Electronmash - the flagship of the domestic computer technology

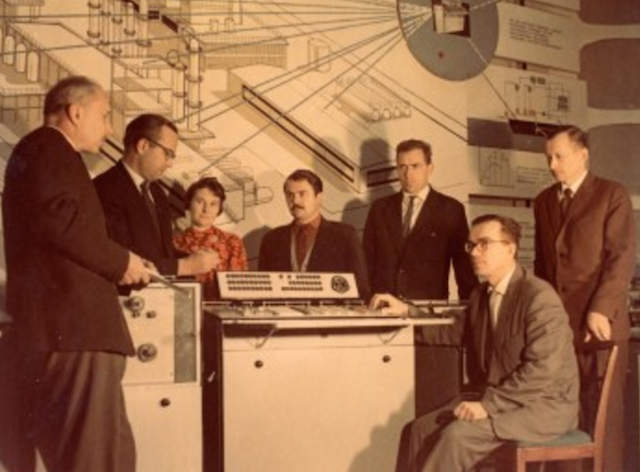

60 years, the USSR. Production boom computing. Across the country, special scientific, research and design organizations and enterprises began to form.

In Kiev, the development of computing at the time was at a high level. After the creation of the first multi-purpose control machine "Dnepr", it turned out that there was simply no place to produce it in series. So there was a need to create a factory where computers could be developed and produced.

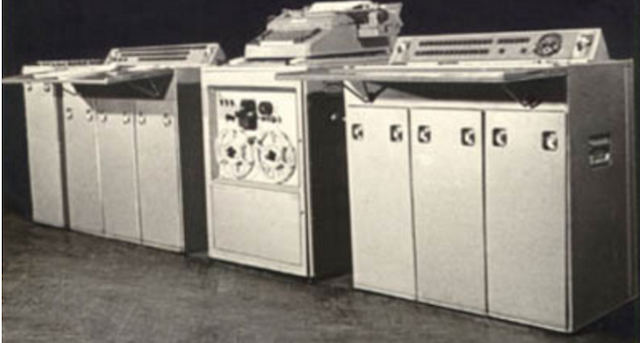

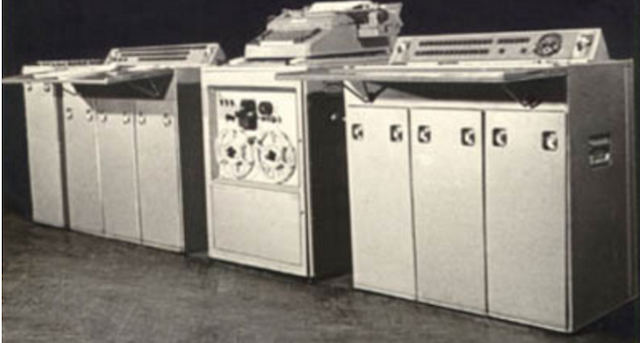

"Dnieper"

')

Dnipro is the first Soviet multi-purpose semiconductor control computer. The machine was developed from 1958 to 1961 at the Institute of Cybernetics of the Academy of Sciences of Ukraine. The project managers were Glushkov (chief designer) and Malinovsky. Such a machine was intended for industrial process control systems. It was a machine with a binary number system, created on transistors, 26-bit (26 binary digits), two-address. The speed of 10 thousand operations per second. The memory device was on ferrite cores (which allowed to increase the reliability of the machine and reduce its dimensions), consisted of sections, which made it possible to change the memory volume. OP 512 words capacity, additional RAM blocks with capacity from 3 to 512 words, additional ROM blocks with capacity from 6 to 512 words. External magnetic tape storage up to 200 thousand words.

A special feature was the presence of a communication device with an object (ODR) built into the machine for connecting it to the sensors and the executive bodies of the object controlled from the machine. Power "Dnepr" was from a three-phase AC 220/380 V, 50 Hz. The address language developed at the Institute of Cybernetics E. L. Yushchenko was adopted as the input language.

... "When the first copy of the car came from the factory, the developers clutched at his head. It was a solid aggregation of parts, where about a thousand soldered joints were made poorly and constantly refused, the connectors spoiled by inept handling. To debug such a machine was simply impossible. It turned out that the plant manager, having heard that the machine is 6 times larger than an oscilloscope, recruited students who had just graduated from school. Yesterday's schoolchildren with soldering irons in their hands began to “solder” the connections into the machine elements and break the connectors by careless handling. Since the installation time of the first UMSN in the Bessemer shop was approaching, the developers of the machine had to solder almost the entire machine and replace many connectors. Only then did the debugging process move. But it cost a lot of hard work around the clock multi-day work of the developers of the machine. "

500 Dnipro were produced, of which a couple of dozen were used in Ukraine, the rest in the Russian Federation, several in the republics of the Soviet Union and abroad.

In 1965, the Kiev Plant of Computing and Control Machines (VUM) began operating in Kiev on the basis of separate divisions of the Radiopribor plant. Initially, the plant employed 460 people. The director in those years was Apollinary Fedorovich Nezabitovsky. In 1972, the VUM was transformed into the Scientific and Production Association "Electronmash", which is considered one of the leaders in the USSR in the production of computing and control equipment.

Apollinary Fedorovich Nezabitovsky

"... You can’t sympathize with all your subordinates - this is a sure way to overwhelm a business. Remember, there are tasks, there are deadlines - demand! And don’t really go into details, because you yourself will also start thinking that this is impossible" - A.F. Nezabitovsky’s words .

Although he was not a professional in the field of computing, any leader could envy his energy and pressure. In a short time, he became a production manager of the plant, and later - a director, from a senior engineer at the Kiev factory "Tochelektropribor". Demanding of employees and respecting the order were respected by colleagues. There were legends about him.

From Golovtsev's memoirs:

"... the gray-haired and benevolent Appolinos Fyodorovich Nezabitovsky (in the epics -" dad ") - headed the materialization of the ideas of the great theorist, provided them - bodiless - with the flesh of electronic computing (in the modern outline - computers). Dad firmly held the steering wheel of an enormous ship, confidently led it among the waves of everyday problems, inevitable envy and rivalry. Workers, kind children, noted decent - the results of labor in accordance with - salary, provided with housing, cheap and tasty factory food, vacation com in sanatoriums and their own holiday homes.

Slackers, talkers useless and windbag heavily hated, banished. And everyone involved in the success of the famous factory was happy. It seemed that there was no limit to perfection, that development would be permanent, strengthening the stability of the colossus. "

Resolute Nezabitovsky "dissolved" in the life of the plant. I did my best to make the plant better than any other, apartment buildings for employees also had to be the best, as well as recreation centers. Solid advantages for the head. Soon a microdistrict appeared, which was built up with factory houses (“Nezabitovschina”).

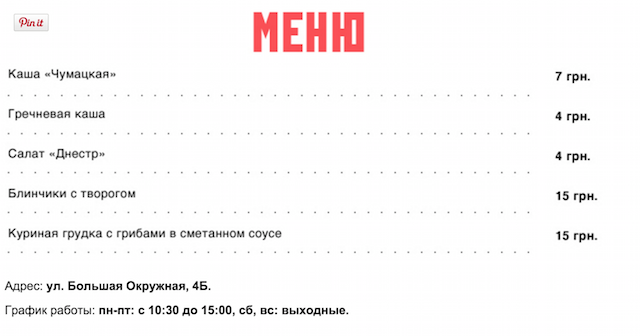

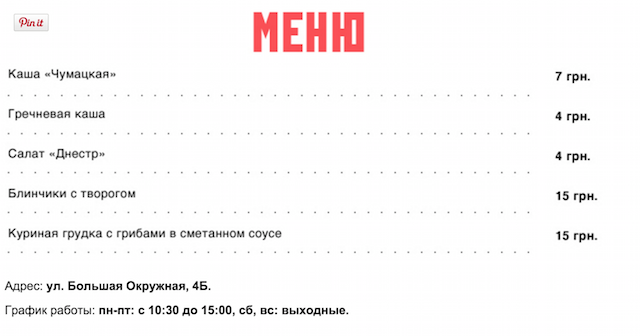

In addition, factory kindergartens, a pioneer camp “VUMovets”, recreation centers on the Desna and Ros rivers, an outpatient clinic (with modern equipment at that time), a sports and fitness complex were built. One of the best factory canteen in the city also belonged to the VUM factory.

By the way, the factory canteen is still working.

price over the past year, 15 hryvnia about 40 rubles

The plant VUM specialized in the production of UVM. This all left a definite imprint on the features of hardware and software that were produced at the factory. Computers were designed to work in real time.

To launch the created equipment into mass production it took a lot of effort and labor, since such machines were an innovation, the specialists - the pioneers were just learning, mastering the "know-how". Nevertheless, the plant managed to recruit qualified specialists from Severodonetsk - Afanasyev, Sergeev, Voynarovsky, from Minsk and Kazan, from the CC of the Ukrainian SSR Academy of Sciences. The plant, without putting “hands,” conducted the training of young specialists, highly qualified employees. When the plant opened educational institutions - technical college and technical college. An implementation department was created (headed by KPI graduate Alexey Alekseevich Sladkov).

The team of the department is truly a team of enthusiasts. They were faced with the task of not only introducing existing hardware and software, but also the task of formulating the requirements for new tools necessary for the automation of real objects. In order to better feel the mood of the plant’s team, it is worth remembering the work on the Whirlwind project - the test automation system for spacecraft propulsion engines intended for flight to the Moon. It was necessary in a short time (up to 300 seconds) to collect a large amount of information from sensors installed on the engine, and also to process it in real time. The Dnepr UMShN was significantly modernized and became the “core” of the Whirlwind system, all this was done very quickly and in 1965 all the products were ready and delivered to the Design Bureau of the space systems.

In 1965 - 1974 more than 2.5 thousand computers were manufactured at the plant ("Dnepr", "Dnepr-1", "Dnepr-2", "Dnepr-21", "Dnepr-22", "Dnepr-22M "," EMRT-2 "," EMRT-3 "," KASHTAN "," Mir "," Mir-1 "," Mir-2 "," Mir-3 "), which were developed under the direction of V.M. Glushkov, and were the best in technical characteristics and software for that time.

The chief designer of Dnipro (as already mentioned) was Boris Malinovsky. Together with the Institute of Cybernetics of the National Academy of Sciences of Ukraine, Kharitonov V.N., Stoyanko D., Faktorovich A.Sh. took part in the creation of the Dnepr-2 system (the main designer was Kukharchuk AG, the deputy chief designer was Sakaev E.I.) ., Seligey OM, Omelyanchuk, Khomyakov V.I., Galuzinsky, Strelchenko, Zaslavsky R., Bezchastny PM, Bulka S.M.

Dnipro-2 was the first system in the USSR that could be used as a basic computing machine for creating integrated control systems at industrial enterprises, research and trade organizations.

"Dnepr-2"

Dnepr-2 UVS consisted of two main parts, the first part - the central computing complex "Dnepr-21" and the second part - the managing complex "Dnepr-22M". Dnipro-21 is a universal digital computer that had a number of features that expand its capabilities and increase efficiency in solving a large class of problems. Such a UVEM provided multi-program operation (powerful interrupt system, circuit address protection, etc.), had an extended command system that allowed typical software situations to be implemented by fewer operations, made it possible to use a large number (up to 96) external devices of any type with unified connections

used addresses and operands of variable length, was the ability to exchange information on unified channels with other machines or specialized devices through a multiplexer, selector or free entry into memory.

"Dnepr-22M" was intended for the exchange of information between the central computer system, the control object and the operator.

The speed of the Dnepr-2 was 16 thousand operations of addition type per second, the number of commands was 177, the memory cell width was 42 bits.

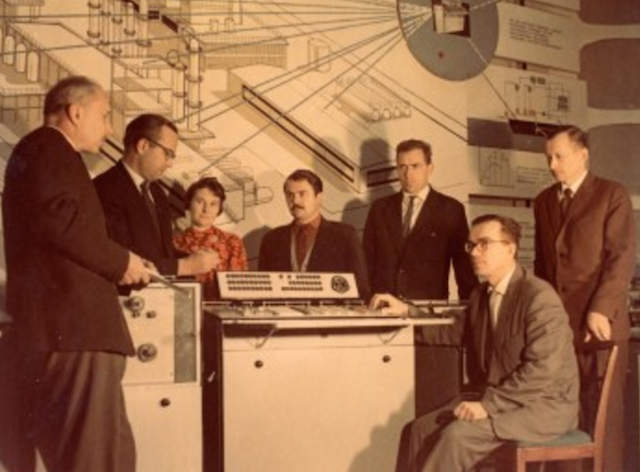

"Mir-1" at the exhibition "Interorgtehnika" (VDNH in 1966)

"Mir-1" was presented at the international exhibition "Interorgtehnika" (VDNH in 1966), received its appreciation and was purchased by IBM. Chestnut was designed to automate batch calculations for procurement, taking into account the requirements of the range and minimizing residues. It was used in the clothing, metallurgical, engineering and other industries. It was the only one in the world according to its purpose. It was patented in the USA, England, France, Germany, Italy, Japan.

"World-1"

The Mir-1 machine is a machine for engineering calculations, weighing 400 kg, consisted of two tables, a typewriter was mounted on one of them, and a debugging console on the other and powered from an AC three-phase network (380 V, 50 Hz ), while consuming no more than 1.5 kW of energy. It also included an information exchange device, a firmware control device, a memory device, an arithmetic unit, and a power supply device.

It was a second-generation computer, such tasks as systems of linear algebraic equations up to 20 orders, systems of ordinary differential equations up to 16 orders, and integral equations could be solved. The computer was a hardware-firmware interpreter of the language ALMIR-65.

The speed of the machine when performing arithmetic operations on 5-bit numbers was 200 - 300 operations per second.

The electronic typewriter with a wide carriage served for input and output of results, the printing speed - 10 characters per second.

OP computer - volume of 4096 12-bit cells, one of the characters of the input language, a service word or the identifier of a standard function was stored in the cell.

The eight-track punched tape served as an external memory in such a computer, the speed of output to the PL-80 punch - up to 80 characters per second, the input speed from the FS-1501 device - up to 1500 characters per second.

It is believed that "Mir" was the first step towards the creation of personal computers.

Already in the early 1970s, about 10 thousand people worked for the benefit of the VUM plant.

In 1972, the VUM was transformed into the research and production association "Electronmash". The Research Institute of Peripheral Equipment (NIIP), headed by Stanislav Sergeevich Zabara, was opened.

Zabara S.S.

From his memoirs: "... Institutional status allowed me to more freely determine the directions of creative research. I became interested in the problem of design automation. According to sound reasoning, I immediately cut off the highly intellectual sphere of design, where it was difficult to rely on quick results. I was more interested in routine processes engineering work, the automation of which, on the one hand, was amenable to algorithmization, and on the other hand, it could clearly manifest itself in increasing productivity and error-free of design operations. She was also fascinated by the idea of informationally integrating the process of design, production and final inspection of products.

For many, this direction caused aggressive skepticism, so I wanted to find companions not by coercion, but by conviction. Such my fellow students-teachers were the heads of NIIP units G.Yu. Veprinsky, A.D. Milner, V.P. Sidorenko, .D. Rukkas. I tell the students, because I convinced them to believe in the idea and did the initial formulation of the tasks, and the teachers, because then they explained to me what difficult problems they encountered when they deepen into these tasks.

Thus, the following systems arose: an automated workstation for design engineering in radio electronics (mainly printed circuit boards) ARM2-01, main developers G.Yu.Veprinsky, MADrodin, E.Sh.Rayz; automated workstation for firmware and circuit design of ARM2-05, main developers A.D. Milner, A. V. Bogachev, M. B. Batkovsky, V. V. Yakovlev; control system of digital and analog blocks of KODIAC elements, main developers V.P. Sidorenko, O.D. Rukkas, E.N. Chichirin, N.S. Bershtein; The system of automated manufacturing and control of wired installation, the main performers are the same as for the CODIAC system.

A feature of all these systems was that they naturally combined automatic and interactive design methods. They were maximally (due to our abilities) take into account the technological requirements of production and the results of the design (information on machine carriers) were directly used by the executive equipment in production.

These systems are widely used in the factory, and also replicated for other enterprises. Without exaggeration, we can say that they have radically influenced the entire assembly and debugging production cycle ... "

The development and mastering of a wide range of external devices, such as drives on magnetic disks and tapes, alphanumeric and graphic screen consoles, printing devices, plotters, input devices for graphic information, devices for recording seismic information, data transmission multiplexers, began. There was a need to build a precision mechanics workshop, a test site, a tool shop. The structure of the research and production association "Electronmash", in addition to the plant VUM, also included a research and development institute of peripheral equipment, the Kiev specialized start-up management and at different times the Vinnitsa plant of automation equipment "Terminal", the Odessa computer plant "Electronmash" , Glukhovsky Plant of Computing Equipment, Lubensky Plant of Calculating Machines “Accounts”, Kiev Scientific-Computing Center GIVTS.

In 1970, the production of the first models of the Aggregator system of computer equipment (M 3000) was mastered. The team of the VUM plant was tasked to move from small-scale to multi-production computer. In 1973, a group of designers and developers created a new computing complex - M-4030.

M-4030

For his development and development of mass production was even awarded the State Prize of the Ukrainian SSR in the field of science and technology. In 1974, the production of the M6000 and M400 computers was mastered, and after 4 years the models of the international system of small computers - SM computers were developed and put into mass production.

In 1981 he was awarded the USSR State Prize for the development and organization of the serial production of the SM-3, SM-4 complexes. Specialists in the field of manufacturing computer equipment from a number of foreign firms directly participated in the creation of computer technology. CM-3 is a good example of such cooperation. Bulgaria, Germany, Hungary, Cuba, Poland, Czechoslovakia took part in the development and production of this complex.

Control computer systems were exported to Algeria, Bulgaria, Hungary, Poland, India, Finland, Sweden, Yugoslavia, Cuba. For such exports, Electronmash was awarded the Golden Mercury award.

CM-4

Since 1973, Elektronmash has cooperated mainly with the Moscow Institute of INEUM through the SM computer, together with which new series of machines were developed and about 30 thousand pieces were manufactured (4030, 4030-1, 3000, 4000, 6000, 400, - 3, CM-4, CM1800, CM 1420, APM2.01, CM 1803, CM 1804, CM 1814, CM 1810, CM 1810.13.01 Nivka, CM 1425, CM 1702)

.

For the development of an automated diagnostic control system for complex electronic components - the KODIAC system in 1984, Electronmash employees were awarded the State Prize of the Ukrainian SSR.

Kodiak

The original automated diagnostic test complex complex blocks of electronic equipment. The problem-oriented complex “Kodiak” was created to solve a difficult scientific and technical problem - the output control of blocks of elements of high complexity.

This complex consisted of a central computer SM-4 and a number of logical control devices (UKBL) and analog (UKBA) units. With the help of "Kodiak"

It became possible to feed a large number of consecutive test signals to an object, such as programmable, pseudo-random, pseudo-dynamic test kits. The response to these signals was analyzed with a special logic analyzer. The complex was equipped with controlled measuring devices, sources of constant and pulsed voltages. This all reduced the debugging cycle of all types of computers, increasing their reliability.

In 1988, development was completed at Electronmash and the launch of the first Poisk-1 and Nyvka personal computers began.

In 1990, a small series of CM1820 machines called “Nyvka” was produced at the VUM PO Electronmash plant.

“Search” - a 16-bit personal computer (ІBM PC XT clone, project of 1988)

The enterprise organized the development and creation of H2S1 (Gerashchenko K.V., Yarmosh A.P.) for the Ministry of Defense and the ADP units (Aptekman B.O.) for atomic energy.

"Electronmash" took part together with the Leningrad Institute "Burevestnik" in the space project "Buran".

In 1986, the employees of Electronmash successfully coped with the state task for the manufacture of printed circuit boards for remote control of tractors, which were used to eliminate the consequences of the accident at the Chernobyl nuclear power plant.

In 1986, due to the health condition of A.F. Nezabitovsky retired. AG became the general director of the association. Nazarchuk, and with his departure in 1990 to work in the Kiev City Council, V.I. became head of Electronmash. Mova

Viktor Ivanovich Mova gave most of his working life to the plant, did a lot for the development of the social sphere and production. Being from 1987 the chief engineer directly supervised the creation and introduction into production of CM1814, SM1425, CM1702 and personal computers.

In 1987, the Electronmash cooperation agreement with the Kiev Polytechnic Institute was prepared to further improve the training and distribution of specialists with higher education. The factory has always relied on young professionals who took their enthusiasm, the desire to create something new.

In early 1988, Electronmash began working on state accounting and financing. And after 1990, global changes began, not only in the country, but also in the enterprise.

What we have now, such a giant as "Electronmash", with ten thousand employees, developed infrastructure, has developed (as one person noticed on the forum):

"... turned into a shame, he stands now as a dumb lesson for those who live nearby, often in houses built by this plant, and not hruschovkam - small cars, and every" VUM "ovsky house was a special project, the construction was enormous pace, when the director was Apollinary Fedorovich Nezabitovsky, thanks to him for this huge, from a thousand people, and a low bow. And today, all residents of the district are forced to return to their factory, but without a robe, and to Auchan, or for Chinese telephones-telephones, at the factory magnetic disks as well if you are not local, and there is no money, then you can settle in a hotel, well, right at the checkpoint. Not to mention warehouses and other things. "

Although in 1993, “Electronmash” mastered the development and production of electronic cash registers. It was released more than 260 thousand pieces of ECCA 25 models and modifications. In 2014, mastered the mass production of the new model EKKA Gnome 302.05.

new model ekka gnome 302.05

Over the years, new technologies in the field of power electronics have been mastered; energy-saving, ecologically safe food products for onboard electric power supply systems of urban transport: trolley buses, trams, subway cars and railways began to be mass-produced.

In that year, it was just 50 years since the creation of Electronmash. According to the leadership, there are plans for the future (hopefully, perhaps even feasible).

Electronmash

In Kiev, the development of computing at the time was at a high level. After the creation of the first multi-purpose control machine "Dnepr", it turned out that there was simply no place to produce it in series. So there was a need to create a factory where computers could be developed and produced.

"Dnieper"

')

Dnipro is the first Soviet multi-purpose semiconductor control computer. The machine was developed from 1958 to 1961 at the Institute of Cybernetics of the Academy of Sciences of Ukraine. The project managers were Glushkov (chief designer) and Malinovsky. Such a machine was intended for industrial process control systems. It was a machine with a binary number system, created on transistors, 26-bit (26 binary digits), two-address. The speed of 10 thousand operations per second. The memory device was on ferrite cores (which allowed to increase the reliability of the machine and reduce its dimensions), consisted of sections, which made it possible to change the memory volume. OP 512 words capacity, additional RAM blocks with capacity from 3 to 512 words, additional ROM blocks with capacity from 6 to 512 words. External magnetic tape storage up to 200 thousand words.

A special feature was the presence of a communication device with an object (ODR) built into the machine for connecting it to the sensors and the executive bodies of the object controlled from the machine. Power "Dnepr" was from a three-phase AC 220/380 V, 50 Hz. The address language developed at the Institute of Cybernetics E. L. Yushchenko was adopted as the input language.

... "When the first copy of the car came from the factory, the developers clutched at his head. It was a solid aggregation of parts, where about a thousand soldered joints were made poorly and constantly refused, the connectors spoiled by inept handling. To debug such a machine was simply impossible. It turned out that the plant manager, having heard that the machine is 6 times larger than an oscilloscope, recruited students who had just graduated from school. Yesterday's schoolchildren with soldering irons in their hands began to “solder” the connections into the machine elements and break the connectors by careless handling. Since the installation time of the first UMSN in the Bessemer shop was approaching, the developers of the machine had to solder almost the entire machine and replace many connectors. Only then did the debugging process move. But it cost a lot of hard work around the clock multi-day work of the developers of the machine. "

500 Dnipro were produced, of which a couple of dozen were used in Ukraine, the rest in the Russian Federation, several in the republics of the Soviet Union and abroad.

In 1965, the Kiev Plant of Computing and Control Machines (VUM) began operating in Kiev on the basis of separate divisions of the Radiopribor plant. Initially, the plant employed 460 people. The director in those years was Apollinary Fedorovich Nezabitovsky. In 1972, the VUM was transformed into the Scientific and Production Association "Electronmash", which is considered one of the leaders in the USSR in the production of computing and control equipment.

Apollinary Fedorovich Nezabitovsky

"... You can’t sympathize with all your subordinates - this is a sure way to overwhelm a business. Remember, there are tasks, there are deadlines - demand! And don’t really go into details, because you yourself will also start thinking that this is impossible" - A.F. Nezabitovsky’s words .

Although he was not a professional in the field of computing, any leader could envy his energy and pressure. In a short time, he became a production manager of the plant, and later - a director, from a senior engineer at the Kiev factory "Tochelektropribor". Demanding of employees and respecting the order were respected by colleagues. There were legends about him.

From Golovtsev's memoirs:

"... the gray-haired and benevolent Appolinos Fyodorovich Nezabitovsky (in the epics -" dad ") - headed the materialization of the ideas of the great theorist, provided them - bodiless - with the flesh of electronic computing (in the modern outline - computers). Dad firmly held the steering wheel of an enormous ship, confidently led it among the waves of everyday problems, inevitable envy and rivalry. Workers, kind children, noted decent - the results of labor in accordance with - salary, provided with housing, cheap and tasty factory food, vacation com in sanatoriums and their own holiday homes.

Slackers, talkers useless and windbag heavily hated, banished. And everyone involved in the success of the famous factory was happy. It seemed that there was no limit to perfection, that development would be permanent, strengthening the stability of the colossus. "

Resolute Nezabitovsky "dissolved" in the life of the plant. I did my best to make the plant better than any other, apartment buildings for employees also had to be the best, as well as recreation centers. Solid advantages for the head. Soon a microdistrict appeared, which was built up with factory houses (“Nezabitovschina”).

In addition, factory kindergartens, a pioneer camp “VUMovets”, recreation centers on the Desna and Ros rivers, an outpatient clinic (with modern equipment at that time), a sports and fitness complex were built. One of the best factory canteen in the city also belonged to the VUM factory.

By the way, the factory canteen is still working.

price over the past year, 15 hryvnia about 40 rubles

The plant VUM specialized in the production of UVM. This all left a definite imprint on the features of hardware and software that were produced at the factory. Computers were designed to work in real time.

To launch the created equipment into mass production it took a lot of effort and labor, since such machines were an innovation, the specialists - the pioneers were just learning, mastering the "know-how". Nevertheless, the plant managed to recruit qualified specialists from Severodonetsk - Afanasyev, Sergeev, Voynarovsky, from Minsk and Kazan, from the CC of the Ukrainian SSR Academy of Sciences. The plant, without putting “hands,” conducted the training of young specialists, highly qualified employees. When the plant opened educational institutions - technical college and technical college. An implementation department was created (headed by KPI graduate Alexey Alekseevich Sladkov).

Alexey Alekseevich Sladkov - master of the computer setup area. After serving in the army, he entered the KPI. He graduated from the faculty, which was then called the primitive "Accounting Machines". He had to continue his studies in graduate school as an excellent student, but was tempted by the promise of the plant director to provide him with an apartment, and therefore he was in my shop.

In the field of electronics, he was just an ac, and this was a very important point at the last stage of working on the machine - setting it up before handing it over to the customer. Thanks to him, the computer maintenance service was subsequently organized, that is, the launch of the machine directly at the consumer. We were of the same age with him, but he had already managed to divorce his wife and lived with his sister. At the same time, he tirelessly repeated that he loved his ex-wife, and it is very difficult for him without her. Periodically, he made an appointment with his ex-wife about a meeting on her territory, but the joint life lasted no more than two or three days. With this tireless love, he did not disdain to meet on sexual grounds with other women. For his subtle humor, bordering on sarcasm, more than half of the female staff of our workshop was in love with him.

The team of the department is truly a team of enthusiasts. They were faced with the task of not only introducing existing hardware and software, but also the task of formulating the requirements for new tools necessary for the automation of real objects. In order to better feel the mood of the plant’s team, it is worth remembering the work on the Whirlwind project - the test automation system for spacecraft propulsion engines intended for flight to the Moon. It was necessary in a short time (up to 300 seconds) to collect a large amount of information from sensors installed on the engine, and also to process it in real time. The Dnepr UMShN was significantly modernized and became the “core” of the Whirlwind system, all this was done very quickly and in 1965 all the products were ready and delivered to the Design Bureau of the space systems.

The introduction of the Whirlwind system has significantly reduced the time needed to test lunar sustainer engines. And the fact that the Soviet Union was the first to fly to the moon, circled and photographed the far side of the moon, the soft landing of the apparatus on the moon, there is a bit of our work. This we remember with pride and will always be remembered and proud.

In 1965 - 1974 more than 2.5 thousand computers were manufactured at the plant ("Dnepr", "Dnepr-1", "Dnepr-2", "Dnepr-21", "Dnepr-22", "Dnepr-22M "," EMRT-2 "," EMRT-3 "," KASHTAN "," Mir "," Mir-1 "," Mir-2 "," Mir-3 "), which were developed under the direction of V.M. Glushkov, and were the best in technical characteristics and software for that time.

The chief designer of Dnipro (as already mentioned) was Boris Malinovsky. Together with the Institute of Cybernetics of the National Academy of Sciences of Ukraine, Kharitonov V.N., Stoyanko D., Faktorovich A.Sh. took part in the creation of the Dnepr-2 system (the main designer was Kukharchuk AG, the deputy chief designer was Sakaev E.I.) ., Seligey OM, Omelyanchuk, Khomyakov V.I., Galuzinsky, Strelchenko, Zaslavsky R., Bezchastny PM, Bulka S.M.

Dnipro-2 was the first system in the USSR that could be used as a basic computing machine for creating integrated control systems at industrial enterprises, research and trade organizations.

"Dnepr-2"

Dnepr-2 UVS consisted of two main parts, the first part - the central computing complex "Dnepr-21" and the second part - the managing complex "Dnepr-22M". Dnipro-21 is a universal digital computer that had a number of features that expand its capabilities and increase efficiency in solving a large class of problems. Such a UVEM provided multi-program operation (powerful interrupt system, circuit address protection, etc.), had an extended command system that allowed typical software situations to be implemented by fewer operations, made it possible to use a large number (up to 96) external devices of any type with unified connections

used addresses and operands of variable length, was the ability to exchange information on unified channels with other machines or specialized devices through a multiplexer, selector or free entry into memory.

"Dnepr-22M" was intended for the exchange of information between the central computer system, the control object and the operator.

The speed of the Dnepr-2 was 16 thousand operations of addition type per second, the number of commands was 177, the memory cell width was 42 bits.

"Mir-1" at the exhibition "Interorgtehnika" (VDNH in 1966)

"Mir-1" was presented at the international exhibition "Interorgtehnika" (VDNH in 1966), received its appreciation and was purchased by IBM. Chestnut was designed to automate batch calculations for procurement, taking into account the requirements of the range and minimizing residues. It was used in the clothing, metallurgical, engineering and other industries. It was the only one in the world according to its purpose. It was patented in the USA, England, France, Germany, Italy, Japan.

"World-1"

The Mir-1 machine is a machine for engineering calculations, weighing 400 kg, consisted of two tables, a typewriter was mounted on one of them, and a debugging console on the other and powered from an AC three-phase network (380 V, 50 Hz ), while consuming no more than 1.5 kW of energy. It also included an information exchange device, a firmware control device, a memory device, an arithmetic unit, and a power supply device.

It was a second-generation computer, such tasks as systems of linear algebraic equations up to 20 orders, systems of ordinary differential equations up to 16 orders, and integral equations could be solved. The computer was a hardware-firmware interpreter of the language ALMIR-65.

The speed of the machine when performing arithmetic operations on 5-bit numbers was 200 - 300 operations per second.

The electronic typewriter with a wide carriage served for input and output of results, the printing speed - 10 characters per second.

OP computer - volume of 4096 12-bit cells, one of the characters of the input language, a service word or the identifier of a standard function was stored in the cell.

The eight-track punched tape served as an external memory in such a computer, the speed of output to the PL-80 punch - up to 80 characters per second, the input speed from the FS-1501 device - up to 1500 characters per second.

It is believed that "Mir" was the first step towards the creation of personal computers.

Already in the early 1970s, about 10 thousand people worked for the benefit of the VUM plant.

In 1972, the VUM was transformed into the research and production association "Electronmash". The Research Institute of Peripheral Equipment (NIIP), headed by Stanislav Sergeevich Zabara, was opened.

Zabara S.S.

From his memoirs: "... Institutional status allowed me to more freely determine the directions of creative research. I became interested in the problem of design automation. According to sound reasoning, I immediately cut off the highly intellectual sphere of design, where it was difficult to rely on quick results. I was more interested in routine processes engineering work, the automation of which, on the one hand, was amenable to algorithmization, and on the other hand, it could clearly manifest itself in increasing productivity and error-free of design operations. She was also fascinated by the idea of informationally integrating the process of design, production and final inspection of products.

For many, this direction caused aggressive skepticism, so I wanted to find companions not by coercion, but by conviction. Such my fellow students-teachers were the heads of NIIP units G.Yu. Veprinsky, A.D. Milner, V.P. Sidorenko, .D. Rukkas. I tell the students, because I convinced them to believe in the idea and did the initial formulation of the tasks, and the teachers, because then they explained to me what difficult problems they encountered when they deepen into these tasks.

Thus, the following systems arose: an automated workstation for design engineering in radio electronics (mainly printed circuit boards) ARM2-01, main developers G.Yu.Veprinsky, MADrodin, E.Sh.Rayz; automated workstation for firmware and circuit design of ARM2-05, main developers A.D. Milner, A. V. Bogachev, M. B. Batkovsky, V. V. Yakovlev; control system of digital and analog blocks of KODIAC elements, main developers V.P. Sidorenko, O.D. Rukkas, E.N. Chichirin, N.S. Bershtein; The system of automated manufacturing and control of wired installation, the main performers are the same as for the CODIAC system.

A feature of all these systems was that they naturally combined automatic and interactive design methods. They were maximally (due to our abilities) take into account the technological requirements of production and the results of the design (information on machine carriers) were directly used by the executive equipment in production.

These systems are widely used in the factory, and also replicated for other enterprises. Without exaggeration, we can say that they have radically influenced the entire assembly and debugging production cycle ... "

The development and mastering of a wide range of external devices, such as drives on magnetic disks and tapes, alphanumeric and graphic screen consoles, printing devices, plotters, input devices for graphic information, devices for recording seismic information, data transmission multiplexers, began. There was a need to build a precision mechanics workshop, a test site, a tool shop. The structure of the research and production association "Electronmash", in addition to the plant VUM, also included a research and development institute of peripheral equipment, the Kiev specialized start-up management and at different times the Vinnitsa plant of automation equipment "Terminal", the Odessa computer plant "Electronmash" , Glukhovsky Plant of Computing Equipment, Lubensky Plant of Calculating Machines “Accounts”, Kiev Scientific-Computing Center GIVTS.

In 1970, the production of the first models of the Aggregator system of computer equipment (M 3000) was mastered. The team of the VUM plant was tasked to move from small-scale to multi-production computer. In 1973, a group of designers and developers created a new computing complex - M-4030.

M-4030

For his development and development of mass production was even awarded the State Prize of the Ukrainian SSR in the field of science and technology. In 1974, the production of the M6000 and M400 computers was mastered, and after 4 years the models of the international system of small computers - SM computers were developed and put into mass production.

In 1981 he was awarded the USSR State Prize for the development and organization of the serial production of the SM-3, SM-4 complexes. Specialists in the field of manufacturing computer equipment from a number of foreign firms directly participated in the creation of computer technology. CM-3 is a good example of such cooperation. Bulgaria, Germany, Hungary, Cuba, Poland, Czechoslovakia took part in the development and production of this complex.

Control computer systems were exported to Algeria, Bulgaria, Hungary, Poland, India, Finland, Sweden, Yugoslavia, Cuba. For such exports, Electronmash was awarded the Golden Mercury award.

CM-4

Since 1973, Elektronmash has cooperated mainly with the Moscow Institute of INEUM through the SM computer, together with which new series of machines were developed and about 30 thousand pieces were manufactured (4030, 4030-1, 3000, 4000, 6000, 400, - 3, CM-4, CM1800, CM 1420, APM2.01, CM 1803, CM 1804, CM 1814, CM 1810, CM 1810.13.01 Nivka, CM 1425, CM 1702)

.

For the development of an automated diagnostic control system for complex electronic components - the KODIAC system in 1984, Electronmash employees were awarded the State Prize of the Ukrainian SSR.

Kodiak

The original automated diagnostic test complex complex blocks of electronic equipment. The problem-oriented complex “Kodiak” was created to solve a difficult scientific and technical problem - the output control of blocks of elements of high complexity.

This complex consisted of a central computer SM-4 and a number of logical control devices (UKBL) and analog (UKBA) units. With the help of "Kodiak"

It became possible to feed a large number of consecutive test signals to an object, such as programmable, pseudo-random, pseudo-dynamic test kits. The response to these signals was analyzed with a special logic analyzer. The complex was equipped with controlled measuring devices, sources of constant and pulsed voltages. This all reduced the debugging cycle of all types of computers, increasing their reliability.

In 1988, development was completed at Electronmash and the launch of the first Poisk-1 and Nyvka personal computers began.

In 1990, a small series of CM1820 machines called “Nyvka” was produced at the VUM PO Electronmash plant.

“Search” - a 16-bit personal computer (ІBM PC XT clone, project of 1988)

The enterprise organized the development and creation of H2S1 (Gerashchenko K.V., Yarmosh A.P.) for the Ministry of Defense and the ADP units (Aptekman B.O.) for atomic energy.

"Electronmash" took part together with the Leningrad Institute "Burevestnik" in the space project "Buran".

In 1986, the employees of Electronmash successfully coped with the state task for the manufacture of printed circuit boards for remote control of tractors, which were used to eliminate the consequences of the accident at the Chernobyl nuclear power plant.

In 1986, due to the health condition of A.F. Nezabitovsky retired. AG became the general director of the association. Nazarchuk, and with his departure in 1990 to work in the Kiev City Council, V.I. became head of Electronmash. Mova

Viktor Ivanovich Mova gave most of his working life to the plant, did a lot for the development of the social sphere and production. Being from 1987 the chief engineer directly supervised the creation and introduction into production of CM1814, SM1425, CM1702 and personal computers.

In 1987, the Electronmash cooperation agreement with the Kiev Polytechnic Institute was prepared to further improve the training and distribution of specialists with higher education. The factory has always relied on young professionals who took their enthusiasm, the desire to create something new.

In early 1988, Electronmash began working on state accounting and financing. And after 1990, global changes began, not only in the country, but also in the enterprise.

What we have now, such a giant as "Electronmash", with ten thousand employees, developed infrastructure, has developed (as one person noticed on the forum):

"... turned into a shame, he stands now as a dumb lesson for those who live nearby, often in houses built by this plant, and not hruschovkam - small cars, and every" VUM "ovsky house was a special project, the construction was enormous pace, when the director was Apollinary Fedorovich Nezabitovsky, thanks to him for this huge, from a thousand people, and a low bow. And today, all residents of the district are forced to return to their factory, but without a robe, and to Auchan, or for Chinese telephones-telephones, at the factory magnetic disks as well if you are not local, and there is no money, then you can settle in a hotel, well, right at the checkpoint. Not to mention warehouses and other things. "

Although in 1993, “Electronmash” mastered the development and production of electronic cash registers. It was released more than 260 thousand pieces of ECCA 25 models and modifications. In 2014, mastered the mass production of the new model EKKA Gnome 302.05.

new model ekka gnome 302.05

Over the years, new technologies in the field of power electronics have been mastered; energy-saving, ecologically safe food products for onboard electric power supply systems of urban transport: trolley buses, trams, subway cars and railways began to be mass-produced.

In that year, it was just 50 years since the creation of Electronmash. According to the leadership, there are plans for the future (hopefully, perhaps even feasible).

Source: https://habr.com/ru/post/390881/

All Articles