LENR or not LENR? (review of experiments to detect LENR effect)

I think the topic LENR (Cold Fusion) is familiar to many, and probably the first thing that will be remembered is the Italian Andrea Rossi - and his E-Cat. But as they say, “not only Rossi is alive LENR” - there are other researchers who also did, do experiments, and get results - negative or positive.

A brief review of these experiments (15) will be made in the next publication (thanks to the material, thanks to the journal “Journal of Forming Directions of Science” unconv-science.org, and personally to Alexander G. Parkhomov)

')

Nickel-hydrogen reactors created after the publication of the report on the experiment in Lugano A.G. Parkhomov

Overview of some of the nickel-hydrogen reactors created in Russia and abroad after the publication of the report on the experiment in Lugano. Excess heat generation over consumed electricity was recorded in the range from 1.2 to 2.7 at a temperature of about 1200. The duration of continuous operation with excessive heat generation up to 3 days. Four reactors for estimating heat generation had special calorimeters.

During the testing of the high-temperature heat generator Rossi in Lugano, which lasted from February 24 to March 29, 2014, the excess heat was recorded over electricity consumed by 3.2 times at a temperature of 1260 and 3.6 times at a temperature of 1400 [1.2] . In spent fuel, the relative content of 6Li significantly increased and the content of 7Li decreased. The content of all nickel isotopes decreased, except for 62Ni. The content of this isotope increased from 3.6% to 99%. No noticeable difference in the radiation situation from the background indicators was detected.

Based on the report of experts observing the operation of the reactor, it can be assumed that this reactor is essentially a ceramic tube sealed with heat-resistant cement containing nickel powder with the addition of lithium aluminum hydride LiAlH4. To initiate the process, the tube must be heated to a temperature of 1200-1400. Based on this assumption, several devices were created in Russia and abroad. A brief description of some of them is devoted to this article.

AP1 reactors

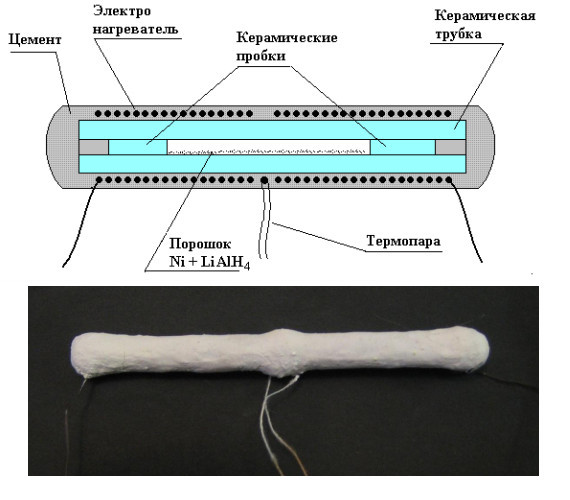

AP1 reactors are the first devices, similar to the high-temperature heat generator of Russia, in which excessive heat release was obtained in December 2014 [3]. For the manufacture of reactors used tubes of corundum ceramics with a length of 120 mm, an outer diameter of 10 mm and an inner diameter of 5 mm. Electric heaters are wound on the tubes. Inside the tubes there is 1 g of Ni powder + 10% lithium aluminum hydride. Thermocouples are in contact with the outer surface of the tubes. The ends of the tubes are sealed with heat-resistant cement. The same cement covers the entire surface of the reactors.

AP1 reactors are the first devices, similar to the high-temperature heat generator of Russia, in which excessive heat release was obtained in December 2014 [3]. For the manufacture of reactors used tubes of corundum ceramics with a length of 120 mm, an outer diameter of 10 mm and an inner diameter of 5 mm. Electric heaters are wound on the tubes. Inside the tubes there is 1 g of Ni powder + 10% lithium aluminum hydride. Thermocouples are in contact with the outer surface of the tubes. The ends of the tubes are sealed with heat-resistant cement. The same cement covers the entire surface of the reactors.To measure the heat produced, a technique based on the amount of boiling water was used. The reactor was in a closed metal vessel. This vessel is immersed in water. The amount of heat released was determined by the mass of water that was added to maintain its constant level and the known value of the heat of vaporization (2260 kJ / kg). The correction for heat loss through thermal insulation was calculated from the cooling rate after the reactor was turned off.

In addition to experiments with reactors loaded with a mixture of Ni + LiAlH4, experiments were carried out with reactor models without fuel. In cases with reactor layouts, as well as with reactors with fuel at temperatures below 1000, the ratio of released thermal energy to absorbed electricity (COP) was close to 1. Significant excess of released thermal energy over absorbed electricity (up to 2.7 times) It was observed only in reactors with fuel at temperatures of about 1100 and above. The level of ionizing radiation during the reactor operation did not noticeably exceed background levels. The neutron flux density was no higher than 0.2 neutrons / cm2s.

The duration of the operation of the AP1 series reactors in the mode of release of excess energy did not exceed 90 minutes. The short duration of the reactor operation is associated with damage caused by local overheating and heater burnout.

Project Dog Bone

Simultaneously with the testing of the AP1 reactors, the work was carried out in the collaboration of the Martin Fleischmann Memorial Project (MFMP) led by Robert Grigne [4]. In one of the reactors made, the fuel (565 mg Ni + 105 mg LiAlH4) was in a sealed corundum tube 250 mm long and 3.8 mm in internal diameter. A silicon carbide heater was outside.

Simultaneously with the testing of the AP1 reactors, the work was carried out in the collaboration of the Martin Fleischmann Memorial Project (MFMP) led by Robert Grigne [4]. In one of the reactors made, the fuel (565 mg Ni + 105 mg LiAlH4) was in a sealed corundum tube 250 mm long and 3.8 mm in internal diameter. A silicon carbide heater was outside.During the test, this reactor exploded at a temperature of about 1050. The reason for the failure was too fast heating and excessive lithium aluminum hydride content in the fuel.

GlowStick project

After the failure of the Dog Bone project, MFMP took as its basis the GlowStick reactor developed by Alan Goldwater [5]. The reactor consists of a ceramic tube on which are placed two identical electric heaters connected in series. One of them heats the fuel mixture (Ni 300 mg + LiAlH4 30 mg), and the other heats the empty portion of the tube. In the presence of excess heat, the temperature of the part of the reactor with fuel must be greater than the temperature of the part without fuel.

After the failure of the Dog Bone project, MFMP took as its basis the GlowStick reactor developed by Alan Goldwater [5]. The reactor consists of a ceramic tube on which are placed two identical electric heaters connected in series. One of them heats the fuel mixture (Ni 300 mg + LiAlH4 30 mg), and the other heats the empty portion of the tube. In the presence of excess heat, the temperature of the part of the reactor with fuel must be greater than the temperature of the part without fuel.During the start-up of the first two GlowStick reactors, excess heat was not detected. The third reactor operated from May 28 to 30, 2015. At a temperature on the surface of the reactor above 600 ℃ (about 1000 ℃ inside the cells), the temperature of the fuel cell was significantly higher (up to 80) the temperature of the empty cell. In this mode, the reactor worked for about 30 hours with an average excess power of 160 W, generating 4.8 kWh (17 MJ) of excess energy.

AP2 Reactor

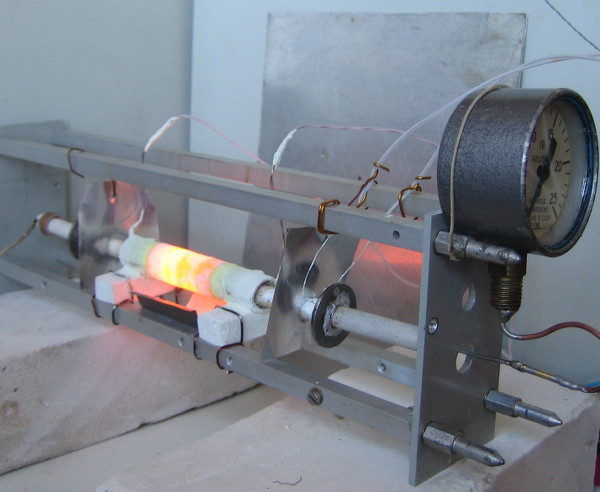

This reactor operated on March 16-20 and March 21-22 [6]. The reactor tube had an inner diameter of 5 mm and an outer diameter of 10 mm. The tube is 29 cm long, and only the central part (7 cm) is heated. The heater is made of alloy H23YU5T (fechral). The ends of the tube are sealed with an epoxy resin sealant. The fuel mixture (640 mg Ni + 60 mg LiAlH4) was in a container of thin stainless steel. Ceramic inserts are inserted into the tube to displace excess air from the reactor tube. A pressure gauge with a measurement limit of 25 bar is connected to the reactor with a thin stainless steel tube.

This reactor operated on March 16-20 and March 21-22 [6]. The reactor tube had an inner diameter of 5 mm and an outer diameter of 10 mm. The tube is 29 cm long, and only the central part (7 cm) is heated. The heater is made of alloy H23YU5T (fechral). The ends of the tube are sealed with an epoxy resin sealant. The fuel mixture (640 mg Ni + 60 mg LiAlH4) was in a container of thin stainless steel. Ceramic inserts are inserted into the tube to displace excess air from the reactor tube. A pressure gauge with a measurement limit of 25 bar is connected to the reactor with a thin stainless steel tube.The electric heater is connected to the mains through a thyristor regulator. An electronic meter was used to measure the energy consumed, which allows the computer to record information about the energy consumed. To control the temperature of the reactor, a thermocouple chromel-alumel is used, the junction of which is located on the surface of the reactor tube in the middle of the heating zone. The signal from the thermocouple was used to adjust the power supplied to the electric heater so that the desired temperature was maintained. The determination of the amount of heat produced was made on the basis of a comparison of the parameters of the reactor containing the fuel mixture and the reactor without the fuel mixture.

A temperature of 1200 on the surface of the reactor tube was achieved in 12 hours as a result of a gradual increase in the power of the electric heater to 630 W. After that, approximately in 1 hour, the power required to maintain the temperature of 1200 decreased to 330 W. For almost 3 days, the power of the electric heater, at which the temperature on the surface of the reactor tube was 1200, was in the range of 300–400 W. The power of heat generation exceeded that consumed by the electric heater, on average, by 2.4 times. The operation of the reactor was interrupted due to burnout heater.

The pressure inside the tube at a temperature of about 180 quickly increased to 5 bar. With further heating, the pressure gradually decreased and at a temperature of more than 900 it became less than atmospheric.

When working with the second heater, the temperature of 1200 was maintained at the power of electrical heating from 500 to 700 watts. The heat generation power exceeded consumed by the electric heater 1.3-1.7 times

In just 4 days of operation of the reactor, more than 40 kWh or 150 MJ were generated in excess of the electricity consumed.

Brian Albiston Experiment (Brian Albiston)

The pressure in the reactor tube at a temperature of about 200 quickly increased to 6 bar. Subsequently, the pressure gradually decreased to 2 bar and remained so until the end of the experiment.

The experiment of Denis Vasilenko

The operation of the reactor at a temperature of more than 1000 lasted for about 6 hours on May 24-26, 2015 and ceased as a result of burnout of the reactor heater with fuel. The strong destruction of cement in the central part of the fuel pipe and the burning of the kanthal coil indicate a significant excess heat generation compared to an empty reactor, where the helix remained intact and the cement was well preserved, although the material, the dimensions of the tube, and the power of the electric heating of both reactors were the same.

Experiments of Evgeny Buriak (VNIIEF, Sarov)

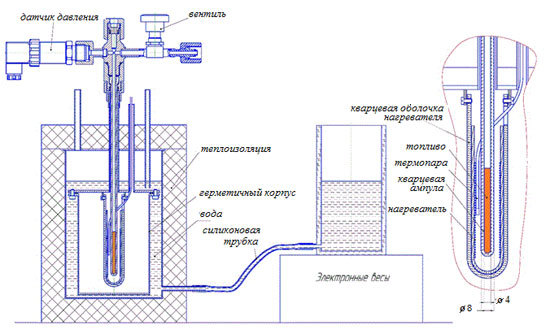

The experiments took place in March-May 2015 [9]. Fuel (500mg Ni + 50mg LiAlH4) was placed in a stainless steel container placed in a quartz ampoule. The nichrome heater was powered by pulses with a duration of 0.76 ms, power was regulated by the frequency of the pulses. The determination of the heat generated was carried out by measuring the mass of evaporated water. Heating at a rate of 0.02 ℃ / s occurred until a temperature of 1000 or 1200 was reached, then for about an hour the temperature was kept stable.

The experiments took place in March-May 2015 [9]. Fuel (500mg Ni + 50mg LiAlH4) was placed in a stainless steel container placed in a quartz ampoule. The nichrome heater was powered by pulses with a duration of 0.76 ms, power was regulated by the frequency of the pulses. The determination of the heat generated was carried out by measuring the mass of evaporated water. Heating at a rate of 0.02 ℃ / s occurred until a temperature of 1000 or 1200 was reached, then for about an hour the temperature was kept stable.Measurements showed that at a temperature of 1000 ℃ the power of excess heat was 42 W (COP = 1.21), at a temperature of 1200 an excess power of 83 W (COP = 1.25).

The pressure inside the reactor quickly increased to 7 bar when the temperature reached 200. After that, the pressure slowly increased and by the end of the experiments reached 8-9 bar.

Heat generator I. Stepanova (MSU), Y. Malakhov and Nguyen Quoc Shi (MEI)

A flow calorimeter was used to determine the heat generated. A damping tank was used to stabilize the flow rate of the water. Water consumption and water temperature at the inlet and outlet of the calorimeter were measured, which made it possible to determine the heat release power in the reactor.

After four attempts to start, which ended with the rapid destruction of the cell due to uncontrolled overheating, on June 19, 2015, as a result of slow heating (9 hours), it was possible to achieve stable operation with release of excess energy. At temperatures below 1000, the temperatures inside and outside the reactor were about the same. At higher temperatures, the temperature inside has become greater than outside, which indicates the presence of additional heat release.

Work with excess heat lasted more than an hour at a temperature of about 1100. Calorimetry showed that 2100 W of heat was released with an applied electrical power of about 850 W (COP = 2.5).

Five flat cassettes with X-ray photographic film were mounted on the outer case of the installation and on the continuation of the axis of the calorimeter. The duration of exposure was almost 12 hours. After the development of films, no effects on the photoemulsion layer were found.

Experiment of a group of researchers from Moscow (LenzandCoLab)

As the plugs used screws M5, brewed with a laser. Thermocouple wires are welded to the middle of the tube. Another thermocouple measured the temperature of the end of the tube. The heater was made of Fekhralev wire wound on a ceramic tube.

Heating to the maximum set temperature of 1350 lasted more than 8 hours. An hour after reaching this temperature, the power of the heater began to decrease, and the temperature of the reactor increased.

In the last minutes of the reactor operation, a temperature jump occurred above the measurement limit (1370), as a result of which the thermocouple burned out, the reactor and heater were destroyed.

Experiment at the Atomic Energy Institute, Beijing, China

Songsheng Jiang, Ni-H Research Group, China Institute of Atomic Energy, Beijing, China

The experiment lasted for 96 hours on May 4-8, 2015. At the beginning of the experiment, the chamber was evacuated, then gradual heating was turned on. As a result of decomposition of LiAlH4 at a temperature of 150-300, the pressure increased to 4 bar. Subsequently, the pressure for 18 hours dropped to - 0.9 bar.

The next day, when the temperature inside the cell with fuel reached 950 ℃ with a heater power of 900 W, the temperature quickly rose to such an extent that the central thermocouple collapsed. The temperature on the cell surface exceeded 1370 ℃ (measurement limit), and became much higher than the temperature around the electric heater, which indicates the appearance of excessive heat generation in the reactor cell with a capacity of at least 600 W. Excess capacity was maintained for about 6 hours. When restarting, a section of a self-sustaining regime lasting about 10 minutes was observed.

During a similar experiment in November 2015, a section of about 120 minutes was observed, when the reactor was operated with the external heating disconnected, emitting about 450 W at a temperature of about 1300 [16].

Experiments of the same Chinese researchers with nickel wire

In the process of gradual heating after reaching a temperature of about 900, a rapid rise in temperature occurred, with all three thermocouples showing a temperature above the measurement limit (1000). Abnormal warm-up lasted about 80 minutes. Two hours later, an increase in temperature of about 3 ℃ took place, lasting 3.5 hours. An estimate of the magnitude of excess heat gives a value of 240W (1,100 kJ) in the first event and 5W (64 kJ) in the second event. Control measurements without nickel wire did not detect any abnormal heat generation. After the experiment, damage to the nickel wire was found. Research on an electron scanning microscope showed strong changes on the surface of the wire.

The experiment of Andrei Hrishanovich

The heat release in a reactor filled with hydrogen was compared with the heat release in a reactor filled with air at the same heating power of the nickel coil by electric current.

It was found that at a hydrogen pressure of 1 bar, heat dissipation in a reactor filled with hydrogen is greater than heat dissipation in a reactor with air by 1.5 times, and at pressures up to 5 bar, it is 2-2.5 times.

Jeff Morris experiment

During heating to temperatures of 312, 398 and 498, the Geiger counter registered a multiple increase in the counting rate compared to the background one.

After the heating was turned off for an hour, the counting rate gradually returned to the background value.

Experiment in RSE INP, Kazakhstan (A.N. Ozernoy, M.F. Vereshchak, I.A.Manakova, I.V. Khromushin)

Conducted a test test of the system with two empty containers. The temperature difference turned out to be zero over the entire range of changes in the ambient temperature from 20 to 1200. After that, an experiment was conducted with a container loaded with fuel and empty containers. Within four hours, the temperature was linearly raised from room temperature to 1200. Then an hour-long exposure at this temperature followed, after which the furnace was turned off and began to cool without forced cooling. When the temperature was set, an increase in the temperature difference between the containers was observed. At the moment of reaching the specified temperature, a slight decrease was found, but then, although the furnace temperature dropped from 1200 to 600, the temperature difference decreased only by 10%.

Using the measured temperature difference between two containers, using the Stefan-Boltzmann law, taking into account the degree of blackness of the container material, it was found that the container emitted about 21 W of thermal power at a temperature difference of 25 ℃ and an ambient temperature of 1200. The test duration was limited to 100 hours. All this time, the temperature difference was about 25 ℃. According to calculations, during the test period, the container with the fuel produced more than 2 kW · h of thermal energy.

Experiments V.N. Zatelepina and D.S. Baranova Laboratory "INLIS"

Several nickel-hydrogen reactors have been tested in different temperature conditions under the effects of high-frequency electric discharge and high-frequency acoustic oscillations [15]. In addition to electric heating, a gas-flame heating has been tested. It was concluded that to initiate a reaction with excessive heat generation, a temperature gradient is necessary.

The behavior of reactors with external heating turned off has been investigated. It has been found that under certain conditions an abnormally rapid decrease in temperature is possible in nickel-hydrogen systems.

FINDINGS

- A mixture of nickel powder and lithium aluminum hydride, which forms hydrogen after decomposition, was usually used as a fuel. The mass of fuel is about 1 g. The exception is the first Chinese experiment (20 g).

- In the second Chinese experiment, as well as in the experiment of Hrishchanovich and Jeff Morris, nickel wire was used in a hydrogen atmosphere.

- Typically, the fuel was in a container of thin stainless steel or nickel, placed in a sealed corundum-based ceramic tube. In addition, experiments were conducted using quartz and stainless steel instead of ceramics.

- Electric heaters were made on the basis of the wire from fehrl (cantal) or nichrome. Such heaters are not able to provide long-term operation of reactors. An alternating, direct or pulsed current was used to power the heaters.

- In all experiments, except for the Chinese and experiments of Hrishanovich and Jeff Morris, there was no preliminary vacuuming. The pressure in the reactor usually did not rise above a few bar at a temperature of 180–200 and with further heating remained at this level or decreased.

- In most experiments, controllers are used that maintain the set temperature. Heating to operating temperature was carried out for several hours.

- Four experiments to estimate heat generation had special calorimeters. In other experiments, the method of comparing reactors with and without fuel was used to estimate heat generation. The excess of heat generation over the consumed electricity was in the range from 1.2 to 2.7.

- The termination of the operation of the reactors occurred either because of their destruction, or because of the end of the working day where it was impossible to work around the clock.

- An increase in the level of radiation was noticed only in the experiments of Jeff Morris.

Literature

Open

[1] Levi G., Foschi E, Höistad B.

[2] Parkhomov A.G. Report of the international commission on testing high-temperature heat generator Rossi. ZHNN, 2014, v.2, № 6, p. 57-61.

[3] Parkhomov A.G. Investigation of an analogue of high-temperature heat generator Rossi. ZhFNN, 2015, v. 3, No. 7, p. 68-72.

[4] www.coldfusionvideos.com/videogallery/wired-magazine-features-explosion

[5] www.quantumheat.org

[6] Parkhomov A.G. The test results of a new version of the analogue of high-temperature heat generator Rossi. ZHNN, 2015, vol. 3, No. 8, p. 34-38.

[7] http://www.hydrogenfusion.blogspot.ru/search?updated-min=201-01-01-01T00:00:00-08:00&updated-max=2016-01-01T00:00:00-08:00&max -results = 6

[8] lenr.seplm.ru/novosti/prezentatsiya-opyta-s-analogogom-ag-parkhomova-denisa-vasilenko-iz-volgograda

[9] yadi.sk/i/JM5BH21QjijAB

[10] Stepanov I.N., Malakhov Yu.I., Shi Nguyen-Quoc. An experiment to register excess energy in a heat cell loaded with a mixture of powders of nickel and lithium aluminum hydride. ZHNN, 2015, v.3, No. 9, p. 90-93

[11] lenr.seplm.ru/novosti/3-soobshcheniya-o-uspeshnom-povtorenii-opyta-s-nikel-vodorodnym-teplogeneratorom-analog-rossi

[12] www.e-catworld.com/wp-content/uploads/2015/07/Excess-heat-production-in-hydrogen-loaded-nickel-wire.pdf

[13] lenr.seplm.ru/novosti/andrei-khrishchanovich-povtoril-opyt-s-yacheikoi-chelani

[14] lenr.seplm.ru/articles/v-kazakhstane-proveli-uspeshnyi-opyt-s-nikel-vodorodnoi-sistemoi

[15] lenr.seplm.ru/konferentsii/doklady-22-rkkhtyaishm

[16] www.e-catworld.com/wp-content/uploads/2016/03/AnomalousHeat_Jiang_2015_English.pdf

[17] www.e-catworld.com/2016/03/05/celani-replication-report-published-radiation-detected-jeff-morris

[2] Parkhomov A.G. Report of the international commission on testing high-temperature heat generator Rossi. ZHNN, 2014, v.2, № 6, p. 57-61.

[3] Parkhomov A.G. Investigation of an analogue of high-temperature heat generator Rossi. ZhFNN, 2015, v. 3, No. 7, p. 68-72.

[4] www.coldfusionvideos.com/videogallery/wired-magazine-features-explosion

[5] www.quantumheat.org

[6] Parkhomov A.G. The test results of a new version of the analogue of high-temperature heat generator Rossi. ZHNN, 2015, vol. 3, No. 8, p. 34-38.

[7] http://www.hydrogenfusion.blogspot.ru/search?updated-min=201-01-01-01T00:00:00-08:00&updated-max=2016-01-01T00:00:00-08:00&max -results = 6

[8] lenr.seplm.ru/novosti/prezentatsiya-opyta-s-analogogom-ag-parkhomova-denisa-vasilenko-iz-volgograda

[9] yadi.sk/i/JM5BH21QjijAB

[10] Stepanov I.N., Malakhov Yu.I., Shi Nguyen-Quoc. An experiment to register excess energy in a heat cell loaded with a mixture of powders of nickel and lithium aluminum hydride. ZHNN, 2015, v.3, No. 9, p. 90-93

[11] lenr.seplm.ru/novosti/3-soobshcheniya-o-uspeshnom-povtorenii-opyta-s-nikel-vodorodnym-teplogeneratorom-analog-rossi

[12] www.e-catworld.com/wp-content/uploads/2015/07/Excess-heat-production-in-hydrogen-loaded-nickel-wire.pdf

[13] lenr.seplm.ru/novosti/andrei-khrishchanovich-povtoril-opyt-s-yacheikoi-chelani

[14] lenr.seplm.ru/articles/v-kazakhstane-proveli-uspeshnyi-opyt-s-nikel-vodorodnoi-sistemoi

[15] lenr.seplm.ru/konferentsii/doklady-22-rkkhtyaishm

[16] www.e-catworld.com/wp-content/uploads/2016/03/AnomalousHeat_Jiang_2015_English.pdf

[17] www.e-catworld.com/2016/03/05/celani-replication-report-published-radiation-detected-jeff-morris

Source: https://habr.com/ru/post/393905/

All Articles