Manipulations with ferromagnetism - the future of drives?

Research in the field of data storage is carried out everywhere. Some scientists are inclined to use new chemical compounds or to change existing ones. Someone tends to futuristic heights in the form of carriers from water or DNA.

Now we are well aware of the methods of reading / writing data, allowing to change the direction of magnetization of a particular area using optical technologies. However, our today's heroes decided to “play around” with ferromagnetism itself. According to them, this is the future of data storage. How exactly did they manage to manipulate ferromagnetism, what are the advantages and disadvantages of this technology, and does it really become a breakthrough in the IT world? We will try to find answers to these questions in the report of scientists. Go.

Ferromagnetism - what is it?

')

Before you begin to describe the technology itself, which allows you to manipulate this physical phenomenon, it is worthwhile to briefly explain what ferromagnetism is.

Types of magnetism (direction of electrons): A - paramagnetism; B - ferromagnetism; C - antiferromagnetism; D - ferrimagnetism; (E) forced ferromagnetism.

Electrons of ferromagnetic substances tend to line up in parallel with respect to the applied magnetic field. In addition, there is a tendency for these magnetic moments to orient each other to maintain a state of low energy. Even if the applied field is absent, the electrons of the substance are spontaneously aligned parallel to each other. All this is possible only at temperatures below the Curie point * .

A piece of iron heated to a temperature above the Curie point is only slightly attracted to the magnet. After cooling, its ferromagnetic properties are restored completely.

* Curie point is a parameter that determines the temperature at which a substance loses its ferromagnetic properties. When the temperature exceeds the boundary established by the Curie point, the intensity of the thermal motion of atoms increases and destroys the magnetic order of the electrons, i.e. the symmetry is broken, and the ferromagnet becomes a paramagnetic (a substance that can be magnetized by an external magnetic field, such as aluminum or lithium).It should be clarified that there are several types of magnetism. And ferromagnetism is the most familiar to us in everyday life. We observe it when we fasten a souvenir magnet to the refrigerator, when we write data to an optical disk, etc.

Manipulations with ferromagnetism

According to researchers, laser manipulation of the properties of substances is not new in the world of data storage technologies. A striking example is CD-RW - rewritable optical discs.

Attempts to combine the speed of laser pulses and magnetic recording density have become the goal of many modern studies. To achieve this hybridization, methods of optical magnetization reversal and thermally-assisted magnetic recording are used. However, such methods do not allow manipulating ferromagnetism as a phenomenon. The saturation of the magnetization (hereinafter Ms) of the substance remains the same during the reading / writing process.

If, however, we find rewritable magnets inside a nonmagnetic substance, it will be much more efficient and more practical than writing data bits in accordance with the direction of the demagnetizing field.

Atom reorganization

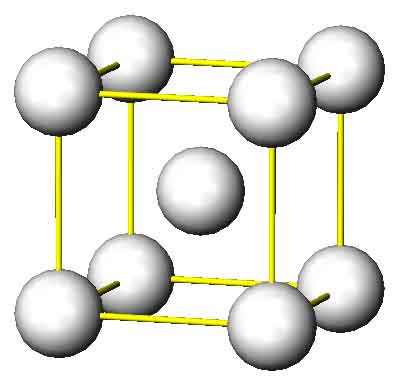

The basis of the research was a layer of Fe 60 Al 40 type B2. Since this layer consists of non-ferromagnets (A = Al, V, Rh), they were reorganized into the structure of a body-centered cubic syngony (type A2). Reorganization implies exchange of Fe and Al atoms.

A2 molecular structure

In the molecular structure of the test substance (Fe 60 Al 40 ), the (001) side consists exclusively of Fe atoms, and the (002) side consists of Al atoms and residues of Fe atoms. This structure has the weakest complex compound Fe – Fe, and is also a paramagnetic.

Thus, if we randomly swap Fe and Al atoms in the B2 structure, the number of neighboring Fe – Fe increases from 2.7 (B2) to 4.8 (A2). The transition from B2 to A2 also slightly increases the lattice parameter, which affects the stimulation of ferromagnetism.

The process of reorganization of atoms can be carried out locally. A focused beam of helium ions can selectively magnetize certain nano-portions of the molecular structure.

Experiment Procedure

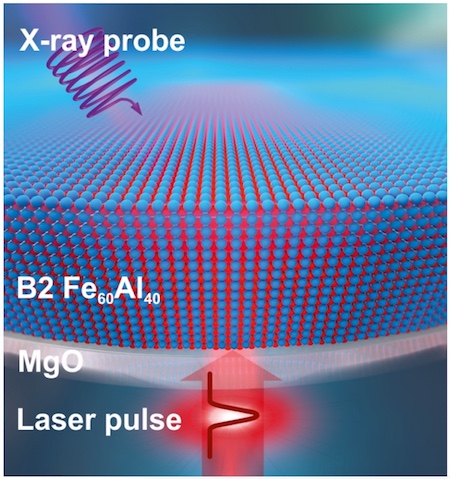

To study the effect of laser pulses on the level of magnetization of the B2 Fe 60 Al 40 layer, a transparent MgO * substrate was used.

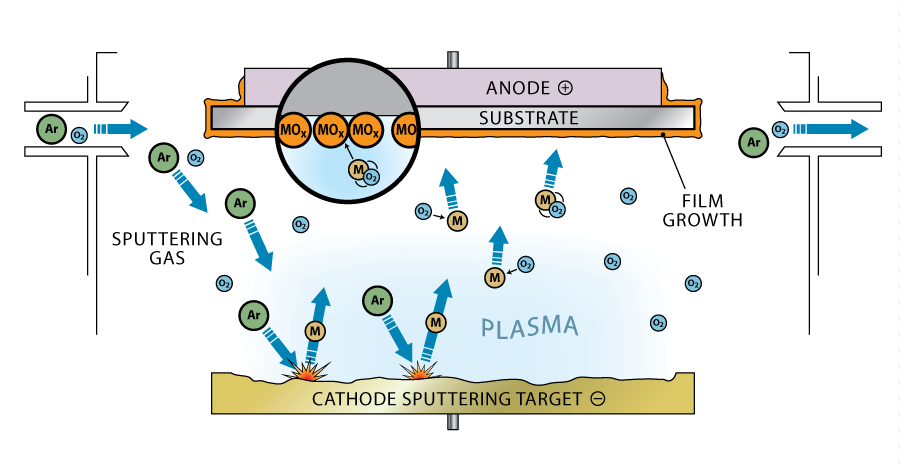

MgO * is magnesium oxide, has a high reflection coefficient (in this case, reflectivity is a quantity that describes the ability of a substance to reflect electromagnetic radiation).Thin films were made by magnetron sputtering * of the target in an argon-containing medium, while the temperature of the substrate was kept at room temperature.

Magnetron sputtering * - a method of deposition of thin films on a substrate by bombarding the cathode (negatively charged electrode) with positive ions in a magnetron discharge plasma.

Magnetron sputtering

A2 The structure of the obtained films of Fe 60 Al 40 was reorganized into B2 using vacuum annealing at a temperature of 773 K (approximately 500 o C).

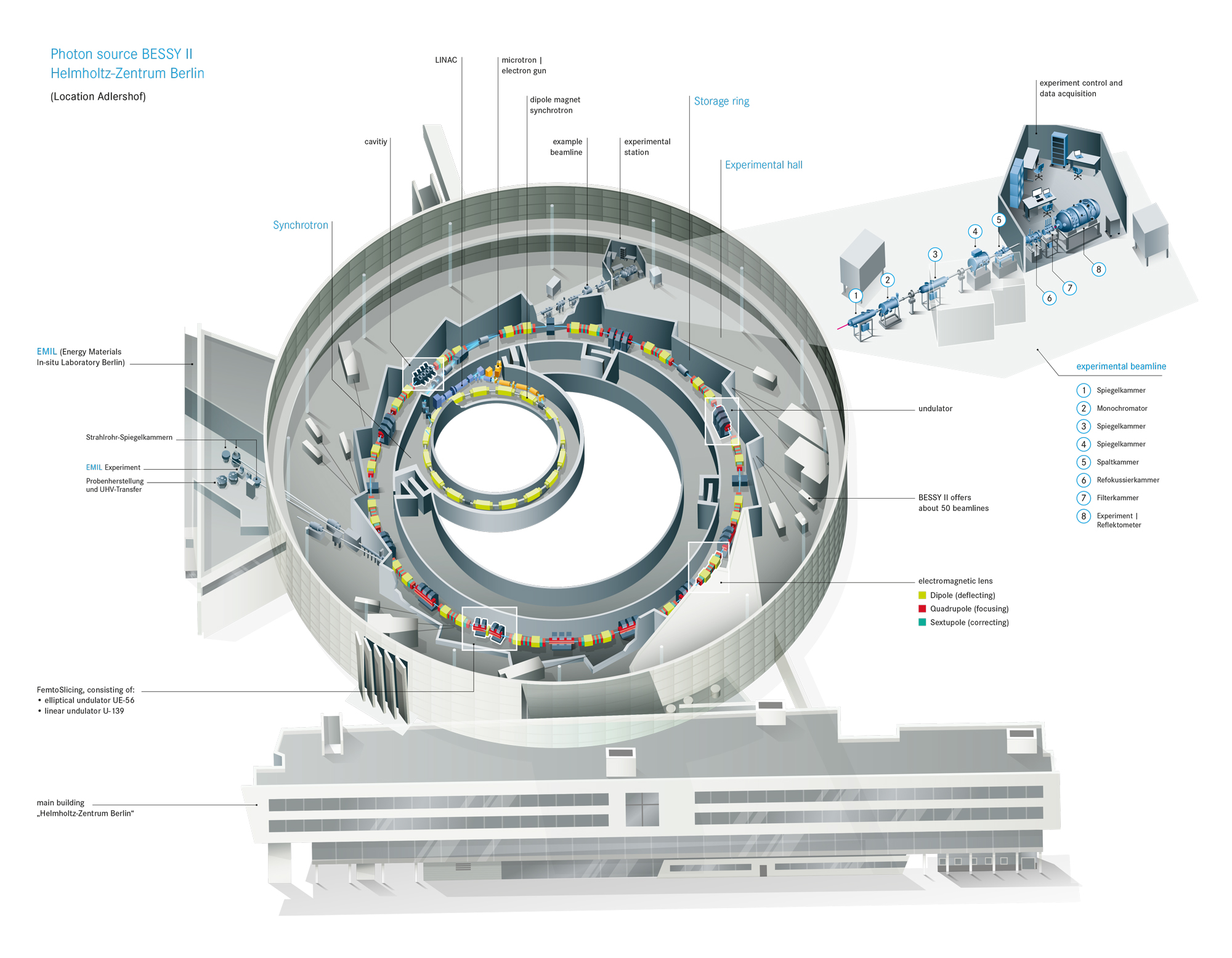

Testing the effects of laser pulses were carried out on a photoemission electron microscope in the walls of BESSY II * in Berlin.

BESSY II * (Berliner Elektronenspeicherring-Gesellschaft für Synchrotronstrahlung II) is a synchrotron with a circumference of 240 meters.

One of the main "participants" of testing is the laser. A titanium-sapphire laser was used, since it has a wide generation band, which allows it to also generate ultrashort pulses necessary for the experiment. The laser wavelength focused on a 2 μm region using a microlens was 800 nm, and the pulse duration was approximately 100 fs (100 femtoseconds, 1 fs = 10-15 s).

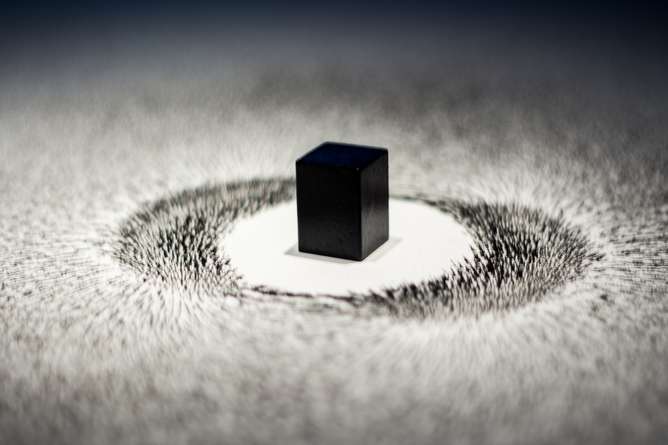

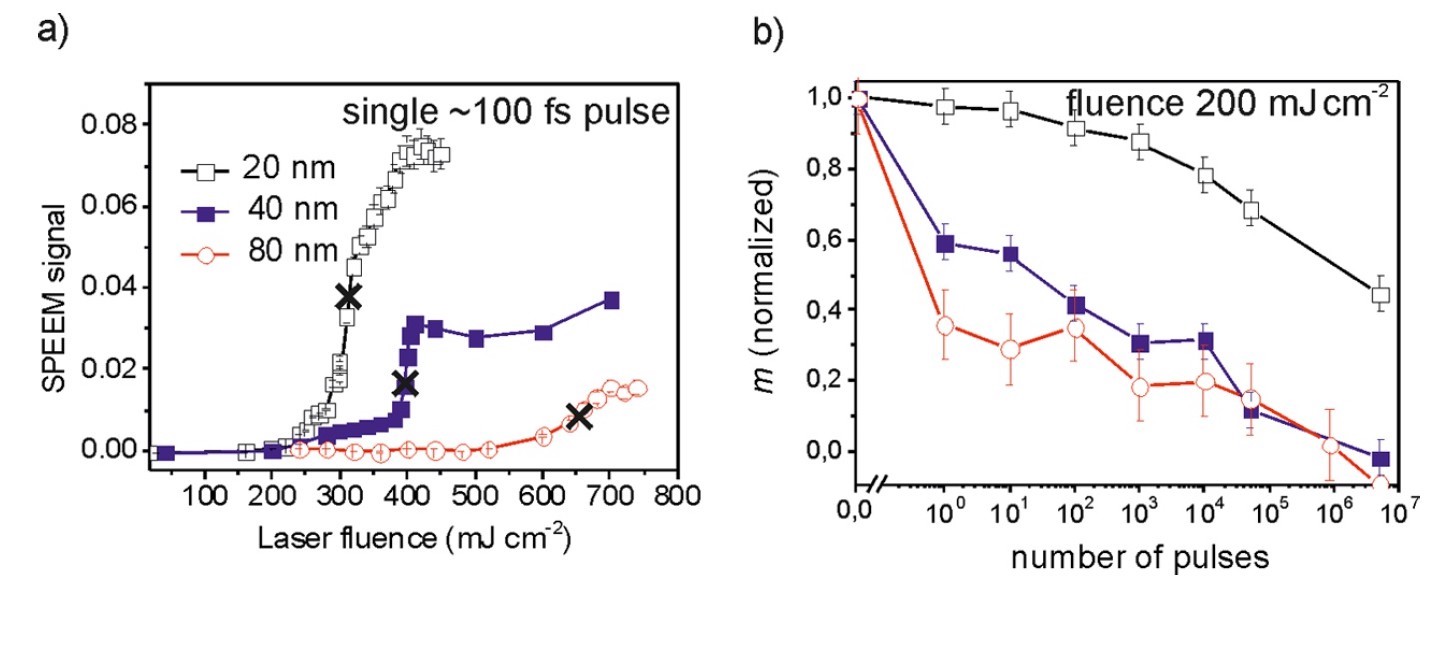

Image # 1: The effect of a 100-fs laser pulse on the space between Fe 60 Al 40 and MgO. The magnetic properties of the surface of Fe 60 Al 40 are investigated using X-rays.

Testing of the impact of laser pulses was carried out on films of B2 Fe 60 Al 40 with a thickness of 20, 40 and 80 nanometers. The pulse repetition rate was 2.5 MHz. To isolate a specific pulse or a train of several pulses, the Pulse Picker was used (literal translation - pulse collector).

One option for the Pulse Picker

Magnetic images of areas affected by laser pulses were recorded at L3 ferromagnetic resonance of Fe (707 eV - electronvolt), through the use of magnetic circular dichroism of x-rays.

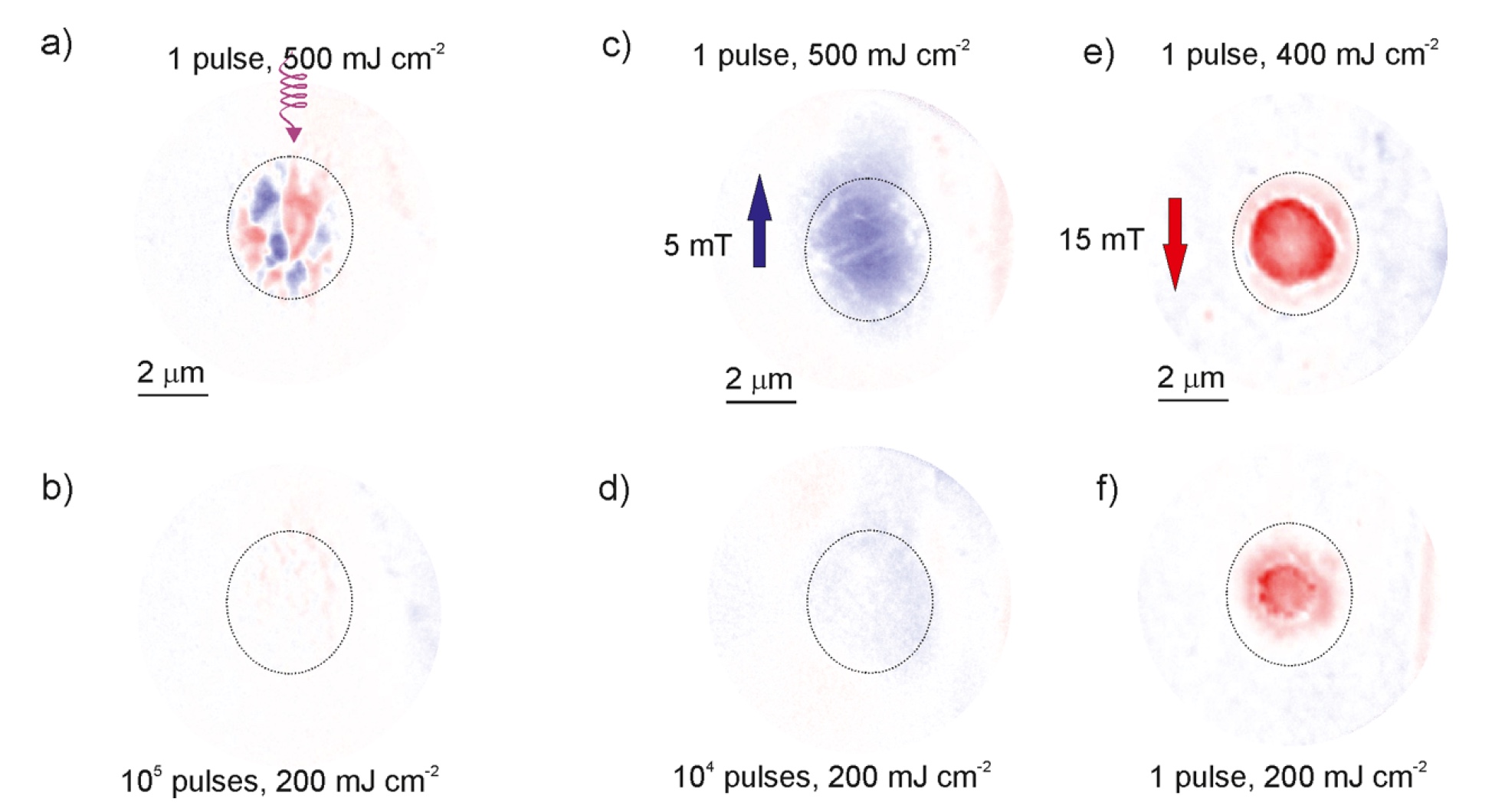

The result of the impact of laser pulses on the test surface (Image No. 2)

The impact on the B2 Fe 60 Al 40 film 40 nm thick with a single laser pulse with a fluence of 500 mJ / cm -2 resulted in a strong surface magnetic contrast ( 2a ). Magnetic contrast is depicted as the difference of two images made using circular polarization and reverse helicity. The magnetization parallel to the x-ray beam is shown in red, and the antiparallel one is shown in blue.

With the number of pulses of 10 5 and a fluence of * 200 mJ / cm -2, the surface magnetization obtained at the first pulse action was eliminated. Image 2b shows that the surface magnetization is greatly reduced, and there is no contrast.

Fluence * is the time integral of the particle flux or energy density.Then, a single pulse (500 mJ / cm -2 ) was re-applied to the test area, but using an external small magnetic field of +5 mT (millitesla). Image 2c shows that the field contributes to the formation of a single magnetic region.

With repeated exposure to 104 pulses (fluence - 200 mJ / cm -2 ), the magnetization again decreased ( 2d ).

For optimization, several more tests were conducted in various conditions.

In the image 2e - the result of a single pulse (fluence - 400 mJ / cm -2 ) with an external magnetic field of -15 mT. Such an effect led to the formation of a single region with strong magnetization.

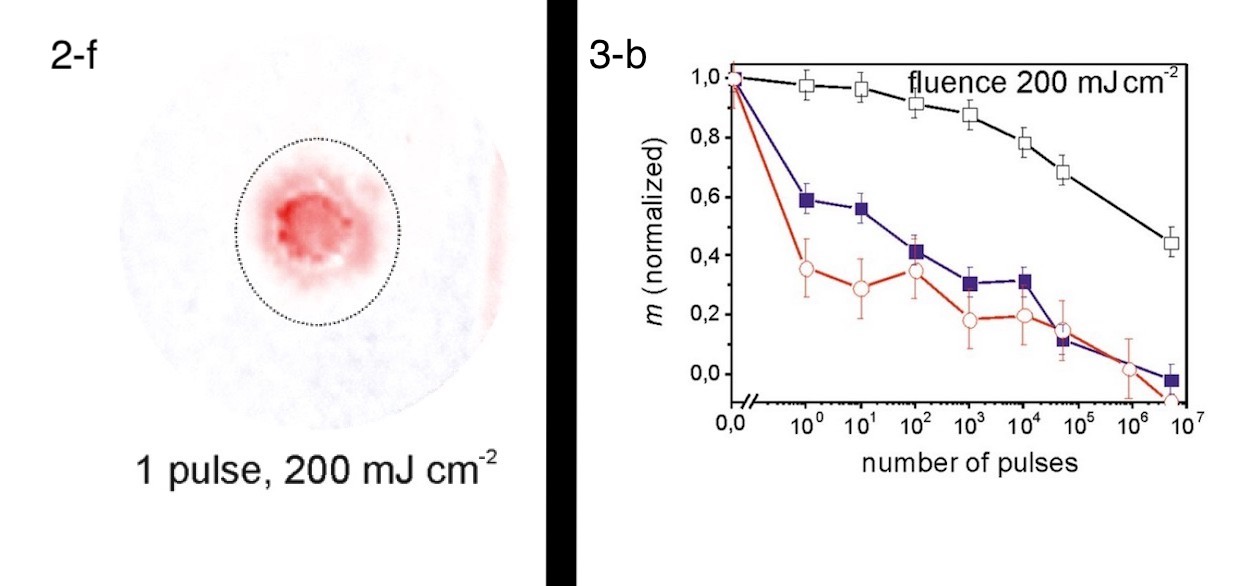

Unlike the previous test variables (a single beam - several rays - a single beam), the test surface was again exposed to only one beam (fluence - 200 mJ / cm -2 ). As a result, the magnetization greatly decreased, by about 40% from the previous figure (image 2f ).

Further, it was required to determine the dependence of the magnetization on the impact density. Therefore, the initial B2 Fe 60 Al 40 film was exposed to a single pulse, and the density increased stepwise from test to test. Magnetic contrast was measured after each pulse. In order to preserve magnetization in one region, a magnetic field of +15 mT was applied.

Image number 3

Image 3a shows an increase in the magnetization of films with a thickness of 20, 40, and 80 nm with increasing laser fluence. Contrast, proportional to the saturation of the magnetization, increases sigmoidly with increasing fluence. The half amplitude of the saturation of the magnetization (black crosses in image 3a ) was achieved with this fluence:

- for a 20 nm film - 300 mJ / cm -2 ;

- for 40 nm film - 390 mJ / cm -2 ;

- for 80 nm film - 650 mJ / cm -2 .

Such a half amplitude can be considered as an effective critical threshold for magnetic recording, as indicated by measurements of the surface magnetization.

Image 3b shows a decrease in magnetization with an increase in the number of laser pulses with a low fluence.

The following fluence indices were used as a recording pulse:

- for a 20 nm film - 400 mJ / cm -2 ;

- for 40 nm film - 400 mJ / cm -2 ;

- for 80 nm film - 700 mJ / cm -2 .

To study the process of erasing, a sequence of pulses possessed a fluence of only 200 mJ / cm -2 . The increase in the number of erase pulses was built in the logarithmic order: 100, 101 ... 104, 5 × 104 and 5 × 106.

"Ex situ" experiment

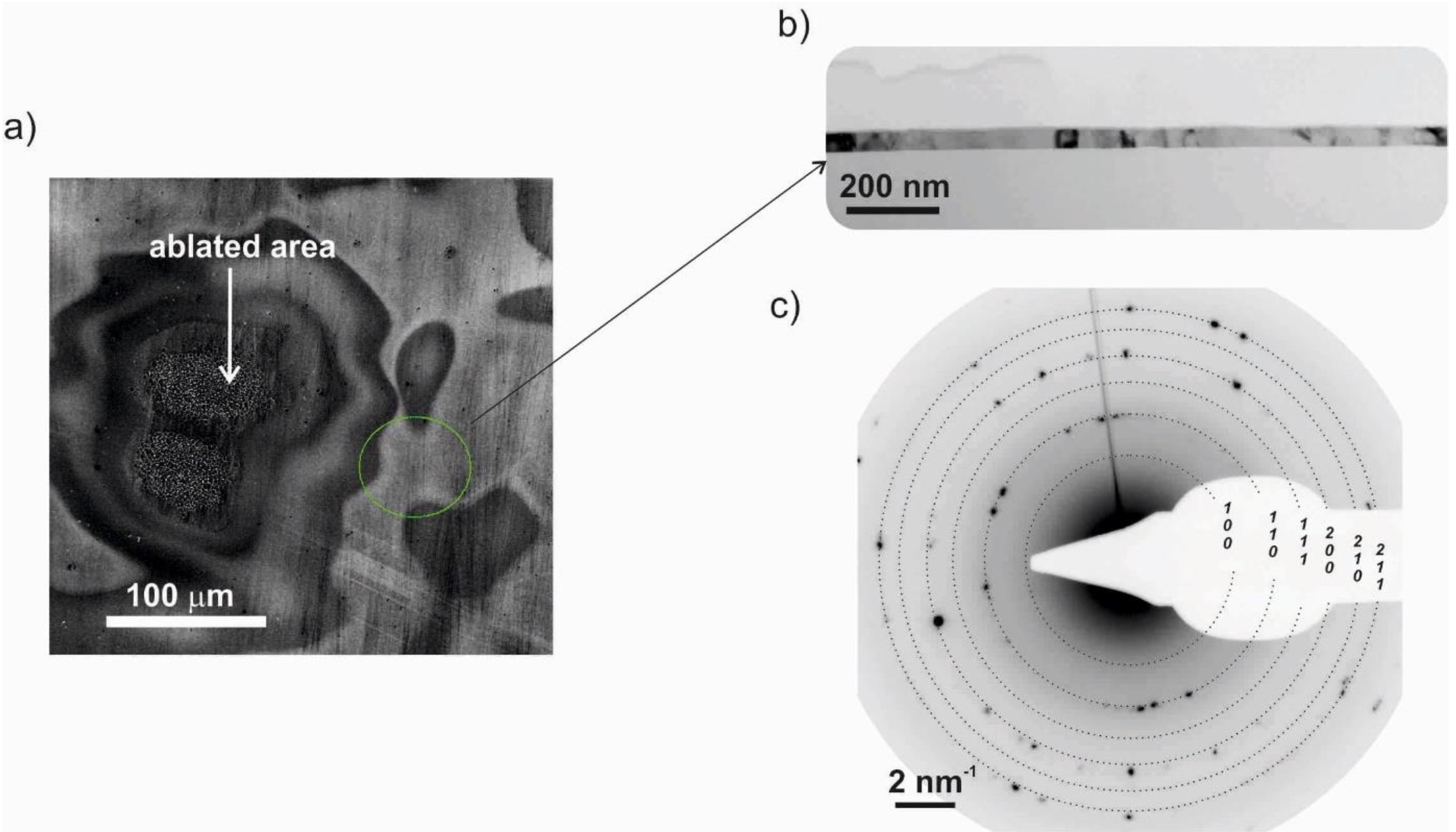

In order to confirm that the molecular reorganization of atoms is responsible for the magnetic recording by means of laser pulses, an “Ex situ” experiment was conducted.

The surface of the B2 Fe 60 Al 40 film 40 nm thick in air was exposed to a Nd: YAG laser with a wavelength of 355 nm. The pulse width was 5 ns. The total number of pulses is 105, and the fluence is 500 mJ / cm -2 .

As a result, an area of 300 μm in diameter was obtained, which was most strongly affected by the laser. The resulting magnetization was determined using the magneto-optical Kerr effect. Around the ablation point * , an annular region with a high magnetization index was detected. For structural analysis, TEM was used (Transmission electron microscopy / Transmission Electron Microscope).

Ablation * is a method of removing a substance from the surface by a laser pulse.

a) - For analysis, a sample was taken with ferromagnetic properties near the ablation area. For this purpose, a device with a focused ion beam was used.

b) - The bright field of the TEM image shows an intact polycrystalline layer 40 nm thick.

c) - SAED (diffraction of electrons in the selected region) confirmed that the structure of Fe 60 Al 40 is of type A2, since there were no superstructural reflections 100, 111 and 210.

Details of this experiment are presented here.

Analysis of test results

For a clearer understanding of the relationship between the conditions controlling the processes of reorganization and the rewritable film magnetization, several simulations were performed. They were carried out on the basis of a continuum model in which such factors were taken into account: laser excitation of electrons in the conduction band; electron-phonon equilibrium; heat transfer; kinetics of melting and hardening. The exposure conditions of the laser are similar to those used in the tests, the results of which are displayed in the image number 1.

Since the results of simulations involving a 40 nm thick film are most pronounced, they will be considered in the analysis.

Melting threshold

The test layer of Fe 60 Al 40 on a MgO substrate was affected by a laser beam of different fluence.

- with a fluence of 173 mJ / cm -2 , the melting threshold of Fe 60 Al 40 / MgO was determined;

- 357 mJ / cm -2 - identification of the second melting region on the film surface;

- 394 mJ / cm -2 - full melting through the entire thickness of the film, when the two melting front, spread through the film and the substrate, and the surface merge together.

Example: ice melting threshold is 0 o C

Such indicators suggest that the rapid hardening of the temporarily molten portion of the film forms an unordered metastable (stable and not very large perturbations) molecular structure of type A2. When cooling the hardened area, the metastable structure can go from type A2 to B2.

Diffusion of vacancies

What is a job? This, roughly speaking, "marriage" of the molecular structure of the crystal. When we have a perfect crystal, all atoms are in place. If in some place there is no atom (although it should be there under ideal conditions), then this place is our vacancy. Diffusion of vacancies is, in simple words, the transition of an atom into a free region, i.e. change his position. It is this mechanism that is the basis of the atomic reorganization of the test substance.

Simplified schematic representation of a vacancy

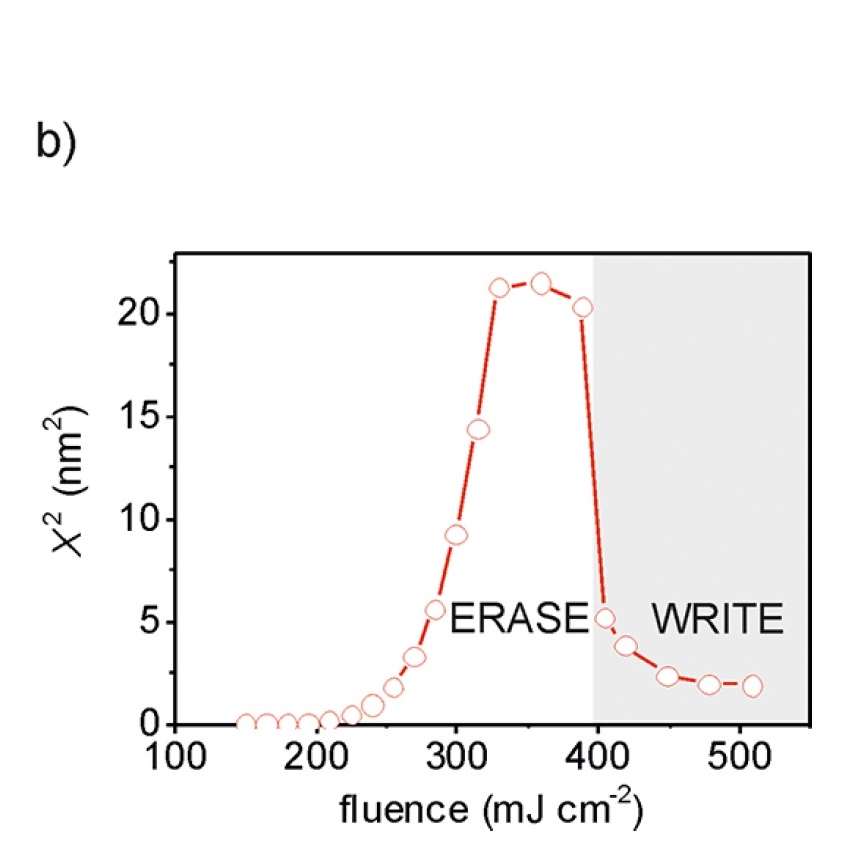

Since the photoemission electron microscope, which was used in data collection, is extremely sensitive to magnetization on the surfaces of thin film layers, the mean square displacement of vacancies ( X2 ) was estimated at the center of the region where the laser beam is directed. The evaluation was carried out starting from the moment of complete hardening of this area until the moment when cooling stops the diffusion of vacancies.

Thermodynamics

The temperature dependence of the thermodynamic driving force with respect to the reorganization of atoms does not allow one to clearly determine the quantitative relation between the X2 values and the kinetics of the phase transition of atoms. However, it provides indicative results of measurements of the degree of atomic rearrangements arising in the process of reorganization of the molecular structure.

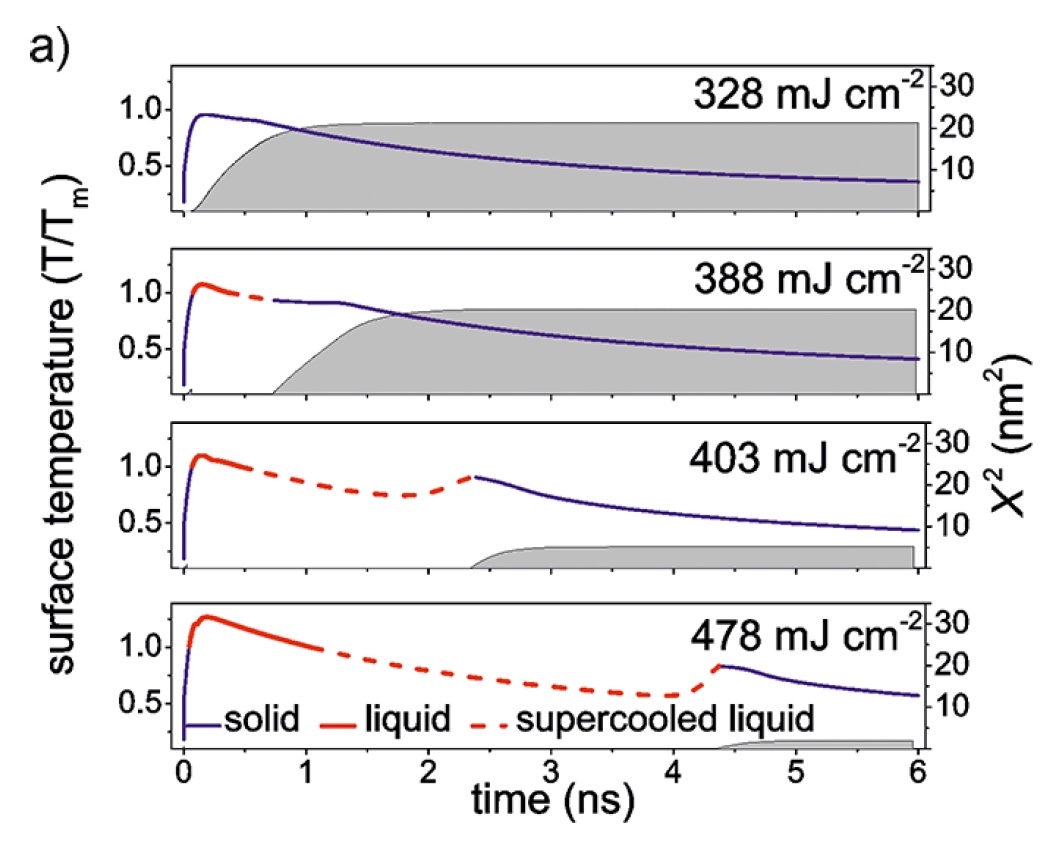

Image number 4a

Image 4a shows the change in surface temperature at the center of the laser beam exposure site (laser “spot” / “dot”) during four simulations. The blue color of the line indicates the solid phase, and the red color - the liquid phase of the substance.

The subcooling * of the fused layer below Tm * is indicated by a red dashed line.

Overcooling * - refers to the process of reducing the temperature of a liquid or gas below the freezing point, but without bringing the substance to a solid state.

Tm * is the melting point when the body transitions from a solid to a liquid state or vice versa.To simplify the calculations, a single value of Tm = 1660 K was established. This value is between the solidus (1630 K) and liquidus (1680 K) values. The gray areas in the plots represent the cumulative mean square vacancy shift (X2).

With a fluence of 328 mJ / cm -2 , before the surface began to melt, the rapid heating of the surface region to almost Tm led to a jump in X2. However, further cooling, to a temperature below ∼0.7 Tm (1160 K), reduced the diffusion of vacancies to an insignificant level. As the fluence increases to 388, the surface temperature becomes higher than Tm, which leads to transient melting of a thin surface layer of the film. In this simulation, the melting fronts propagating from the surface and from the film / substrate interface are not connected. In this case, a rapid growth of the crystalline part of the film is observed, which leads to hardening with a very slight supercooling of the substance. As you can see from the graph, the red dashed line is very short.

The relatively high surface temperature at the time of its re-hardening guarantees the diffusion of vacancies during the subsequent cooling of the surface, while the level of X2 drops to about the same as with a fluence of 328 mJ / cm -2 .

The probability of rapid growth of the crystalline part is excluded if the surface temperature is above the threshold of complete melting throughout the entire thickness of the film. And the hardening of the fused area can pass exclusively through the lateral spread of the hardening front from the edges of the area to the center of the laser spot.

The relatively large size of the fused area and the limited speed of the hardening front (≤130 m / s) allow the hardening process to proceed more slowly, which in turn leads to a more powerful supercooling of the fused material in the central region of the laser spot.

In practice, this gives the following results. With a sharp increase in the hardening time (from 740 ps (picoseconds) at 388 mJ / cm -2 to 2.4 ns (nanoseconds) at 403 mJ / cm -2 ), the surface temperature decreases at the moment of complete hardening from 0.93 to 0.91 Tm.

A value of 0.91 Tm also reflects the maximum that occur during a temperature surge, which occurs during local heat generation of hardening. However, this heat is quickly dissipated due to the large local temperature gradient around the freshly hardened surface.

The low temperature in the re-hardened surface area severely limits the diffusion of vacancies and leads to saturation of the X2 value at 403 mJ / cm -2 , which is 4 times less than at 388 mJ / cm -2 .

With a further increase in the fluence, the hardening time of the central portion of the laser spot increases, and the diffusion of vacancies is suppressed.

In practice, this gave the following results. With an increase in fluence from 403 to 478 mJ / cm -2, the surface temperature at the time of hardening dropped from 0.91 to 0.83 Tm. X2 saturation has dropped to a level where the required atomic reorganization is out of the question. This is displayed in the fourth image graph 4a .

Image number 4b

In the image above ( 4b ), X2 is presented as a function of the laser fluence to more clearly illustrate its effect on the diffusion of vacancies. Below the induction limit of the second melting front, the diffusion length of vacancies increases exponentially with increasing fluence.

At the beginning of the surface melting, X2 is saturated almost at a constant level. Only with an increase in the laser fluence, a slight drop occurs, which is associated with a strong supercooling of the re-hardening surface area.

Above the full melting threshold, the time required to re-harden the central portion of the laser spot increases dramatically. Because of this, there is a much stronger supercooling preceding re-hardening, which limits the diffusion of vacancies during cooling of the hardened surface and reduces the likelihood of atomic rearrangement of the molecular structure from A2 to B2. As a result, the disorganization of the structure and magnetization should remain in the central part of the laser spot after a rapid decrease in temperature to room temperature.

Below the threshold for complete melting of the surface, the diffusion of vacancies can be sufficiently active to ensure the process of reorganization of atoms. As can be seen in image 4b, the peak indicator is X2 = 21.5 nm 2 , which corresponds to approximately 320 vacancy jumps. The maximum concentration of vacancies arising from the rapid non-uniform hardening of metals is 10 -3 . Given this, it can be assumed that approximately 32% of the atoms changed their position due to the diffusion of vacancies.

The above parameters allow us to conclude that the reorganization can occur when exposed to a single laser pulse. Although, nevertheless, it is impossible to accurately determine the relationship between the total number of vacancy jumps during cooling and the relative share of the equilibrium B2 phases and the metastable A2 phases generated by laser irradiation.

This conclusion fits in with the test results shown in images 2f and 2b . We see that the magnetization has significantly decreased after exposure to films with a thickness of 40 and 80 nm of a single laser pulse.

The generation of ferromagnetic regions under the influence of laser pulses in the absence of a magnetic field corresponds to the predicted scheme of melting and re-hardening (image 2a ).

It is expected that the re-hardening will take place through the following processes:

- resumption of solid areas of the film;

- heterogeneous nucleation * film / substrate areas;

- homogeneous nucleation * of crystallites inside the melt in the case of deep supercooling (for example, 0.6 Tm with a single beam fluence of 478 mJ / cm -2 / image 4a ).

Heterogeneous nucleation * - the first stage of transition from one thermodynamic phase to another within a heterogeneous system (consists of two or several phases).

Homogeneous nucleation * - the emergence of the beginnings of a new phase within the existing one.In the process of re-hardening in the areas of growth, heat is generated, which leads to an uneven temperature distribution over the laser impact zone. Such temperature inhomogeneity can persist until the Curie point is reached. The areas are magnetized at a local temperature Tc - ΔT. Their field shifts the local magnetic moments to the edges of the region where the temperature is still Tc + ΔT, thereby inducing magnetized domains (region / region) (image 2a ).

To avoid the formation of multiple magnetized domains, a small magnetic field is applied during laser irradiation. This allows you to effectively avoid inhomogeneous scattered field and form a single magnetic domain (image 2c and 2e ).

Image number 5

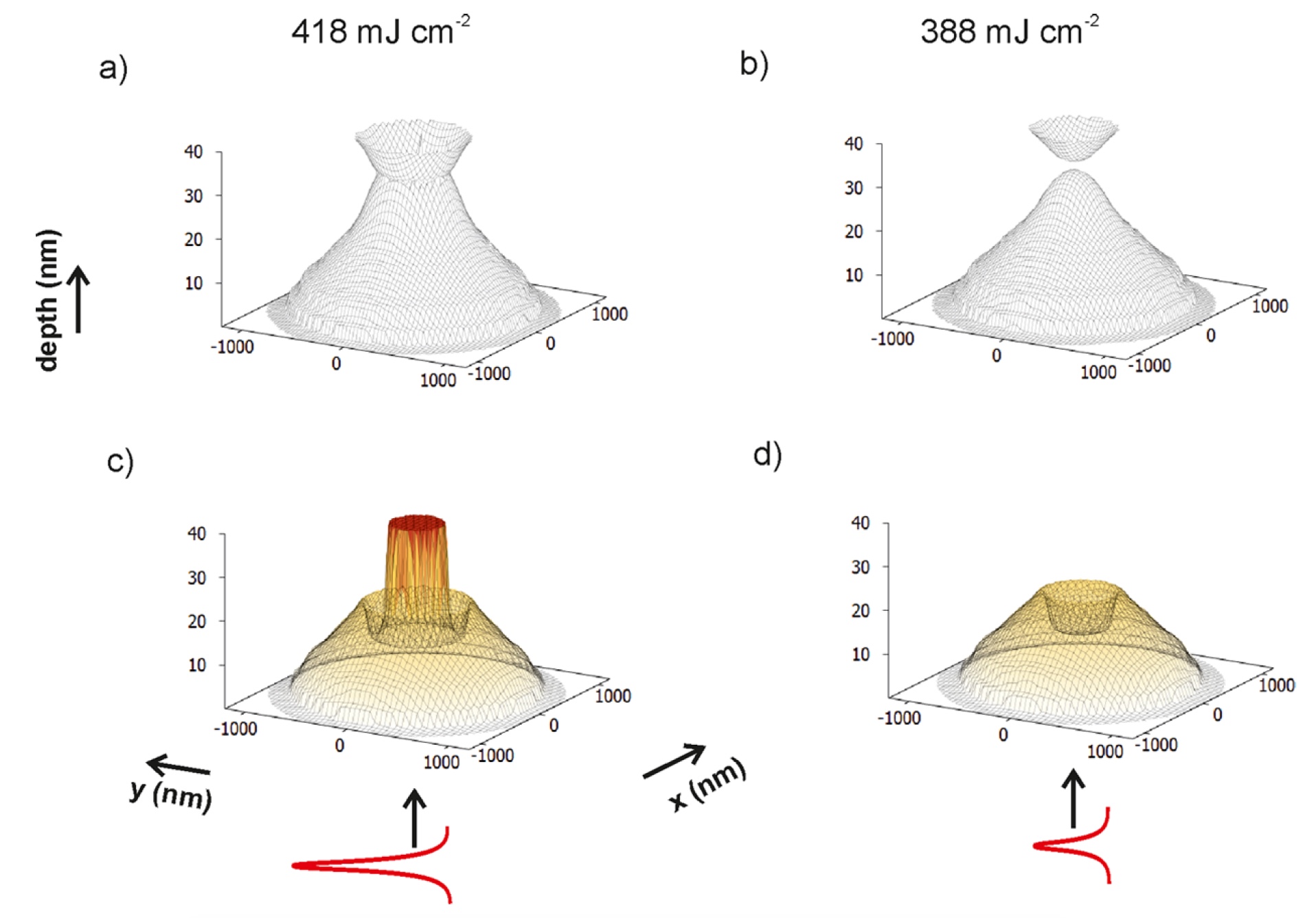

The above images ( a and b ) demonstrate the melting process with laser fluence of 388 and 418, X2 for both variants is 11 nm 2 (images c and d ).

When the fluence is 418 mJ / cm -2 , melting fronts appear on the surface and in the film / substrate region, which leads to the appearance of a melting region. The hardening process of this area occurs due to the spread of the hardening front and takes several nanoseconds. The temperature of the fused section begins to decrease and at the time of complete hardening it reaches too low a level so that atomic reorganization is possible.

Image 5c shows an area approximately 500 nm in diameter. This is the area of magnetization of the surface. At the level of convergence of the film / substrate, the magnetization region corresponds (practically) to the region of the laser spot. The area of magnetization increases with increasing fluence.

With a fluence of 388 mJ / cm -2, the two melting fronts, propagating from the film / substrate convergence and the film surface, remain separated (image 5b ). As soon as the temperature falls below the melting point, the melting fronts propagate vertically, which leads to a very rapid re-hardening. However, at the end of the hardening process, the temperature is still high, which is accompanied by active diffusion of vacancies. Diffusion atomic reorganization leads to the transformation of a metastable A2 structure formed during the melting and re-hardening of film sections into an equilibrium B2 structure. This process completely eliminates the surface magnetization, as we can see in image 5d .

The findings of researchers

Using the B2 film as an example, evidence was obtained of the ability to “turn on” and “turn off” ferromagnetism using laser pulses and structural reorganization of atoms. Simulations have revealed the critical role of supercooling of melt sites in the process of atom reorganization. The same pulse of the film was applied 10 times in a row by a laser pulse with a fluence greater than the maximum allowable. In this case, damage to the film was not detected. Reuse of the film may be limited either by ablation of the material or by contamination during laser irradiation. However, this can be avoided by using a protective surface layer (MgO).

In order to increase the maximum possible level of supercooling before re-hardening to control diffusion and reorganization, as well as to achieve optimal variable properties of lasers, it is necessary to investigate the thermal conductivity of the substrate and add a buffer layer.

The idea of rewritable magnetization in conjunction with lasers can be implemented on various other materials that demonstrate the ability to reorganize their structure. The study of such substances can help to understand femtosecond laser heating and cooling of the layers. In particular, the mechanisms and kinetics of ordering and disordering, which are still not completely clear. The results of these studies can expand the range of search for new alloys, demonstrating the reversibility of changes in magnetic properties due to laser exposure.

You can get acquainted with the research of scientists in more detail using their report.

Epilogue

, , . , - , , , , .

, , - - . , , , , . , , .

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249 in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?

Source: https://habr.com/ru/post/374481/

All Articles