Open-source open-hardware TC / "variwatt" mod for vaping on STM32

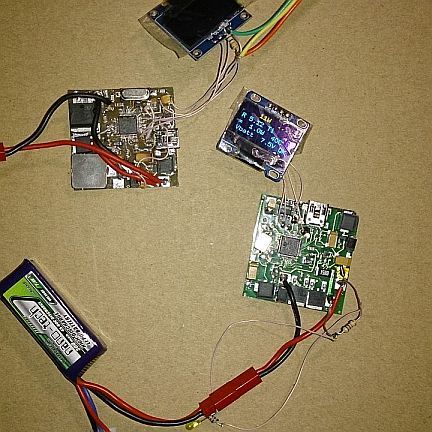

Since my previous mod on Arduin had many limitations, as well as in terms of self-education, I decided to make a new version on STM32F373C8T6. This is my first project on STM32, there are quite a few flaws in it. I hope someone else will be interested, and we can make it better!

Project on github

')

Characteristics of the resulting device:

39x40x7 double-layer board (it would be necessary to make a 4-layer version, smaller, and with elements on one side, so that the reverse side can be used for touch pads, which will allow you to simply stick the board to the reverse side of the front panel)

Uses 2S (two cells in series) lithium batteries, which is safer, easier to wind spirals and easier to find small light batteries among those designed for RC models

Built-in boost controller for USB charging (with balanced port, to guarantee non-recharge of one of the cells)

Touch buttons (no need to make holes in the case, just stick the pieces of foil on the back side and the inscription / corrugated surface with the front)

Cheap components - just one STM32F373C8T6 chip (costs from $ 3 per piece) and several inexpensive MOSFETs

100+ watts of power (theoretical — even closer to 200, but not tested)

128x64 0.96 "OLED screen (clearly visible in the light, only $ 4)

Flashlight on two 70mA white LEDs (really useful option in the device, which is always at hand)

Software supports:

Titanium, nickel (ni200), NiFE30, stainless steel 316L and 304 for thermocontrol spirals

Power limiting mode (“variwatt”), from 0.5 watts to maximum (with correction for battery voltage)

Slow start mode to prevent "shooting" and burning thin spirals

Almost all important parameters are changed via the setup menu (saved in flash memory)

Current problems / plans:

To support the variant of the circuit with a choke coil (real stabilization of the coil current and increased thermal control frequency)

Correct the sleep mode (I could not figure it out completely), while it eats 3-4 milliamperes, which will discharge the 500 mAh battery in a few days

The PID controller went out of my way and was badly tuned (due to problems with USB debugging, I couldn’t find the coefficients properly)

The board needs to be remade a bit, smaller and with the back side only for sensors

Small display support

Optimize the size of the firmware (already rests on the limit of 60 kilobytes): (

Understand USB debugging (STM libraries are terribly awkward and often buggy)

Project on github

')

Characteristics of the resulting device:

39x40x7 double-layer board (it would be necessary to make a 4-layer version, smaller, and with elements on one side, so that the reverse side can be used for touch pads, which will allow you to simply stick the board to the reverse side of the front panel)

Uses 2S (two cells in series) lithium batteries, which is safer, easier to wind spirals and easier to find small light batteries among those designed for RC models

Built-in boost controller for USB charging (with balanced port, to guarantee non-recharge of one of the cells)

Touch buttons (no need to make holes in the case, just stick the pieces of foil on the back side and the inscription / corrugated surface with the front)

Cheap components - just one STM32F373C8T6 chip (costs from $ 3 per piece) and several inexpensive MOSFETs

100+ watts of power (theoretical — even closer to 200, but not tested)

128x64 0.96 "OLED screen (clearly visible in the light, only $ 4)

Flashlight on two 70mA white LEDs (really useful option in the device, which is always at hand)

Software supports:

Titanium, nickel (ni200), NiFE30, stainless steel 316L and 304 for thermocontrol spirals

Power limiting mode (“variwatt”), from 0.5 watts to maximum (with correction for battery voltage)

Slow start mode to prevent "shooting" and burning thin spirals

Almost all important parameters are changed via the setup menu (saved in flash memory)

Current problems / plans:

To support the variant of the circuit with a choke coil (real stabilization of the coil current and increased thermal control frequency)

Correct the sleep mode (I could not figure it out completely), while it eats 3-4 milliamperes, which will discharge the 500 mAh battery in a few days

The PID controller went out of my way and was badly tuned (due to problems with USB debugging, I couldn’t find the coefficients properly)

The board needs to be remade a bit, smaller and with the back side only for sensors

Small display support

Optimize the size of the firmware (already rests on the limit of 60 kilobytes): (

Understand USB debugging (STM libraries are terribly awkward and often buggy)

Source: https://habr.com/ru/post/393093/

All Articles