Review of the most popular 3D printers: UP! Plus 2 and Cube 3

About 20 years ago not everyone could afford to have a laser printer at home. And in general, they were perceived as exotic. And now home 3D-printers are becoming commonplace. Now it is a fully developed class of devices sold in stores and not requiring knowledge of electronics for their assembly. Overview of two representatives of household 3D-printers, UP! Plus 2 and Cube 3, we bring to your attention.

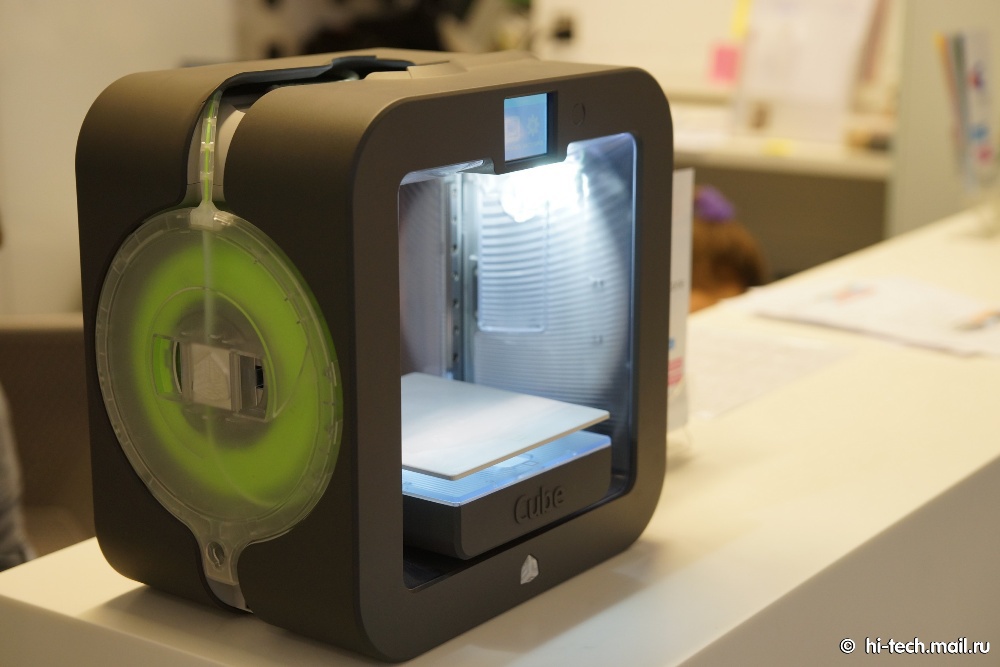

Cubify Cube 3

This printer was developed by the American company 3D Systems, which can be called one of the pioneers in the field of 3D printers for both professional and home use. The Cube 3 model quickly became one of the most popular on the market.

')

As often happens with various new types of devices, 3D printers have gone from super-expensive gigantism to small desktop boxes that are accessible to quite wide sections of the population. By the way, 3D Systems officially declares that when developing software for Cubify series printers they expected the child to understand it. In the literal sense.

Cube 3 was announced at CES 2014, but in Russia it has not yet appeared in retail sales. Although it is promised soon. If you really need, then you can buy a printer in the Russian office of 3D Systems for $ 1,799 (in the US it costs $ 1,099).

Main characteristics

- Maximum print volume: 152.5 x 152.5 x 152.5 mm

- Print resolution: 0.07 mm

- Printing Volume: 3.5 L

- Print speed: 10-100 cm³ / hour

- Type of workspace: open

- Materials used: ABS, PLA

- File format: .STL

- Connection: USB, Wi-Fi (802.11b / g)

- Supported OS: Windows: XP, Vista, 7, 8; MAC OS X

- Dimensions: 335 x 338 x 280 mm

- Weight: 7.7 kg

Design and construction

The appearance of the printer is significantly different from the previous model, the Cube 2. It doesn’t look like a deliberately technical one ; on the contrary, the exterior of the Cube 3 allows it to fit very well into the interior. The print zone, equipped with a backlight, is not closed by anything, you can watch the process without hindrance. At the same time have to regularly wipe the dust.

On the sides of the working area there are vertical guides, along which the platform with the created product moves along the vertical plane. It is printed directly on a smooth plate attached to the platform with magnets. Coil with plastic thread is located on the left. In Cube 3, you don’t even have to feed the thread yourself into the print head; you just need to insert the tube coming out of the spool into a special socket. True, this is one of the main disadvantages: you can not use consumables from other manufacturers, only proprietary coils from 3D Systems.

In front of the working area is a small touch screen. It allows you to control the printer, including launching a platform calibration, as well as view a color model of the product. Next to the screen is the power button. The power connector and USB are on the sides, at the bottom of the printer. Also, the printer is equipped with a Wi-Fi-module.

The ideology of ease of use is manifested in the fact that the printer is ready to work right out of the box. Just install the work surface on the platform.

Software

To work with the printer, you need to install the Cubify application. It exists in versions for Windows, Mac, Android and iOS. The interface makes a very favorable impression, it is clear that the authors paid a lot of attention to their offspring: the size of the interface elements, their composition and location are well thought out.

Cubify has quite limited capabilities; you cannot control every element of the product being created. But the application can really master even a child, it is very user friendly.

The application has a built-in store where you can purchase other software for 3D printing and 3D scanning. Thus, 3D Systems forms a whole ecosystem within which users can choose the “device-software” combinations themselves. Using the applications offered in the store, you can draw three-dimensional models and convert photos into them, as well as use the camera as a 3D printer. There are both paid and free applications that will be of interest to users of higher-end 3D printers.

In work

Included with the Cube 3 are two PLA plastic coils and glue. The printer allows you to use PLA and ABS plastics, although nothing structurally prevents the use of other materials, but it all comes down to the aforementioned branded coils. However, the manufacturer plans to soon begin production and nylon thread for their printers.

The device works only with STL files. Before printing, the work surface must be lubricated with special glue that comes in the kit. Using the touch screen, you can adjust the print resolution. The speed, unfortunately, is not configurable.

The above model chess rook printer printed 4 hours 50 minutes. Despite the resolution of 70 microns, the quality turned out to be very decent, almost no additional processing was required. So Cube 3 is quite suitable for modeling, and not just for home crafts. The printer is very quiet for this class of devices, so it can be kept in the living room.

UP! Plus 2

The second device in our review is an updated version of the main model in the line of the Chinese company PP3DP. Do not pay attention to the "Chinese", its parent company Tiertime has long gained a high reputation in the market of industrial 3D-printers. UP! Plus 2 went on sale in 2013, which is a very long time by the standards of the young 3D printer market. However, the device still remains attractive to buyers. The printer is small, easy to learn and comes with a convenient UPWare application. By the way, the device is available in our country in retail. The cost is about 89 thousand rubles.

Main characteristics

- Maximum printing capacity: 140x140x135 mm

- Print resolution: 0.15mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm

- Printing Volume: 2.6 L

- Print speed: up to 100 cm³ / hour

- Platform Autocalibration

- Type of workspace: open

- Materials used: ABS, PLA

- File format: .STL

- Connection: USB

- Supported OS: Windows: XP, Vista, 7, 8; MAC OS X

- Dimensions: 245 x 250 x 350 mm

- Weight: 5 kg

Design and construction

The appearance of the printer is the most gikovskaya. The working area is fully open. Asymmetric metal frame with a large coil does not look too aesthetically pleasing, so the printer is unlikely to become an interior decoration. It would be better to place it in a technical room or in a closet. By the way, some plastic parts of the device are printed on a 3D printer.

The procedure for preparing to work is simple: just fix the working platform, calibrate using software, install the spool of thread and stretch it to the extruder. Behind is the power button, front - identification button. Also on the case there is a power connector and USB. The printer does not have a screen, all control is carried out from a computer.

The head and platform move in a horizontal plane, but perpendicular to each other. One of the drawbacks of all printers with an open work area is the possibility of too fast or uneven cooling of the melted thread due to drafts or too low temperature in the room, which can degrade the quality of the product. So we recommend to pay attention to this moment.

Software

Branded application to work with the printer looks very inconspicuous, especially compared to Cubify. Periodically there are problems with the encoding, because of what the text turns into a set of question marks. However, it is not difficult to deal with the application, it is easy to learn, there are versions for Windows and Mac.

The application allows you to adjust not only the quality but also the print speed and thread consumption. In addition, there is an intelligent system for automatic creation of substrates and supports for products, so in most cases you can not provide for their presence in the model. UPWare allows you to work with a variety of popular 3D editors, from Autodesk Inventor to 3DSMax.

In addition to these settings, UPWare allows you to select the scale, the orientation of the model, the thickness of the layers and walls, the degree of filling. After printing starts, the printer can be disconnected from the computer, it will finish working offline. If you connect again, you can check at what stage is the printing process, as well as stop it to replace the coil.

In work

Calibrating the printer is not as simple as in the case of the Cube 3, but there is nothing particularly difficult about it. On the print head, you need to install a calibrator, connect it to the required connector, run head level adjustment in the program, and then do the same with the platform.

Unfortunately, the printer is not equipped with Wi-Fi, so that all interaction with it is carried out by cable. The printer is also easy to set up and manage, but still not as much as the Cube 3.

UP! Plus 2 also prints with two types of plastic, PLA and ABS. The kit comes with one coil of ABS-thread. It's nice that the coil design allows you to use consumables from other manufacturers, including materials such as nylon and Crystal Flex. True, this quality and speed of printing will be unpredictable, but you can print.

The minimum resolution when printing with ABS plastic is 150 microns, the maximum speed is up to 100 cubic centimeters per hour. For an amateur device is quite decent options. The same chess rook was printed in 9 hours and 40 minutes. The noise is moderate; you will not have to pinch your ears or make a face near the printer.

Our opinion

On the example of Cube 3 and UP! Plus 2 very clearly demonstrated the transformation of 3D printers, their penetration into the mass segment. Both devices require only minimal preparation for the first launch, in fact, they already work out of the box. The software is simple to learn, does not force to delve into the settings and allows you to print "at the touch of a button." At the same time, the print quality is more than decent for the amateur level; if you wish, you can use finished products as prototypes.

Cube 3 has a pleasant appearance and is very easy to use. It can be controlled via Wi-Fi, including from mobile devices. Printing accuracy is almost 2 times higher than that of UP! Plus 2. The disadvantages include proprietary consumables.

UP! Plus 2, on the contrary, is "omnivorous" both from the point of view of manufacturers of consumables, and from the point of view of the materials used. The cost of the printer is slightly lower than that of the Cube 3. The disadvantages include not too attractive appearance, a little more complex configuration and management, the lack of a built-in screen and Wi-Fi, a resolution of 150 microns, and also not fully thought out software.

Both devices are equally suitable for amateur modellers and designers, as well as appropriate to be in children's circles. Of course, the market for such devices is still small, mostly these devices are still classified as “a fad for geeks.” However, the demand for 3D printers will gradually grow as they continue to improve.

Source: https://habr.com/ru/post/376009/

All Articles