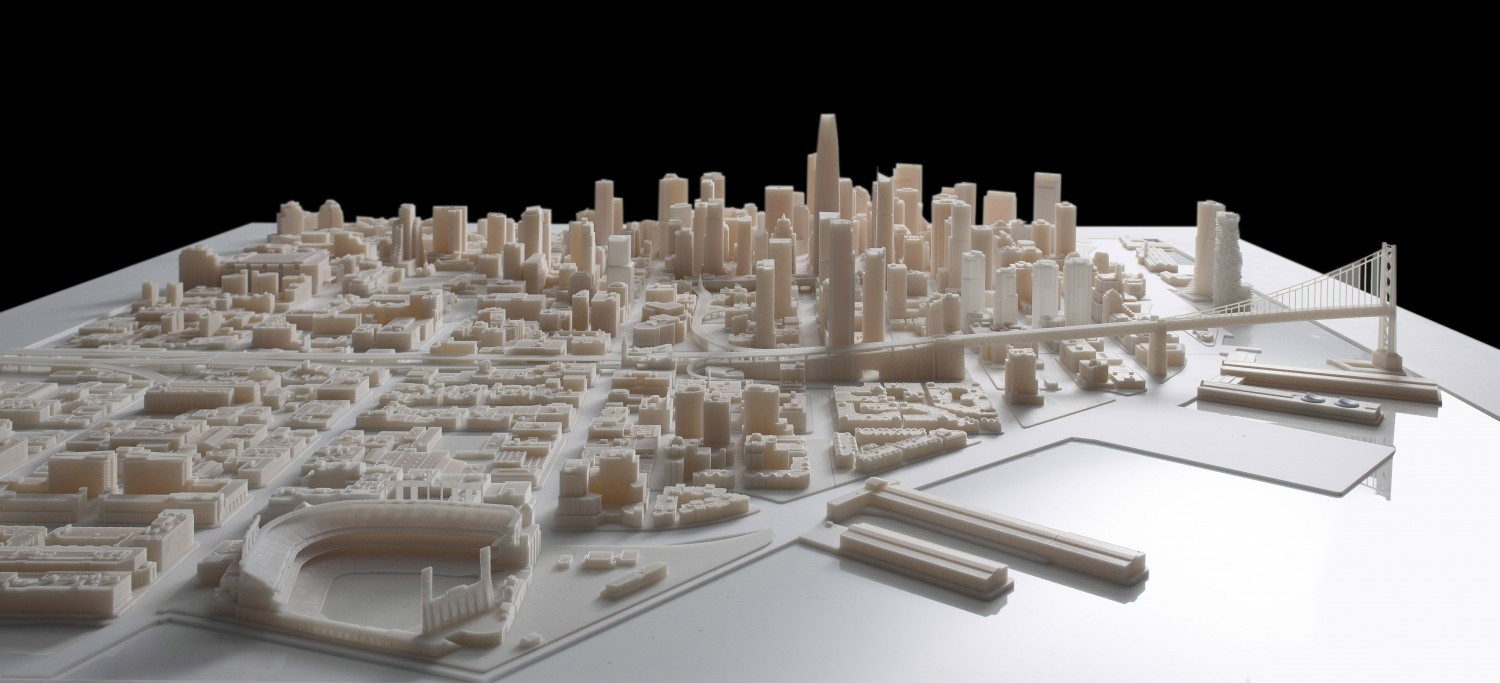

The largest three-dimensional model of the city, printed on a 3D-printer

I love cities, 3D models, mockups ... City printed on a 3D printer? Perfect! In 2014, in San Francisco, the largest printed interactive 3D-model of the city was presented, and a year and a half later, this status was still with it. The layout still doesn’t cover the whole city, but the 115 blocks of northeastern San Francisco with a print resolution of 16 microns and an appropriate level of detail are truly impressive results. It is strange that no one wrote about it here. I will correct injustice.

The model was developed by Steelblue's creative agency, which deals with the marketing of large construction projects, under the auspices of Autodesk, commissioned by the large real estate developer Tishman Speyer. It was made in Avtodeskov's “Pier 9 creative workshops” from VeroWhite photopolymer on two Objet500 Connex 3D printers with a 500x400x200 mm print camera. This printer combines a three-dimensional camera and a high print speed with very thin layers, making it possible to quickly and accurately create large parts or even several parts from different materials. But even on such equipment, printing took 2 months, 5 days a week, 18 hours a day. The total weight of 68 kg is no joke. But there is still a post-processing stage manually, approximately 45 minutes per quarter.

')

The three-dimensional model was created on the basis of a large amount of heterogeneous data. In the course went and topographic maps, and three-dimensional scanning, and photographs, and architectural projects from the archive. The area covered included many local sights, which were recreated with great care. Modeling took about 6 years: from 2008 to 2014. Even existing three-dimensional building models from previous projects did not take advantage of: at a scale of 1: 1250 and the printer resolution it was easier to build new ones than to simplify the old ones. The minimum size of detailing is approximately 30 cm in the real world.

Video of the creation process

The purpose of the creation of this large-scale object is to help the developer in town planning. Any unit can be replaced and see what happens. One of the advantages of 3D printing, the authors call the ability to easily maintain the relevance of the model. Another plus is higher detailing, production speed and lower cost than a traditional handmade model. The main point of creating a layout in general is that it allows you to feel the space in a way that however realistic a picture on the screen does not help. Although the virtual part of the model also has an important role: the work goes on in it, and the layout itself serves for presentations.

In addition to the actual model of the city (in the state in 2017, when some large objects will be completed), the projector includes a projector located under the ceiling, which creates an interactive component for every taste. You can impose on the layout of the future subway lines or roads (even to model the flow of vehicles on them), you can sign the streets or display zoning on some basis. You can imitate the movement of the sun across the sky and trace the zones of the shadow. Only the limits of fantasy limit the way to use the backlight.

Demonstration of the possibilities of working with the projector

The original with all related hardware and software remains with the customer, “Tishman Speyer”. In the copy, which will be shown to the public in the Autodesk gallery, they plan to illuminate the backlight in the table itself from below, for beauty. In Steelblue, we are ready to expand the model with new quarters, develop a more functional version of the backlight with several projectors, and also want to print other cities, but with such laboriousness and cost of several hundred thousand dollars, the layout of San Francisco is unique in terms of territory .

Sources:

Presentation of the layout on the site “Autodesk” , ibid - a report on printing in the workshop „Pier 9“

The story of Jeff Mottle, owner of the architectural magazine CGarchitect, about the work of Steelblue on this object and future plans

Jacob Gubler's own website, the main modeler of this project, also features similar, but smaller, Boston and Manhattan prints, as well as a San Francisco print made from transparent Veroclear material.

Source: https://habr.com/ru/post/390145/

All Articles