New elastomer stretches to 100x of its size and recovers from damage.

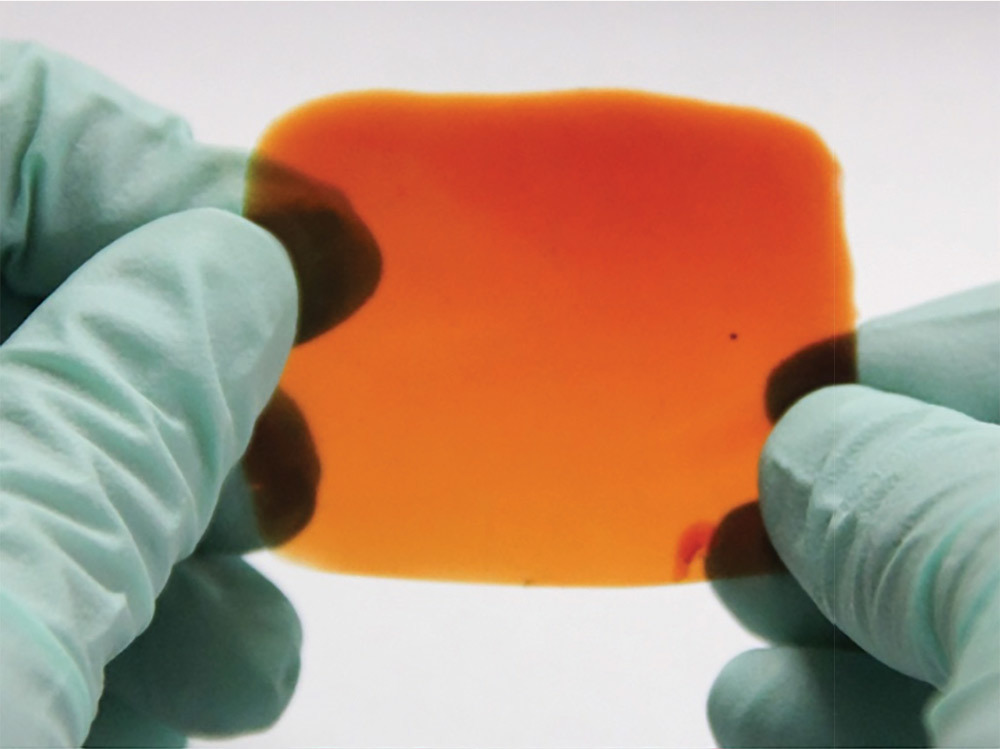

Stanford chemists have developed a material that stretches 100 times the original size and then shrinks back without losing properties. It also reacts to the electric field and recovers from damage.

The unique properties of the new elastomer offer tremendous opportunities for its use in various industries, including in robotics and medicine, for example, as the basis for artificial skin and artificial muscles.

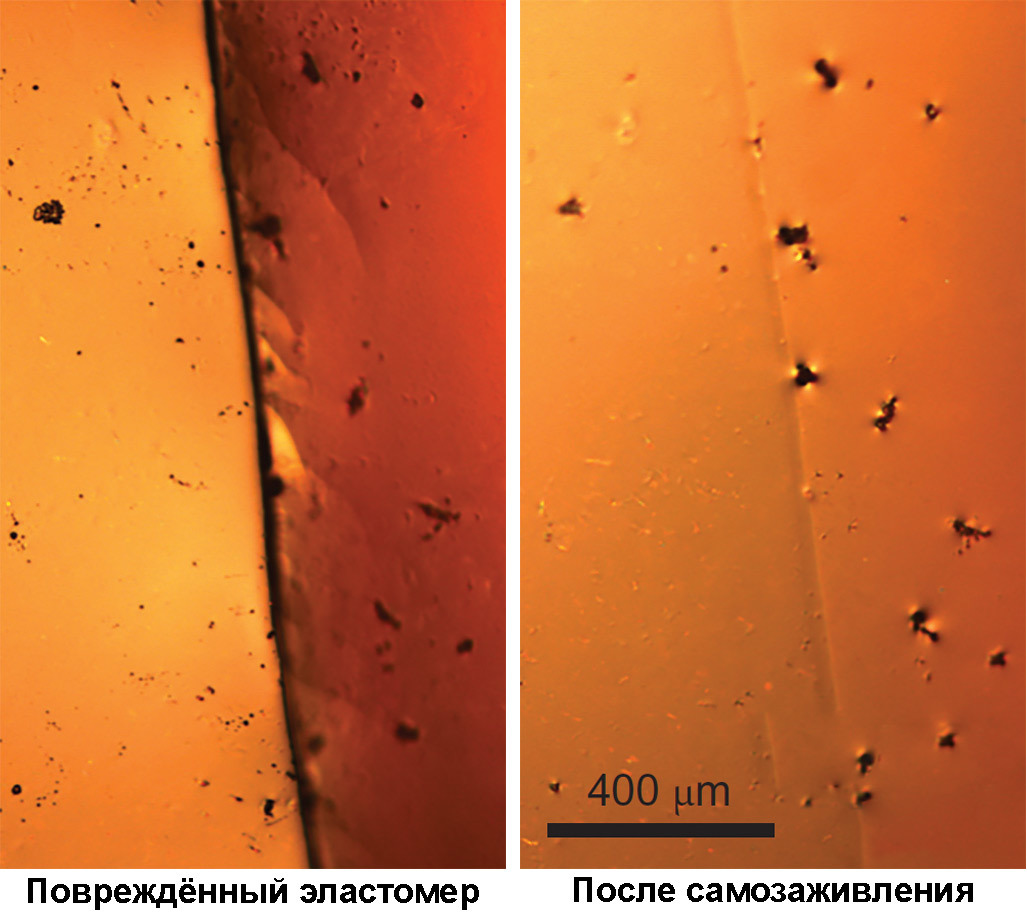

Artificial muscles can now be used in consumer electronics and robotics, but the slightest defects and damage dramatically reduce the elasticity of the material. Existing elastomers are usually stretched only two to three times. In addition, they cannot be restored after punctures or scratches without any outside intervention (for example, heating). The new elastomer is devoid of all these shortcomings, says Genan Bao , professor of chemical engineering at Stanford University.

')

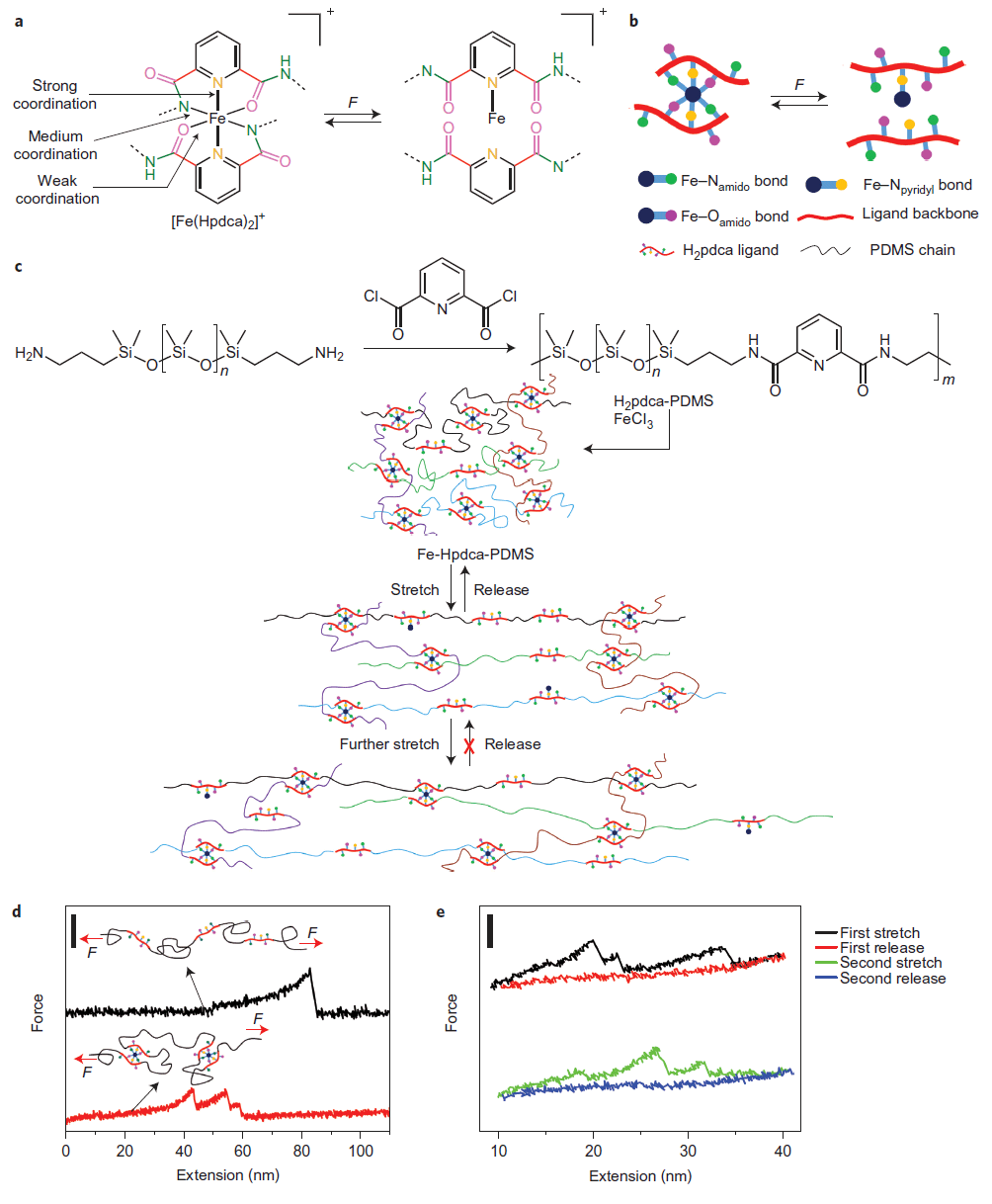

The inventors explain how the polymer can stretch to such an incredible distance. Like self-healing, this property is explained by a cardinal improvement in the process of cross-linking - special chemical bonds between polymer molecules. During this process, the linear chains of the molecules are connected in a network structure similar to a fishing net.

To improve the properties of the material, scientists first designed special organic molecules that are attached to short strands of polymers in their cross-links, creating structures called ligands. These ligands then combine to form longer polymer chains, like spring coils with their inherent extensibility.

Then metal ions are added to the material, which are chemically bound to the ligands. As a result, when the resulting material is stretched, the nodes in the structure are weakened - and allow the ligands to separate from each other. If the tension is gone, then the proximity of metal ions and ligands again tightens the grid. Each metal ion is associated with at least two ligands, and even if one of the bonds is lost as a result of tension or damage, it is then able to restore this bond if it is close enough to the ligand.

The chemical structure of the material explains why it restores itself after damage. Self-healing occurs at temperatures from -20 ° C and above, special heating is not required.

The physical properties of the elastomer — its elasticity or healing rate — can be varied by changing the amount and type of metal ions added to the organic material. Due to the metal, the polymer also reacts to the electric field, that is, such artificial muscles can be controlled by electronic pulses from a computer.

The material is great for making artificial leather, which can be stretched on the prostheses of people with lost limbs. Of course, the self-healing elastomer is suitable for covering the housings and covers of wearable electronics, smartphones, medical devices, implants, etc.

The scientific work of Zhenin Bao and his colleagues was published in the journal Nature Chemistry (doi: 10.1038 / nchem.2492, pdf ).

Source: https://habr.com/ru/post/393387/

All Articles