Test configuration:

Motherboard: Asus H110T (4 x USB3.0, HDMI, DisplayPort, 2 x Ethernet 1Gb, Audio)

Processor: Intel Core i7-6700 (8M, 3.40 GHz)

Memory: Kingston 2 x 4Gb DDR4 2133MHz

SSD: Kingston M.2 2260 SATA III 128G (530/360 Mb / sec)

SSHD: 1Tb Seagate (ST1000LM014)

WI-FI: M.2 WI-FI 802.11AC | BT 4.0 Broadcom

The Skylake processors were not as hot as their predecessors Haswell, and having the same calculated TDP, they heat much less. Now the recommendations for lowering the voltage of the processor are no longer necessary, but simply desirable. In this mode, the system consumes less energy than with the rated voltage of the CPU, and the fan speed at maximum loads is lower.

It should be noted here that as the load on the CPU increases, the temperatures of the other components of the system have not changed, but on the contrary, their cooling only becomes better. This directly affects the life cycle of motherboards and such “hot” components as M.2 SSD PCI-e drives. And of course, on the life of the built-in power supply. Its temperature, by the way, does not rise above 50 ° C even at maximum loads.

I was pleasantly surprised by the gaming capabilities of Skylake processors. Most of the games at a resolution of 1366 x 768 with average graphics settings and above were quite playable, and did not fall below 30 frames per second. Even in GTAV it was possible to play normally. Although, I agree that IGP HD 530 is not for such games.

We still manage to keep the palm in the UCFF PC form factor both in size and speed of work. With the updated design, we managed to make the appearance more attractive, reduce the noise characteristics, and in the new configurations add support for Skylake processors, high-speed SSD drives and M.2 wireless adapters. And all this works fine, in the case, the volume of only 2 liters.

Join our group VKontakte and go to the page on Facebook .

I will be glad to answer any questions on our website in the form of feedback.

Sincerely, Alexander.

Source: https://habr.com/ru/post/394933/

All Articles