CNC muscled (3D Pantograph)

In the modern world, in the community of people who love to do things with their own hands and at the same time do not shy away from technology, such a thing as a desktop CNC machine is extremely popular. Although these devices have become quite affordable, they are still expensive. The cheapest Chinese version, today, will cost you 700-800 American money and it probably will not work out of the box right away, but will require an effort to bring it to mind. The manufacture of a CNC machine can cost less on its own, but usually requires access to various types of woodworking and metalworking equipment and the ability to use it to produce parts with high precision.

But people are always looking for ways to achieve goals with affordable means.

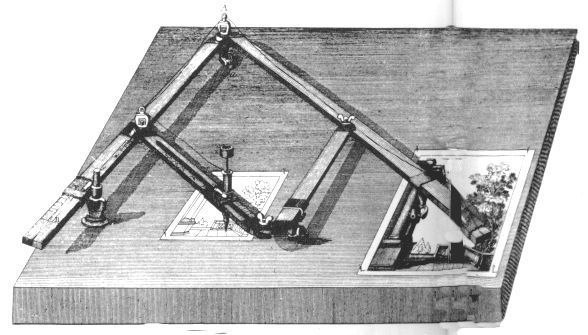

In some tasks for CNC machines, namely when it is necessary to repeat the same detail many times, the pantograph invented in 1603 by Christoph Scheiner - a device for copying maps, plans and other vector drawings, can help.

')

The classic pantograph consists of two vertices, one of which is fixed with a pen-pointer, with which the patterned pattern is outlined. In the second, a writing instrument is fixed, which, through a system of levers and hinges, repeats the movements of the first vertex by drawing a copy on the second sheet. Often, the pantographs incorporated the function of scaling the original image.

Simple and ingenious idea. Now, and how to copy a certain volume object? To do this, add a Z-coordinate to the pantograph and replace the pencil with a drill, or better high-speed spindle, and we will get a 3D pantograph.

Machines for copying wooden products on such a principle are produced for example by the American firm Gemini and only their prices are such that for this money you can buy a good CNC machine from China. Therefore, what the DIY community has achieved in this area is more interesting.

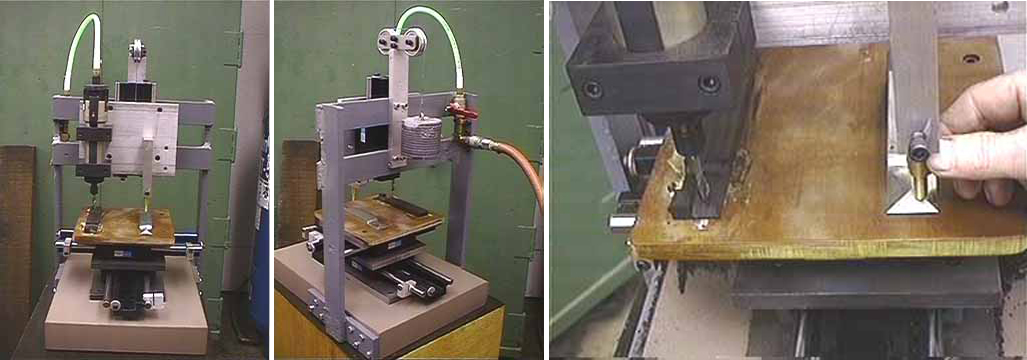

Frank Ford (Frank Ford) is engaged in the manufacture of acoustic guitars. At the same time, he has to make many identical guitar parts, such as string holders. Charter to do it manually, but not wanting to bother with the purchase and adjustment of the CNC, he made for himself a duplicator . Since he was important high accuracy of copying, his tool is made entirely of metal. The stylus, which removes the form and the spindle is fixed on a common frame, which moves only along the Z axis. Movement along the X and Y axes is carried out using the table on which the workpieces are fixed. Another original in its design is that, as a spindle, it uses a pneumatic drive operating at 40,000 rpm.

Nevertheless, even though it is a self-made, but still expensive version of the 3D pantograph. There are cheaper.

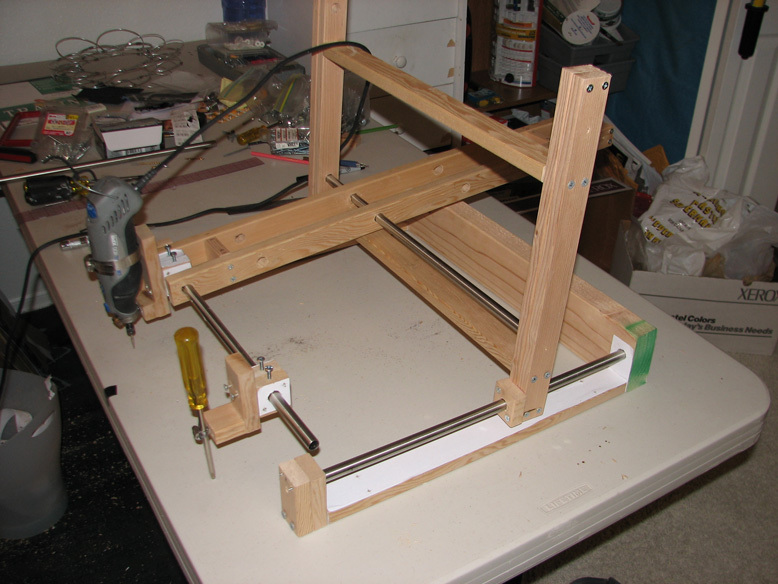

For example, Adran (Adran), dreaming about his own CNC machine, but without the means to do so. He designed himself a duplicator from a Dremel drill, three metal guides and wooden slats of standard sizes from the store. A standard screwdriver is used as a probe. Its design can be easily repeated, because He posted the drawings and all the manufacturing steps on the Instructables website.

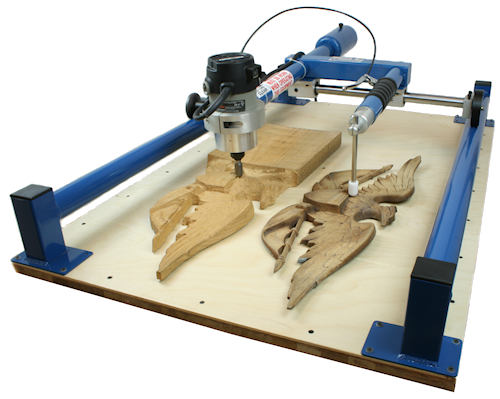

However, the manual drill, not the most successful tool for such work, the speed of removal of material from her is too small. Here Matthias Wandel from Canada used a hand router in his 3D pantograph . What gave him enough power to quickly copy items in the tree. As an example of working with such a duplicator, here is his video, where he makes a copy of the form of an old dial telephone (English).

Its design can also be repeated, because He posted the blueprints and manufacturing instructions on his website Woodgears.ca. Even if you are not friends with English, there you can easily understand the whole process from numerous photographs.

If the topic of 3D pantographs interested you, then on English-language resources examples of such devices can be found by tags: carving duplicator, duplicarver, pantorouter.

Source: https://habr.com/ru/post/374957/

All Articles