The first winding package for a toroidal coil of an ITER superconducting magnet is manufactured.

An experimental thermonuclear reactor (ITER) is being built in the south of France, parts of which are manufactured in all parts of the world, including the USA, Russia, China, the EU, India, Japan, etc. The ITER installation will test the possibility of using thermonuclear fusion to generate electricity.

In the European Union, the project is led by Fusion for Energy . Among other things, Europe must produce 10 out of 18 winding packs of a superconducting magnet. A magnet will hold a plasma with a temperature of about 150 ppm, inside the toroidal field. Each of the D-shaped winding packages has a mass of about 110 tons, approximately like a Boeing 747. Dimensions - 14 by 9 m, thickness about 1 m.

')

After manufacturing 20 kilometers of winding, the material was delivered to the factories of the companies ASG (Italy), Iberdrola (Spain) and Elytt Energy (Spain), where the magnets are assembled. The winding was applied to the base of stainless steel - radial plates manufactured by CNIM and SIMIC .

The conductor is carefully wrapped, insulated and placed in the grooves of the plates before the final coating.

The core of the coil consists of seven articulated steel plates, pipes added along which liquid helium will circulate. For the core, the docking of the radial plates is completed, an insulating layer is applied. After insulation under vacuum pressure, the core will be sent to SIMIC for tests, and on return it will be inserted into the massive body of the coil.

Other components of the toroidal electromagnet are produced according to plan. In March, the release of radial plates accelerated: 45 out of 70 have already been manufactured. All components for the second coil are also ready for assembly.

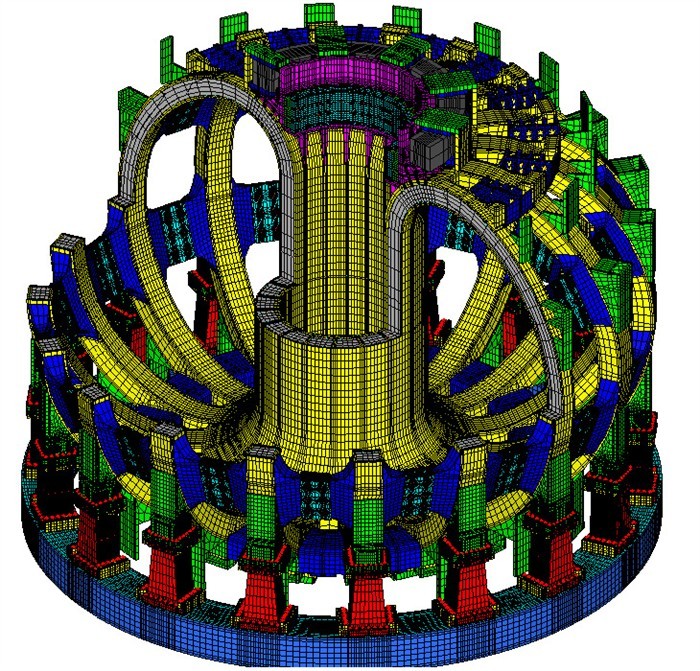

This is how the magnet will look like in its final form.

Construction of structures at the construction site ITER is also in full swing.

Source: https://habr.com/ru/post/391983/

All Articles