How "Motorika" makes prostheses for children

The prostheses from the Russian startup “Motorika” are already being used by 6 boys and girls, and now another 4 children are preparing for installation. Three adults use traction prostheses, and one - myo-prosthesis.

I first mentioned traction prostheses for children from a startup from the Tomsk Nanotechnology Center in October 2015 when I wrote a review of the Open Innovations forum . In December 2015, the team launched a crowdfunding campaign on Planeta.ru - in order to tell as many people as possible how to make beautiful and functional prostheses instead of useless rubber hand simulators.

The team is constantly looking for new heroes who need such an artificial limb. The application can be left on the company's website or on social networks - Vkontakte and Facebook .

')

Under the cut - a little more about how prostheses are made in Motorika.

Anya and Ilya Cech, co-founder Motorki

At the first stage, experts take measurements. With a simple injury, this can be done remotely - the future user, together with his parents, takes measurements according to the instructions. With a complex injury, you need to make a sleeve under the stump. First, prosthetists mold the liner, and then experts scan it using a 3D scanner. The girl Masha, for whom this prosthesis was made, has her thumb preserved, so you need to start preparing the liner right away.

This is a scan of Masha's case.

All the details of the prosthesis are printed on a 3D printer according to the size and features of the brush. For SLS printing, Motorika uses industrial printers.

Next, experts make additional elements: metal strips for the reliability of small knots, springs. In order that fingers did not slide, use silicone naptechnik.

Assembly of all elements of the prosthesis takes from 1 to 3 days. Traction cables are adjustable - you can adjust the prosthesis so that all fingers are compressed simultaneously or in a certain order.

The liner for Masha was made at a prosthetic enterprise according to classical technology using resins. It now remains to connect all the parts of the prosthesis - the sleeve, the cover and the frame, and put it on the handle.

This is an old prosthesis, which will soon be replaced with a new pink one.

Already 6 children use these prostheses. This girl's name is Anya.

This is Daniel.

Ksyusha

Malika.

And this is Light.

Such a prosthesis is being prepared for installation by a girl on March 2-3 - she will be 6 years old on March 4.

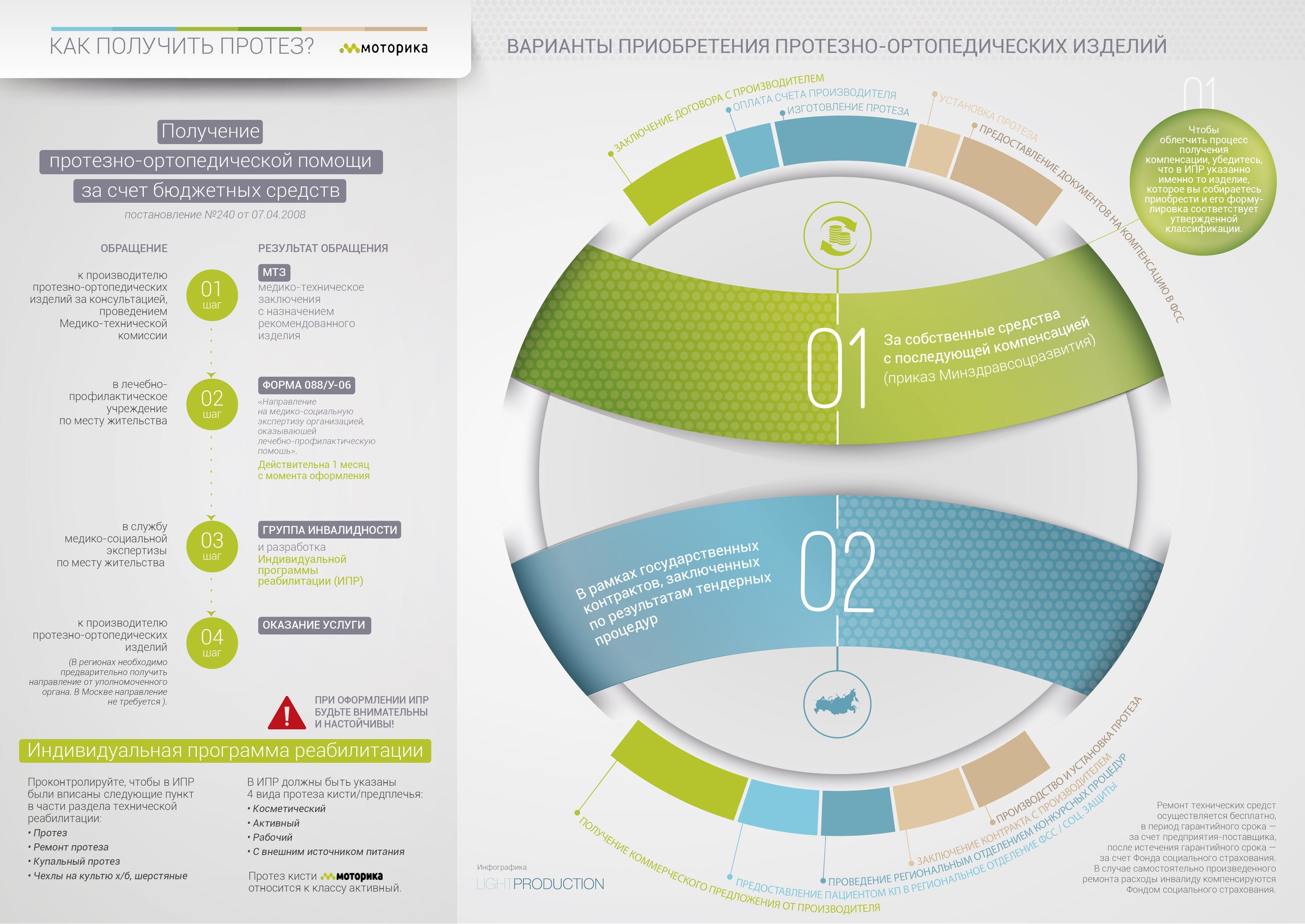

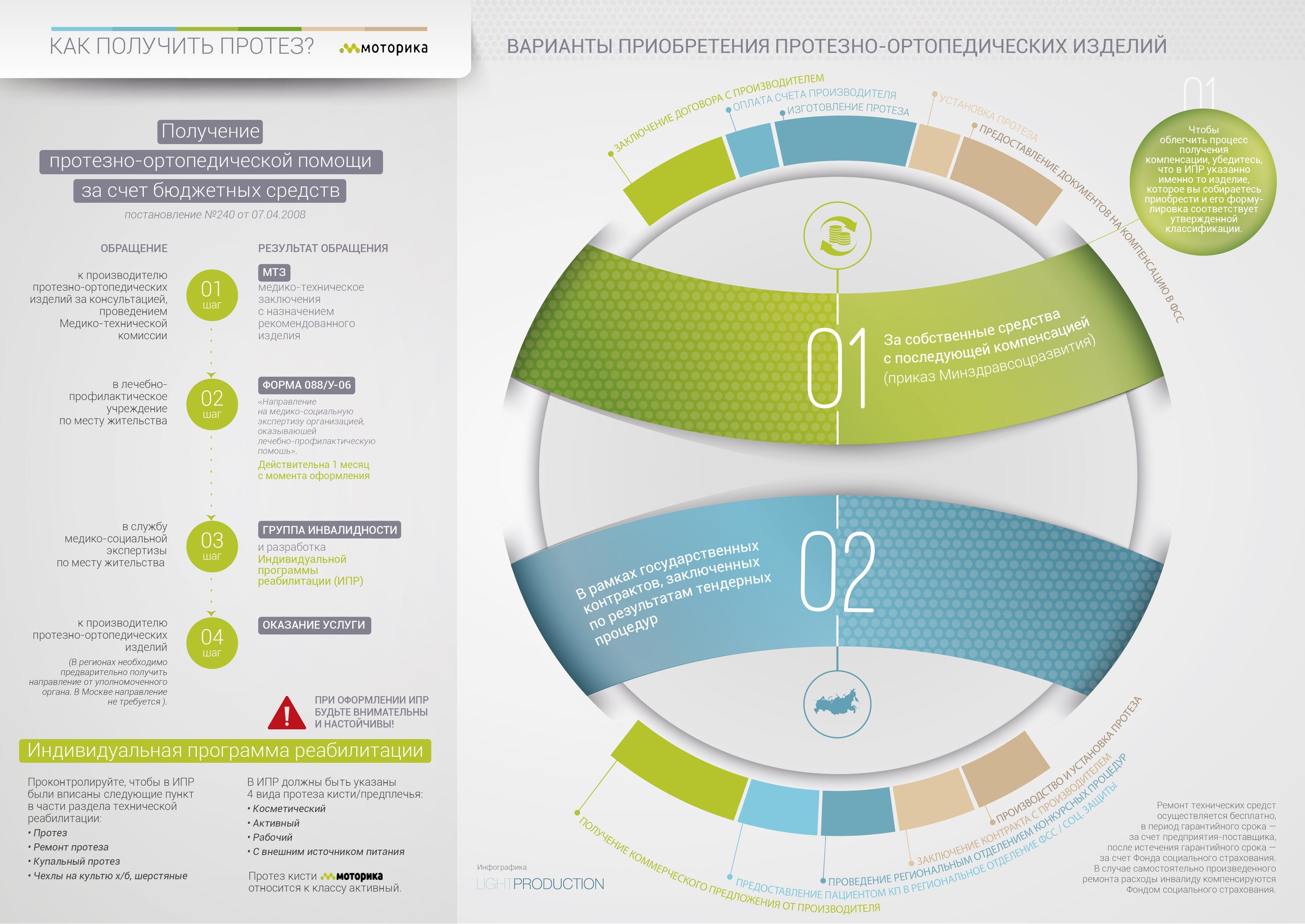

To get a prosthesis, you can pay for it yourself, or you can get compensation from the Social Insurance Fund. Brochure clickable.

The prosthesis costs from 50 to 100 thousand rubles. This cost includes the second prosthesis for a year - children grow quickly, it is necessary to change it every 6-8 months, as well as the work of an engineer to fit each specific model and the work of the prosthetist to create a sleeve and fit the prosthesis to the patient.

“In any case, children end up getting a prosthesis for free. For this, for a long time, we knocked thresholds, spent a lot of time and money and were certified, ”writes Vasily Khlebnikov, co-founder of Motorika.

I first mentioned traction prostheses for children from a startup from the Tomsk Nanotechnology Center in October 2015 when I wrote a review of the Open Innovations forum . In December 2015, the team launched a crowdfunding campaign on Planeta.ru - in order to tell as many people as possible how to make beautiful and functional prostheses instead of useless rubber hand simulators.

The team is constantly looking for new heroes who need such an artificial limb. The application can be left on the company's website or on social networks - Vkontakte and Facebook .

')

Under the cut - a little more about how prostheses are made in Motorika.

Anya and Ilya Cech, co-founder Motorki

At the first stage, experts take measurements. With a simple injury, this can be done remotely - the future user, together with his parents, takes measurements according to the instructions. With a complex injury, you need to make a sleeve under the stump. First, prosthetists mold the liner, and then experts scan it using a 3D scanner. The girl Masha, for whom this prosthesis was made, has her thumb preserved, so you need to start preparing the liner right away.

This is a scan of Masha's case.

All the details of the prosthesis are printed on a 3D printer according to the size and features of the brush. For SLS printing, Motorika uses industrial printers.

Next, experts make additional elements: metal strips for the reliability of small knots, springs. In order that fingers did not slide, use silicone naptechnik.

Assembly of all elements of the prosthesis takes from 1 to 3 days. Traction cables are adjustable - you can adjust the prosthesis so that all fingers are compressed simultaneously or in a certain order.

The liner for Masha was made at a prosthetic enterprise according to classical technology using resins. It now remains to connect all the parts of the prosthesis - the sleeve, the cover and the frame, and put it on the handle.

This is an old prosthesis, which will soon be replaced with a new pink one.

Already 6 children use these prostheses. This girl's name is Anya.

This is Daniel.

Ksyusha

Malika.

And this is Light.

Such a prosthesis is being prepared for installation by a girl on March 2-3 - she will be 6 years old on March 4.

To get a prosthesis, you can pay for it yourself, or you can get compensation from the Social Insurance Fund. Brochure clickable.

The prosthesis costs from 50 to 100 thousand rubles. This cost includes the second prosthesis for a year - children grow quickly, it is necessary to change it every 6-8 months, as well as the work of an engineer to fit each specific model and the work of the prosthetist to create a sleeve and fit the prosthesis to the patient.

“In any case, children end up getting a prosthesis for free. For this, for a long time, we knocked thresholds, spent a lot of time and money and were certified, ”writes Vasily Khlebnikov, co-founder of Motorika.

Source: https://habr.com/ru/post/390981/

All Articles