The heyday of manufacturing automation in China

According to the International Federation of Robotics (IFR), in recent years, China has been the largest market for industrial robots, and over the next two years, the number of such robots in factories and factories in China will exceed their number in the EU or US. And this is just the beginning. According to the same federation, there are only 30 robots per 10,000 workers in China, compared to 323 in Japan and 437 in South Korea.

Factory automation is an important issue for Japanese investors. Half of the foreign firms that provide industrial robots to China are Japanese, about 6 out of 10 industrial robots sold in China are created precisely in Japan.

')

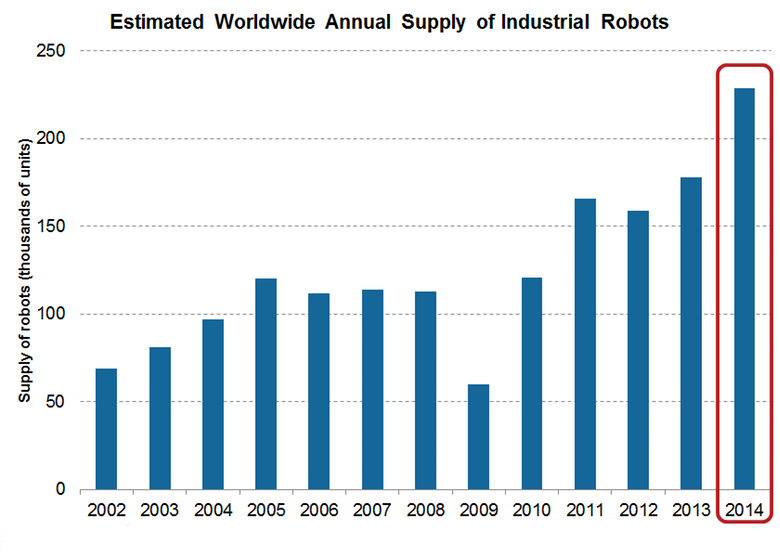

Automation of factories in China gained large and unprecedented speed. According to the calculations of the International Federation of Robotics, only in 2014 there was a significant jump in sales of industrial robots around the world by 29%, which is 229,261 units. In particular, the widespread use of robots is observed in the automotive sector and in the manufacture of electronics.

China is the world's largest market for robots and automated components, and in 2014 it reached 25% of the total number of robots used. According to the federation, compared with 2013, the growth of sales of industrial robots in China reached 56%, which is 57,096 units. The pace of automation is impressive. Between 2010 and 2014, the total use of industrial robots in China grew by an average of 40% annually.

China is the leader in the number of industrial robots in new markets (VWO), but is still inferior to Korea, Japan (DXJ), USA (VTI) and Germany (EWG).

The goal of Shenzhen Everwin Precision Technology is to reduce the number of workers by 90% while attracting more than 1,000 industrial robots. Other plants in the Pearl River Delta are already actively introducing robots in production. Thus, the factory of Changying Precision Technology in Dongguan has already reduced the number of workers from 650 to 60 people thanks to the automation of production. According to the People's Daily, this figure may drop to 20 employees. In addition, People's Daily claims that productivity per person has increased significantly: from 8,000 to 21,000 units, i.e. by 162.5%. The number of defects and errors also decreased: from 25 to 5%, thus increasing production efficiency.

Source: https://habr.com/ru/post/391955/

All Articles