Absolutely silent, compact fanless computer on a full desktop processor. DIY implementation

Once, once again doing the computation of the “fanned” fan in a classical system integrator, I thought about the topic of a silent, ideal personal computer for myself. The result - on KDPV.

The main tasks that I perform on the PC are the development of simple things in CAD, editing documents in Word / Excel, as well as viewing the

0. Formation of the TZ to itself and why even for Excel it is precisely the powerful silent PC that is needed.

The most braking part of any computer is always the user.

')

The user gets tired of the sound of the computer - even in the sanitary norms, the noise levels at workplaces are prescribed. After going through the company with a sound meter program on a smartphone, I found that half of the ITD and administration offices do not pass according to the requirements for workplaces for creative activity , and the second half passes barely. And the reason for this is just noisy classic system blocks. Perfect PC should be silent.

The user is angry when the programs open slowly. Yes, 3-4 seconds of loading of Excel on the scale of the working day are insignificant, but these seconds annoy most of all. Perfect PC should be responsive. That is, to cope with short-term peak loads.

And since my workplace is in my kitchen, the computer must also be compact .

')

The user gets tired of the sound of the computer - even in the sanitary norms, the noise levels at workplaces are prescribed. After going through the company with a sound meter program on a smartphone, I found that half of the ITD and administration offices do not pass according to the requirements for workplaces for creative activity , and the second half passes barely. And the reason for this is just noisy classic system blocks. Perfect PC should be silent.

The user is angry when the programs open slowly. Yes, 3-4 seconds of loading of Excel on the scale of the working day are insignificant, but these seconds annoy most of all. Perfect PC should be responsive. That is, to cope with short-term peak loads.

And since my workplace is in my kitchen, the computer must also be compact .

1. Realization in the open air

Based on the requirements for computing power, processors like Atom and Celeron have disappeared - the home laptop and work computers on them cause a continuous negative.

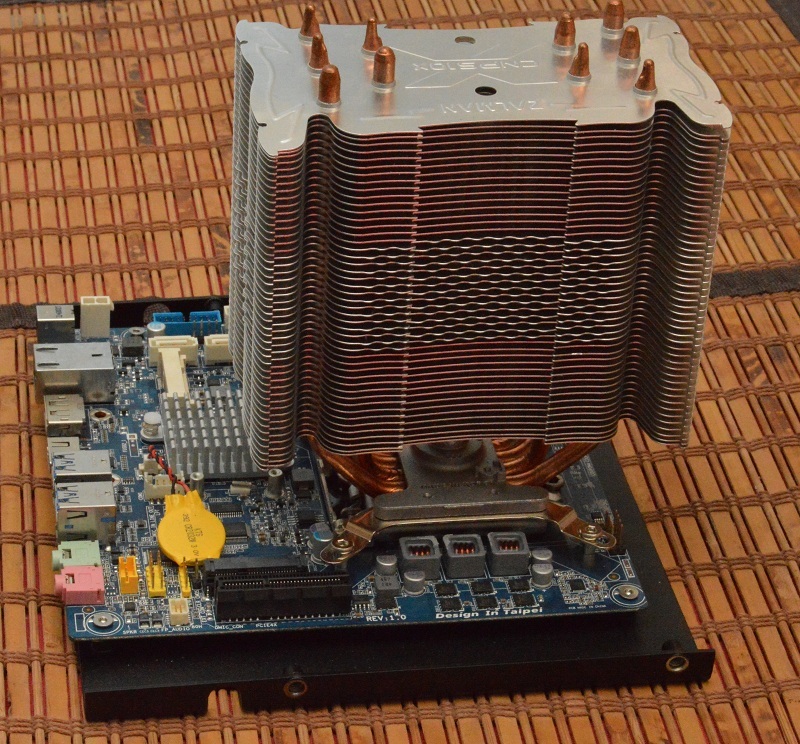

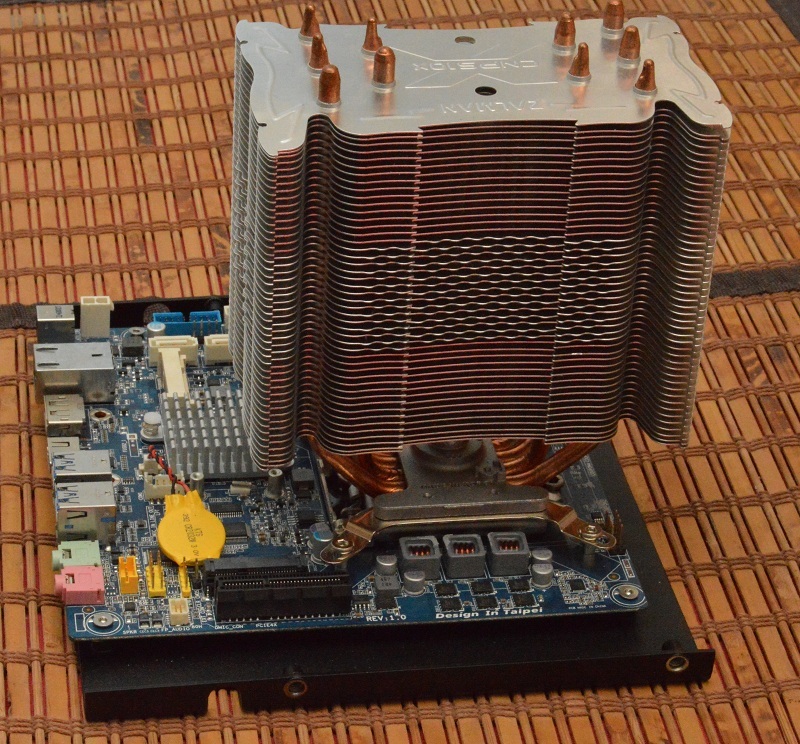

In order for a full-fledged desktop processor to be cooled passively, it must emit little heat. The choice is obvious - Core i3 4130T with TDP = 35W. The initially selected small Titan cooler did not work - it had to be replaced by Zalman CNPS-10X.

For compactness, the motherboard format is mini ITX. Find a high-quality passive ATX power supply at affordable prices is unrealistic. Therefore, the selected motherboard Gigabyte GA-H87TN, able to eat one constant voltage from 9 to 19V. The power supply to it - Mean Well RS-150-12, 150W, 12V. We have been using the products of this company for ten years already - and none have failed.

WIFI module - Tp-Link PCI-E. In order not to make cuts under the bar - I just unscrewed the bar. Laying holes for the antenna and the indicator to the body.

RAM 8 gigabytes and SSD Crucial 2.5 "format for 120 gigabytes. Buying just such an SSD was a mistake - at that time I just did not know about the existence of the msata standard present on the motherboard.

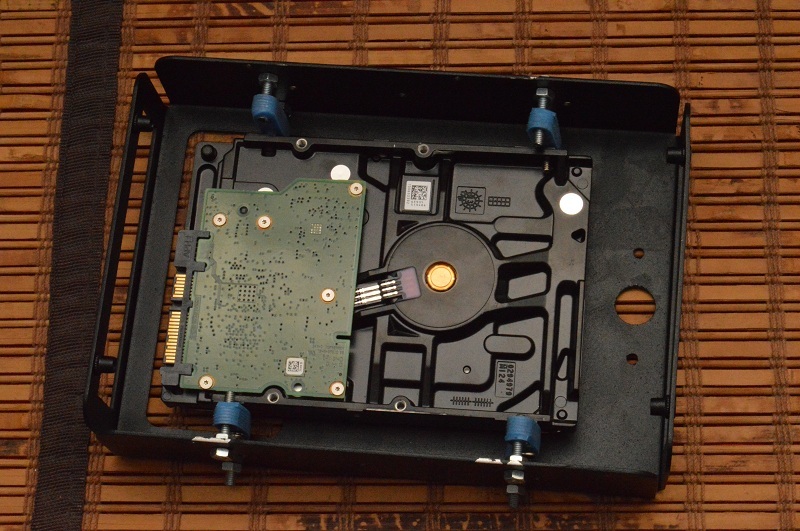

And one more mistake was the decision to install a 1 Tb Seagate hard drive.

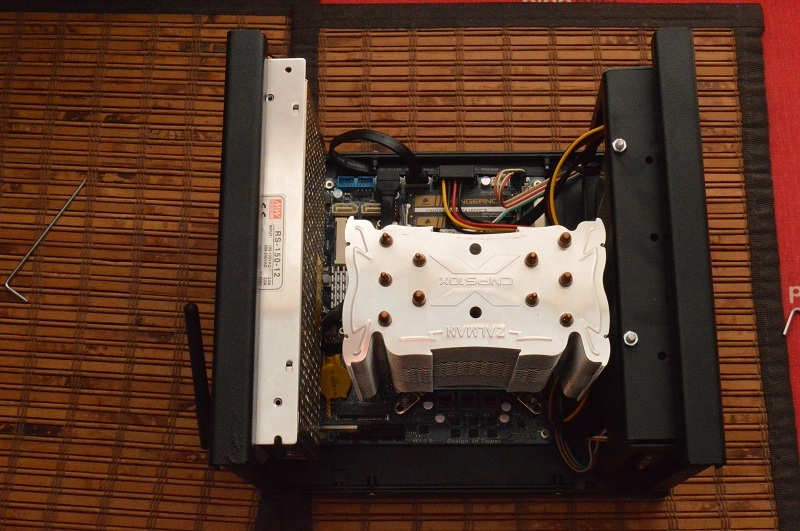

In order for a full-fledged desktop processor to be cooled passively, it must emit little heat. The choice is obvious - Core i3 4130T with TDP = 35W. The initially selected small Titan cooler did not work - it had to be replaced by Zalman CNPS-10X.

For compactness, the motherboard format is mini ITX. Find a high-quality passive ATX power supply at affordable prices is unrealistic. Therefore, the selected motherboard Gigabyte GA-H87TN, able to eat one constant voltage from 9 to 19V. The power supply to it - Mean Well RS-150-12, 150W, 12V. We have been using the products of this company for ten years already - and none have failed.

WIFI module - Tp-Link PCI-E. In order not to make cuts under the bar - I just unscrewed the bar. Laying holes for the antenna and the indicator to the body.

RAM 8 gigabytes and SSD Crucial 2.5 "format for 120 gigabytes. Buying just such an SSD was a mistake - at that time I just did not know about the existence of the msata standard present on the motherboard.

And one more mistake was the decision to install a 1 Tb Seagate hard drive.

2. Case: design, manufacture, assembly (+ pictures)

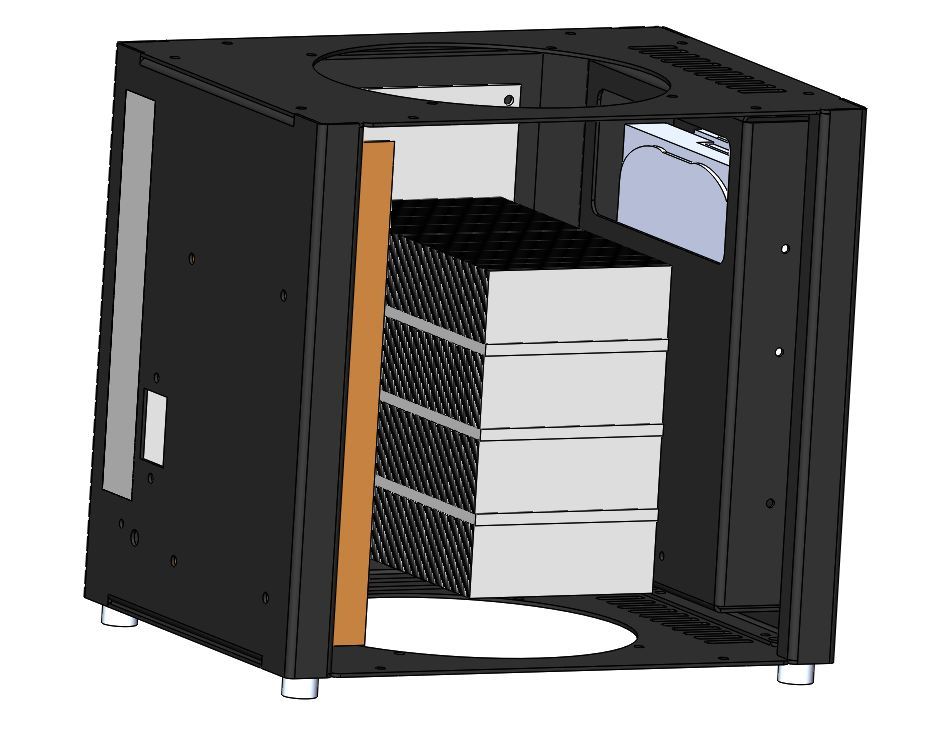

Since the chosen power supply unit is very far from ATX in shape / size, it was not possible to choose a ready-made compact case capable of accommodating a processor cooler with a nameplate height of 152mm. Well, nice, because in fact its height is greater. Sat down for the design.

There were no questions to laser cutting - it was more difficult with a sheet bending machine. Our equipment can bend the minimum shelf size "10mm + material thickness" and strictly with a bend radius of 1.5mm.

Since the installation of the hard disk was planned, measures were taken to combat vibration. We do not have a coordinate-piercing machine, so there is nothing to form developed ribs in thin material. Recalling the American saying “Bigger is better”, the material was chosen to be galvanized steel with a thickness of 1.5 mm.

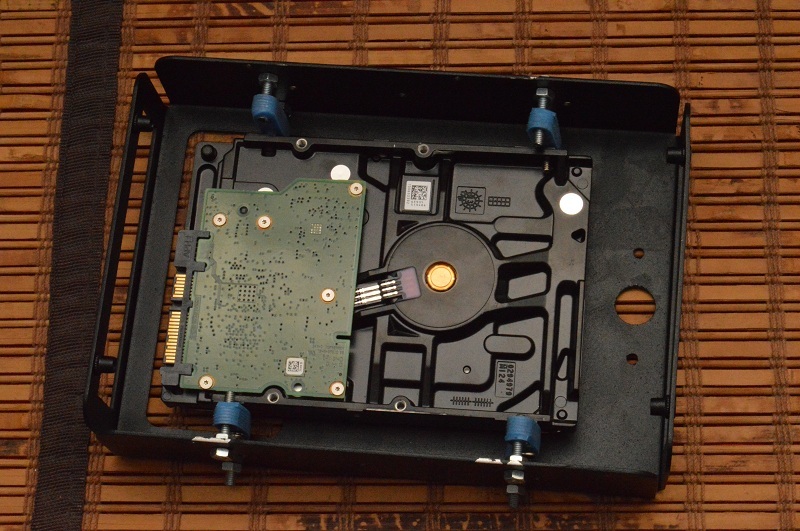

The power button - sharpened aluminum, legs - too. The legs - anti-vibration silicone liners. HDD - vertical layout, silicone suspensions. (How to make a mold for pouring silicone without a milling machine can be seen in the picture below).

The edges of the cooler - vertically.

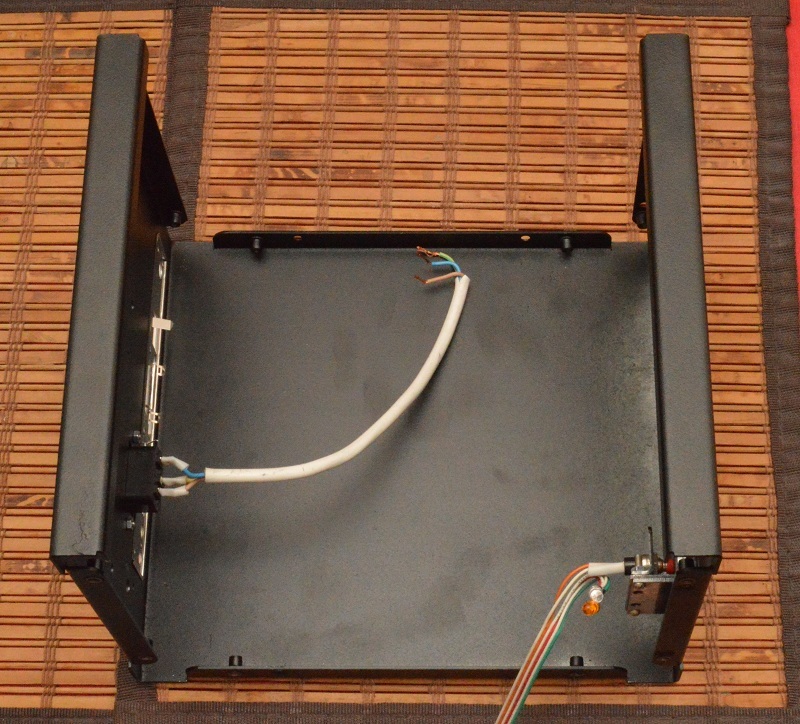

The power supply unit is flat on the back wall so that the heat transfers to the case.

The most interesting question was in the ventilation holes - which ones to do? From the course of physics and this article clearly shows that the outlet should be more input.

In order not to cut several variants of the upper and lower covers, it was decided to adjust the ratio of the height of the legs. Color - black matte. This is how it looked on the screen:

And so in the gland:

The ill-fated HDD with silicone suspensions. When connected, the suspensions completely remove the vibration, but the noise remains. And if in an ordinary PC the HDD noise is hiding behind the fan ones, then it had to be turned off.

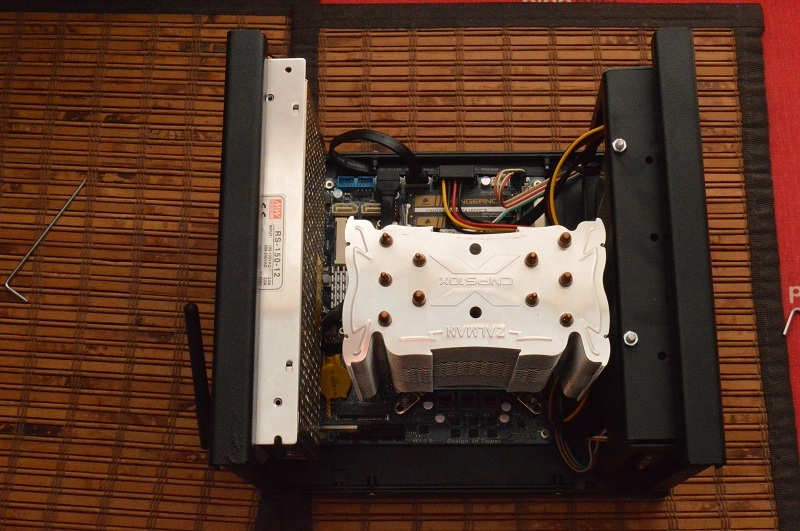

Motherboard on the bracket.

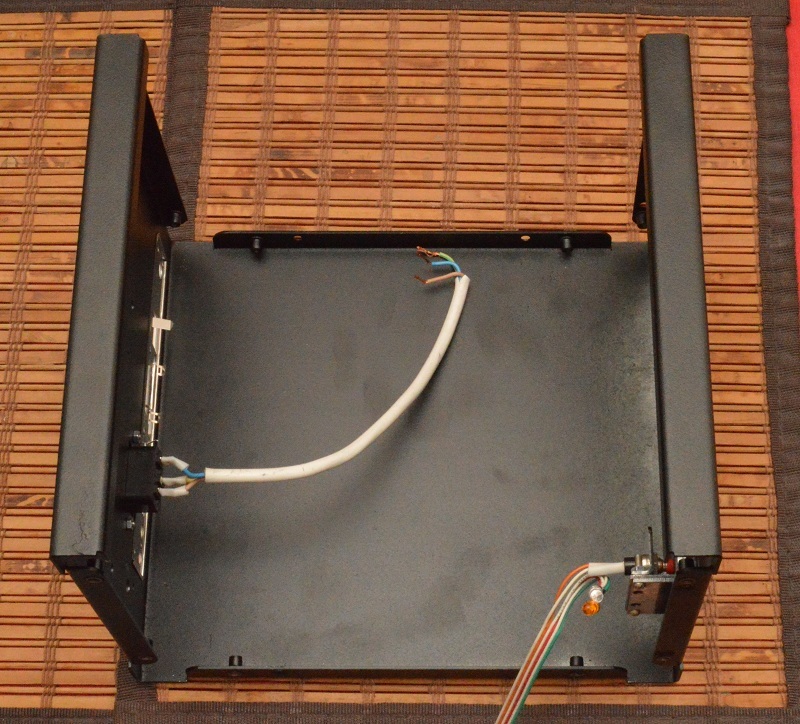

The main part is the casing. All connections in the product are made using rivets-nuts.

Here is the layout. The power supply is on the left, bolted to the back wall and resets the heat to it.

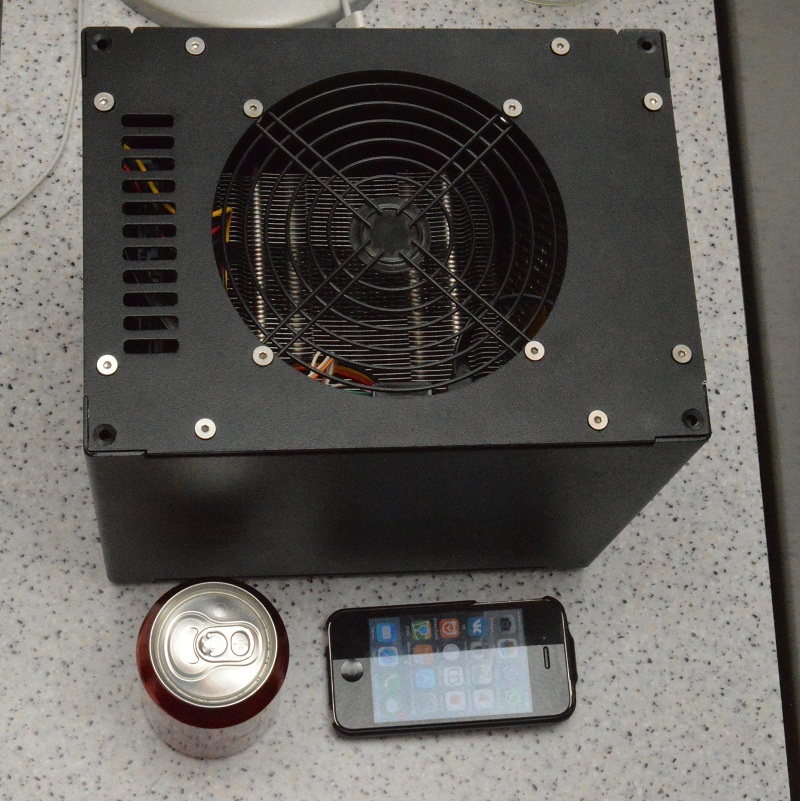

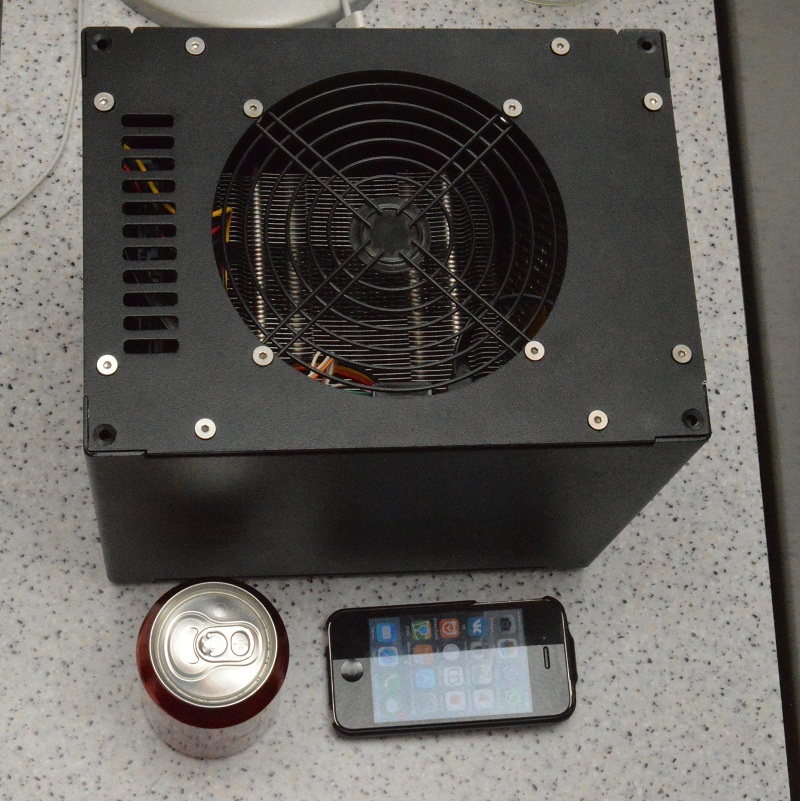

I do not work in sales of soda - a jar here for scale.

And I do not work at Apple (sorry).

8-inch tablet, silent sistemnik, usual sistemnik.

There were no questions to laser cutting - it was more difficult with a sheet bending machine. Our equipment can bend the minimum shelf size "10mm + material thickness" and strictly with a bend radius of 1.5mm.

Since the installation of the hard disk was planned, measures were taken to combat vibration. We do not have a coordinate-piercing machine, so there is nothing to form developed ribs in thin material. Recalling the American saying “Bigger is better”, the material was chosen to be galvanized steel with a thickness of 1.5 mm.

The power button - sharpened aluminum, legs - too. The legs - anti-vibration silicone liners. HDD - vertical layout, silicone suspensions. (How to make a mold for pouring silicone without a milling machine can be seen in the picture below).

The edges of the cooler - vertically.

The power supply unit is flat on the back wall so that the heat transfers to the case.

The most interesting question was in the ventilation holes - which ones to do? From the course of physics and this article clearly shows that the outlet should be more input.

In order not to cut several variants of the upper and lower covers, it was decided to adjust the ratio of the height of the legs. Color - black matte. This is how it looked on the screen:

And so in the gland:

The ill-fated HDD with silicone suspensions. When connected, the suspensions completely remove the vibration, but the noise remains. And if in an ordinary PC the HDD noise is hiding behind the fan ones, then it had to be turned off.

Motherboard on the bracket.

The main part is the casing. All connections in the product are made using rivets-nuts.

Here is the layout. The power supply is on the left, bolted to the back wall and resets the heat to it.

I do not work in sales of soda - a jar here for scale.

And I do not work at Apple (sorry).

8-inch tablet, silent sistemnik, usual sistemnik.

3. Current results, problems, prospects (+ pictures)

The result of this whole action is as follows:

Productivity is enough. Appearance - not a masterpiece, but not striking. Non-specialists are mistaken for a serial product; specialists see an error on the top cover.

The linX stress test surely heats up the processor before throttling. After the first day of normal operation (installation of software + actual work), the maximum temperatures recorded by the openhardware monitor are the following:

Processor - 59 degrees

SSD - 39 degrees.

In idle time on the SSD - 35 degrees, on the processor 37. (on an open stand, the processor warmed up to 40. That is, the “chimney” concept works.)

Problem 1: hard disk noise. At the local city "zhelezyachny forum" offered a couple of options, I will try. Until I decide - the hard drive will be disconnected.

Problem 2: Theoretically, you still need to make protection against overheating. The layout is already there.

Problem 3: To tidy up the appearance of the top cover, you need to lengthen 8 slots by 1 mm and increase 4 limbs by 1 mm. But for this the body needs to be re-manufactured. The whole. Therefore, the question is postponed until the next update - I have a desire to add USB to the front panel and so, improve the appearance.

Productivity is enough. Appearance - not a masterpiece, but not striking. Non-specialists are mistaken for a serial product; specialists see an error on the top cover.

The linX stress test surely heats up the processor before throttling. After the first day of normal operation (installation of software + actual work), the maximum temperatures recorded by the openhardware monitor are the following:

Processor - 59 degrees

SSD - 39 degrees.

In idle time on the SSD - 35 degrees, on the processor 37. (on an open stand, the processor warmed up to 40. That is, the “chimney” concept works.)

Problem 1: hard disk noise. At the local city "zhelezyachny forum" offered a couple of options, I will try. Until I decide - the hard drive will be disconnected.

Problem 2: Theoretically, you still need to make protection against overheating. The layout is already there.

Problem 3: To tidy up the appearance of the top cover, you need to lengthen 8 slots by 1 mm and increase 4 limbs by 1 mm. But for this the body needs to be re-manufactured. The whole. Therefore, the question is postponed until the next update - I have a desire to add USB to the front panel and so, improve the appearance.

Conclusion:

The main result - I can not hear the computer and that's fine. There is no longer a daily sense of relief in the ears after the PC turns off. The body was originally planned to be anodized aluminum, but most likely it will wait for the next versions. Man-hours and money spent a lot - probably, would be enough for Mac-mini. Only Mac mini still has a laptop processor and a fan. Most of the time, as usual, was spent on small things. For each Circuit had to go to different parts of the city.

There is a saying in the industry: “the first sample is to understand how not to do it, the second sample is to understand how to do it, the third one is to do it right”.

This sample completed its task. If someone is wondering what will happen next - stay tuned.

Source: https://habr.com/ru/post/391699/

All Articles