Homemade 3D printer on SCARA mechanics, v3

Homemade 3D printer on SCARA mechanics, v3

Video work v3 speeds 100+ mm / sec.

Previous versions v1 and v2

Details about the previous printer can be found here .

Print video of the previous version

Previous mechanic in OpenScad

What was not so with such mechanics:

- transfer of rotation for a length of 30 cm through an m5 stud and an aluminum tube ID: 6 OD: 8 gave errors due to slight twisting, at the end of 30 cm it reached 0.5 degrees - correctable

- low rigidity of levers - correctable

- expensive math - even optimized could not be calculated (on Mega) faster than 50 mm / sec

- Z hanging platform - 2 bearings on each guide solved problem v1, but I was not satisfied with the rigidity

V3

The v2 version turned out to be a file - I even allowed the idea to abandon this direction and assemble the usual simple mechanics, but the desire to do something unusual would not let me rest.

Actually, after several days of reflection, I decided that I would continue to work in the direction of the SCARA mechanic.

Hand mechanics - in the classic SCARA one of the motors is at the end of the first hand, this adds weight to the carryout and the requirements for stiffness of the hand, in fact, I really wanted to avoid it, v1 and v2 solved this problem, for v3 this is solved with a lever and short straps.

Video (very short) how it works

For homing, micro switches were added for each lever.

')

Z axis - this time I decided that I would have a static platform and the mechanic itself would move on Z, there are several advantages in this:

- a static platform that can be freely separated from the base and moved to replace, and in case of emergency, simply fold and set aside so as not to interfere

- as it is not strange, the rigidity of the base only benefited from this since two 8mm guides were added to its structure

- compactness

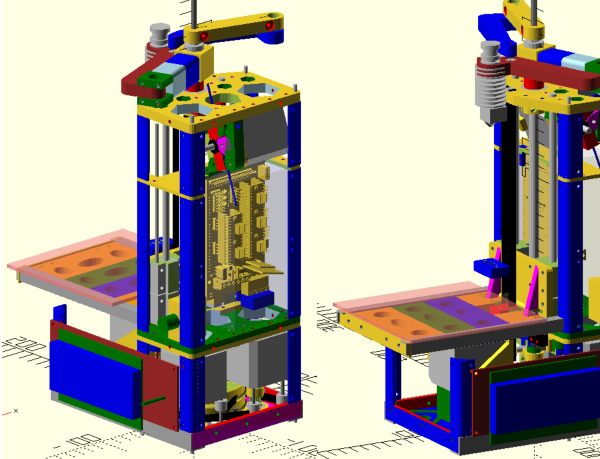

Sectional view (without home switches)

Z min switch

Everyone is here

Electronics - This time I decided to take out the electronics (Ramps 1.4 + DRV + LCD2004) in a separate unit - also not without reason - after the third assembly / disassembly of the printer I was tired of doing this and I built a box that will roam from one my project to another (by itself it will be necessary to change only the firmware)

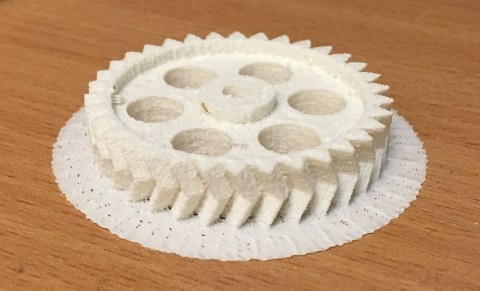

The extruder - since the mechanics allowed us to drive at speeds of 100+ a simple extruder was not enough - I had to design a Geared extruder.

OpenScad files (scarav3.scad)

Firmware

Result

I am more than satisfied with the result, the print quality on this printer suits me.

From the problems it can be noted that there is a small wave along the XY axes (due to the discreteness of the walkers and the number of splitting steps - now it is 50)

Further ideas:

- A higher transfer ratio of at least x5 (now x4)

- Reduce the weight of the arms and increase their rigidity - I will make it from aluminum

- E3D v6 - weight reduction

- Smaller shagi - current on 4kg * cm are a bit redundant

- Reducing the length of the ptfe tube - a very important indicator not for a direct extruder - there is even an idea to hang the extruder on the axis of rotation of the hands - will work if the previous item is completed

- Reducing dimensions - the highest priority in height

Source: https://habr.com/ru/post/393593/

All Articles