Everybody get out of the printer: a printed robot with a hydraulic drive can walk from birth

Engineers from the Laboratory of Computational Science and Artificial Intelligence at the Massachusetts Institute of Technology have developed a technology with which solid, flexible, and liquid components of a structure can be printed on an ordinary commercially available 3D printer.

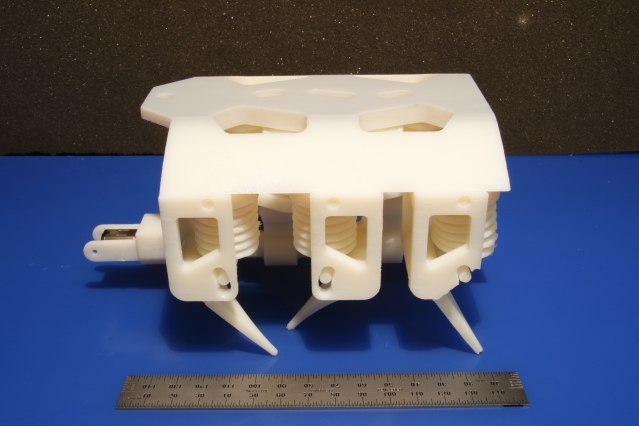

Thanks to this technology, it was possible, for example, to print a ready-made walking robot with hydraulic drive. It does not need to be collected at all - it is enough to add one motor, and the battery, and the robot will go straight from the printing table.

')

A six-legged robot weighing just under a kilogram and 15 cm long rearranges the limbs thanks to 12 hydraulic pumps driven by the crankshaft.

Printing with several materials has become possible thanks to inkjet technology. Droplets with a diameter of 20-30 microns, issued by the print head, are arranged with high accuracy on the substrate. Ultraviolet cures parts printed by photopolymer - they must become solid.

“In total, there are eight nozzles in the printhead, which allows us to simultaneously place different materials close to each other,” explains Robert MacCurdy of MIT. “This gives us the opportunity to control the distribution of the material with precision and to print complex structures, including channels that are pre-filled with liquid.”

As an additional demonstration of the capabilities of the new technology, engineers unpacked the soft manipulator for another MIT project, Baxter's robot , using soft hydraulic manipulators.

In the current version, the robot matures in the printer for 22 hours. Engineers claim that with the development of 3D printing and an increase in the resolution of printers, this process will gradually accelerate.

Source: https://habr.com/ru/post/392751/

All Articles