The robot on three axes

The author: Nikolai Khabarov

Many people, hearing the "robot", represent a kind of human-like device. However, the robot does not always look like this. Sometimes a robot is just a “smart machine” capable of making different things. Let's see what kinds of such robots exist, how they can be used and programmed to create different things.

The first robot machine

')

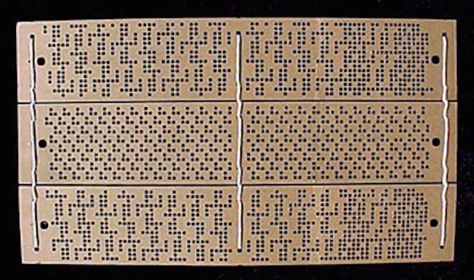

One of the first robots of this kind was created back in 1804 - a jacquard loom, which could be programmed to make fabrics with different patterns using a punched card, which we see on the right:

Such a punch card was inserted into the machine and asked for it a sequence of pulling the threads, due to which the machine produced a fabric with a corresponding pattern. Changing the punch card, you could get a different pattern on the same machine.

CNC machine

Later on, numerical control machines (CNC, or CNC) appeared:

Such machines allow you to make various things with the help of programs using tools that are worn on the axis of the machine that moves in three directions - along the X, Y and Z axes.

Milling machine

One of the most common machines of this kind - milling, which allows you to process metals, plexiglas or wood. In the machine you can put the workpiece from the appropriate material, and from it, depending on the program, you get different things. As we see, the milling cutter moves in three axes relative to the workpiece, sawing through the pattern according to a given program:

In addition to the cutters, you can use a variety of drills. The material can be any if it can be drilled or sawed. The accuracy of these machines is very high - even the cheapest ones provide 1/400 millimeter head positioning accuracy. These machines can be really big:

There are also milling machines with five axes. They are quite complicated and expensive - it is not easy to provide a mechanic that would precisely move the mill in five axes to work with strong materials. For example, such a machine rotates the workpiece around its axis and the mill itself along five axes:

Plasma cutting

In CNC machines, you can use plasma cutters to easily cut metal. Here is an example of a plasma cutter:

The plasma torch works in the same way as electric arc welding: an arc is ignited, and air is heated into this arc under low pressure, which heats up to 10–15 thousand degrees; due to heating, the pressure increases, and this jet cuts through the metal. Cheap plasma cutters, which anyone can buy in a store, can cut through 13 mm of steel. By fixing such a plasma cutter on a CNC machine, you can cut through quite thick sheets of metal with very high precision.

Laser cutting

Also recently, laser cutters have been used on CNC machines. Unlike plasma cutters, which can cut only metal, a laser cutter can cut almost any material.

However, there are some safety issues with the laser cutter: for example, the machine shown in the photo above is equipped with a few hundred watts CO 2 laser. In this case, the laser beam is invisible, because it is in the infrared range. This requires special security measures.

The video below shows an example of a simple laser cutter, a semiconductor laser on a machine that I assembled myself. Then he cuts through the inscription on a piece of paper - the emblem of DeviceHive, one of the company's internal projects. It is a 300-millimate semiconductor laser with a wavelength of 405 nanometers. Such power allows you to cut paper and burn on plywood:

3D printers

Another very popular area of application for robotic machines is 3D printers:

In fact, a 3D printer is the same machine with the same three axes, but at the same time equipped with an extruder:

An extruder is a small device with a stepper motor and a heater that advances plastic wire, melts it, and with the help of layers forms a plastic product. As a rule, ABS or PLA is used. Below is an example of using an extruder on the same machine on which the laser was attached. We see the gradual overlay of layers for printing a three-dimensional triangle:

Opentrons

Another interesting application of robotic machines was proposed by the young company OpenTrons - for biological experiments:

This is a three-axis design, as a working tool on which chemical pipettes for transfusion of liquids are attached. Various chemicals and biomaterials are laid out on the desktop, and the robot mixes them according to a predetermined program. And users can upload programs of ready-made experiments to the network.

Food stamp

3D printers are used not only for printing plastic, but also, for example, for printing food:

Printing buildings

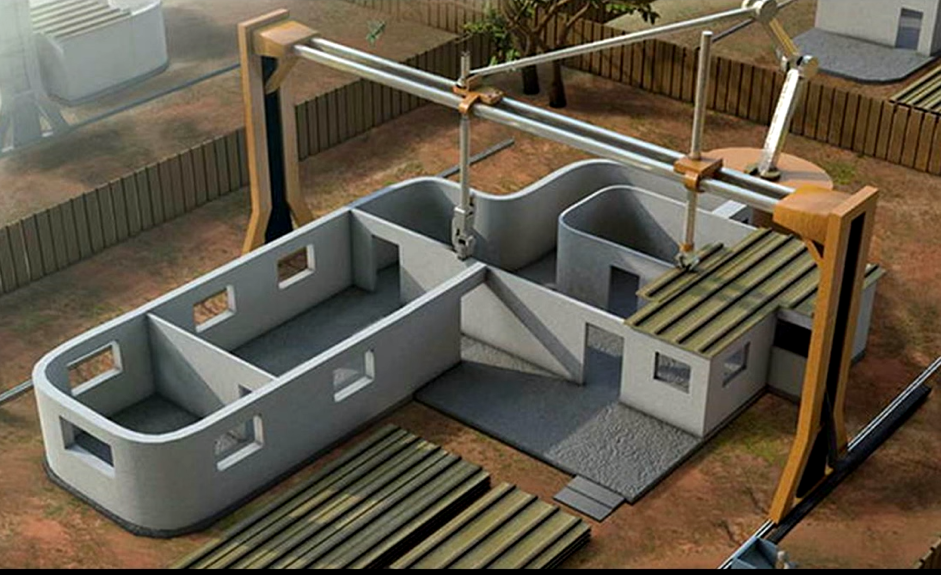

Also interesting is the idea of printing buildings:

Of course, for printing buildings, the CNC setting must be very large, but the principle remains the same: there is movement in three axes, and the building is built from cement. At the same time, special cement is needed so that the building can be built without reinforcement; or the robot needs to add reinforcement, which will make it much more difficult. Such a robot can work day and night without stopping:

Tesla factory

The Tesla plant is almost completely automated. If you look closely, you can see that the robots in the photo are all the same CNC machines. They have several axes along which the tool moves. With the help of such robots going car body by welding.

Code to control the machines

Such machines are controlled, as a rule, with the help of the so-called G-code. G-code describes the movement of the axes of the machine. Below in the second column, the code describes how to circle the letter W:

The first line (G90 G40 G17) specifies the mode of operation of the machine. The second line includes a spindle at a speed of 500 revolutions per minute. In the third line, G0 is the command to move the head at idle (at maximum speed and in the safest category). In the fourth line, Z-1.0 indicates that the machine needs to approach the workpiece. In the fifth line, G1 is the working stroke when the machine starts sawing or squeezing something out of itself. Etc.

To create such a G-code from 3D-models, drawings or even SVG-drawings, there are many programs.

Sample homemade machine

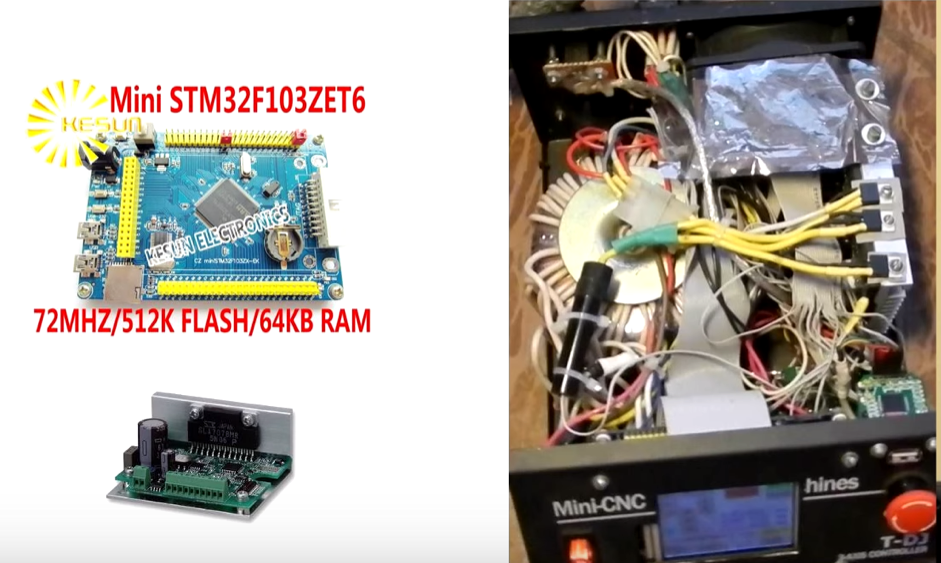

Below is a machine that I assembled myself on the basis of a standard frame (above), which you can safely buy:

I added an extruder for a 3D printer and a small semiconductor laser to the frame, in addition to the usual cutter. Before that, we saw two videos (with 3D printing and a laser) showing work on such a machine.

Here's what's inside the machine:

Here we see a small STM32 microcontroller. The firmware takes about 200 KB. Using this microcontroller, you can control five axes and two different devices using pulse width modulation (either spindle speed or laser power). The microcontroller itself, as we can see in the photo, is under the screen. The entire rear end is a power supply and stepper motor drivers that stand on the machine. The bottom left of the image, as an example of a stepper motor driver, is a board with a microchip, which is also sold separately. Such a device can produce different items with high accuracy. Here is a small demo video of this machine:

The firmware of the machine was written from scratch in pure C-code. You can try to design such a machine yourself - all the sources can be taken on GitHub .

Source: https://habr.com/ru/post/393287/

All Articles