Engineers have created a solid and elastic metallic glass.

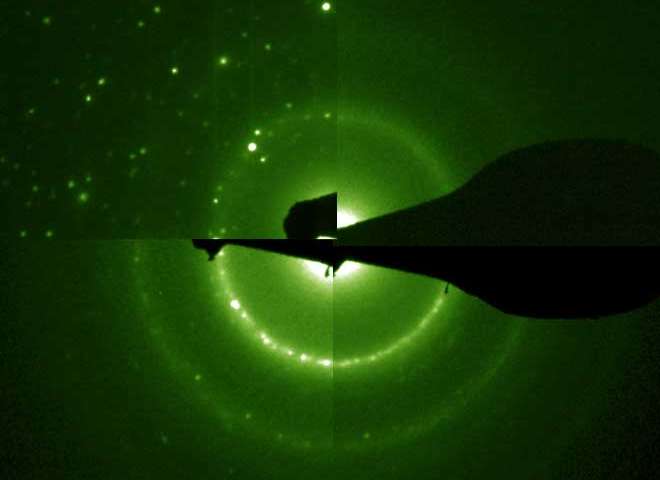

Obtained using a transmission electron microscope image of different levels of crystallization of amorphous metal

Engineers from the University of Southern California received a new type of metallic glass , characterized by increased elasticity. The material combines seemingly incompatible properties - hardness, strength and elasticity. The material, which received the technological name SAM2X5-630, has the highest impact strength of all known metallic glass.

Metallic glasses, or amorphous metals, are a class of metallic solids with an amorphous structure. Unlike metals with their crystalline structure, that of amorphous metals is similar to the atomic structure of supercooled melts.

On the left, a ball of new metallic glass is jumping, on the right, of ordinary steel.

')

The material is able to withstand strong blows, while it does not crumble and does not break, but returns the original shape. The potential of its use is almost unlimited - from drills and body armor to implants for strengthening bones and protecting satellite satellites.

Usually, amorphous metals are obtained by heating to 630 ° C and then very fast (about a degree per second) cooling. The material SAM2X5-630 was obtained by heating a powder composition based on iron (Fe 49.7 Cr 17.7 Mn 1.9 Mo 7.4 W 1.6 B 15.2 C 3.8 Si 2.4 ).

The unique properties of the metal come from the successful finding of the combination of the heating temperature and cooling rate — these are the conditions that the resulting composition has experienced that lead to the formation of local foci of a weakly pronounced crystalline structure. Other conditions of heating or cooling result in a completely amorphous metal with a random arrangement of atoms.

“It has almost no internal structure, and in this it is similar to glass, but there are crystallization regions,” said Veronica Eliasson, an assistant professor from the Viterbi Engineering School at the university, and lead author. “We still have no idea why a small number of crystallized areas in metallic glass lead to such strong differences in the reactions to the impact.”

The dynamic elastic limit of Hugoniot (the maximum effect that the material can withstand without irreversible deformation) was determined for SAM2X5-630 in the region of 12 GPa. In stainless steel, this indicator is 0.2 GPa, in tungsten carbide (used to create hard tools and cores of armor-piercing bullets) —4.5 GPa, in diamonds — up to 60 GPa.

The study of amorphous metals began in 1960 at the California Institute of Technology - a group of scientists obtained the first metallic glass Au 75 Si 25 . Since then, many similar materials with interesting properties have been obtained, but so far the area of their practical application cannot be called broad because of their high cost.

For example, recently obtained in Japan Ti 40 Cu 36 Pd 14 Zr 10 is non-carcinogenic, three times stronger than titanium, it wears little, does not form powder during friction, and its modulus longitudinal elasticity almost coincides with human bones — in potential, it can be used as excellent artificial replacement of joints.

Source: https://habr.com/ru/post/392699/

All Articles