Fullerene, a step forward

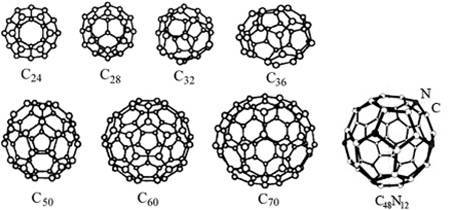

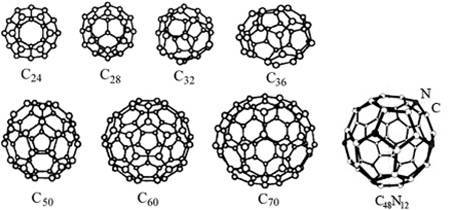

Fullerene is one of the forms of pure carbon, in which atoms are interconnected into a crystal lattice resembling a soccer ball. Depending on the number of atoms, fullerenes can be lower (from 24x to 70 atoms) and higher (70 or more atoms). Of practical interest are fullerene molecules with 60 and 70 atoms as the most common (C60 and C70, respectively).

Fullerenes, isomeric series:

Due to its unique properties: bactericidal, antioxidizing, sorbing, fullerenes in the future have a serious prospect of application in medicine:

')

• Additive to organic oils, cosmetology, medical cosmetics: remedies for psoriasis, dermatitis and fungus, remedies for hair loss, remedies for getting rid of scars, stretch marks, pigmentation.

• Pharmacological drugs: anti-burn and wound-healing drugs (accelerating the healing process 2-2.5 times, pain relief), non-toxic antibacterial and disinfectants, drugs for gastritis, ulcers, gastrointestinal cancer, tuberculosis and bacterial ulcers, ACNE. Ophthalmologic and gynecologic drugs (does not corrode the mucous membrane). Immunostimulating and antiallergic drugs (simultaneously). Potentially cancer drugs.

• Dietary supplements: fullerene is a powerful antioxidant (antioxidant capacity is 135 times higher than that of ascorbic acid), it neutralizes free radicals.

Wound coverage using hydrated fullerenes (fullerenols C (60/70) OH (X)):

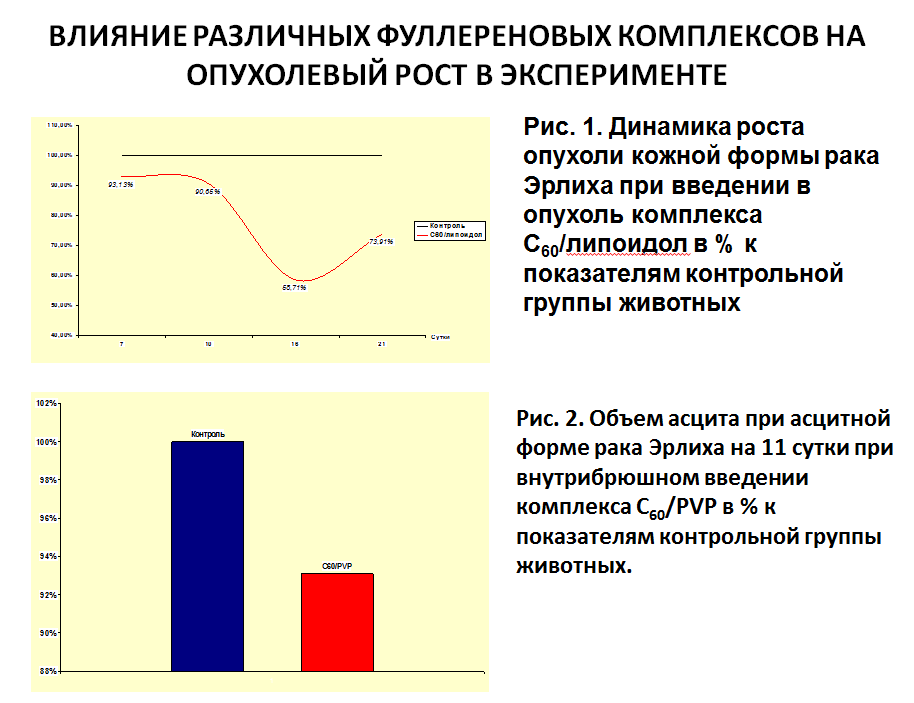

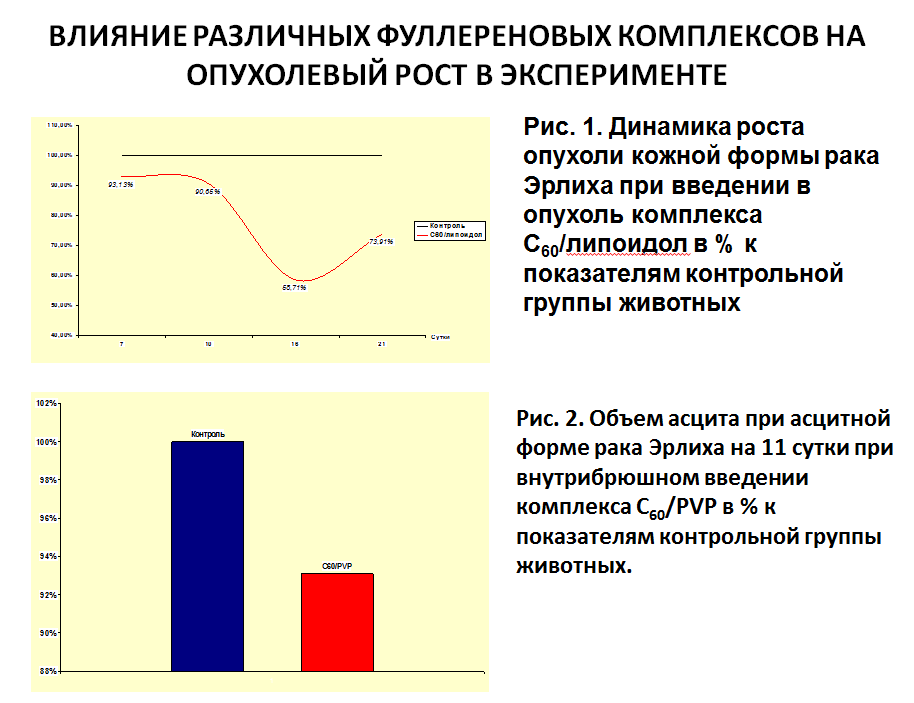

The effect of fullerenes on tumor growth:

Being a stable form of carbon nanoparticles, fullerenes provide uniform properties of technical single crystals and films.

Electronics and optics:

• Nonlinear optics: films for optical lenses.

• Superconducting compounds: high density silicon carbide, derived from fullerenes.

• Solar cells: high-density silicon carbide films increase solar energy efficiency by up to + 30%.

Industrial and construction materials:

• Additive to industrial oils, rubber and plastics: the efficiency of engine oil increases by 2-3 times, the service life of rubber and plastic products increases by 4 times, and the cold resistance of these products increases.

• Protective coatings: improved non-stick coatings and low friction coatings.

• Dispersion strengthened composite materials.

• Fullerene additives for growth of diamond films.

Fullerene film:

Fullerite model:

The only way to get substantial amounts of fullerene is so-called. Kretschmer method, where two carbon rods are burned in a plasma arc. It allows to obtain 0.2-0.5% of fullerene based on the mass of rods. This is a slow process and it takes several days and a huge amount of electricity to produce a significant amount of product (modern installations consume about 50 kW). But there is more to come, further it is necessary to "wash" the fullerene from unnecessary carbon soot. This, depending on the technology used, takes from 2 to 4 weeks. This consumes a large amount of solvent, because to water, the fullerene does not dissolve.

Schematic diagram of the installation of Krechmer:

Thus, due to the exorbitant complexity and high cost of production, fullerenes have always caused a purely scientific interest, but no more.

Russian scientists at the Laboratory of Nanocarbon Materials at the St. Petersburg State Polytechnical University have achieved significant results both in the field of production of fullerene, and in the area of its washing and its important modifications. The methods developed by them make it possible to intensify the process of burning carbon rods, which made it possible to increase the efficiency of the transfer of soot to fullerene to a few percent (15–20 times).

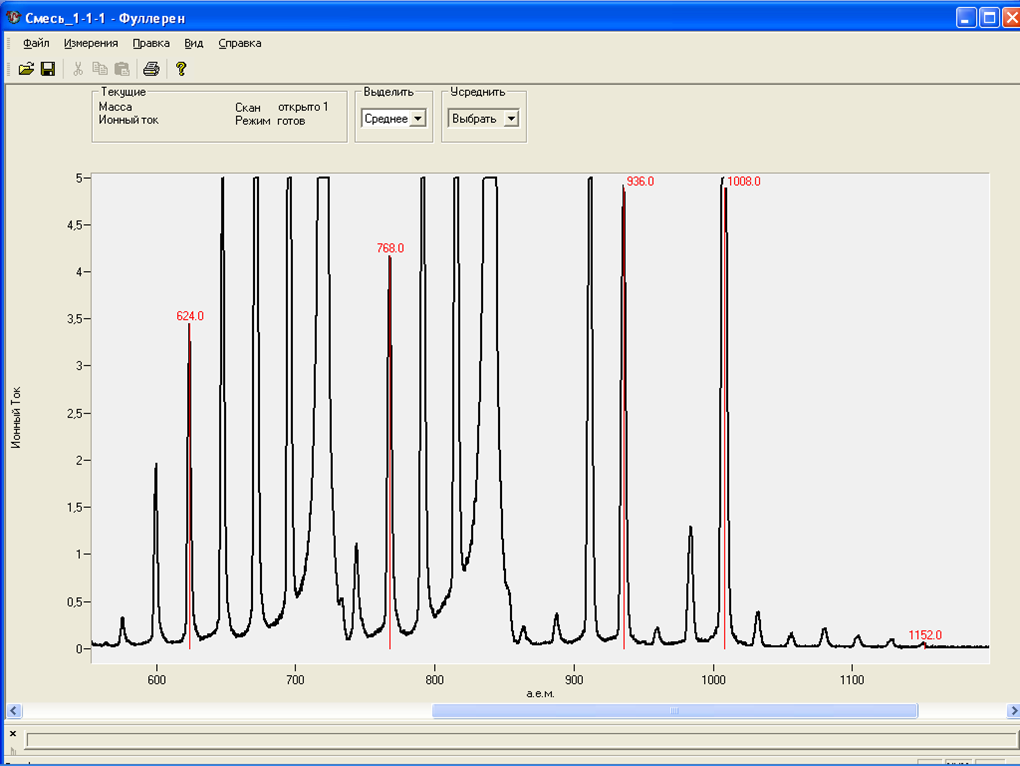

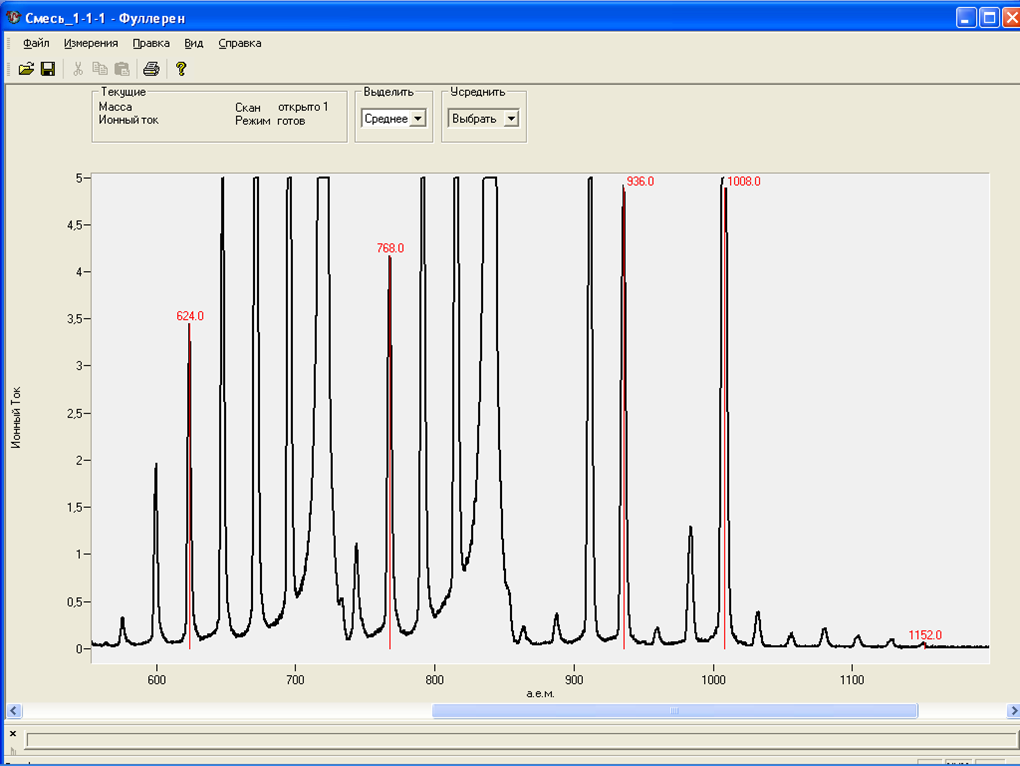

The laboratory also analyzes the quality of the product. For this, the most modern control methods are used: chromatographic, IR-spectrometric, mass-spectrometric.

Fullerene mass spectrogram:

Currently, the laboratory is actively cooperating with several medical and technical research institutes. The result of this cooperation has already become completed studies and patents ( one , two ).

Fullerenes, isomeric series:

Due to its unique properties: bactericidal, antioxidizing, sorbing, fullerenes in the future have a serious prospect of application in medicine:

')

• Additive to organic oils, cosmetology, medical cosmetics: remedies for psoriasis, dermatitis and fungus, remedies for hair loss, remedies for getting rid of scars, stretch marks, pigmentation.

• Pharmacological drugs: anti-burn and wound-healing drugs (accelerating the healing process 2-2.5 times, pain relief), non-toxic antibacterial and disinfectants, drugs for gastritis, ulcers, gastrointestinal cancer, tuberculosis and bacterial ulcers, ACNE. Ophthalmologic and gynecologic drugs (does not corrode the mucous membrane). Immunostimulating and antiallergic drugs (simultaneously). Potentially cancer drugs.

• Dietary supplements: fullerene is a powerful antioxidant (antioxidant capacity is 135 times higher than that of ascorbic acid), it neutralizes free radicals.

Wound coverage using hydrated fullerenes (fullerenols C (60/70) OH (X)):

The effect of fullerenes on tumor growth:

Application of fullerene spray on 3rd degree burn

1st day of application:

14th day of application:

AKNE before and after the 10-day course of treatment:

14th day of application:

AKNE before and after the 10-day course of treatment:

Being a stable form of carbon nanoparticles, fullerenes provide uniform properties of technical single crystals and films.

Electronics and optics:

• Nonlinear optics: films for optical lenses.

• Superconducting compounds: high density silicon carbide, derived from fullerenes.

• Solar cells: high-density silicon carbide films increase solar energy efficiency by up to + 30%.

Industrial and construction materials:

• Additive to industrial oils, rubber and plastics: the efficiency of engine oil increases by 2-3 times, the service life of rubber and plastic products increases by 4 times, and the cold resistance of these products increases.

• Protective coatings: improved non-stick coatings and low friction coatings.

• Dispersion strengthened composite materials.

• Fullerene additives for growth of diamond films.

Fullerene film:

Fullerite model:

The only way to get substantial amounts of fullerene is so-called. Kretschmer method, where two carbon rods are burned in a plasma arc. It allows to obtain 0.2-0.5% of fullerene based on the mass of rods. This is a slow process and it takes several days and a huge amount of electricity to produce a significant amount of product (modern installations consume about 50 kW). But there is more to come, further it is necessary to "wash" the fullerene from unnecessary carbon soot. This, depending on the technology used, takes from 2 to 4 weeks. This consumes a large amount of solvent, because to water, the fullerene does not dissolve.

Schematic diagram of the installation of Krechmer:

Thus, due to the exorbitant complexity and high cost of production, fullerenes have always caused a purely scientific interest, but no more.

Russian scientists at the Laboratory of Nanocarbon Materials at the St. Petersburg State Polytechnical University have achieved significant results both in the field of production of fullerene, and in the area of its washing and its important modifications. The methods developed by them make it possible to intensify the process of burning carbon rods, which made it possible to increase the efficiency of the transfer of soot to fullerene to a few percent (15–20 times).

The laboratory also analyzes the quality of the product. For this, the most modern control methods are used: chromatographic, IR-spectrometric, mass-spectrometric.

Fullerene mass spectrogram:

Currently, the laboratory is actively cooperating with several medical and technical research institutes. The result of this cooperation has already become completed studies and patents ( one , two ).

Source: https://habr.com/ru/post/375947/

All Articles