About the practical benefits of 3D printing

Many people think that the technology of three-dimensional construction of the object is something complex and far from real life, and people who have purchased 3D printers use them rather for their own entertainment than for practical purposes.

In my practice, I had to observe both.

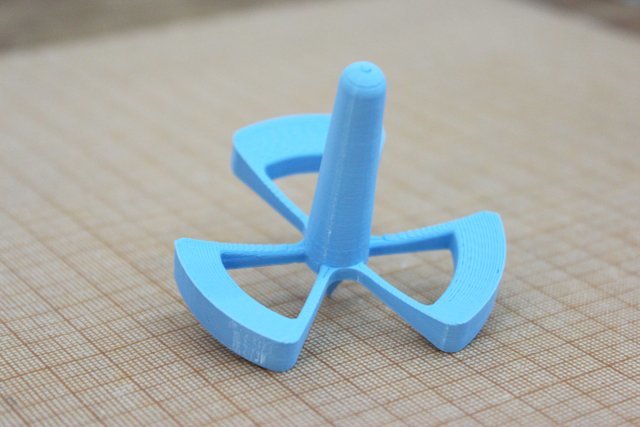

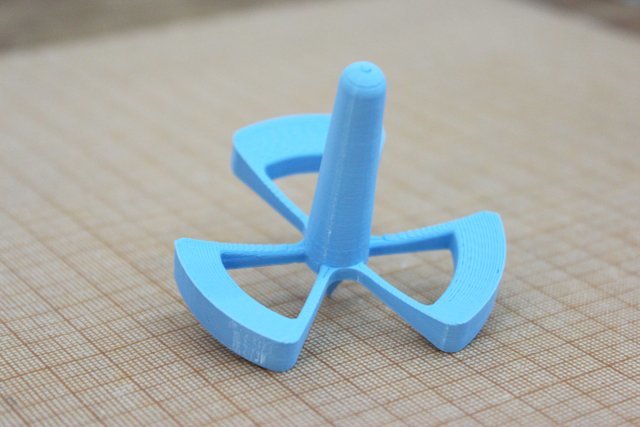

It all depends on setting goals. For example, to take and print on a 3D printer any stationery item (sharpener or container) is not a big deal. Like, for example, this small office "anti-stress" is a pendulum made of PLA plastic. Spin with your fingers and throw on the office desk. While he is spinning, we are distracted.

')

To simplify the process, you need to go to the popular site of free 3D models storage, download the one you like and download to your 3D printer. In a few hours we will get the result. And for many fairly experienced users of 3D printers, this process, to some extent, can be called entertainment.

A slightly different thing is the manufacture of parts and assemblies using 3D printing, which have direct practical application.

Here you have to devote a lot of time to the 3D model itself before you start printing it. It is necessary to check everything, after the end of the printing process, to adjust all surfaces to the entire structure and then draw conclusions about the prototype. This is a complete work on the creation of an industrial design. Although, probably, you will not surprise anyone with the prototypes from PLA, FLEX or ABS. But these are all objects whose value for a person can be disputed.

For people who have already encountered various 3D printing technologies, the advantages of prototyping here are pretty obvious. Well, compared with the manufacture of traditional methods in production. Depending on the specific industry, the time spent on making a particular prototype can vary greatly. However, in any case, the development, modeling and manufacturing of the prototype lasts quite a long time and, accordingly, includes a lot of budget expenses.

In this sense, 3D printing is the fastest possible result, regardless of the type of object construction technology - FDM, SLA or MJM. If you have an idea how to make an object, then you give a technical task for the manufacture of a model in 3D of any company specializing in these services. The idea may require the involvement of industrial designers, of course. With a clear formulation of all requirements for the prototype, the final production can take only 3 days (it all depends on the idea). If you already have a drawing or 3D model, production takes place in just a few hours. However, the cost of the cost of plastic thread and 3D printing service is incommensurably small compared with the cost of materials for the manufacture of a prototype in an industrial environment.

It is not often, however, that you have to print items on whose use someone’s life depends, ultimately, or health, at a minimum.

How, you ask, can someone's life depend on 3D printing technology? Directly, perhaps, in any way. But orthoses, mock-ups of medical prostheses, prototypes of various medical devices, including for resuscitation, directly involved in the process of saving lives and health. And reading about it, we, of course, think about the person.

It is understandable. Since 1990, Russia has been a member of the International Society for Prosthetics and Orthopedics (ISPO), having an office in St. Petersburg. Its main goal of this community is to promote the provision of highly qualified medical care. More than 500 specialists from all regions of the Russian Federation are involved in the case. Thus, we have a lot of achievements in the field of manufacturing orthopedic products, limb prosthetics and the manufacture of rehabilitation tools for humans. An impressive experience, no doubt, and prototyping with the help of 3D printing (from well-known foreign manufacturers, for the most part) has a significant role in its development.

And what about our smaller brothers? What of the developments we have in the field of veterinary medicine?

Again, many interesting proposals for the restoration of limbs in animals can be found on foreign network resources. Not "cosmic" amounts for the implementation of a specific project, but how much joy from a grateful pet! We have such services rather rare.

Recently I was touched by an atypical case in my practice from this area. Faced with a puppy dysplasia of the hip joints.

Veterinarians are well aware of the essence of the issue, and non-windwinds easily, if they wish, find the definition of the disease and, also, understand the essence of the problem, both for the dog and for its owner. In a nutshell, this is an anatomical defect of the acetabulum underdevelopment, representing the danger of impaired locomotor functions of the hind limbs. As a result, the dog quickly gets tired, its hind limbs are shaking, it may limp, and when walking, it wags noticeably backwards, in general, trouble. It is believed that large breeds are susceptible to this hereditary disease: St. Bernards, Newfoundlands, Labradors, Sheepdogs, Bobtails, Golden Retrievers, Chow Chows, Rottweilers, etc. Diseases are also affected by cats.

In order to make an accurate diagnosis, veterinarians conduct a study under general anesthesia. Then determine the appropriate method of treatment. It can beat the correction of animal nutrition, drug treatment with nonsteroidal anti-inflammatory drugs. Such treatment is aimed at eliminating pain and increasing joint mobility, as well as slowing the development of arthrosis. But most often, doctors suggest surgery: pelvic osteotomy, intertrochanteric osteotomy of the femur, total hip replacement or resection of the femoral head (for large dogs). As for cats, according to my personal observations, most often the only option is one - an operation.

In our case, a volitional decision was made with a sick puppy to conduct only a therapeutic treatment with the use of specially designed orthoses. They are designed to reduce the load on the joint, by limiting the angle of extension of the limb, which is determined only by a specialist in this field.

This is part of a hinged orthosis made from a flexible FLEX plastic 3D printer. For its manufacture it took the removal of biometric data from the sick limb of the dog. Specialists in the manufacture of orthoses made it with a 3D scanner. Then, according to the scanned model, the limbs were developed by an individual orthosis. Only after that his prototype was printed.

It is clear that this technology requires fitting and making the necessary adjustments. It may be necessary to strengthen some parts of the orthosis, or, conversely, to reduce the wall thickness. It should also be remembered that the puppy is growing and after some time it will be necessary to produce a new type of orthosis.

Each case, of course, should be considered individually, but, as practice shows, such a comprehensive treatment gives the result.

In my practice, I had to observe both.

It all depends on setting goals. For example, to take and print on a 3D printer any stationery item (sharpener or container) is not a big deal. Like, for example, this small office "anti-stress" is a pendulum made of PLA plastic. Spin with your fingers and throw on the office desk. While he is spinning, we are distracted.

')

To simplify the process, you need to go to the popular site of free 3D models storage, download the one you like and download to your 3D printer. In a few hours we will get the result. And for many fairly experienced users of 3D printers, this process, to some extent, can be called entertainment.

A slightly different thing is the manufacture of parts and assemblies using 3D printing, which have direct practical application.

Here you have to devote a lot of time to the 3D model itself before you start printing it. It is necessary to check everything, after the end of the printing process, to adjust all surfaces to the entire structure and then draw conclusions about the prototype. This is a complete work on the creation of an industrial design. Although, probably, you will not surprise anyone with the prototypes from PLA, FLEX or ABS. But these are all objects whose value for a person can be disputed.

For people who have already encountered various 3D printing technologies, the advantages of prototyping here are pretty obvious. Well, compared with the manufacture of traditional methods in production. Depending on the specific industry, the time spent on making a particular prototype can vary greatly. However, in any case, the development, modeling and manufacturing of the prototype lasts quite a long time and, accordingly, includes a lot of budget expenses.

In this sense, 3D printing is the fastest possible result, regardless of the type of object construction technology - FDM, SLA or MJM. If you have an idea how to make an object, then you give a technical task for the manufacture of a model in 3D of any company specializing in these services. The idea may require the involvement of industrial designers, of course. With a clear formulation of all requirements for the prototype, the final production can take only 3 days (it all depends on the idea). If you already have a drawing or 3D model, production takes place in just a few hours. However, the cost of the cost of plastic thread and 3D printing service is incommensurably small compared with the cost of materials for the manufacture of a prototype in an industrial environment.

It is not often, however, that you have to print items on whose use someone’s life depends, ultimately, or health, at a minimum.

How, you ask, can someone's life depend on 3D printing technology? Directly, perhaps, in any way. But orthoses, mock-ups of medical prostheses, prototypes of various medical devices, including for resuscitation, directly involved in the process of saving lives and health. And reading about it, we, of course, think about the person.

It is understandable. Since 1990, Russia has been a member of the International Society for Prosthetics and Orthopedics (ISPO), having an office in St. Petersburg. Its main goal of this community is to promote the provision of highly qualified medical care. More than 500 specialists from all regions of the Russian Federation are involved in the case. Thus, we have a lot of achievements in the field of manufacturing orthopedic products, limb prosthetics and the manufacture of rehabilitation tools for humans. An impressive experience, no doubt, and prototyping with the help of 3D printing (from well-known foreign manufacturers, for the most part) has a significant role in its development.

And what about our smaller brothers? What of the developments we have in the field of veterinary medicine?

Again, many interesting proposals for the restoration of limbs in animals can be found on foreign network resources. Not "cosmic" amounts for the implementation of a specific project, but how much joy from a grateful pet! We have such services rather rare.

Recently I was touched by an atypical case in my practice from this area. Faced with a puppy dysplasia of the hip joints.

Veterinarians are well aware of the essence of the issue, and non-windwinds easily, if they wish, find the definition of the disease and, also, understand the essence of the problem, both for the dog and for its owner. In a nutshell, this is an anatomical defect of the acetabulum underdevelopment, representing the danger of impaired locomotor functions of the hind limbs. As a result, the dog quickly gets tired, its hind limbs are shaking, it may limp, and when walking, it wags noticeably backwards, in general, trouble. It is believed that large breeds are susceptible to this hereditary disease: St. Bernards, Newfoundlands, Labradors, Sheepdogs, Bobtails, Golden Retrievers, Chow Chows, Rottweilers, etc. Diseases are also affected by cats.

In order to make an accurate diagnosis, veterinarians conduct a study under general anesthesia. Then determine the appropriate method of treatment. It can beat the correction of animal nutrition, drug treatment with nonsteroidal anti-inflammatory drugs. Such treatment is aimed at eliminating pain and increasing joint mobility, as well as slowing the development of arthrosis. But most often, doctors suggest surgery: pelvic osteotomy, intertrochanteric osteotomy of the femur, total hip replacement or resection of the femoral head (for large dogs). As for cats, according to my personal observations, most often the only option is one - an operation.

In our case, a volitional decision was made with a sick puppy to conduct only a therapeutic treatment with the use of specially designed orthoses. They are designed to reduce the load on the joint, by limiting the angle of extension of the limb, which is determined only by a specialist in this field.

This is part of a hinged orthosis made from a flexible FLEX plastic 3D printer. For its manufacture it took the removal of biometric data from the sick limb of the dog. Specialists in the manufacture of orthoses made it with a 3D scanner. Then, according to the scanned model, the limbs were developed by an individual orthosis. Only after that his prototype was printed.

It is clear that this technology requires fitting and making the necessary adjustments. It may be necessary to strengthen some parts of the orthosis, or, conversely, to reduce the wall thickness. It should also be remembered that the puppy is growing and after some time it will be necessary to produce a new type of orthosis.

Each case, of course, should be considered individually, but, as practice shows, such a comprehensive treatment gives the result.

Source: https://habr.com/ru/post/391953/

All Articles