How and where are the world's largest diamonds grown

The largest and high-quality artificial diamonds are grown today in the vicinity of Sestroretsk, next to St. Petersburg. We will tell you about our Russian company NDT and how the best girls' friends are born.

The certificate for a record-sized synthetic diamond weighing 10.02 carats, E color and purity VS1 was issued by the International Gemological Institute of Hong Kong (IGI) of the Russian company New Diamond Technology (NDT). Precious stones with such characteristics for the jewelry world are a rather trivial phenomenon, but an artificial stone cut from 32 carat synthetic diamond is an event for the market of synthetic diamonds, and this event is unique.

')

Production, which managed to grow a record crystal is concentrated in a small shop in one of the technology parks near Sestroretsk. The capacities of the enterprise are limited to more than three dozen hydraulic presses, inside which, under conditions of high temperatures and pressures, microns per micron, diamonds of the highest quality grow. On the control panels of the controllers for each press reflects the current parameters. “The general principles of diamond synthesis are well known and have been used in industry for more than half a century. But the details of the synthesis modes are one of our company's know-how, ”shared production director Roman Kolyadin. "... Precision air conditioners maintain the microclimate in the workshop with an accuracy of tenths of a degree. At the same time, even a small draft can lead to an undesirable deviation in temperature, which can significantly degrade the quality of the diamond," the expert adds.

A brief history excursion

The first attempts to synthesize artificial diamond were made at the end of the XVIII century, when scientists came to the final conclusion that carbon is the basis of the diamond. Since the end of the XIX century, scientists have tried to turn cheap and affordable forms of carbon (coal or graphite) into a hard and shiny diamond. Statements about the success achieved were made by many, including renowned scientists, including the French chemist Henri Moissan and the British physicist William Crookes. Somewhat later, it was found that none of them could produce real evidence of the result obtained. The first artificial diamond presented to the world was obtained in 1954 in the laboratory of General Electric.

Interestingly, in the process of producing synthetic diamond at GE, they were guided by the “technology” that nature itself uses. As experts reasoned, natural diamonds are formed at a temperature of about 1,300 ° C and a pressure of about 50,000 atm. in the thickness of the mantle of the planet at a depth of hundreds of kilometers below the surface of the Earth. Crystals are brought to the surface by lamproites, kimberlites and other igneous rocks. To simulate the described conditions in the laboratory, GE specialists used a press that pressed a cell inside which graphite and an iron-nickel-cobalt melt were placed, acting as a catalyst and solvent.

GE specialists called their technology HPHT (High Pressure High Temperature - high pressure, high temperature). Over time, it was she who was taken as the basis for obtaining inexpensive technical diamonds and diamond powder.

How are diamonds grown today?

Industrial production of synthetic diamonds today is carried out mainly on one of two technologies - the above-mentioned HPHT technology and CVD technology. Exotic techniques are less used, such as the synthesis of diamond nanocrystals from graphite in an explosion or an experimental method of obtaining micron diamonds from a suspension of graphite particles in organic solvents under the influence of ultrasonic cavitation.

HPHT

The technology is reduced to the process of growing diamond single crystals at a high temperature (about 1500 ° C, with the desired gradient) and high pressure (50–70 thousand atm.). A hydraulic press compresses a special container, inside which is a metal melt (iron, nickel, cobalt, etc.) and graphite. On the substrate is placed one or more seed - small diamond crystals. An electric current flows through the chamber, heating the melt to the desired temperature. Under these conditions, the metal serves as a solvent and catalyst for the crystallization of carbon on the seed in the form of diamond. The process of growing one large or several smaller crystals lasts, on average, 12–13 days.

The volume of industrial production of artificial diamonds and diamond dust today reaches billions of carats per year. In the 1970s, using HPHT technology, they learned how to make medium quality jewelery weighing up to 1 carat.

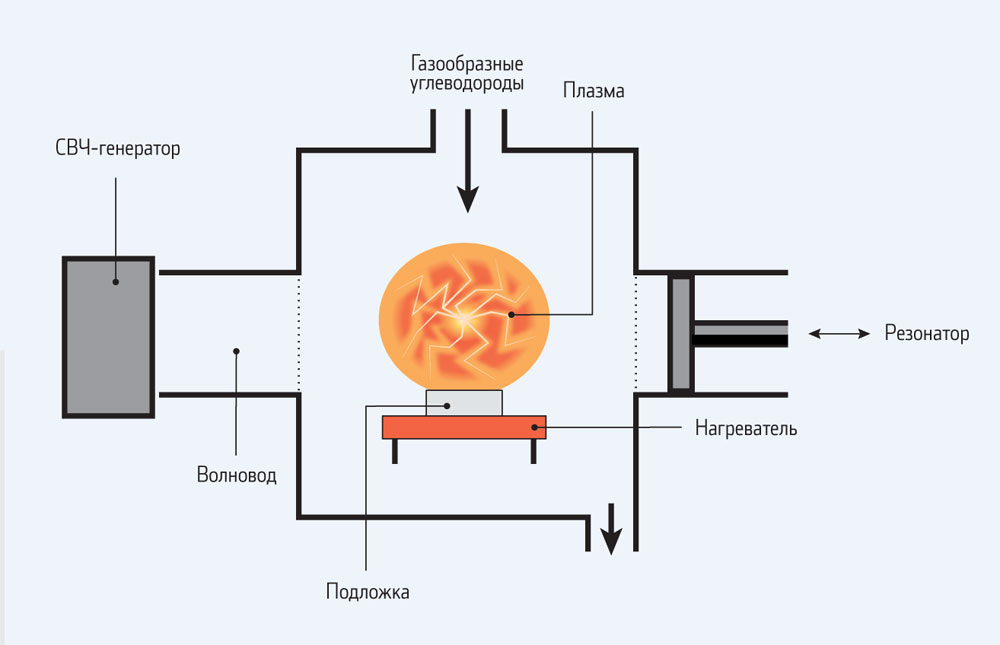

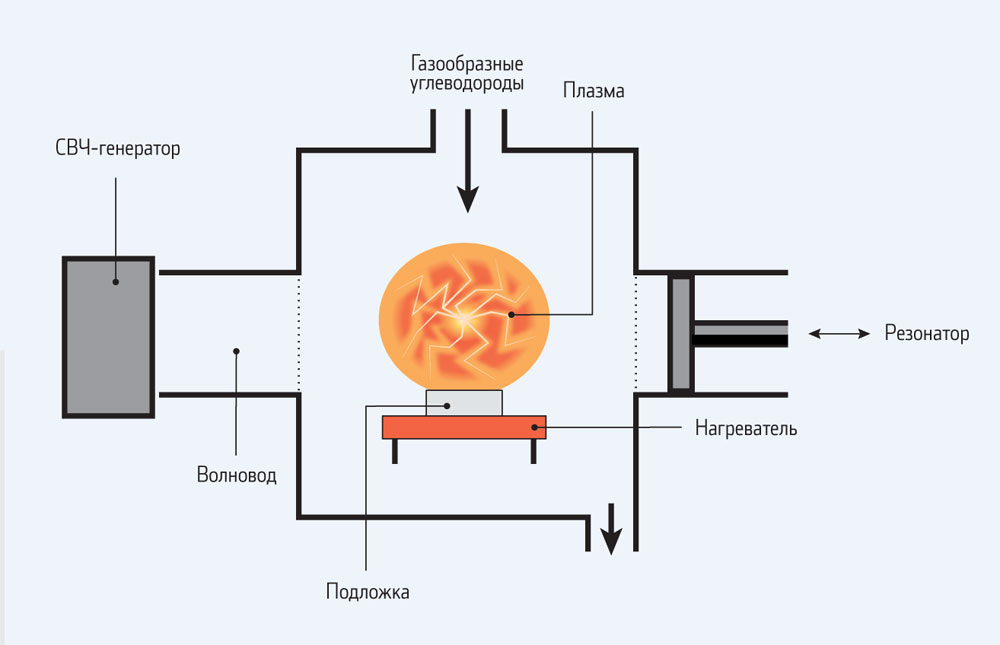

CVD

Since the 1960s, the world's leading laboratories have been developing an alternative, less expensive diamond synthesis technology - CVD (Chemical Vapor Deposition, vapor deposition). In the process of synthesis, diamonds are deposited on a substrate, heated to 600–700 ° C from a hydrocarbon gas, which is ionized with microwave radiation or heated to high temperatures. When deposited on silicon or polycrystalline diamond, a polycrystalline plate is obtained, which has limited use in electronics and optics. Growth rate - from 0.1 to 100 microns / h. Plate thickness is usually limited to 2–3 mm, so diamonds cut from it can be used as jewelry, but their size, as a rule, does not exceed 1 carat.

The possibilities of this synthesis method in the early 2000s attracted a lot of attention from both small startups and large companies, such as Element Six, a member of the De Beers industrial group.

The potential of the HPHT method, until recently, remained highly undervalued. “When we bought equipment a few years ago, we were all in one voice saying that industrial presses are suitable only for the synthesis of diamond powders,” says Nikolai Khikhinashvili. All attention and resources were focused mainly on improving the CVD method. At the same time, HPHT technology was considered a niche, since the vast majority of specialists simply did not believe that it could be used to grow rather large and high-quality crystals. And, nevertheless, according to Nikolai, NDT specialists managed to offer their own synthesis technology, which allows to obtain diamonds of such quality and size, which until this moment could only be achieved by working with natural crystals. As for cutting technology, then grown in the laboratory, and natural diamonds are processed in exactly the same way.

Best friends girls

“Of course, we are not the only ones who grow diamonds larger than 5–6 carats,” Nikolay shares. - But absolutely all companies today are subject to the principle of "two out of three": large, high-quality, commercially viable. Our company was the first to master the technology that allows to obtain large crystals of high quality diamond at an acceptable cost. 32 presses allow us to grow about 3000 carats per month, and at the same time all the stones of very high quality - diamonds of the D, E, F color categories and purity from the purest IF to SI, mainly type II. 80% of our products are jewelry diamonds weighing from 0.5 to 1.5 carats, although technological capabilities allow us to grow diamond of any size to order. ” As proof of this, Nikolay showed a crystal the size of a 10-ruble coin to journalists: “This one, for example, 28 carats. After cutting a carat diamond will turn out to be 15 ".

Since the beginning of the 2000s, the world diamond monopolist, the concern De Beers, has expressed concerns about the prospect of entering the jewelry market for synthetic diamonds, which, according to management, could undermine its business. But, as time has shown, synthetic diamonds are not competitors to natural stones, as they occupy in comparison an insignificantly small share of the jewelry market. In addition, during the improvement of their production technologies, research methods were developed, which allow fairly confidently and accurately to identify synthetic diamonds. Among the characteristic features of the synthesis, metal inclusions should be mentioned, and in colored diamonds, easily identifiable growth sectors. In addition, artificial stones obtained using HPHT technology, CVD in comparison with natural natural diamonds in UV rays have a different nature of luminescence.

“How do consumers treat grown diamonds?” Quite favorably, says Nikolay, especially the modern youth, for whom it turns out to be important that these diamonds are conflict-free and created by people with the help of high technologies without interfering with nature. Well and, not least, the cost of such stones is approximately twice as low. Of course, the certificate should reflect that the stones were grown, but it is clear that the owner of the ring with such a diamond will not need to carry a certificate! At the same time, both the physical and chemical properties of diamonds grown in the NDT laboratory are identical to natural ones, ”the expert concluded.

What is common between diamond and nitrogen

Depending on the nitrogen content, diamonds can be assigned to one of two main types. Type I diamonds contain up to 0.2% nitrogen, the atoms of which are located in the lattice sites by groups (Ia) or singly (Ib). Diamonds of this type prevail among natural diamonds (98%). Most often, such stones are not colorless. Type IIa diamonds contain almost no nitrogen (less than 0.001%). Such crystals in the realm of natural minerals - a rarity, only 1.8%. Practically, nitrogen-free diamonds with an admixture of boron (IIb) are not found (in 0.2% of cases). Boron atoms in the lattice sites determine their electrical conductivity and give diamonds a bluish tint.

Diamonds in industrial production

Jewelry diamonds are a very profitable business for NDT and similar companies, but already today another, more priority and, in all likelihood, long-term trend is clearly visible. NDT technical director Alexander Kolyadin likes to repeat: “If you can’t make anything from a diamond anymore, make a diamond.” In fact, the industry is the most promising direction of the market for large, high-quality synthetic diamonds. “No natural diamond can be used in special optics or electronics,” says Alexander Kolyadin, “because there are too many defects in them initially. But the plates, cut from diamonds of our production, have almost perfect crystal lattice. Therefore, some research organizations to which we provide our samples for study, hardly believe in the measurement results obtained - they are so close to ideal. At the same time, it is possible to achieve another significant result - to ensure the repeatability of characteristics, which is of fundamental importance for a number of industrial areas. Diamonds are a kind of heat sink, windows for special optics and synchrotrons, this is power microelectronics, which are being developed and improved all over the world today. ”

The lion’s share of the company's budget revenue is still provided by jewelry diamonds. At the same time, the emerging trends suggest that in the coming years the demand for synthetic diamonds and diamond plates for special optics, microelectronics and other high-tech industrial spheres will increase in a progression.

“The industrial sector is still 20% of our production, but in three years we plan to bring it up to 50%, especially since demand is growing rapidly. Now we mainly make 4 x 4 and 5 x 5 mm plates, cut out a few 7 x 7 and 8 x 8 mm and even 10 x 10 mm by request, but it’s still premature to talk about mass production. Our next goal, says Nikolai Khikhinashvili, is the transition to the manufacture of inch diamond plates. This is the “golden size” and the necessary minimum, which is very much in demand in the mass electronic and optical industry. And to obtain such plates, you will need to grow a diamond crystal weighing a hundred carats. " Provide the first "prototypes" of such plates in the NDT plan by the end of this year.

A source

That's all, with you there was a simple service for choosing sophisticated Dronk.Ru equipment. Do not forget to subscribe to our blog , there will be many more interesting things.

LetyShops cashback service sponsor . Return money for any purchases on the Internet. Read more about what a cashback service is in our article. We choose a cashback service for the 6th anniversary of Aliexpress.

The certificate for a record-sized synthetic diamond weighing 10.02 carats, E color and purity VS1 was issued by the International Gemological Institute of Hong Kong (IGI) of the Russian company New Diamond Technology (NDT). Precious stones with such characteristics for the jewelry world are a rather trivial phenomenon, but an artificial stone cut from 32 carat synthetic diamond is an event for the market of synthetic diamonds, and this event is unique.

')

Production, which managed to grow a record crystal is concentrated in a small shop in one of the technology parks near Sestroretsk. The capacities of the enterprise are limited to more than three dozen hydraulic presses, inside which, under conditions of high temperatures and pressures, microns per micron, diamonds of the highest quality grow. On the control panels of the controllers for each press reflects the current parameters. “The general principles of diamond synthesis are well known and have been used in industry for more than half a century. But the details of the synthesis modes are one of our company's know-how, ”shared production director Roman Kolyadin. "... Precision air conditioners maintain the microclimate in the workshop with an accuracy of tenths of a degree. At the same time, even a small draft can lead to an undesirable deviation in temperature, which can significantly degrade the quality of the diamond," the expert adds.

A brief history excursion

The first attempts to synthesize artificial diamond were made at the end of the XVIII century, when scientists came to the final conclusion that carbon is the basis of the diamond. Since the end of the XIX century, scientists have tried to turn cheap and affordable forms of carbon (coal or graphite) into a hard and shiny diamond. Statements about the success achieved were made by many, including renowned scientists, including the French chemist Henri Moissan and the British physicist William Crookes. Somewhat later, it was found that none of them could produce real evidence of the result obtained. The first artificial diamond presented to the world was obtained in 1954 in the laboratory of General Electric.

Interestingly, in the process of producing synthetic diamond at GE, they were guided by the “technology” that nature itself uses. As experts reasoned, natural diamonds are formed at a temperature of about 1,300 ° C and a pressure of about 50,000 atm. in the thickness of the mantle of the planet at a depth of hundreds of kilometers below the surface of the Earth. Crystals are brought to the surface by lamproites, kimberlites and other igneous rocks. To simulate the described conditions in the laboratory, GE specialists used a press that pressed a cell inside which graphite and an iron-nickel-cobalt melt were placed, acting as a catalyst and solvent.

GE specialists called their technology HPHT (High Pressure High Temperature - high pressure, high temperature). Over time, it was she who was taken as the basis for obtaining inexpensive technical diamonds and diamond powder.

How are diamonds grown today?

Industrial production of synthetic diamonds today is carried out mainly on one of two technologies - the above-mentioned HPHT technology and CVD technology. Exotic techniques are less used, such as the synthesis of diamond nanocrystals from graphite in an explosion or an experimental method of obtaining micron diamonds from a suspension of graphite particles in organic solvents under the influence of ultrasonic cavitation.

HPHT

The technology is reduced to the process of growing diamond single crystals at a high temperature (about 1500 ° C, with the desired gradient) and high pressure (50–70 thousand atm.). A hydraulic press compresses a special container, inside which is a metal melt (iron, nickel, cobalt, etc.) and graphite. On the substrate is placed one or more seed - small diamond crystals. An electric current flows through the chamber, heating the melt to the desired temperature. Under these conditions, the metal serves as a solvent and catalyst for the crystallization of carbon on the seed in the form of diamond. The process of growing one large or several smaller crystals lasts, on average, 12–13 days.

The volume of industrial production of artificial diamonds and diamond dust today reaches billions of carats per year. In the 1970s, using HPHT technology, they learned how to make medium quality jewelery weighing up to 1 carat.

CVD

Since the 1960s, the world's leading laboratories have been developing an alternative, less expensive diamond synthesis technology - CVD (Chemical Vapor Deposition, vapor deposition). In the process of synthesis, diamonds are deposited on a substrate, heated to 600–700 ° C from a hydrocarbon gas, which is ionized with microwave radiation or heated to high temperatures. When deposited on silicon or polycrystalline diamond, a polycrystalline plate is obtained, which has limited use in electronics and optics. Growth rate - from 0.1 to 100 microns / h. Plate thickness is usually limited to 2–3 mm, so diamonds cut from it can be used as jewelry, but their size, as a rule, does not exceed 1 carat.

The possibilities of this synthesis method in the early 2000s attracted a lot of attention from both small startups and large companies, such as Element Six, a member of the De Beers industrial group.

The potential of the HPHT method, until recently, remained highly undervalued. “When we bought equipment a few years ago, we were all in one voice saying that industrial presses are suitable only for the synthesis of diamond powders,” says Nikolai Khikhinashvili. All attention and resources were focused mainly on improving the CVD method. At the same time, HPHT technology was considered a niche, since the vast majority of specialists simply did not believe that it could be used to grow rather large and high-quality crystals. And, nevertheless, according to Nikolai, NDT specialists managed to offer their own synthesis technology, which allows to obtain diamonds of such quality and size, which until this moment could only be achieved by working with natural crystals. As for cutting technology, then grown in the laboratory, and natural diamonds are processed in exactly the same way.

Best friends girls

“Of course, we are not the only ones who grow diamonds larger than 5–6 carats,” Nikolay shares. - But absolutely all companies today are subject to the principle of "two out of three": large, high-quality, commercially viable. Our company was the first to master the technology that allows to obtain large crystals of high quality diamond at an acceptable cost. 32 presses allow us to grow about 3000 carats per month, and at the same time all the stones of very high quality - diamonds of the D, E, F color categories and purity from the purest IF to SI, mainly type II. 80% of our products are jewelry diamonds weighing from 0.5 to 1.5 carats, although technological capabilities allow us to grow diamond of any size to order. ” As proof of this, Nikolay showed a crystal the size of a 10-ruble coin to journalists: “This one, for example, 28 carats. After cutting a carat diamond will turn out to be 15 ".

Since the beginning of the 2000s, the world diamond monopolist, the concern De Beers, has expressed concerns about the prospect of entering the jewelry market for synthetic diamonds, which, according to management, could undermine its business. But, as time has shown, synthetic diamonds are not competitors to natural stones, as they occupy in comparison an insignificantly small share of the jewelry market. In addition, during the improvement of their production technologies, research methods were developed, which allow fairly confidently and accurately to identify synthetic diamonds. Among the characteristic features of the synthesis, metal inclusions should be mentioned, and in colored diamonds, easily identifiable growth sectors. In addition, artificial stones obtained using HPHT technology, CVD in comparison with natural natural diamonds in UV rays have a different nature of luminescence.

“How do consumers treat grown diamonds?” Quite favorably, says Nikolay, especially the modern youth, for whom it turns out to be important that these diamonds are conflict-free and created by people with the help of high technologies without interfering with nature. Well and, not least, the cost of such stones is approximately twice as low. Of course, the certificate should reflect that the stones were grown, but it is clear that the owner of the ring with such a diamond will not need to carry a certificate! At the same time, both the physical and chemical properties of diamonds grown in the NDT laboratory are identical to natural ones, ”the expert concluded.

What is common between diamond and nitrogen

Depending on the nitrogen content, diamonds can be assigned to one of two main types. Type I diamonds contain up to 0.2% nitrogen, the atoms of which are located in the lattice sites by groups (Ia) or singly (Ib). Diamonds of this type prevail among natural diamonds (98%). Most often, such stones are not colorless. Type IIa diamonds contain almost no nitrogen (less than 0.001%). Such crystals in the realm of natural minerals - a rarity, only 1.8%. Practically, nitrogen-free diamonds with an admixture of boron (IIb) are not found (in 0.2% of cases). Boron atoms in the lattice sites determine their electrical conductivity and give diamonds a bluish tint.

Diamonds in industrial production

Jewelry diamonds are a very profitable business for NDT and similar companies, but already today another, more priority and, in all likelihood, long-term trend is clearly visible. NDT technical director Alexander Kolyadin likes to repeat: “If you can’t make anything from a diamond anymore, make a diamond.” In fact, the industry is the most promising direction of the market for large, high-quality synthetic diamonds. “No natural diamond can be used in special optics or electronics,” says Alexander Kolyadin, “because there are too many defects in them initially. But the plates, cut from diamonds of our production, have almost perfect crystal lattice. Therefore, some research organizations to which we provide our samples for study, hardly believe in the measurement results obtained - they are so close to ideal. At the same time, it is possible to achieve another significant result - to ensure the repeatability of characteristics, which is of fundamental importance for a number of industrial areas. Diamonds are a kind of heat sink, windows for special optics and synchrotrons, this is power microelectronics, which are being developed and improved all over the world today. ”

The lion’s share of the company's budget revenue is still provided by jewelry diamonds. At the same time, the emerging trends suggest that in the coming years the demand for synthetic diamonds and diamond plates for special optics, microelectronics and other high-tech industrial spheres will increase in a progression.

“The industrial sector is still 20% of our production, but in three years we plan to bring it up to 50%, especially since demand is growing rapidly. Now we mainly make 4 x 4 and 5 x 5 mm plates, cut out a few 7 x 7 and 8 x 8 mm and even 10 x 10 mm by request, but it’s still premature to talk about mass production. Our next goal, says Nikolai Khikhinashvili, is the transition to the manufacture of inch diamond plates. This is the “golden size” and the necessary minimum, which is very much in demand in the mass electronic and optical industry. And to obtain such plates, you will need to grow a diamond crystal weighing a hundred carats. " Provide the first "prototypes" of such plates in the NDT plan by the end of this year.

A source

That's all, with you there was a simple service for choosing sophisticated Dronk.Ru equipment. Do not forget to subscribe to our blog , there will be many more interesting things.

LetyShops cashback service sponsor . Return money for any purchases on the Internet. Read more about what a cashback service is in our article. We choose a cashback service for the 6th anniversary of Aliexpress.

Source: https://habr.com/ru/post/393875/

All Articles