About Boeing's patent “3D printing of free forms using levitating parts”

Welcome to the pages of the blog iCover ! Engineers from the Boeing aircraft manufacturing corporation, who are actively introducing three-dimensional printing technology in various fields, have patented an interesting new 3D printing technology for objects that are in levitation during printing. The patent application was filed back in 2014, and now on PatentYogi a video was presented illustrating the development.

According to Boeing's patent , “There is a need to develop a method and device for additive manufacturing that will allow the manufacture of objects without a platform or supporting materials for stabilization. In addition, this technology removes restrictions on the types and properties of objects, allowing you to create complex parts as a whole. ”

The proposed implementation of 3D printing is really drastically different from the existing methods, both in its principles and in the final result, and if not for Boeing’s authority, confirmed by many successful patents, it could be considered that what we see below is not more than a living imagination.

')

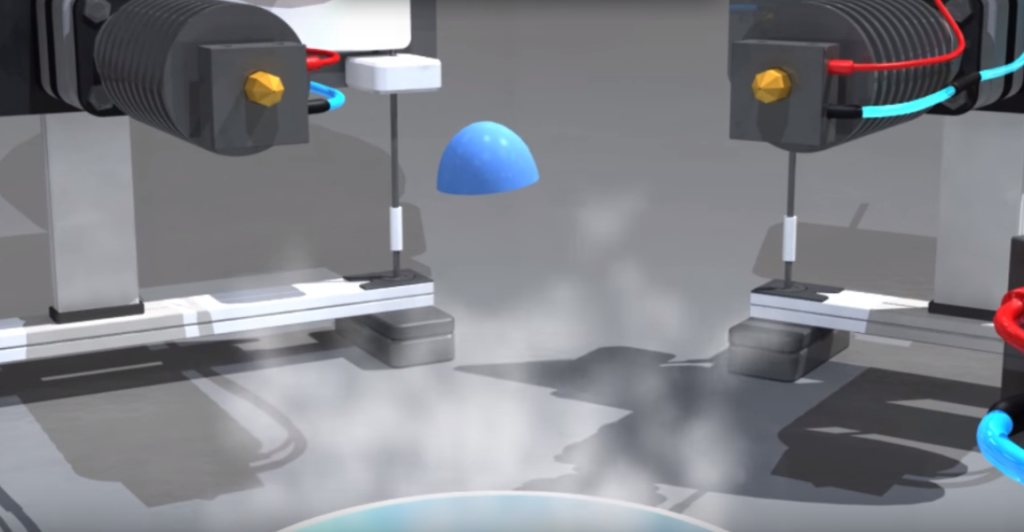

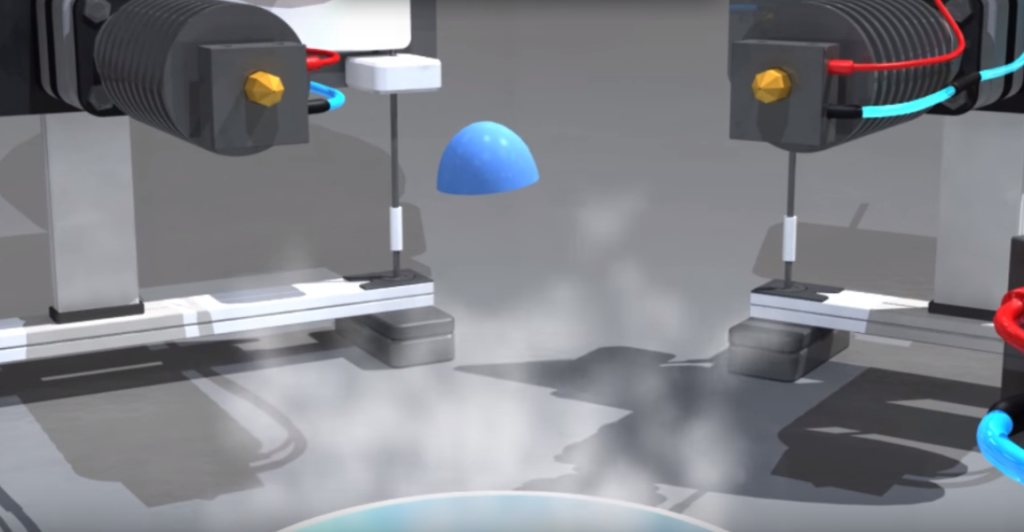

When printing, it is proposed to use several 3d printers at once. Instead of the usual printing platform, Boeing technology uses a powerful source of magnetic or acoustic field.

According to experts in the field of 3D printing, the idea looks very promising. The technology allows you to move away from the traditional principles of printing from the bottom up. T. n. The “nugget” (the original, pre-cooled billet with the properties of a super-conductor) is covered with material from several sides, supported by a magnetic or acoustic field in the desired position. Rotation of the workpiece in the field during the printing process allows you to create 3D objects of desired shapes and sizes. Since the printing process simultaneously uses the capabilities of several 3D printers, the printing speed increases significantly.

According to the resource 3DPrint.com , the patent stipulates that 3D printing using this technology can be carried out using the principle of acoustic levitation. “The levitation method involves the generation of standing acoustic waves so powerful that they force the nugget to hang in the air, after which it is held in the air through an acoustic reflector that reflects sound waves in accordance with the wave pattern while the print heads do their job” - explains the principle of Claire’s work Scott

John Biggs, editor of TechCrunch, commented on what he saw as follows: “The current rendering is small balls that turn into smooth surfaces. - All this seems somewhat implausible. All that can be assumed is that they use a specific additive system. At the same time, several printheads involved in printing a single object at the same time allow for much higher speed, accuracy and scale of printing. ”

Boeing plans to use the capabilities of the developed technology when printing fragments of various designs and systems of airliners.

Source 1

Source 2

If the development of Boeing is destined to be realized, and not disappear among piles of other futuristic patents, then this will open up brilliant prospects for its use in many industries. And just as the 3D press was destined to remove many of the limitations of traditional production, the proposed technology could bypass the existing limitations typical of existing 3D printing methods.

Dear readers, we are always happy to meet and wait for you on the pages of our blog. We are ready to continue to share with you the latest news, review materials and other publications, and we will try to do everything possible so that the time spent with us will be useful for you. And, of course, do not forget to subscribe to our headings .

Our other articles and events

According to Boeing's patent , “There is a need to develop a method and device for additive manufacturing that will allow the manufacture of objects without a platform or supporting materials for stabilization. In addition, this technology removes restrictions on the types and properties of objects, allowing you to create complex parts as a whole. ”

The proposed implementation of 3D printing is really drastically different from the existing methods, both in its principles and in the final result, and if not for Boeing’s authority, confirmed by many successful patents, it could be considered that what we see below is not more than a living imagination.

')

When printing, it is proposed to use several 3d printers at once. Instead of the usual printing platform, Boeing technology uses a powerful source of magnetic or acoustic field.

According to experts in the field of 3D printing, the idea looks very promising. The technology allows you to move away from the traditional principles of printing from the bottom up. T. n. The “nugget” (the original, pre-cooled billet with the properties of a super-conductor) is covered with material from several sides, supported by a magnetic or acoustic field in the desired position. Rotation of the workpiece in the field during the printing process allows you to create 3D objects of desired shapes and sizes. Since the printing process simultaneously uses the capabilities of several 3D printers, the printing speed increases significantly.

According to the resource 3DPrint.com , the patent stipulates that 3D printing using this technology can be carried out using the principle of acoustic levitation. “The levitation method involves the generation of standing acoustic waves so powerful that they force the nugget to hang in the air, after which it is held in the air through an acoustic reflector that reflects sound waves in accordance with the wave pattern while the print heads do their job” - explains the principle of Claire’s work Scott

John Biggs, editor of TechCrunch, commented on what he saw as follows: “The current rendering is small balls that turn into smooth surfaces. - All this seems somewhat implausible. All that can be assumed is that they use a specific additive system. At the same time, several printheads involved in printing a single object at the same time allow for much higher speed, accuracy and scale of printing. ”

Boeing plans to use the capabilities of the developed technology when printing fragments of various designs and systems of airliners.

Source 1

Source 2

If the development of Boeing is destined to be realized, and not disappear among piles of other futuristic patents, then this will open up brilliant prospects for its use in many industries. And just as the 3D press was destined to remove many of the limitations of traditional production, the proposed technology could bypass the existing limitations typical of existing 3D printing methods.

Dear readers, we are always happy to meet and wait for you on the pages of our blog. We are ready to continue to share with you the latest news, review materials and other publications, and we will try to do everything possible so that the time spent with us will be useful for you. And, of course, do not forget to subscribe to our headings .

Our other articles and events

Source: https://habr.com/ru/post/391123/

All Articles